Patents

Literature

34results about How to "Smooth silk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing high-performance modified polyethylene monofilaments for manufacturing fishing net

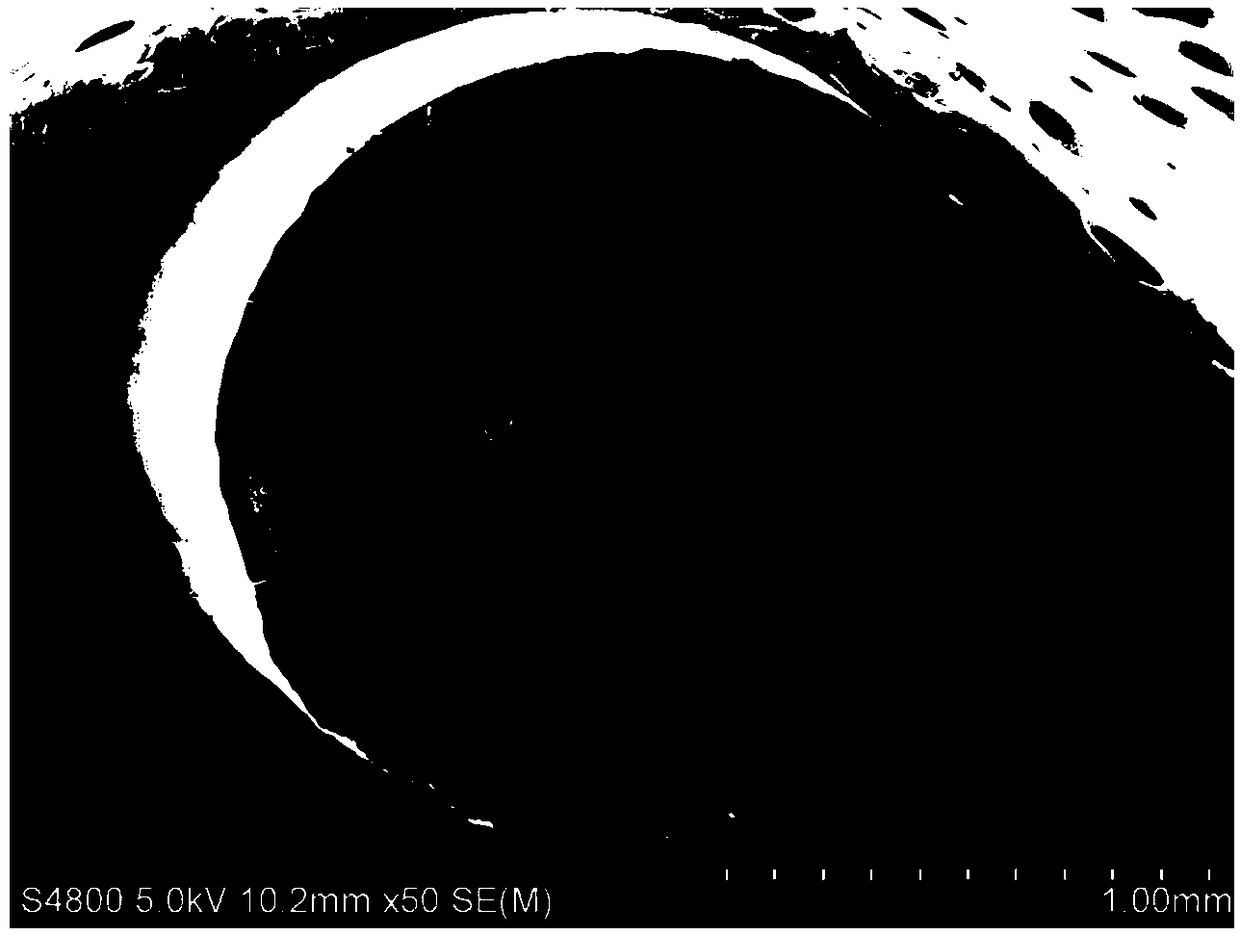

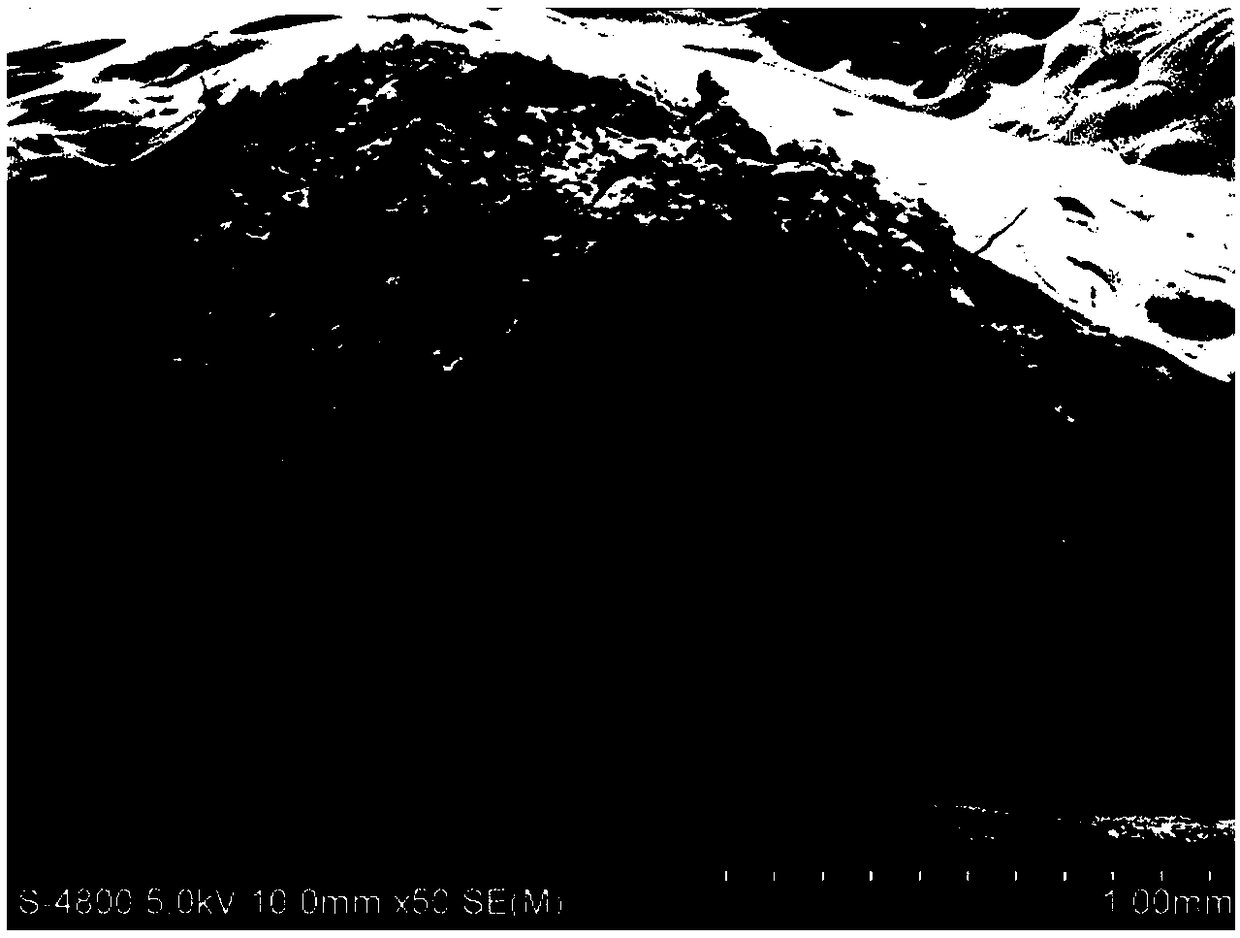

InactiveCN101851795AIncrease heat treatment temperatureHigh breaking strengthSpinning head liquid feederFilament manufactureWinding machineElastomer

The invention discloses a method for processing high-performance modified polyethylene monofilaments for manufacturing a fishing net, relates to a method for processing polyethylene monofilaments for manufacturing a fishing net and aims to provide a method for processing the high-performance modified polyethylene monofilaments for manufacturing the fishing net. In the technical scheme of the invention, a stirring machine, a single-screw extruder, a twice-drafting electrical heating drafting machine, a filament winding machine and a filament separating machine are adopted. The method is characterized by comprising the following steps of: mixing a sieved spinning-grade dry HDPE resin, a dry VERSIFYTM 6002 elastomer, white oil or a turpentine aid; uniformly mixing the materials to obtain an HDPE / VERSIFYTM 6002 elastomer blend and fusing and extruding the blend by using the single-screw extruder; cooling and pre-drafting fused and extruded primary filaments, thermally drafting the pre-drafted filaments twice, rapidly cooling the thermally-drafted filaments from which oil is removed with high-pressure air current and winding modified PE monofilaments by using the winding machine; and separating the modified PE monofilaments into the high-performance modified polyethylene monofilaments for manufacturing the fishing net by using the filament separating machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

