Spring type speed limiter tensioning device constant in tensioning force

A tensioning device and tensioning force technology, applied in the field of elevators, can solve problems such as loss of safety barriers, insufficient tensioning force, and affecting the life of steel wire ropes, and achieve the effect of ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

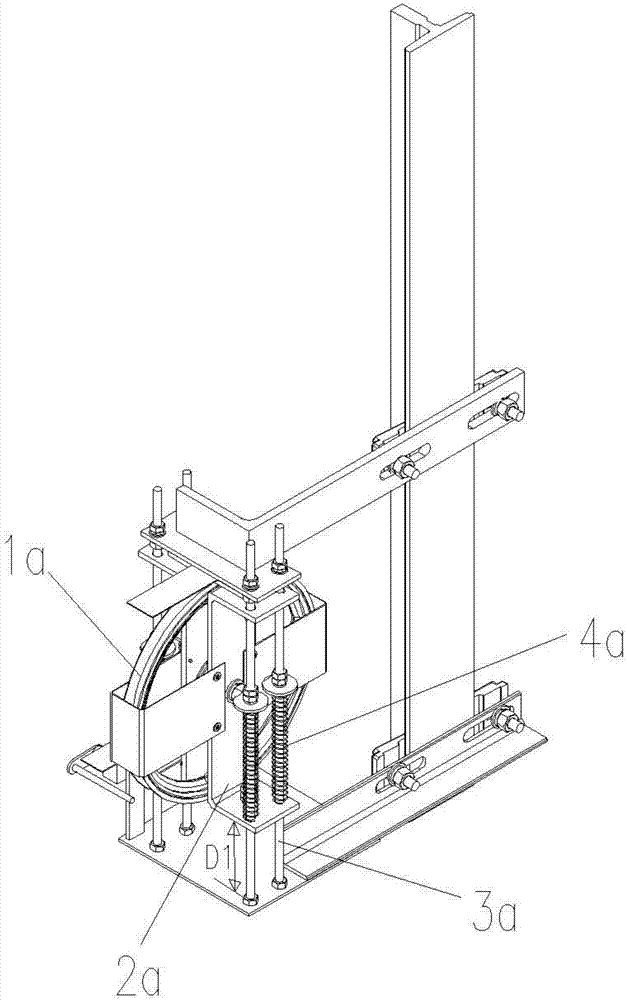

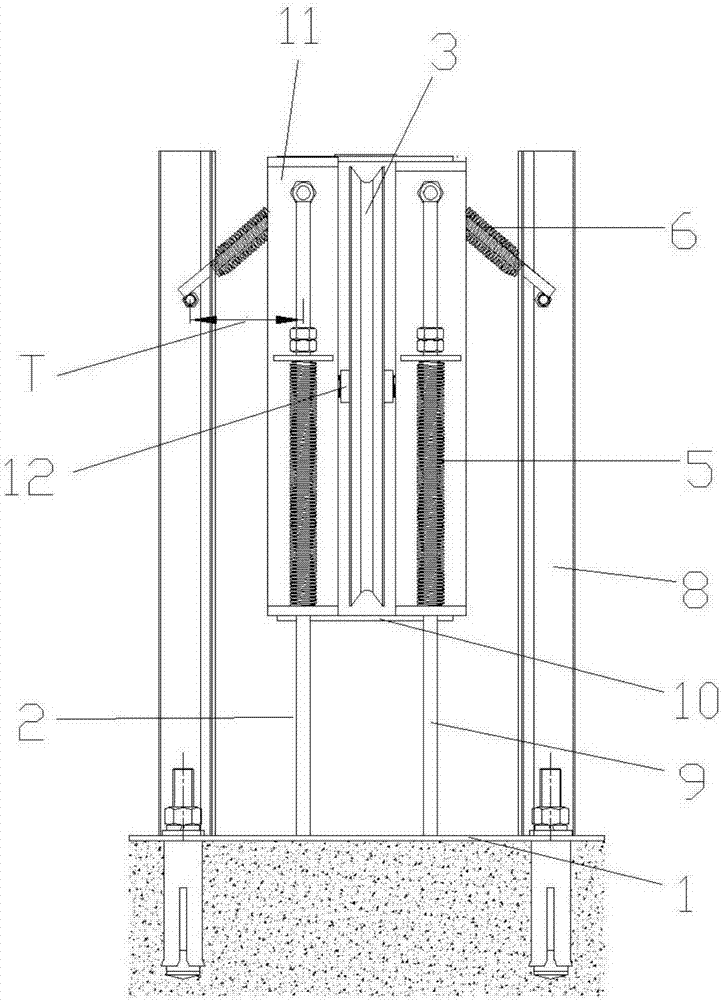

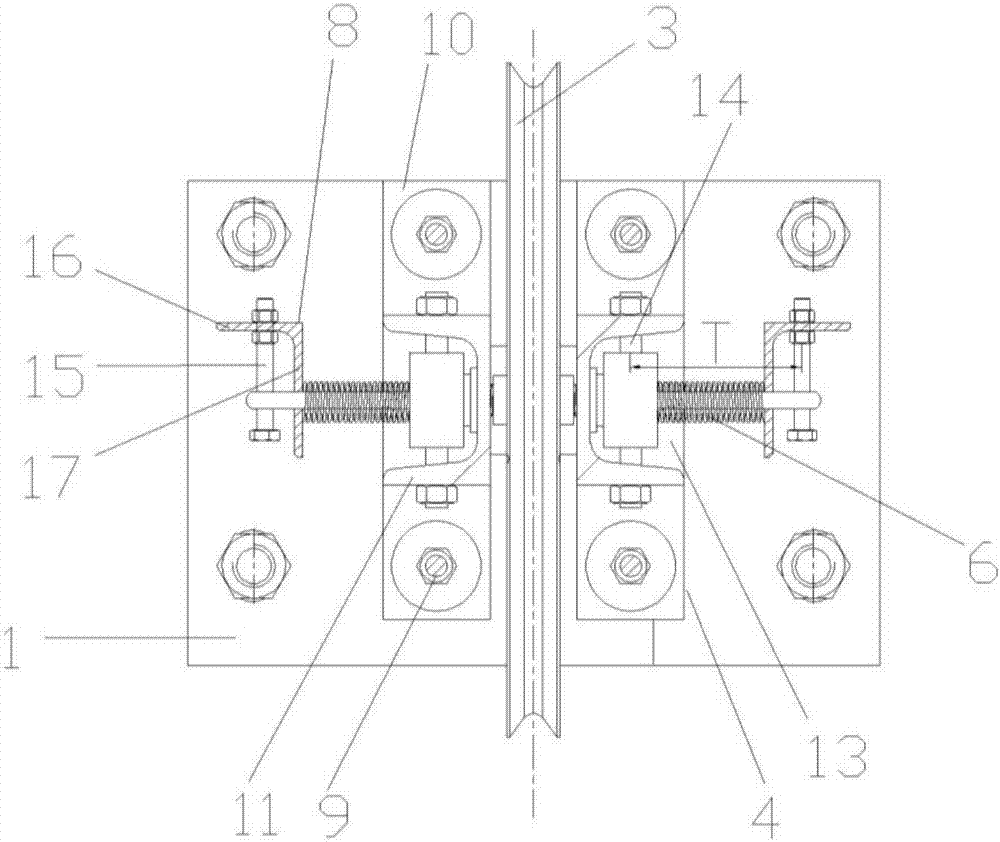

[0030] Such as Figure 2 to Figure 4 As shown, a spring type speed governor tensioning device with constant tension force includes a base 1, a guide assembly 2 fixed on the base 1, and a tensioning device installed on the guide assembly 2 and sliding up and down along the guide assembly 2. The wheel assembly, the tension wheel assembly includes a tension wheel 3, a sheave mounting seat 4, a main compression spring assembly for providing a tension force in the vertical direction for the tension wheel 3, and the base 1 is located on the sheave Both sides of the mounting base 4 are respectively symmetrically provided with two auxiliary compression spring assemblies, and each auxiliary compression spring assembly includes an auxiliary compression spring 6 and is used to adjust the force direction and size of the auxiliary compression spring 6 when the wire rope is elongated. As for the adjustment mechanism, the two secondary compression spring components are respectively connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com