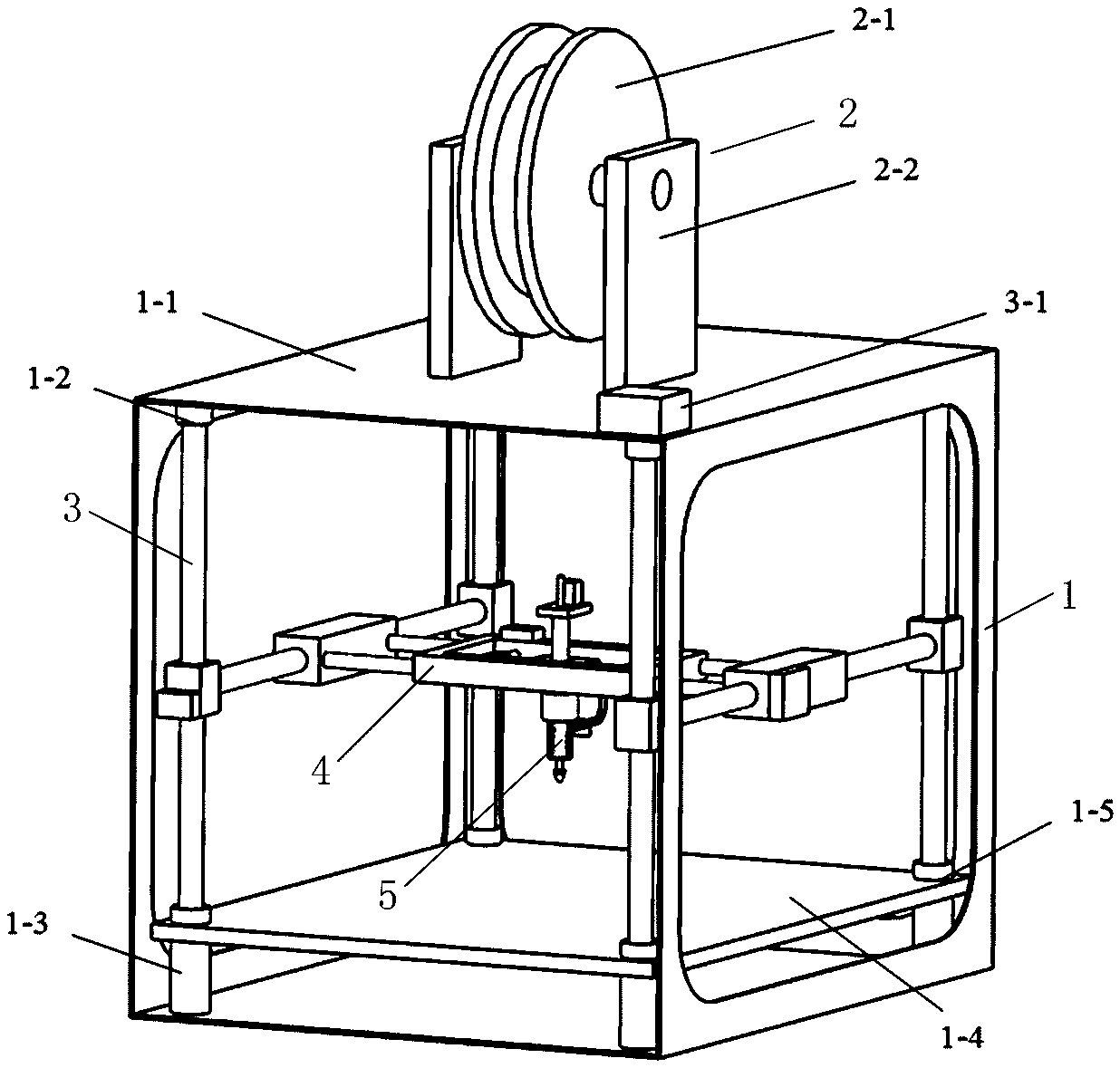

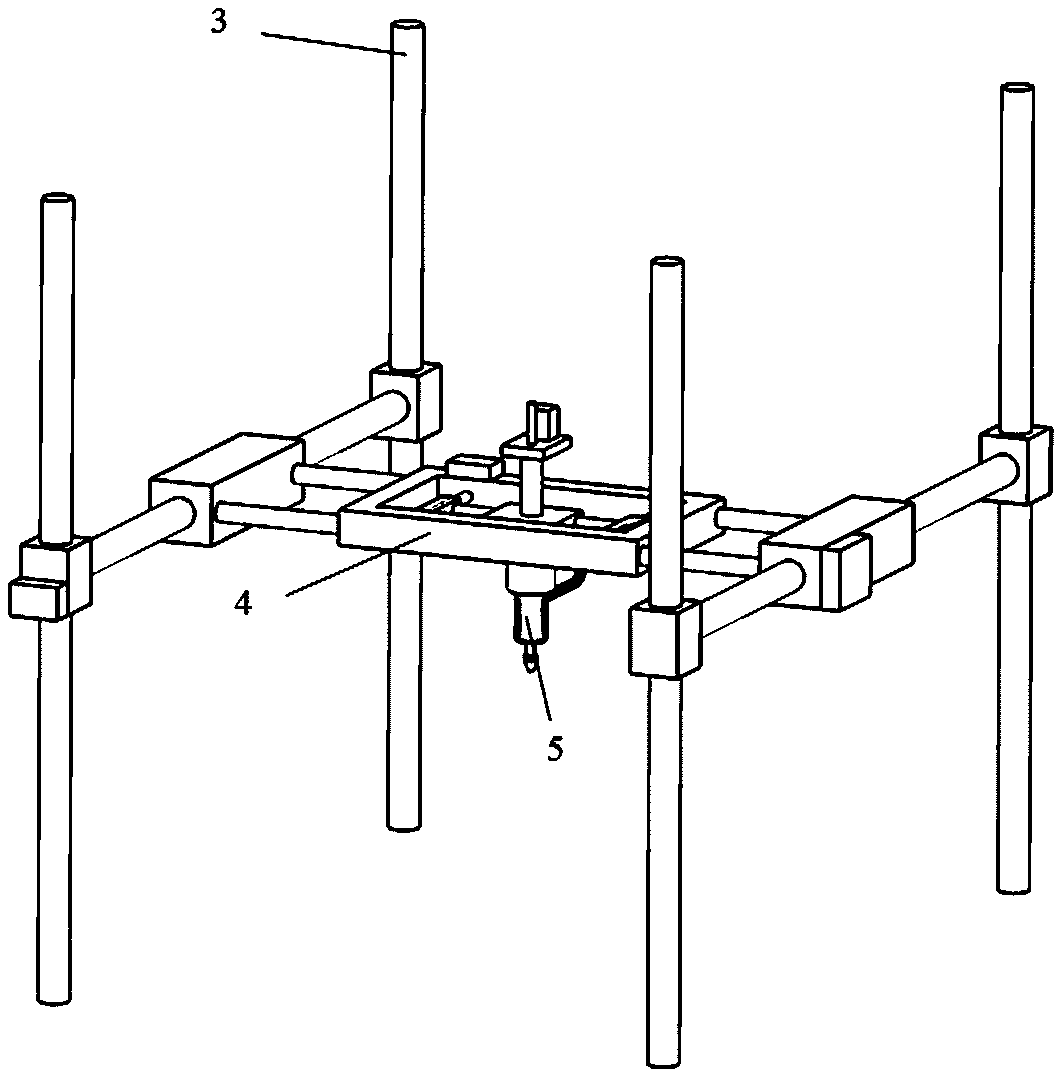

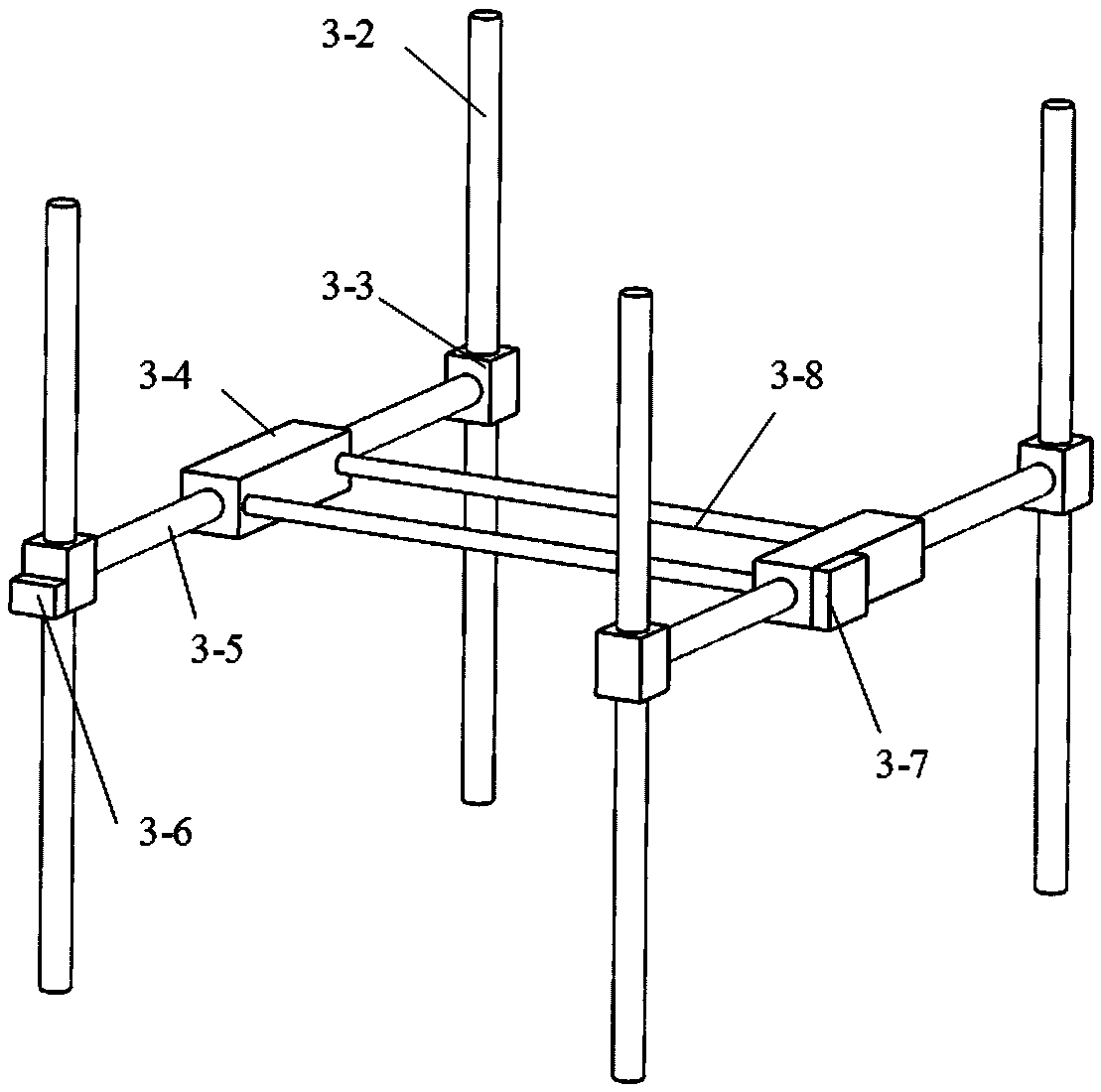

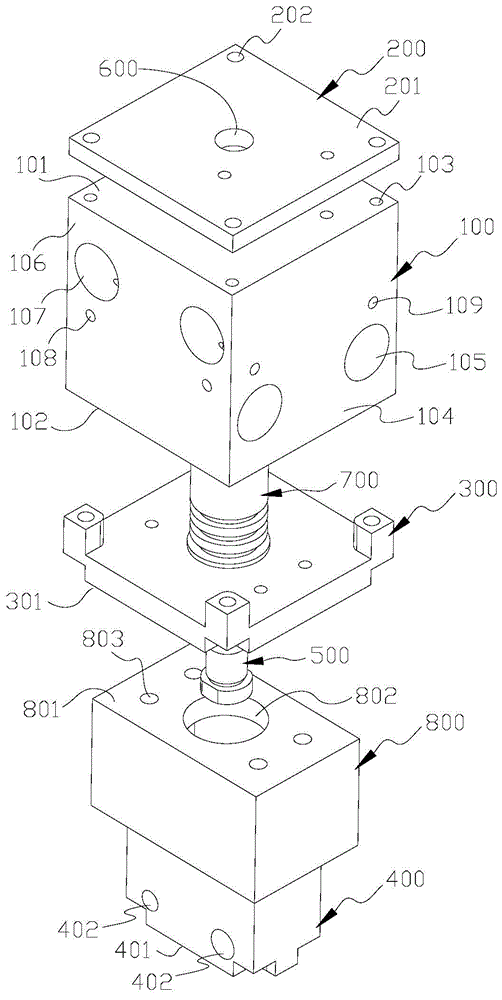

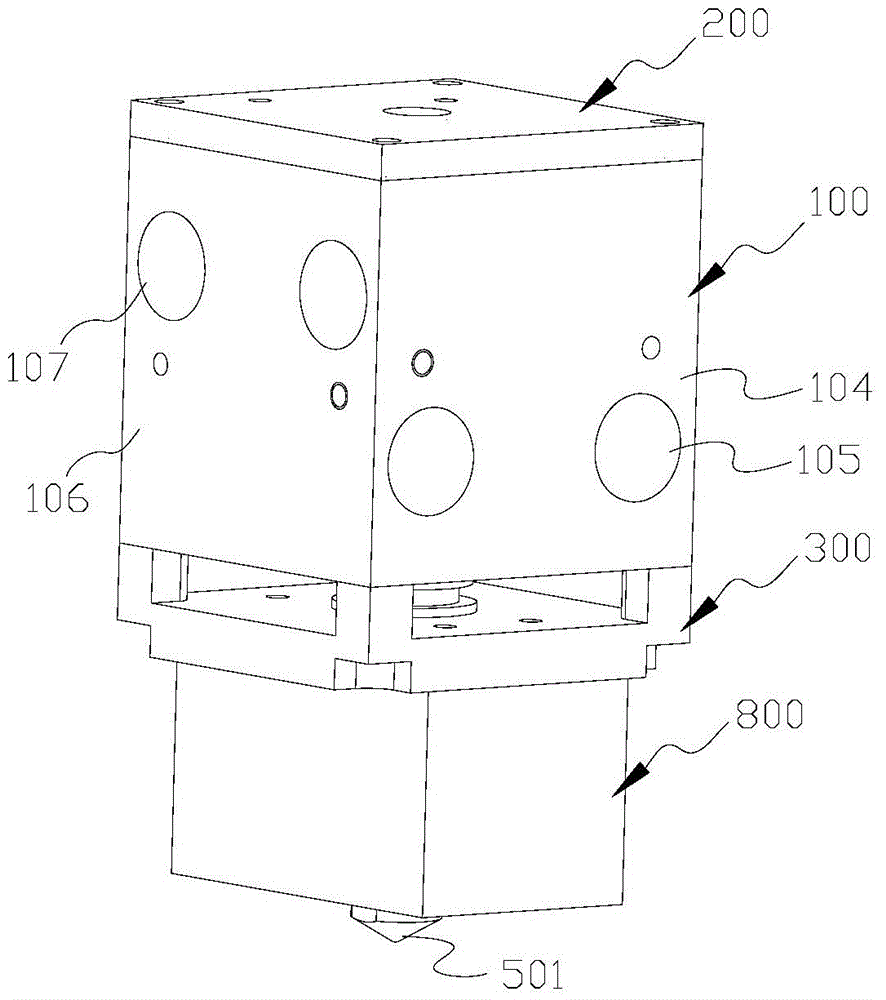

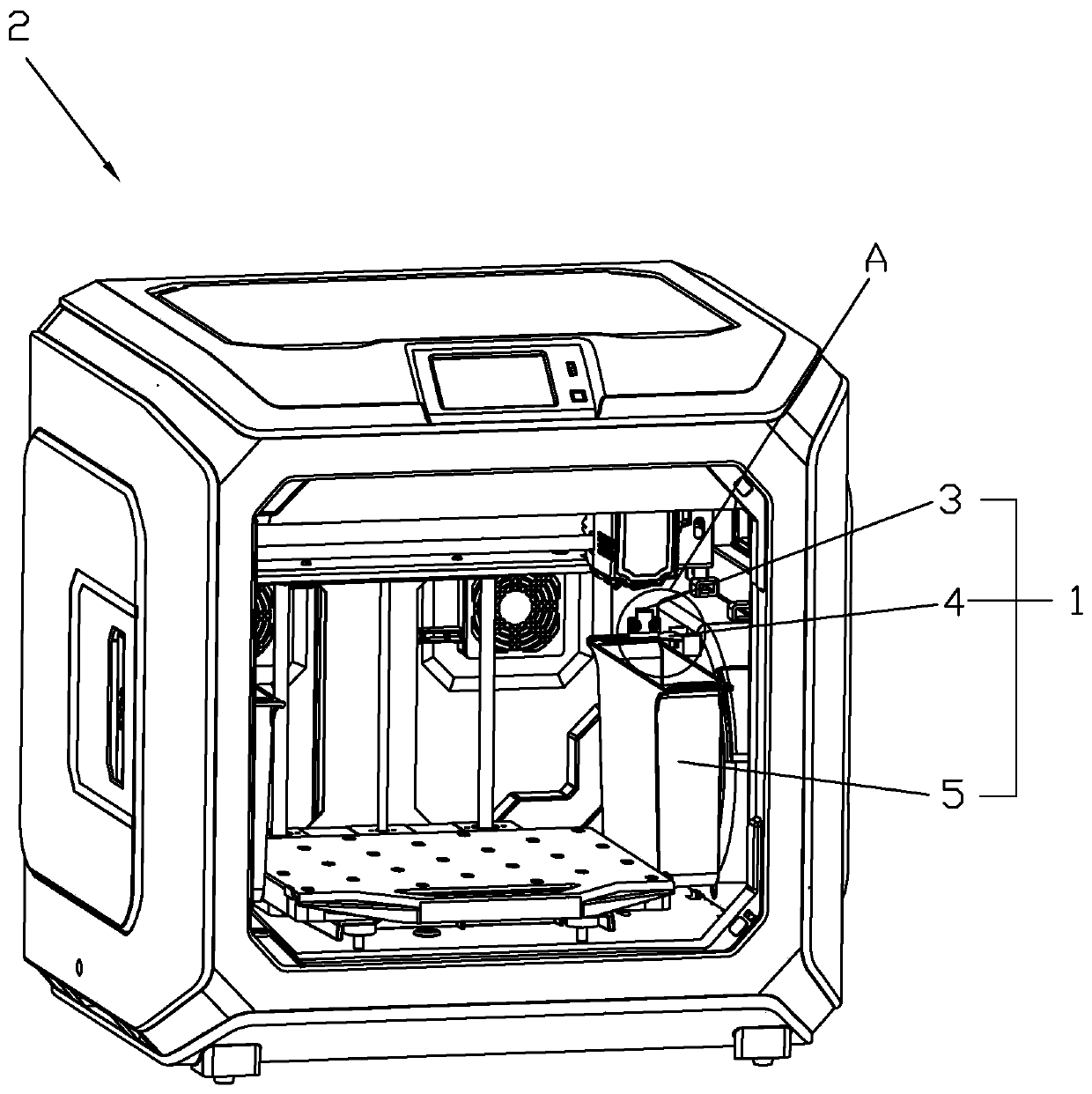

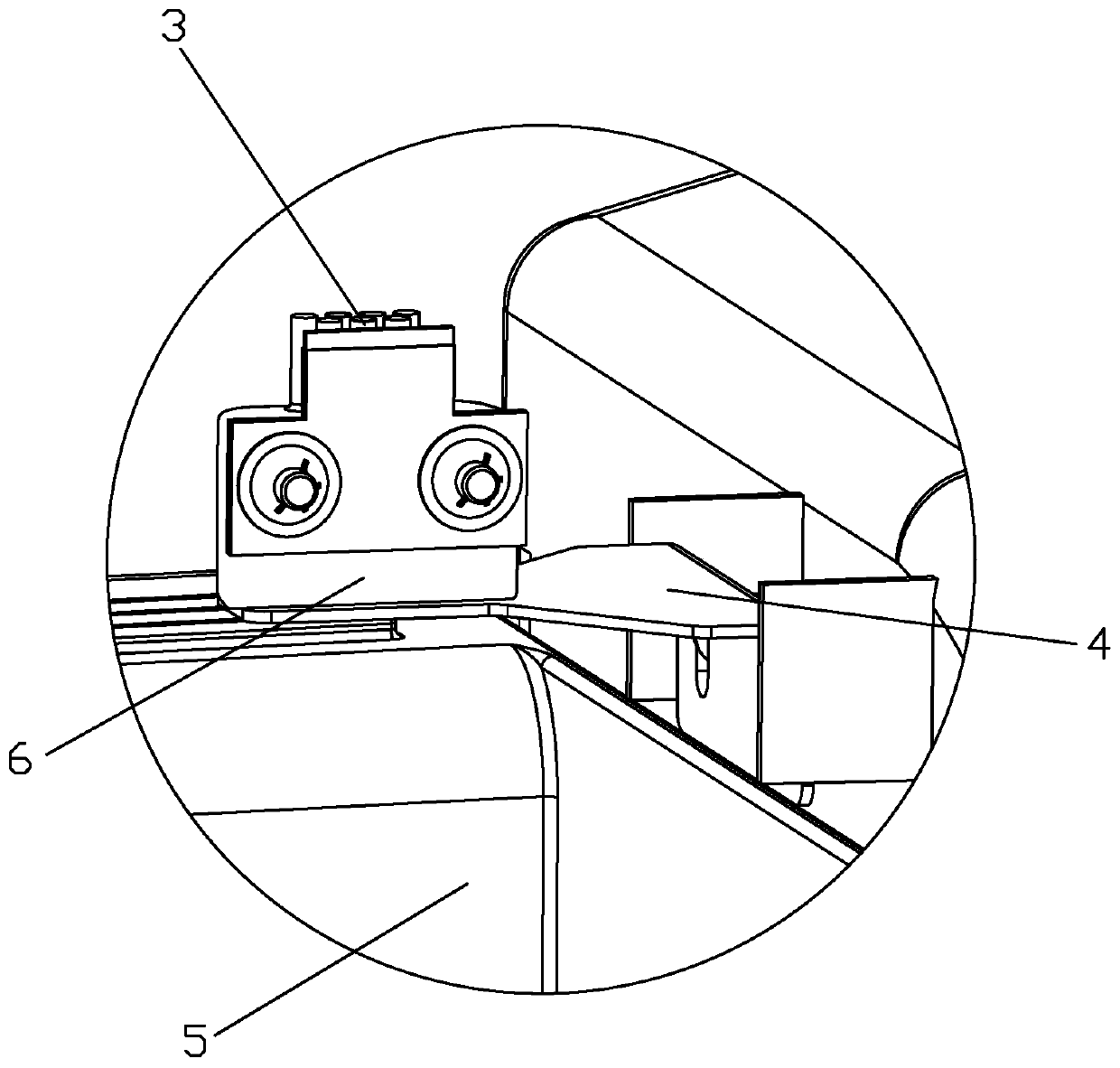

Novel precise 3D printer

ActiveCN105500715AReduce movement distanceLow forming precisionAdditive manufacturing apparatusFine structureEngineering

Owner:WUXI VOCATIONAL & TECHN COLLEGE

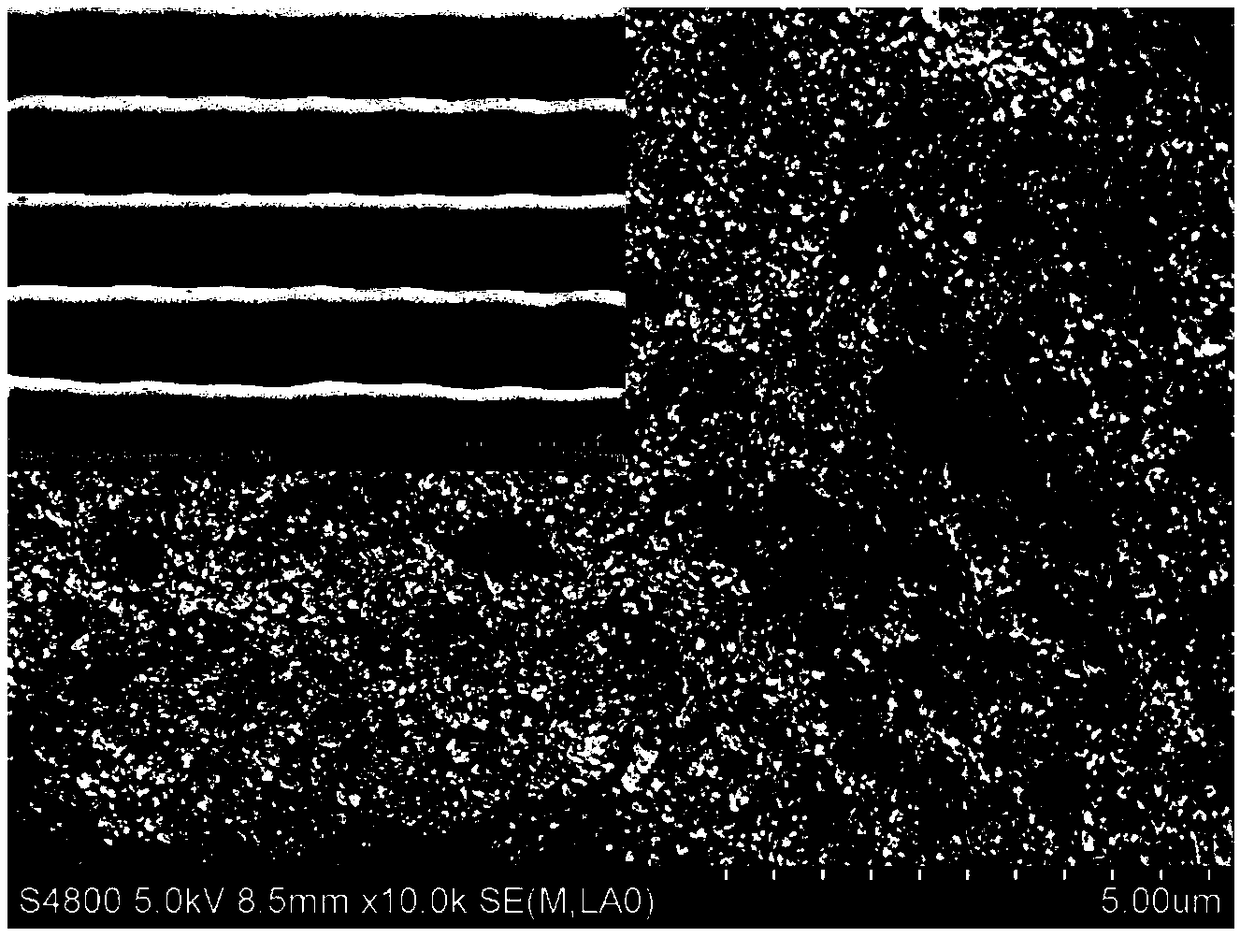

Biodegradable hard tissue repair composite scaffold prepared by 3D printing technology and preparation method thereof

PendingCN109260522AEvenly dispersedGood dispersionAdditive manufacturing apparatus3D object support structuresMelt extrusionHard tissue

The invention discloses a biodegradable hard tissue repair composite scaffold prepared by 3D printing technology and a preparation method thereof, belonging to the field of biomedical materials. The composite scaffold combines degradable high molecular polymer and biologically active calcium phosphate together through a wet composite method, complements each other in advantages, and obtains a hardtissue repair scaffold material with excellent mechanical properties and biologically active through a 3D printing technology of melt extrusion (FDM). Silane coupling agent was used to modify the surface of calcium phosphate nano-powder, which enhanced the combination of calcium phosphate and polymer, and improved the fluidity and integrity of outgoing wire in the preparation of FDM standard wire.

Owner:SICHUAN UNIV

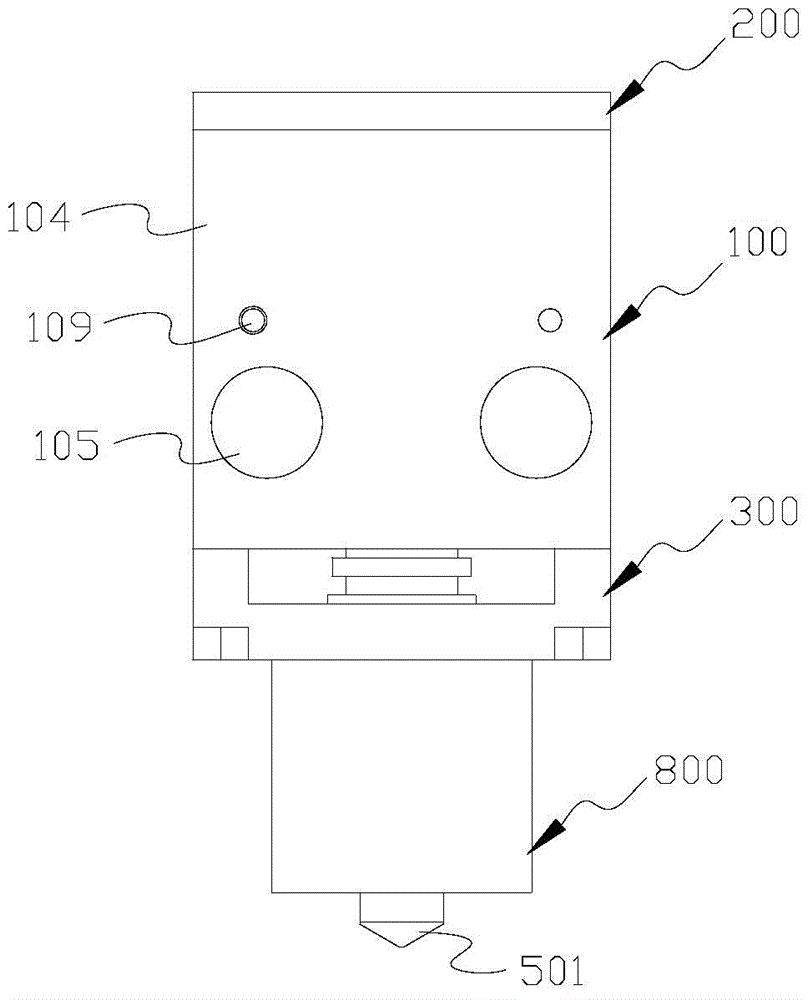

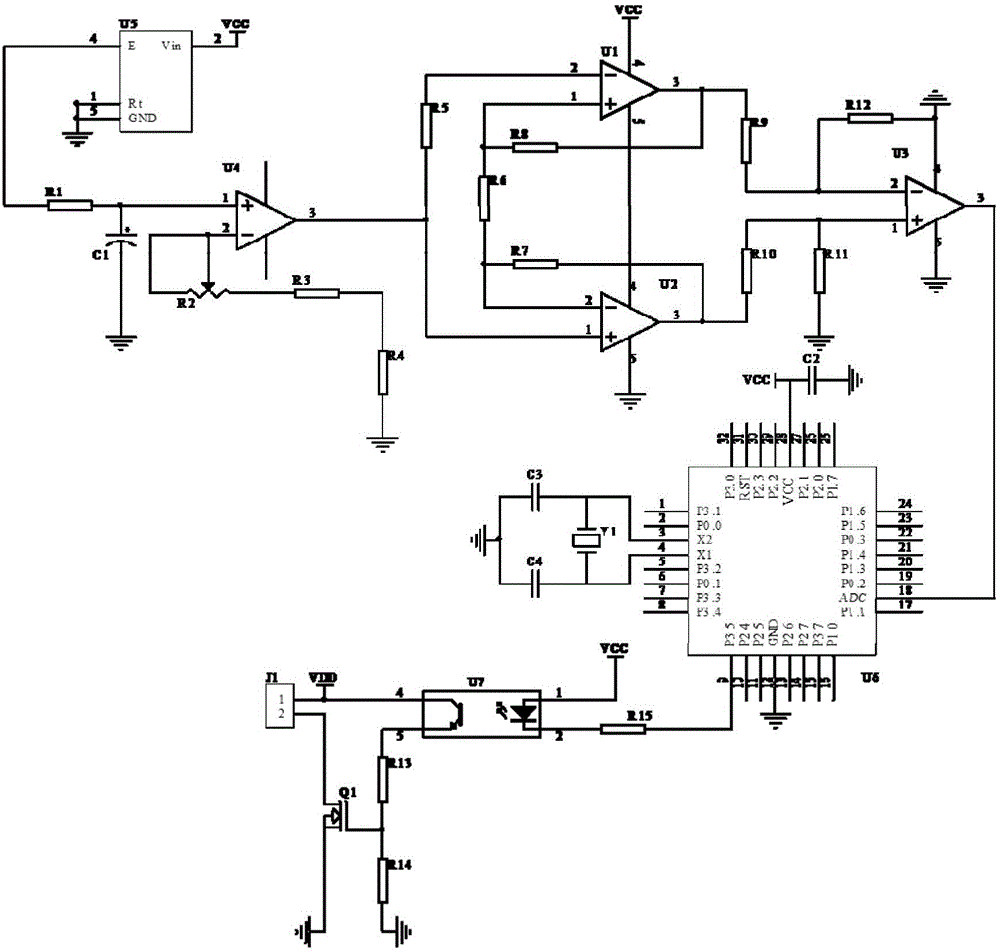

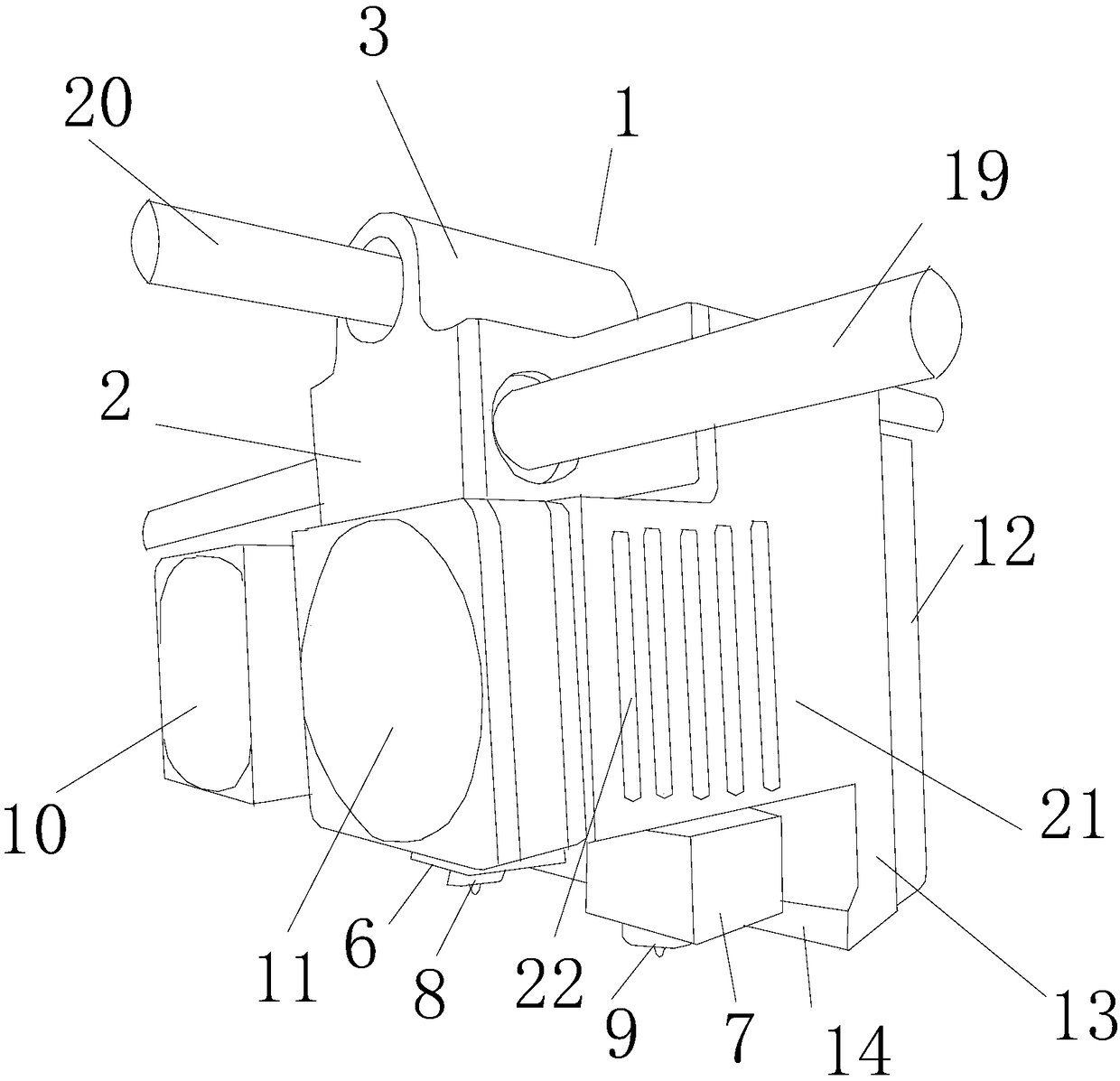

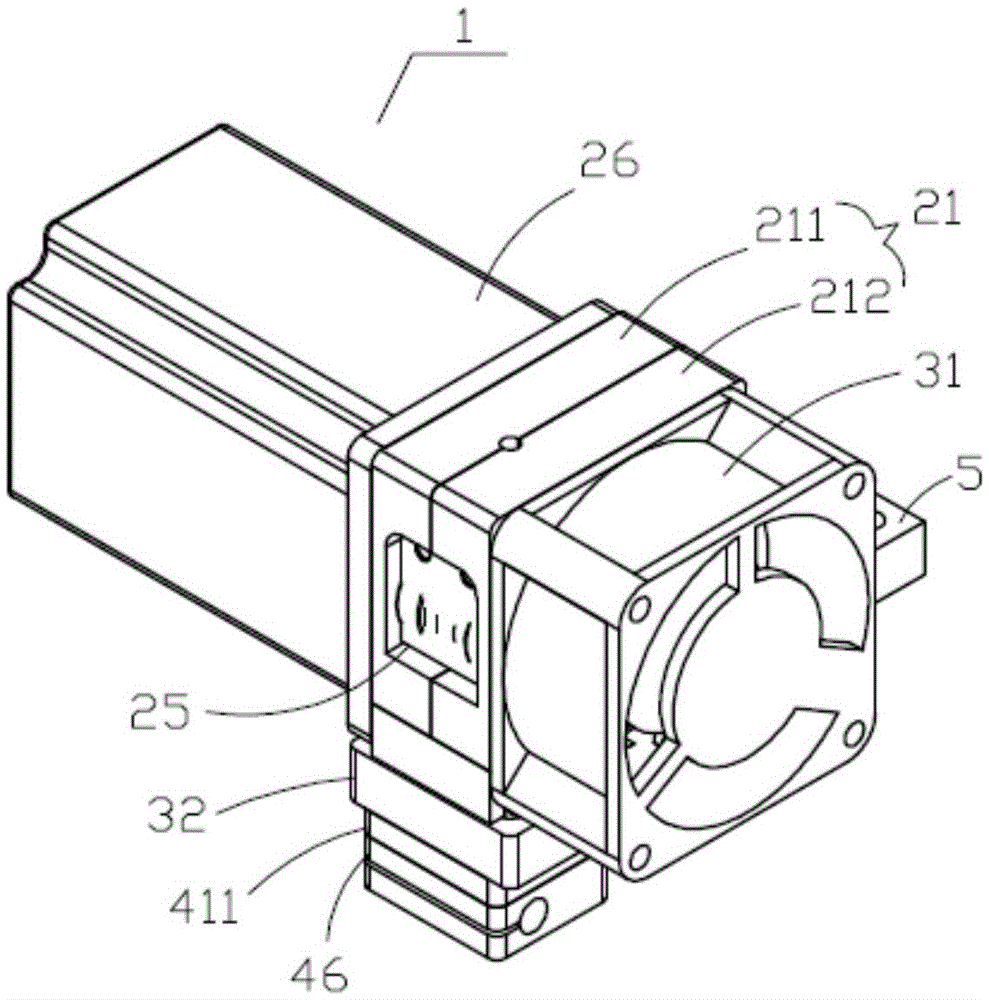

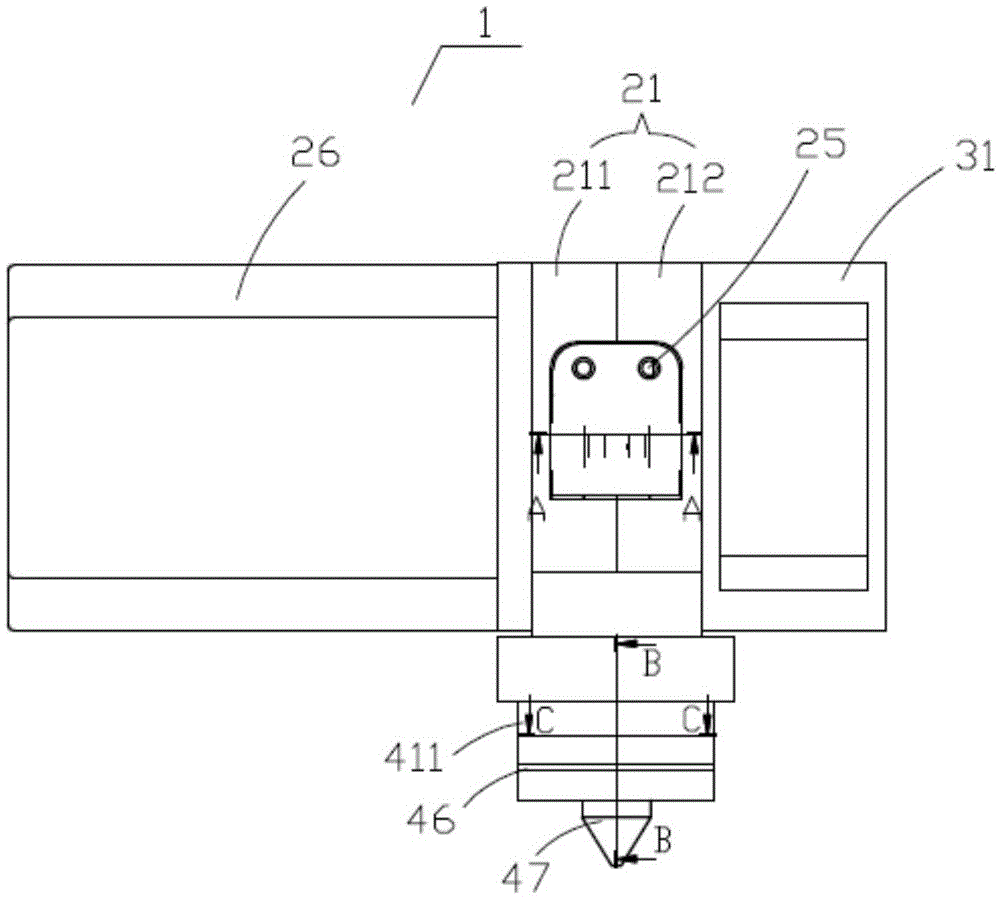

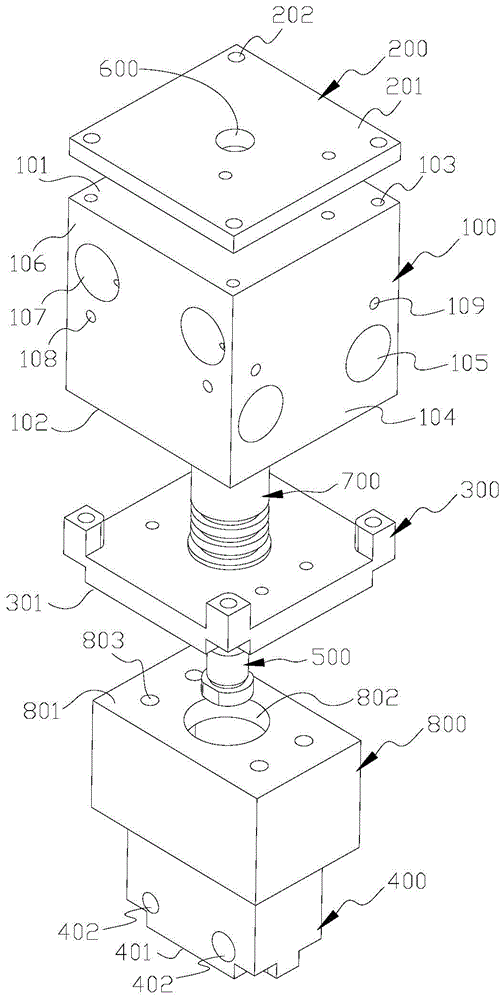

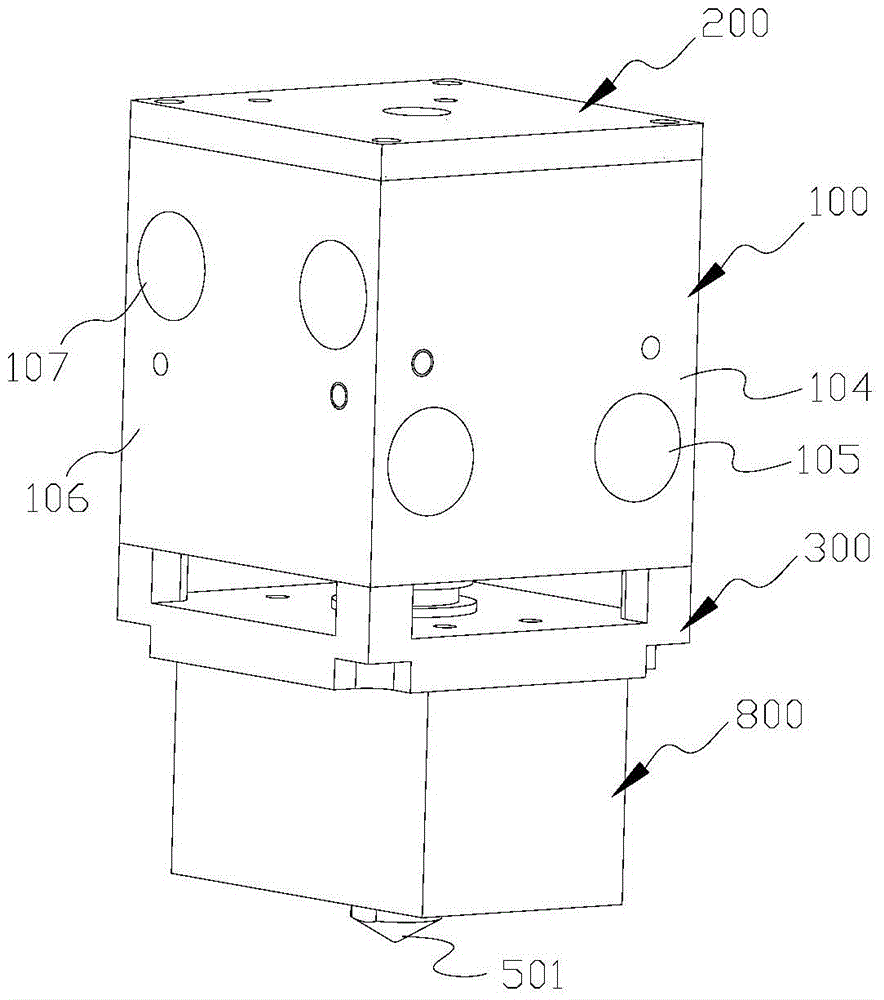

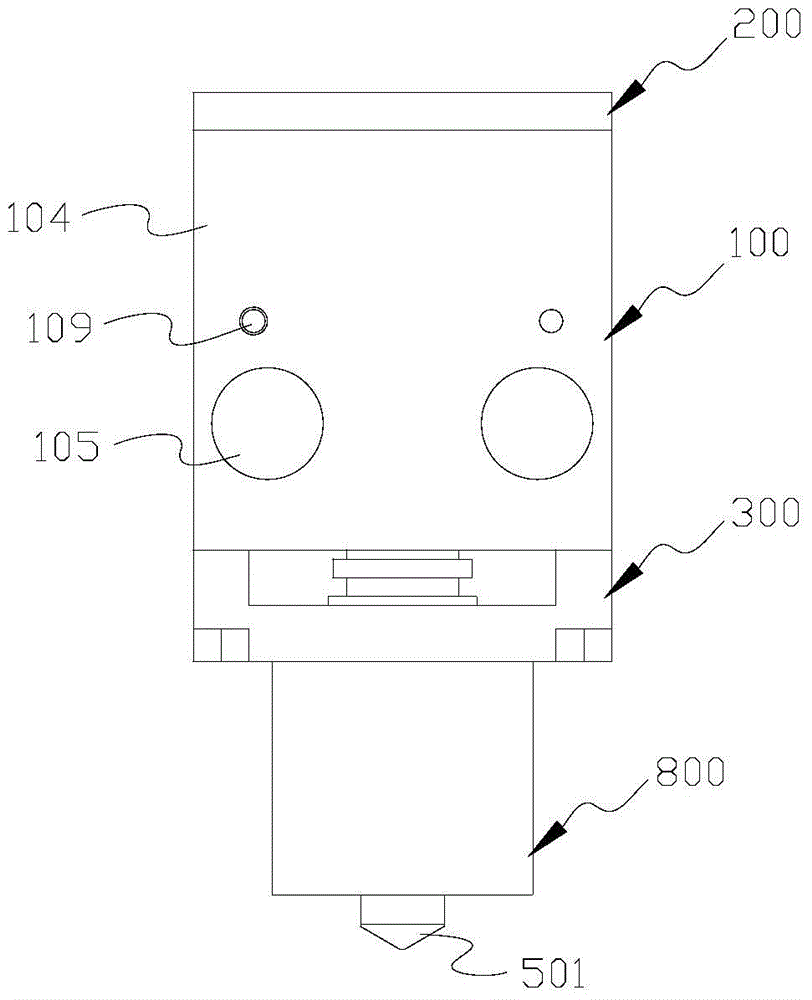

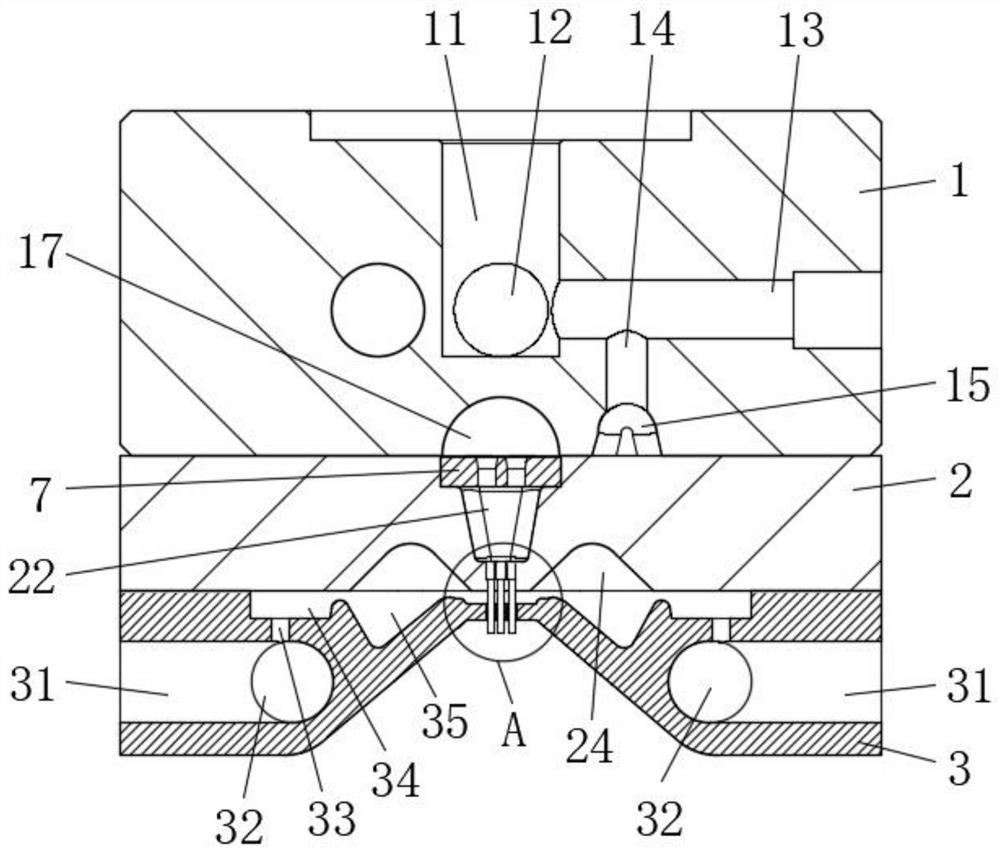

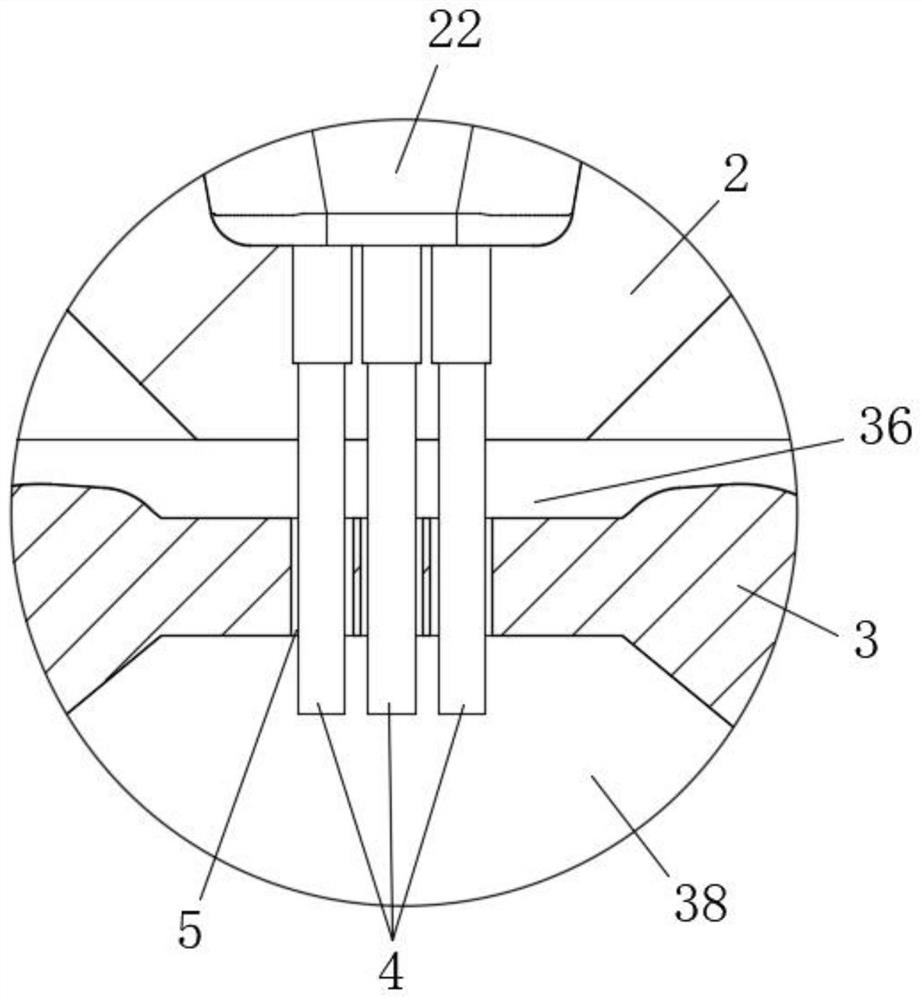

Intelligent nozzle of 3D (Three-Dimensional) printer

InactiveCN103950199AAvoid wear and tearAvoid the problem of open circuit or even short circuit3d printEngineering

The invention discloses an intelligent nozzle of a 3D (Three-Dimensional) printer. The intelligent nozzle of the 3D printer comprises a fixed bracket, a cover plate, a concave bracket, a heat conduction block and a material guide pipe, wherein the cover plate is mounted at the top of the fixed bracket; the concave bracket is mounted at the bottom of the fixed bracket; the heat conduction block is mounted at the bottom of the concave bracket; an extrusion head is arranged at the front end of the material guide pipe; the material guide pipe is vertically arranged in the fixed bracket; the extrusion head is exposed out of the bottom of the heat conduction block; the intelligent nozzle of the 3D printer also comprises at least one heating part and at least one temperature sensing part; the heating part and the temperature sensing part are mounted in the heat conduction block. The extrusion head of the intelligent nozzle comprises the heating part and the temperature sensing part and is capable of accurately controlling the thread extrusion temperature, guaranteeing the smooth thread extrusion and automatically cleaning the nozzle; all circuit lines are fixed in the nozzle, so that the problem that the circuit lines are abraded, broken and cut out in the process of moving the extrusion head is avoided.

Owner:上海骧远信息科技有限公司

Radiation protection double-layer chiffon silk fabric

The invention discloses radiation protection double-layer chiffon silk fabric which is double-layer double-face weave yarn-dyed fabric. A mulberry silk plain weave structure is arranged on the surface layer, and a mulberry silk and silver fiber pilotaxitic texture is arranged on the inner layer. The warp density of the inner layer is larger than or equal to 20 / cm, the weft density of the inner layer is larger than or equal to 20 / cm, the warp density of silver fibers is 20-25 / m, and the weft warp density of the silver fibers is 38-45 / m. The surface layer and the inner layer are connected through binding places. The radiation protection double-layer chiffon silk fabric has good radiation protection performance, meanwhile, the problem that existing anti-electromagnetic radiation fabric is poor in appearance is solved, and the new process of weaving real silk and silver fiber interweaving products is created.

Owner:DING SHENG SILK

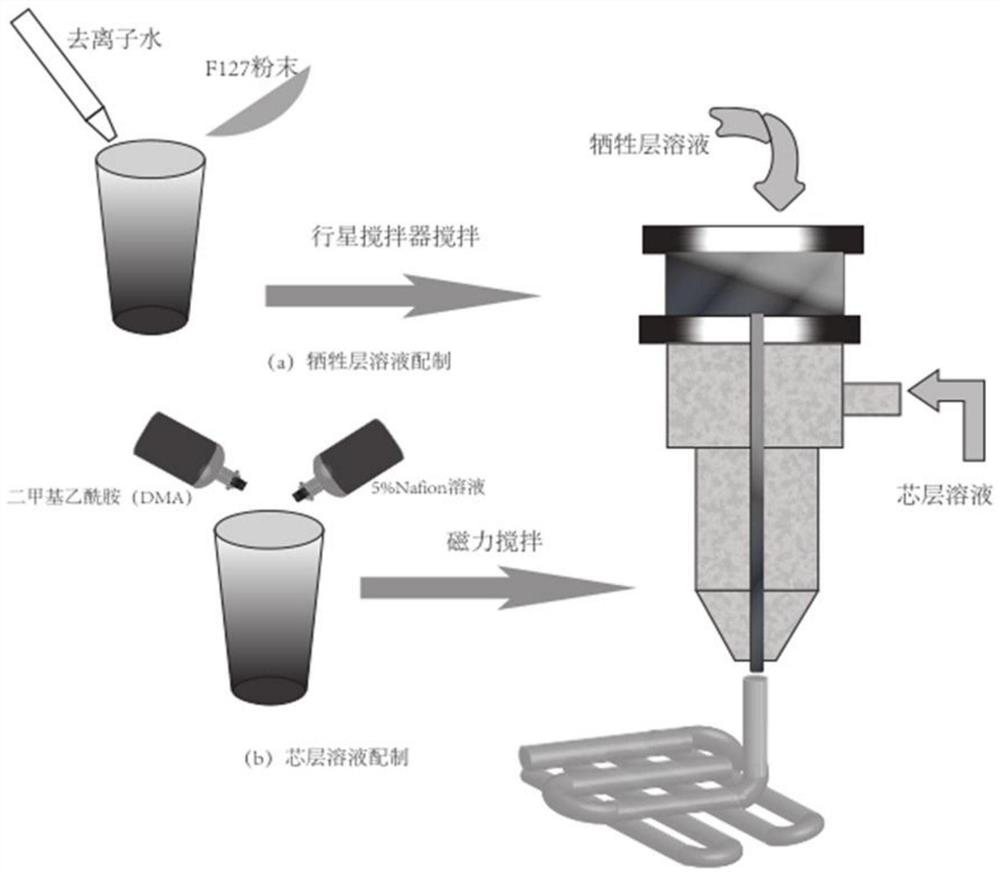

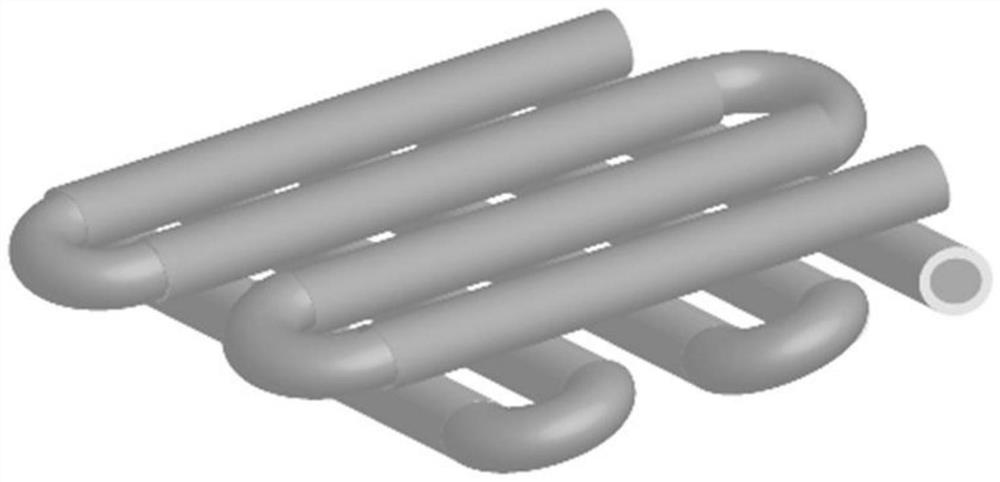

Direct writing printing method of Nafion hollow tube structure

PendingCN113021878ASolving Rapid Manufacturing ChallengesAchieve preparationAdditive manufacturing apparatus3D object support structuresAcetamidePoloxamer

The invention discloses a direct writing printing method of a Nafion hollow tube structure. The direct writing printing method comprises the following steps that an ionic polymer solution Nafion and dimethyl acetamide are mixed and stirred, and then the mixture is subjected to vacuum-pumping treatment to obtain Nafion matrix 3D printing ink with the concentration of 45%; poloxamer powder is mixed with deionized water, and the mixture is stirred to obtain a colorless transparent gelatinous sacrificial layer printing ink; printing process parameters are set, direct writing printing is conducted through the prepared Nafion matrix 3D printing ink and sacrificial layer printing ink, and the hollow structure is obtained; and the obtained hollow structure is placed in vacuum to be subjected to heating curing treatment, then the cured structure is placed in water to remove the sacrificial layer, and the Nafion hollow pipe structure is obtained. According to the method, the 3D printing technology and the Nafion casting film are combined, and rapid manufacturing of the personalized multi-parameter Nafion hollow tube structure can be achieved.

Owner:SHAOYANG UNIV

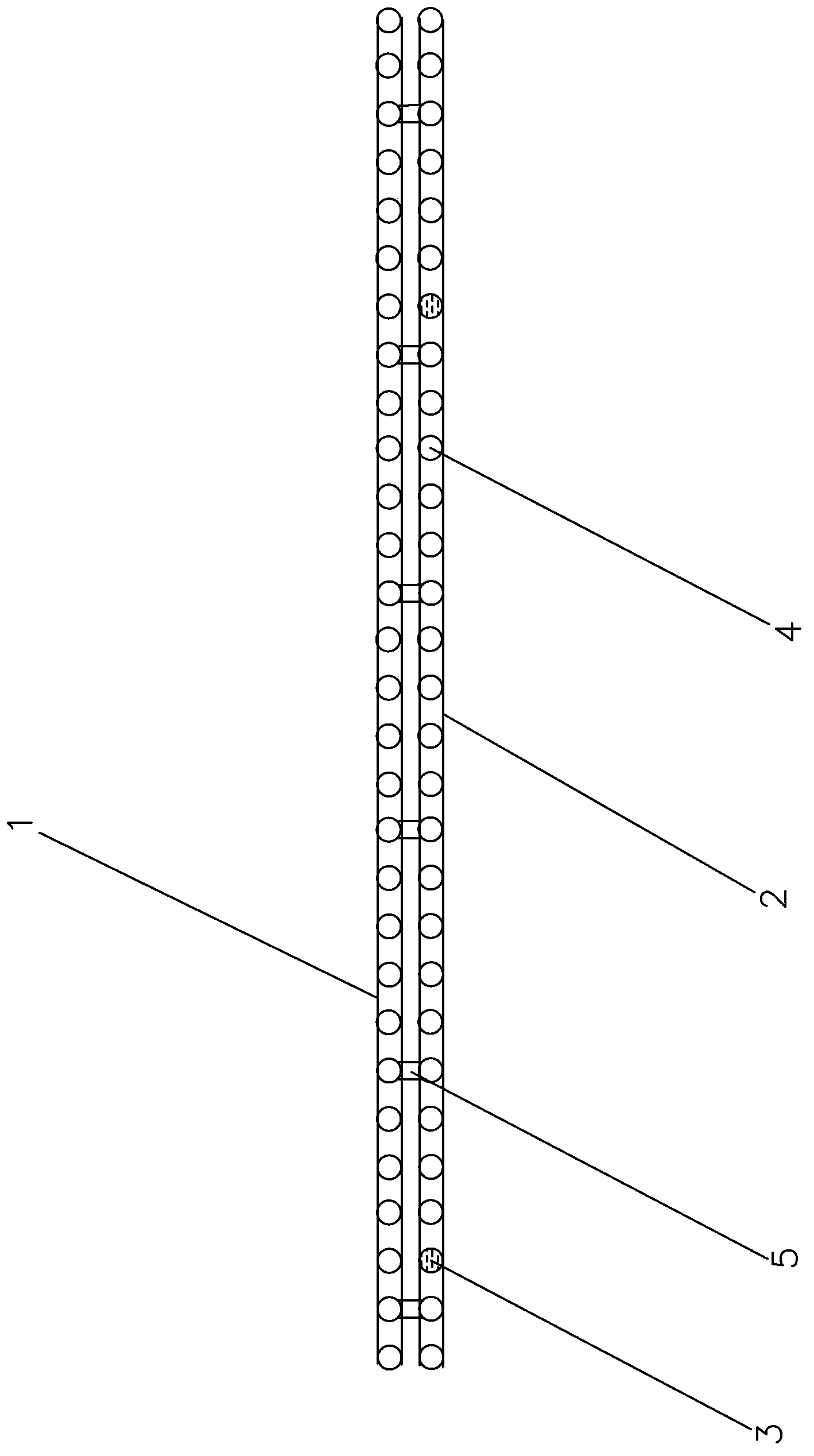

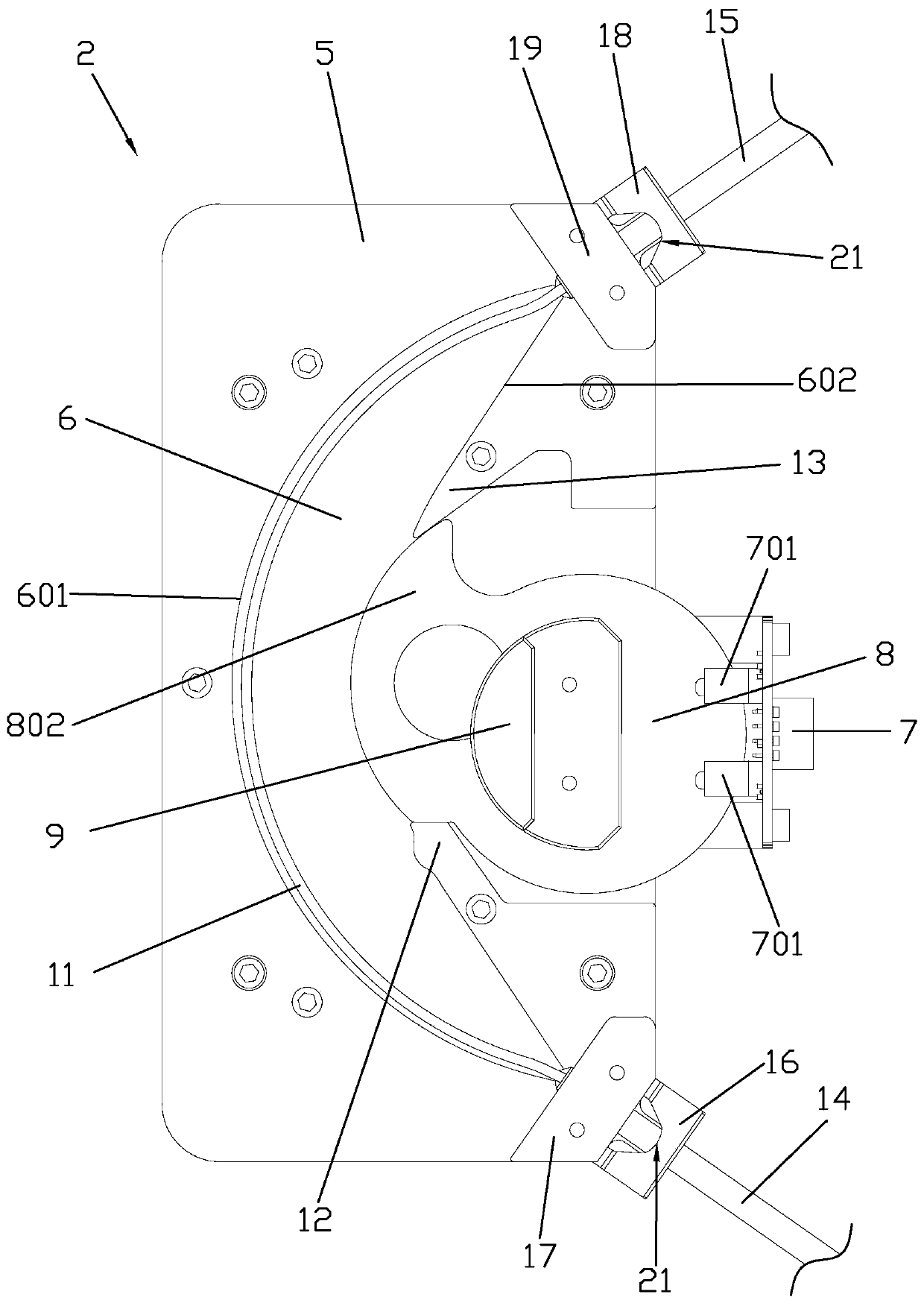

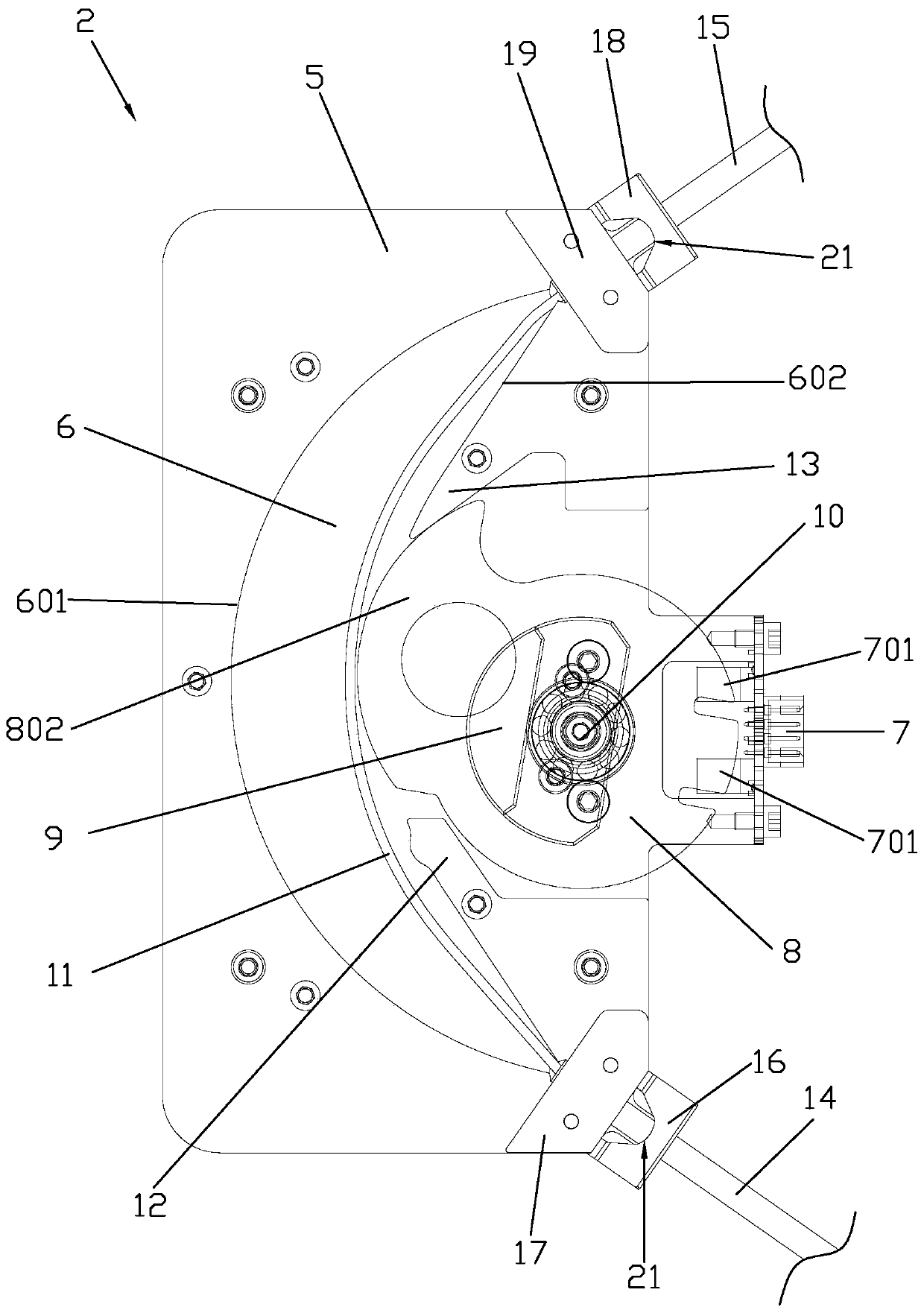

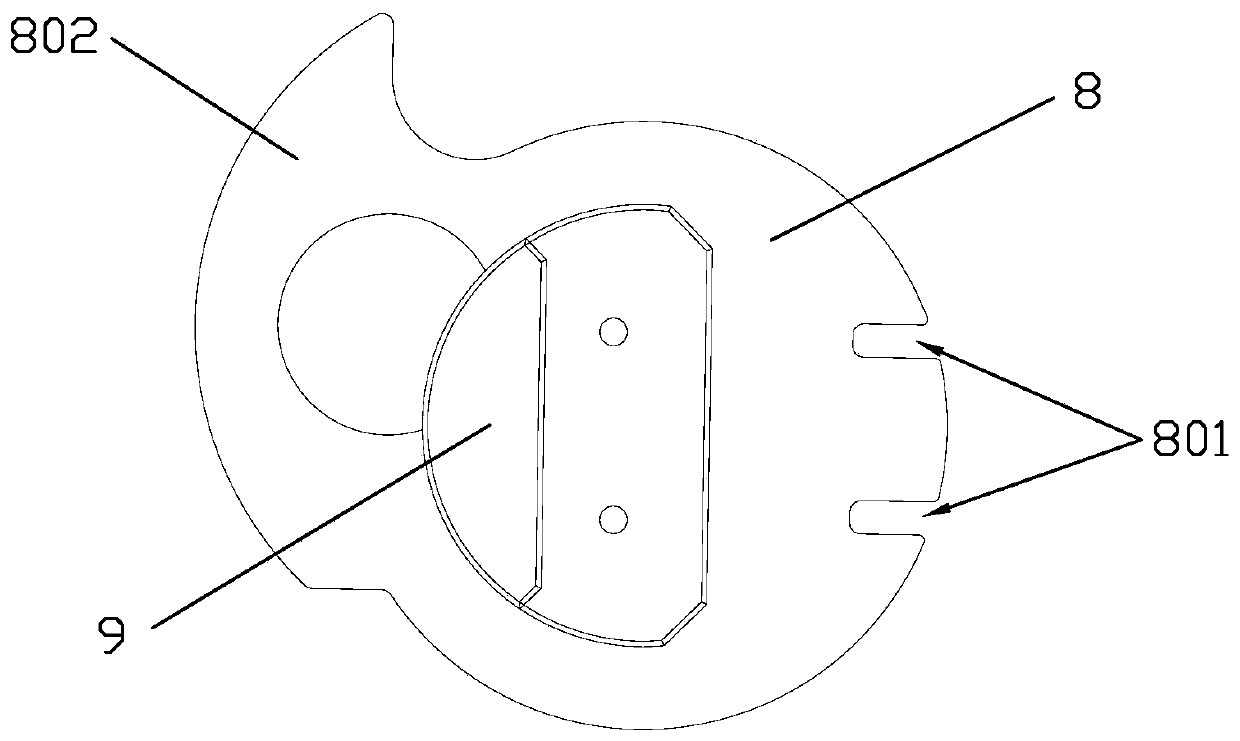

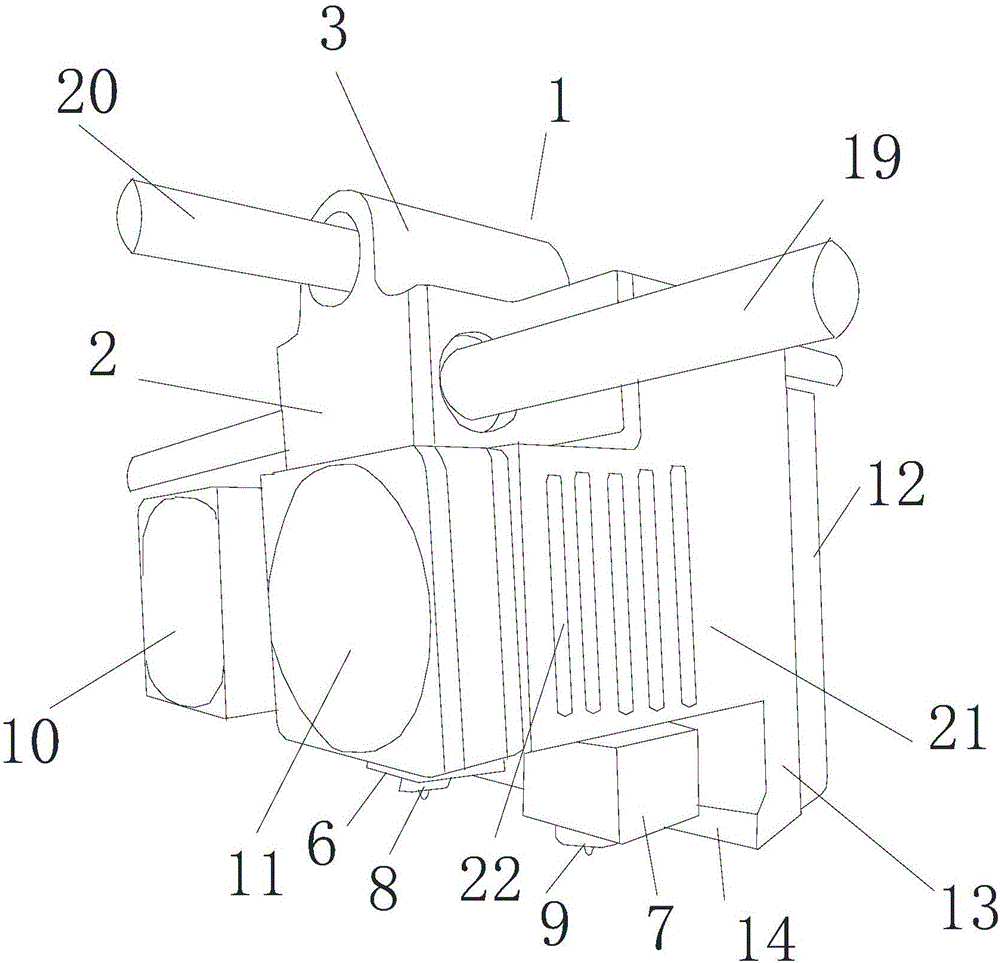

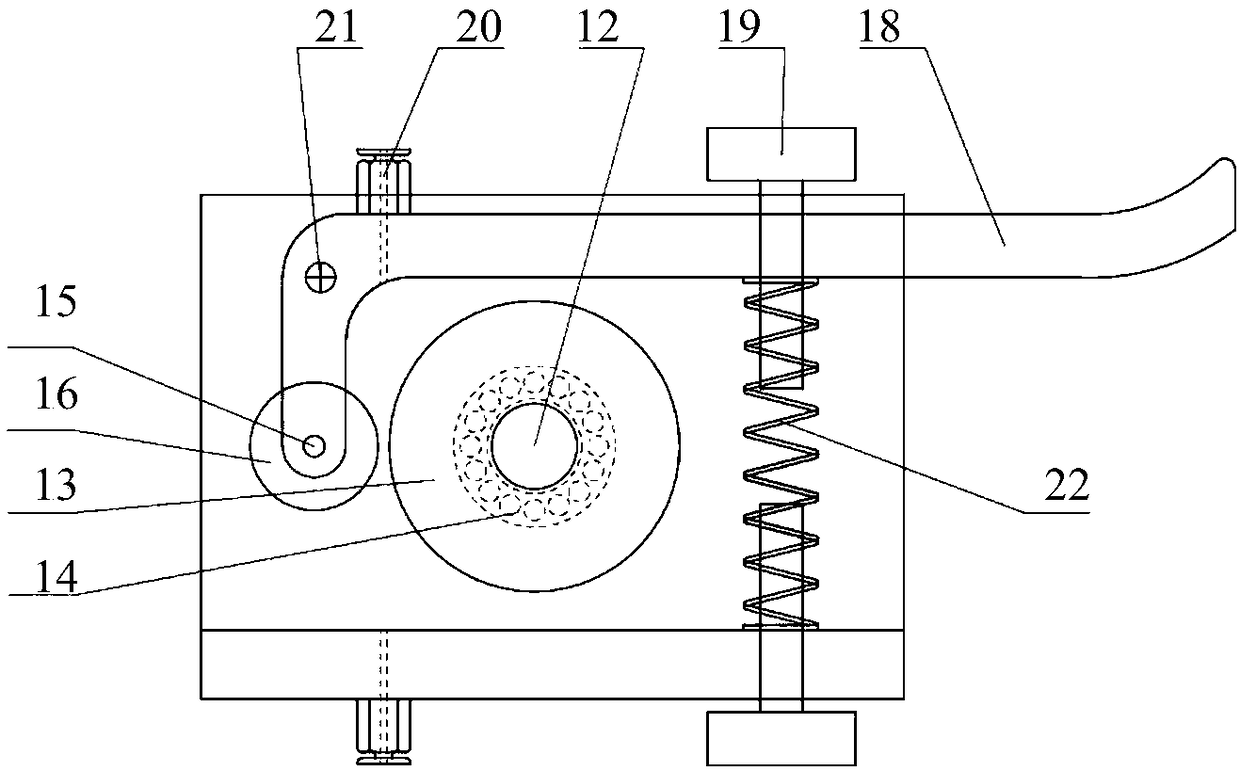

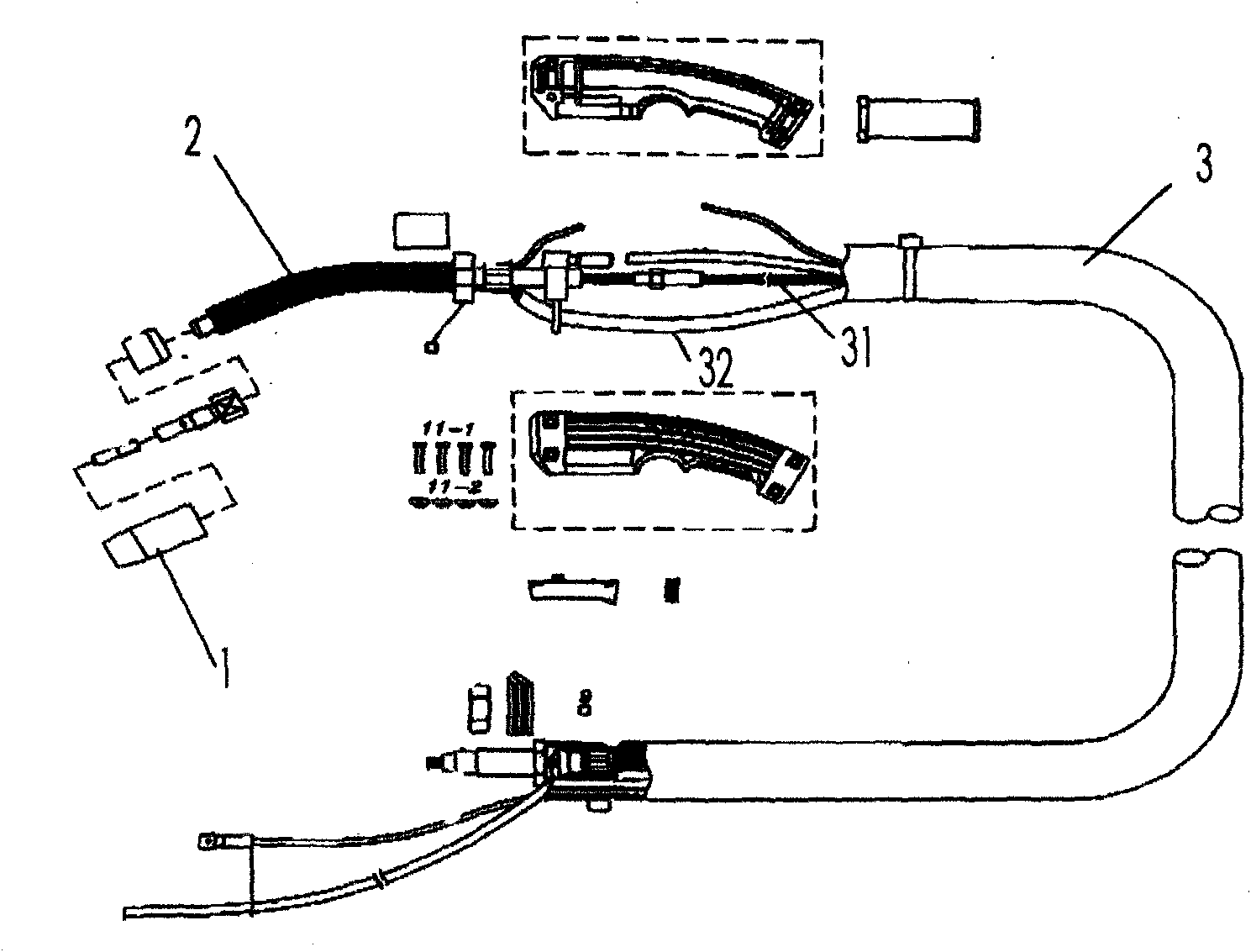

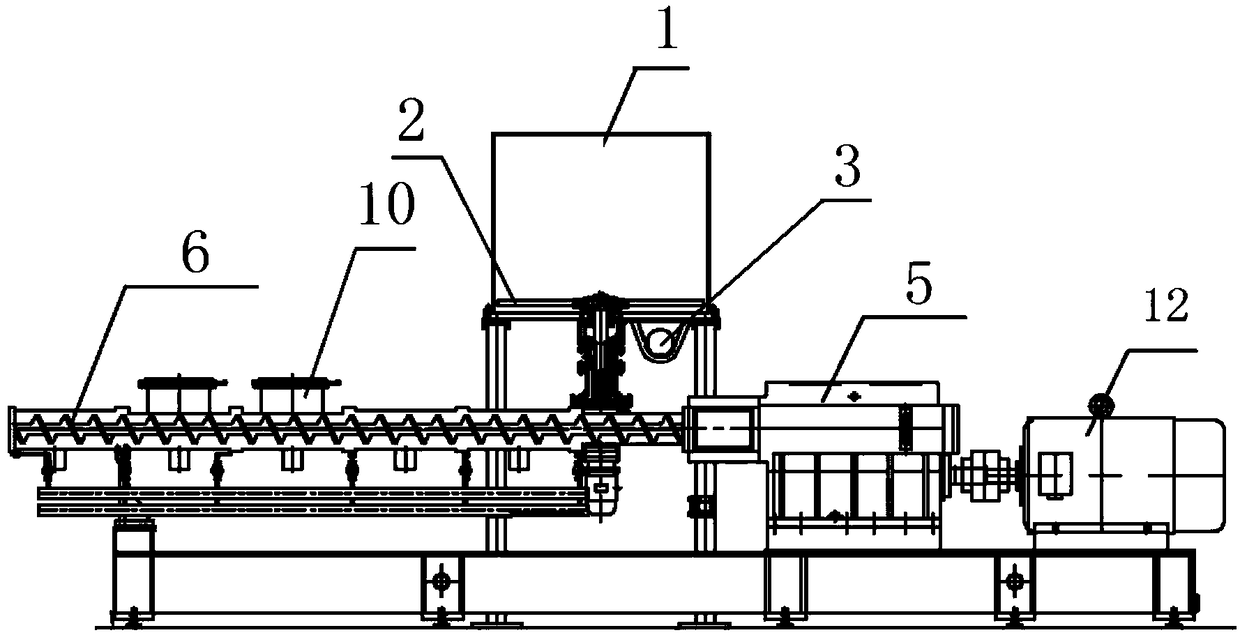

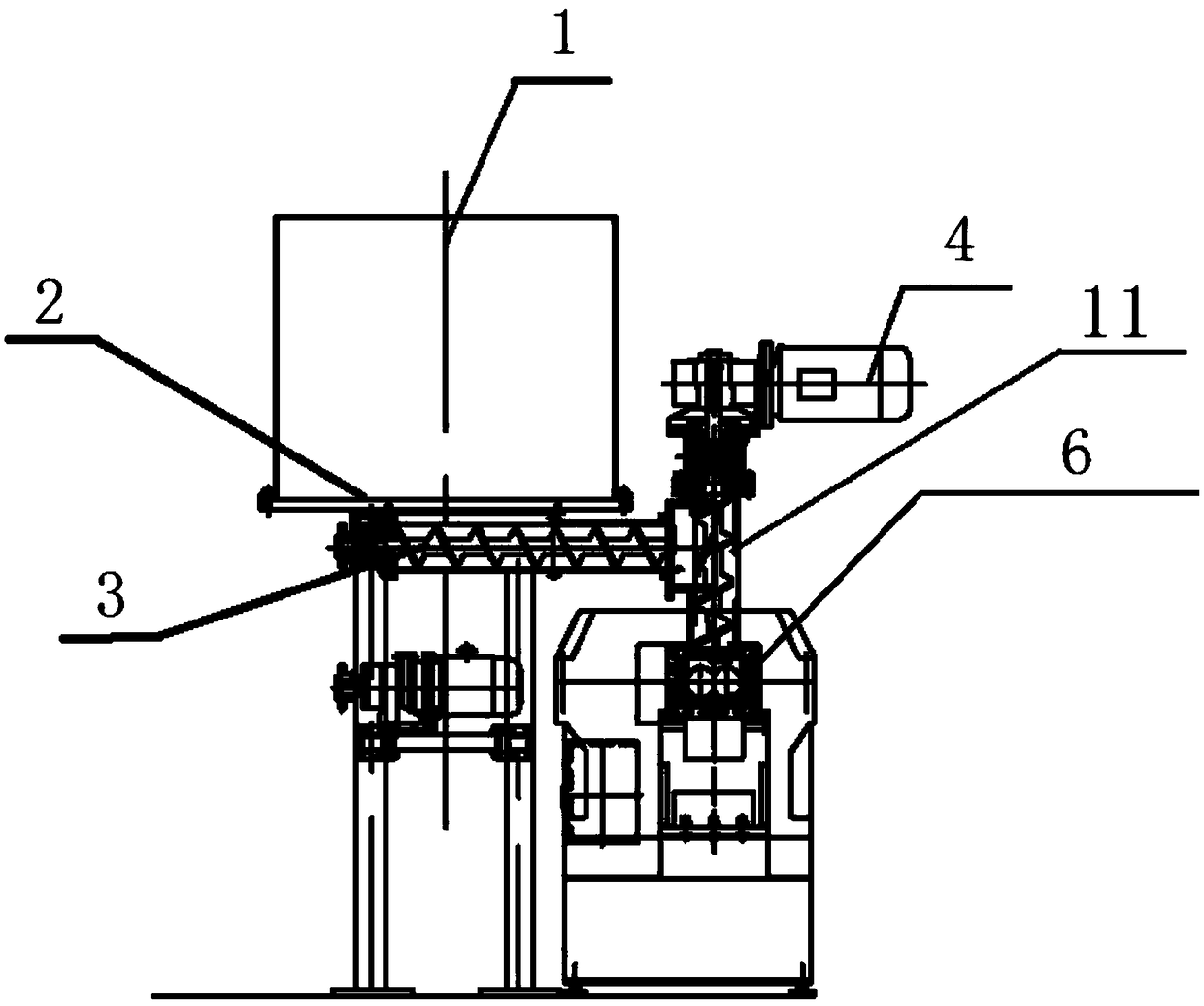

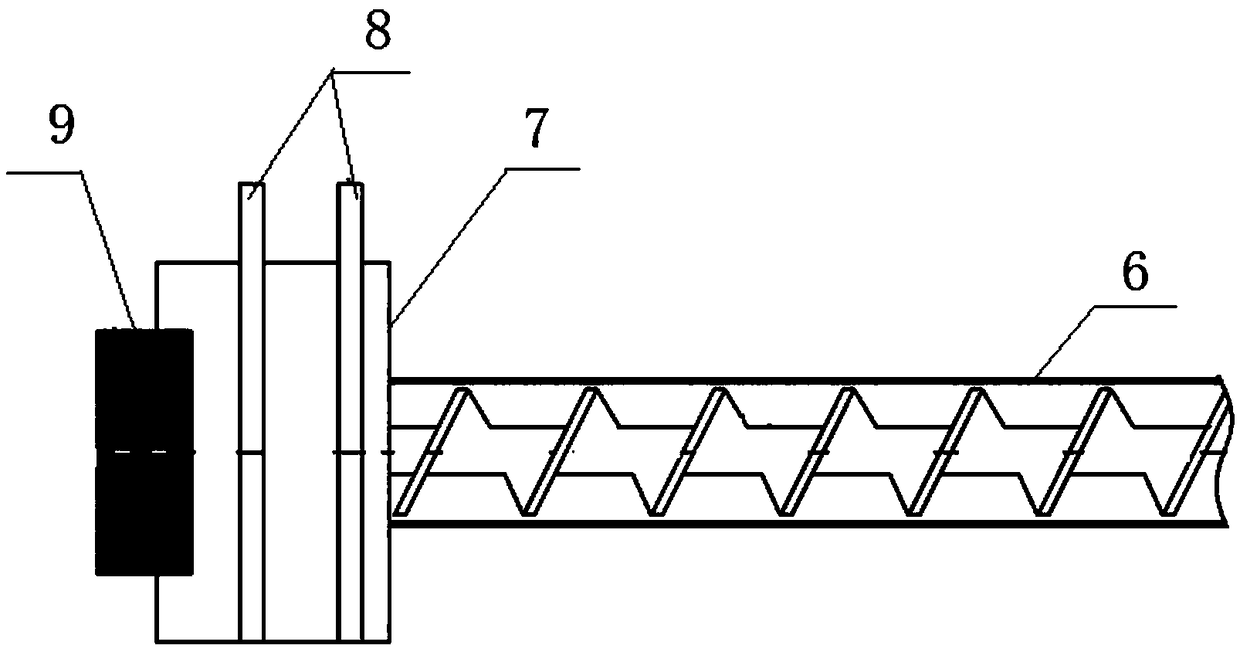

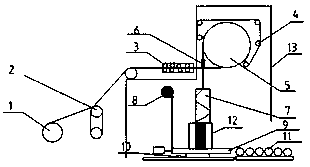

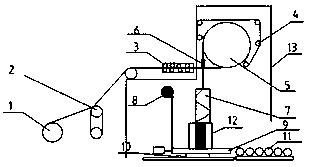

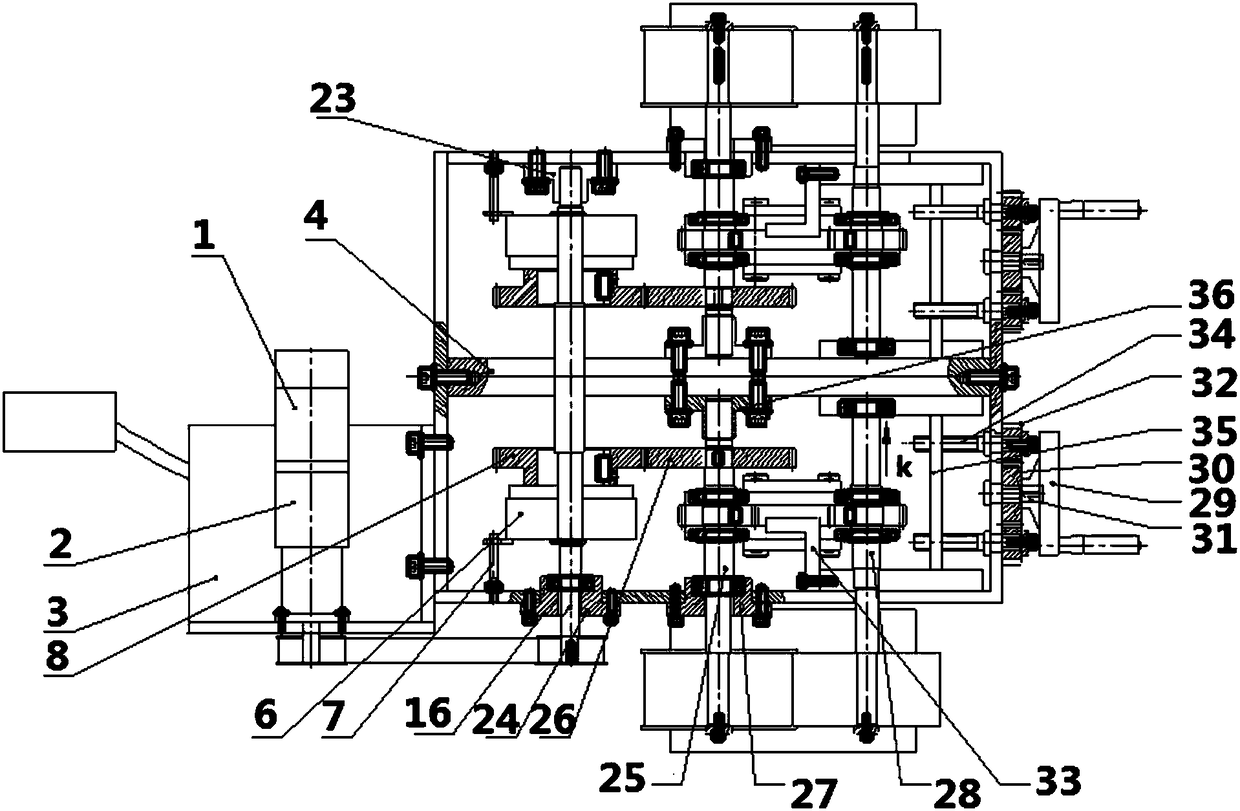

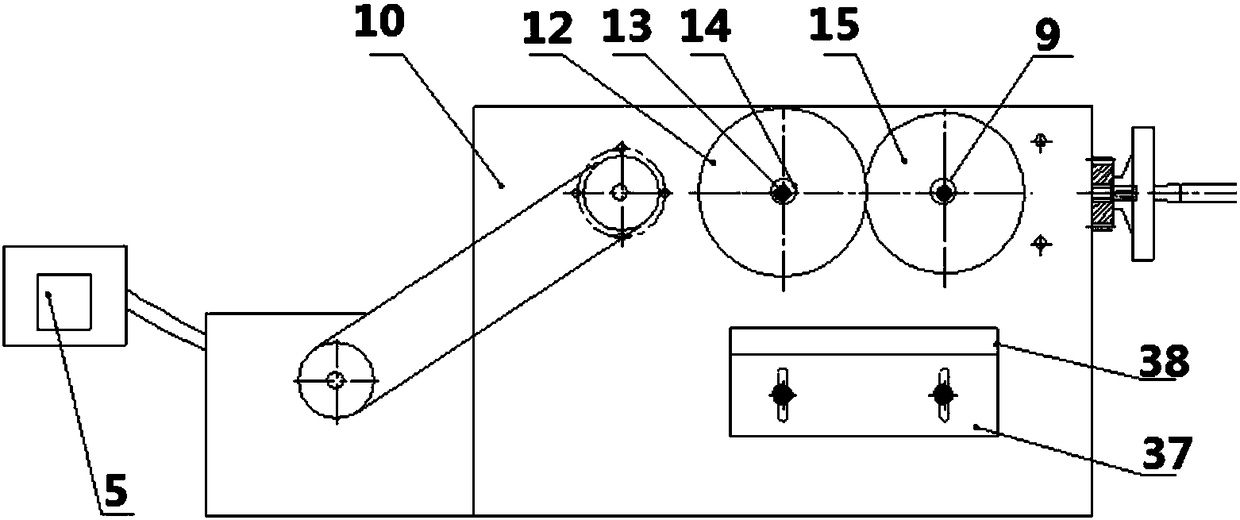

3D (three-dimensional) printer silk material conveying mechanism and silk feeding method thereof

PendingCN110509541AImprove stabilitySmooth silkAdditive manufacturing apparatus3D object support structuresEngineering3d printer

The invention discloses a 3D (three-dimensional) printer silk material conveying mechanism. The 3D printer silk material conveying mechanism is characterized in that a silk material used for providingsilk to a nozzle is placed in a silk material box, the silk material is conveyed to the nozzle through a power system, and the power system comprises a silk material pushing device close to one end of the silk material box, a silk material pulling device close to one end of the nozzle and a silk material buffer device arranged between the silk material pushing device and the silk material pullingdevice. A silk feeding method includes that the silk material pushing device stops running after pushing a segment of the silk material to the silk material buffer device, the silk material pulling device continuously runs and pulls the silk material, and when the silk material in the silk material buffer device is tightened, the silk material pushing device continuously pushes the segment of thesilk material to the silk material buffer device. According to the 3D printer silk material conveying mechanism, the silk material buffer device is arranged between the silk material pushing device and the silk material pulling device, the silk material pushing device discontinuously provides pushing force, the silk material pulling device continuously provides pulling force, the silk material pushing device and the silk material pulling device can continuously output silk without need for synchronously moving, and printing quality is improved.

Owner:ZHEJIANG FLASHFORGE 3D TECH CO LTD

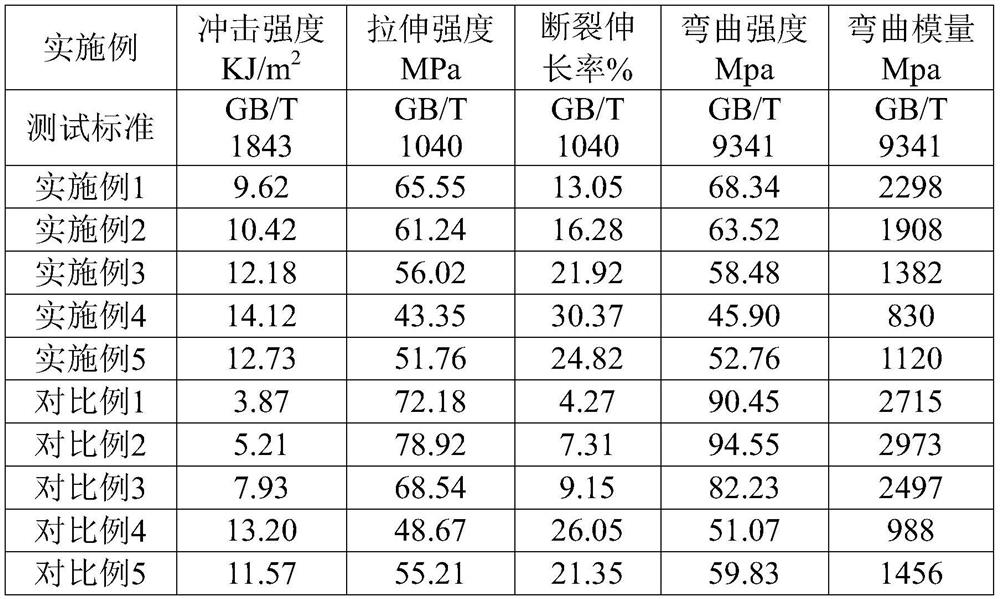

Polyamide 6 modified material for additive manufacturing, and preparation method thereof

InactiveCN107778846ASimple processGood modification effectAdditive manufacturing apparatusPolyamideGlass fiber

The invention relates to the field of additive manufacturing consumables, and discloses a polyamide 6 modified material for additive manufacturing, and a preparation method thereof. The polyamide 6 modified material comprises, by mass, 62-78% of polyamide 6 (PA6), 8-15% of glass fibers, 8-20% of a toughener, 5-10% of a compatibilizer, 0.3-2% of an antioxidant and 0.2-1% of a fiber glass exposure inhibitor. The preparation method has a simple process, and has the following remarkable modification effects: 1, the glass fibers and the toughener are added, so the mechanical strength and the toughness of the prepared polyamide 6 modified material are obviously improved, and the strengthening and toughening effects are remarkable; 2, the preferable glass fiber exposure inhibitor is added, so thefree fluidity of the material is improved, and the processing performances are improved, thereby the surface glossiness of the material is high; 3, the material has a lower shrinkage rate and a higher thermal deformation temperature than traditional nylon materials; and 4, printing verifies that silks are smoothly produced from nozzles during 3D printing, and the material has the advantages of low warping, high precision and good appearance quality, and is very suitable for producing consumables for FDM additive manufacturing.

Owner:四川鑫达企业集团有限公司

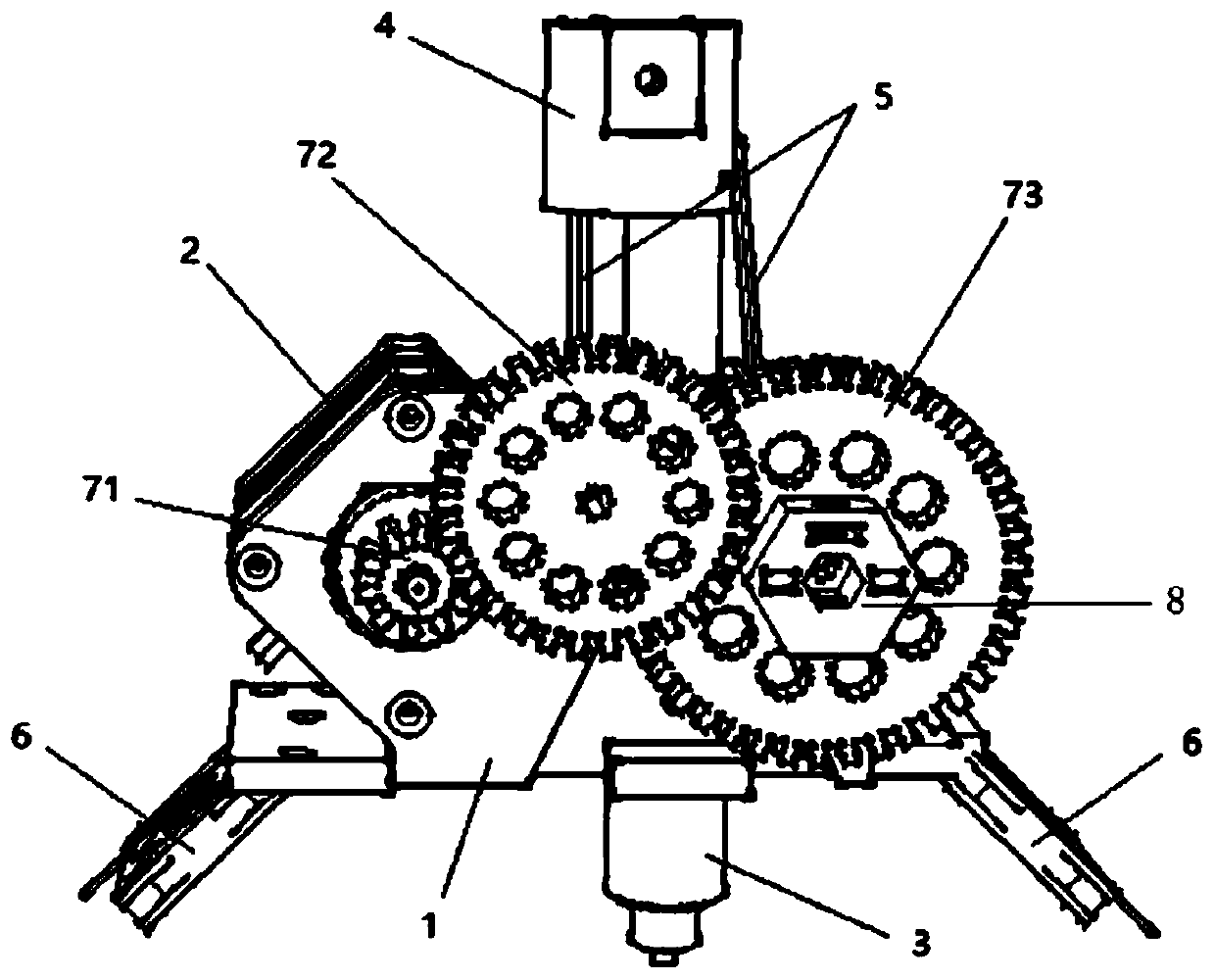

Preparation method and device for wire extruding mechanism with double spray heads

The invention discloses a preparation method for a wire extruding mechanism with double spray heads. The preparation method comprises the following steps: (1) preparing a fixed seat; (2) preparing a first heat radiating aluminum part and a second heat radiating aluminum part; (3) preparing a first heating aluminum block and a second heating aluminum block; (4) preparing a first nozzle and a second nozzle; (5) preparing a cooling fan; (6) arranging air guide channels; and (7) assembling all the prepared parts to prepare the wire extruding mechanism with double spray heads. The invention also discloses a preparation device adopting the method. The preparation method has the beneficial effects that the design of the double spray heads and double air channels is adopted. By using the two spray heads, consumables which have different colors or are made of different materials are stacked to form a required object, and each air channel is cooled to radiate heat, so that a wire is more smoothly extruded, and the surface of the object is more smooth. Double-color printing can be realized. The power is relatively high when a complex model is printed. Due to the adoption of an independent cooling mechanism, the wire is stable in performance and higher in surface quality and is smoothly extruded. Each of the cooling mechanism and the wire extruding mechanism forms an independent body so as to be conveniently maintained and cleared.

Owner:HENAN ZHUCHENG ELECTRONICS TECH CO LTD

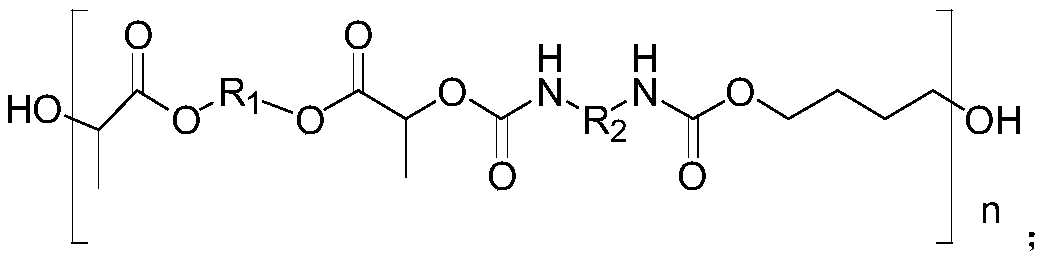

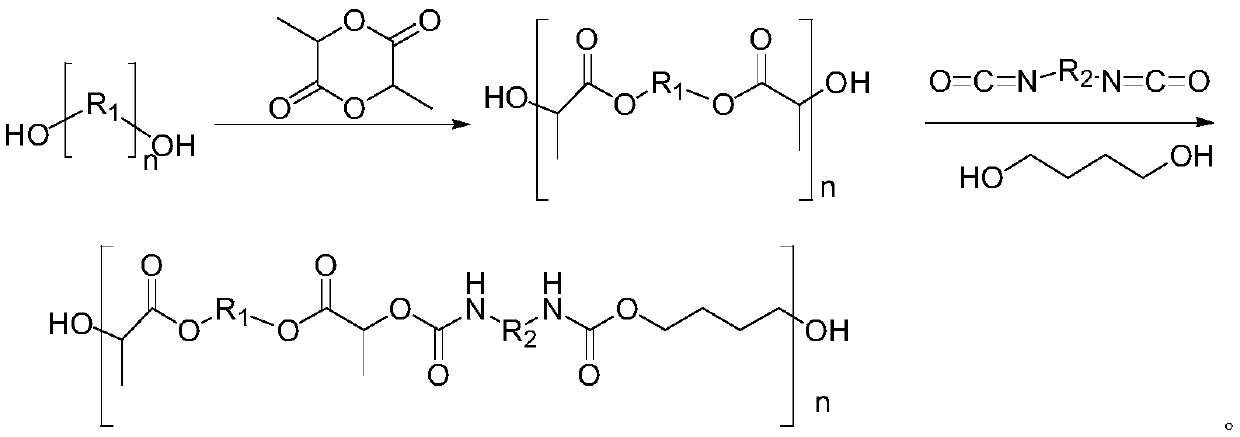

Polylactic acid-based thermoplastic polyurethane modified polylactic acid composite material and preparation method and application thereof in 3D printing consumables

ActiveCN111378262AImprove toughnessImprove roundnessAdditive manufacturing apparatusPolylactic acidThermoplastic polyurethane

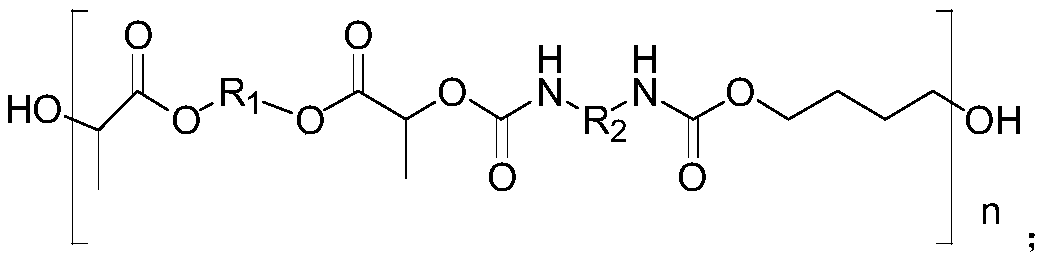

The invention discloses a polylactic acid-based thermoplastic polyurethane modified polylactic acid composite material and a preparation method and application thereof in 3D printing consumables, which belong to the technical field of 3D printing. The material comprises the following raw material components in parts by mass: 60-90 parts of polylactic acid, 3 to 20 parts of polylactic acid-based thermoplastic polyurethane, 1-5 parts of an inorganic filler, 1-5 parts of a cross-linking agent, and 0.2 to 1 part of a stabilizing agent. The structural general formula of the polylactic acid-based thermoplastic polyurethane is shown in the specification, and a group R1 in the structural general formula is selected from polyalkyl ether, the group R2 is selected from one of straight-chain hexyl ormethane diphenyl, and the mesh number of the inorganic filler is 3000 to 5000 meshes. The composite material is good in 3D printing performance and high in printing precision.

Owner:XIAOGAN ESUN NEW MATERIAL +1

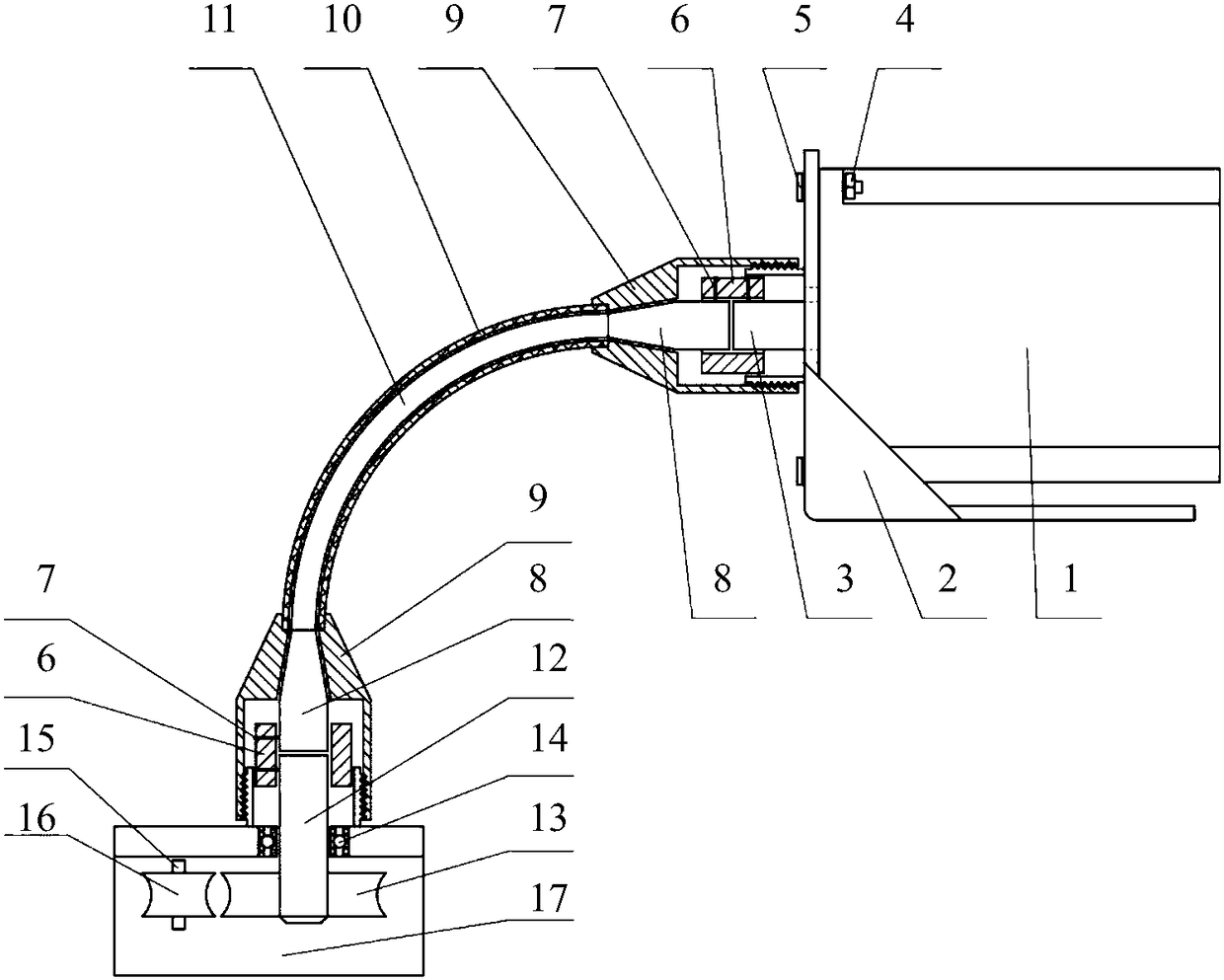

3D printing material extruder

InactiveCN108327267AIncrease flexibilitySmall inertiaAdditive manufacturing apparatusMovement controlEngineering

The invention discloses a 3D printing material extruder in remote driving and short extruding. A driving function device and a material extruding function device are separated; and torque is transmitted through a soft shaft, continuous and stable output of the torque can be guaranteed, relative movement can also happen, and the installing flexibility is greatly improved. The driving function device is installed on a 3D printer support, and does not move along with a printing sprayer, the inertia of the printing sprayer is greatly reduced, and movement control of the printing sprayer can be more accurate. Especially for a fast printing and forming model, the control precision on the printing sprayer is improved, and the forming rate of the model can be greatly increased; and the material extruding function device is installed on a 3D printing sprayer support and moves along with the printing sprayer, material wires extruded by a driving extruding wheel and a driven pressing wheel are made to enter a throat pipe at a shortest distance, and wire outflow stability and uniformity are kept. Especially for a flexible material, the distance between the material extruding device and the throat pipe is shortened, and the problem that because of material wire bending and stretching and shrinking, wire outflow is not uniform can be solved to the maximum extent.

Owner:DALIAN UNIV OF TECH

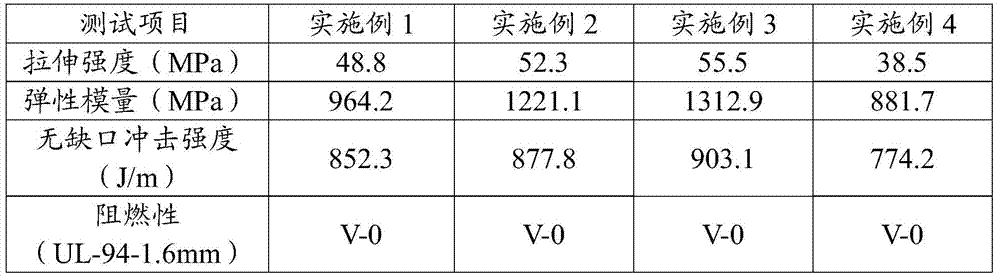

A kind of flame retardant composite material for 3D printing and preparation method thereof

The invention provides a flame-retardant composite material for 3D printing, which comprises the following raw materials in parts by weight: 60-95 parts of nylon resin, 5-40 parts of ABS (acrylonitrile-butadiene-styrene) resin, 0.3-2 parts of lubricant, 5-20 parts of compatilizer, 0.2-1 part of antioxidant and 5-30 parts of amorphous red phosphorus. The flame-retardant composite material for 3D printing is free of halogen, and can not pollute the environment in the material combustion and use process; and under the interactions among the amorphous red phosphorus, ABS resin and other raw materials, the flame retardancy and toughness of the material are enhanced. The added lubricant lowers the friction factor of the composite material, improves the free mobility of the composite material, avoids the material decomposition caused by local overheating and enhances the appearance quality and surface smoothness of the product. When the flame-retardant composite material for 3D printing is used for 3D printing, the wire sprayed by the sprayer is smooth, and the printed product has high precision and favorable surface quality.

Owner:陈梓煜

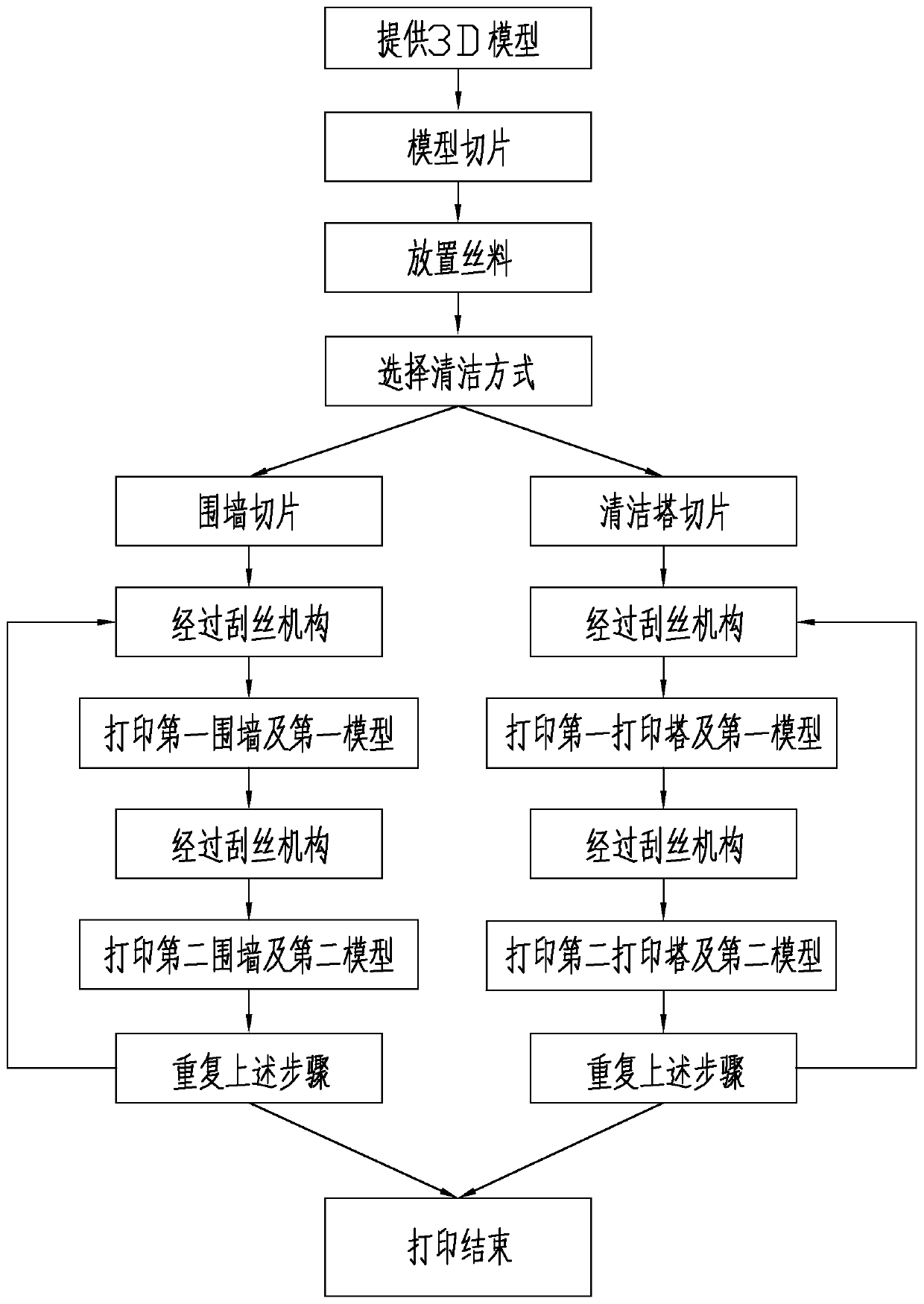

Multi-spray head 3D printing method

InactiveCN110576601ASmooth silkImprove printing qualityAdditive manufacturing apparatus3D object support structuresSoftware3D printing

The invention discloses a multi-spray head 3D printing method which comprises the following steps: (1) drawing a 3D model; (2) slicing the model: importing a 3D model document into slicing software, wherein the slicing software slices the 3D model document in layers according to printing parameters, inputs the printing parameters of a cleaning mechanism, and generates layered slices of the cleaning structure according to the 3D model document; and (3) printing in turn: printing the cleaning structure and the 3D model by using a first spray head and a second spray head in turn. The multi-sprayhead 3D printing method is suitable for a multi-spray head printer which employs two silk materials of different types or silk materials of same type but different colors. As the cleaning mechanism isprinted by the printing spray heads before the 3D model is printed, residual silk materials on the printing spray heads are blocked by the cleaning mechanism, so that the printing spray heads are cleaned. In the process of printing the cleaning mechanism, the printing spray heads are heated continuously to feed silk, so that the printing spray heads feed the silk smoothly as the 3D model is printed after the printing spray heads feed the silk stably, and therefore, the printing quality is improved.

Owner:ZHEJIANG FLASHFORGE 3D TECH CO LTD

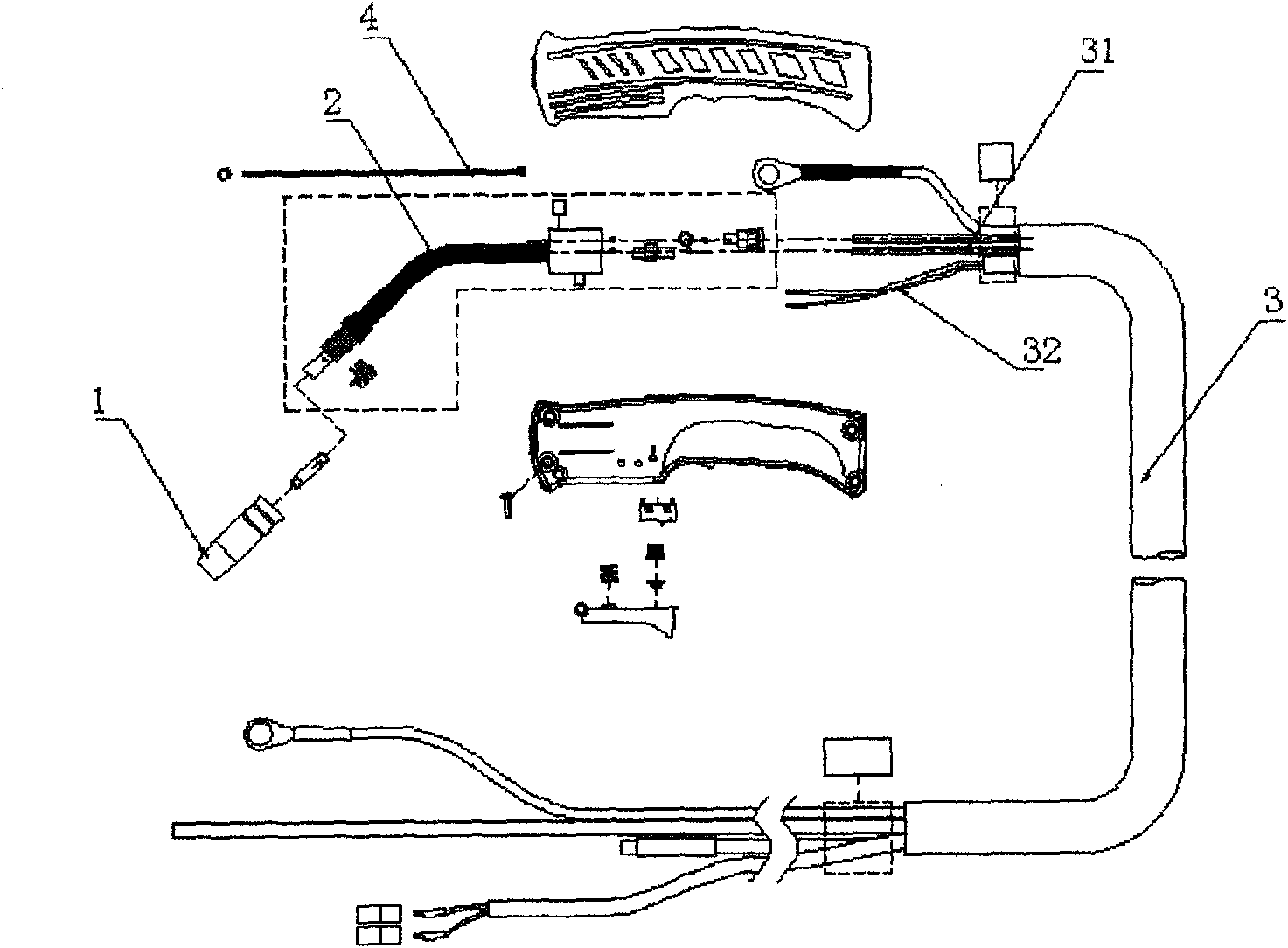

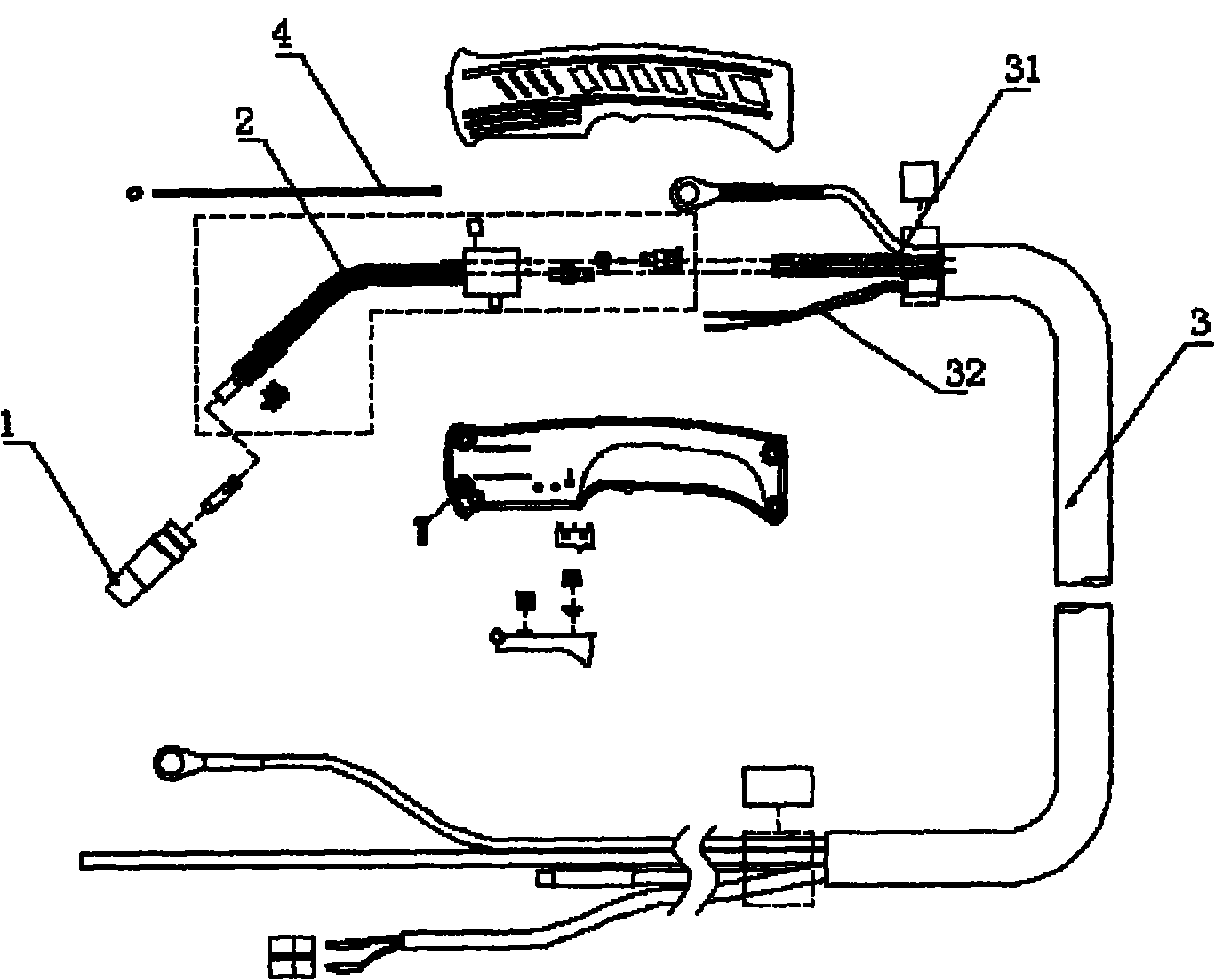

Structure-improved welding torch

InactiveCN102152043AEffective guidanceSmooth entryWelding/cutting auxillary devicesAuxillary welding devicesEngineeringGuide tube

The invention discloses a structure-improved welding torch, which comprises a shrinking crater, an elbow and a cable sleeve. One end of the shrinking crater is communicated and fixedly connected with the other end of the elbow; one end of the elbow is fixedly connected with the cable sleeve; a welding wire tube and a cable assembly are arranged in the cable sleeve; a short conduit of a hollow tubular shape is fixedly arranged in one end of the elbow; one end of the short conduit is communicated with the welding wire tube in the cable sleeve; and the other end of the short conduit is communicated with the inner cavity of the elbow. As the short conduit communicated with the welding wire tube is arranged in the elbow tube of the welding torch, a welding wire is effectively guided, therefore, the welding wire is guaranteed to smoothly enter the elbow tube and to be discharged smoothly during welding, so that the welding quality is improved, and the welding time is shortened. Meanwhile, the feeling of fatigue of users is effectively reduced by leading the bending angle of the elbow tube to satisfy ergonomics.

Owner:昆山日皓焊切器材有限公司

Copolymerization toughening modified material for 3D printing PLA (polylactic acid) and preparation method of copolymerization toughening modified material

PendingCN114539750AFix compatibility issuesGood compatibilityAdditive manufacturing apparatusBio-packagingPolymer science3d printed

The invention discloses a copolymerization toughening modified material for 3D printing PLA (polylactic acid) and a preparation method of the copolymerization toughening modified material. The material is prepared from the following components in parts by weight: 60 to 90 parts of polylactic acid, 10 to 40 parts of thermoplastic polyurethane elastomer, 0.5 to 5 parts of epoxy polymer, 0.1 to 0.5 part of diglycidyl ether derivative, 0.2 to 1 part of lubricant, 0.2 to 1 part of heat stabilizer and 1 to 10 parts of inorganic filler, the preparation method comprises the following steps: drying the components, uniformly mixing, and carrying out melt co-extrusion by using a double-screw extruder. According to the method, the problems of thermodynamic incompatibility and phase separation in the blending extrusion process of PLA and TPU are solved, the toughening effect has long-acting stability, and when the method is applied to 3D printing, wire output is smooth, and the wire drawing effect is good.

Owner:SHENZHEN ESUN IND +1

A preparation method and device for a double-nozzle wire-extruding mechanism

ActiveCN106608046BIncrease powerImprove performanceApplying layer meansColor printingMaterials science

The invention discloses a preparation method for a wire extruding mechanism with double spray heads. The preparation method comprises the following steps: (1) preparing a fixed seat; (2) preparing a first heat radiating aluminum part and a second heat radiating aluminum part; (3) preparing a first heating aluminum block and a second heating aluminum block; (4) preparing a first nozzle and a second nozzle; (5) preparing a cooling fan; (6) arranging air guide channels; and (7) assembling all the prepared parts to prepare the wire extruding mechanism with double spray heads. The invention also discloses a preparation device adopting the method. The preparation method has the beneficial effects that the design of the double spray heads and double air channels is adopted. By using the two spray heads, consumables which have different colors or are made of different materials are stacked to form a required object, and each air channel is cooled to radiate heat, so that a wire is more smoothly extruded, and the surface of the object is more smooth. Double-color printing can be realized. The power is relatively high when a complex model is printed. Due to the adoption of an independent cooling mechanism, the wire is stable in performance and higher in surface quality and is smoothly extruded. Each of the cooling mechanism and the wire extruding mechanism forms an independent body so as to be conveniently maintained and cleared.

Owner:HENAN ZHUCHENG ELECTRONICS TECH CO LTD

A wax material 3d printer head

The invention provides a 3D printer head of wax material, and overcomes the defect that in the prior art, wax material cannot be extruded out smoothly. The 3D printer head comprises an extrusion part, a ventilation part, a heating part and a wire outlet part, wherein the wire outlet part comprises a fixed seat and a line bank; the line bank is fixed at the rear end of the fixed seat; the extrusion part, the ventilation part and the heating part are both mounted on the fixed seat. The 3D printer head adopts a 57 stepper motor, so as to increase the motor torsion and ensure that the thrust of the extrusion part is large enough to extrude out a wax material line with the diameter of 3 mm; a leaf spring is arranged to be used for pressing the wax material and provide enough pressure to ensure that the wax material can be extruded out smoothly; a driving roller made of rubber material replaces a copper gear, so that the wax material is protected from wearing and the copper gear is prevented from scratching the wax material during driving; the aperture of a spray nozzle is 0.8 / 1.0 / 1.2 mm, so that the wax material is prevented from excessive melting at the heating part and more smooth line outlet is ensured.

Owner:FUJIAN HAIYUAN THREE DIMENSIONAL PRINTING HIGH TECH

Converged system device for PET dense and forced feeding equipment and twin-screw extrusion equipment

The invention discloses a converged system device for PET dense and forced feeding equipment and twin-screw extrusion equipment. The converged system device comprises a forced feeder and an extruder,wherein an output end of the forced feeder is connected with an input end of the extruder; the forced feeder comprises a rag storage cylinder, a spiral auger and a twin-screw forced feeding device indifferent directions; the extruder comprises a second motor, a reduction gearbox and an extrusion screw, wherein an output end of the second motor is connected with the reduction gearbox, an output end of the reduction gearbox is connected with the extrusion screw, a heating device sleeves outside the extrusion screw, and the output end of the extrusion screw is arranged to fit the filtering device. The converged system device can effectively feed loose rag into the extruder by using the forced feeder and the extruder cooperatively, and at the same time, the forced feeder can regulate densityof the rag that is fed into the extruder, thereby facilitating rag filling under the action of the extrusion screw; the heating and the extrusion by the extrusion screw simultaneously realize more uniform silk yielding, thereby greatly reducing defective products.

Owner:无锡市熔杰再生资源有限公司

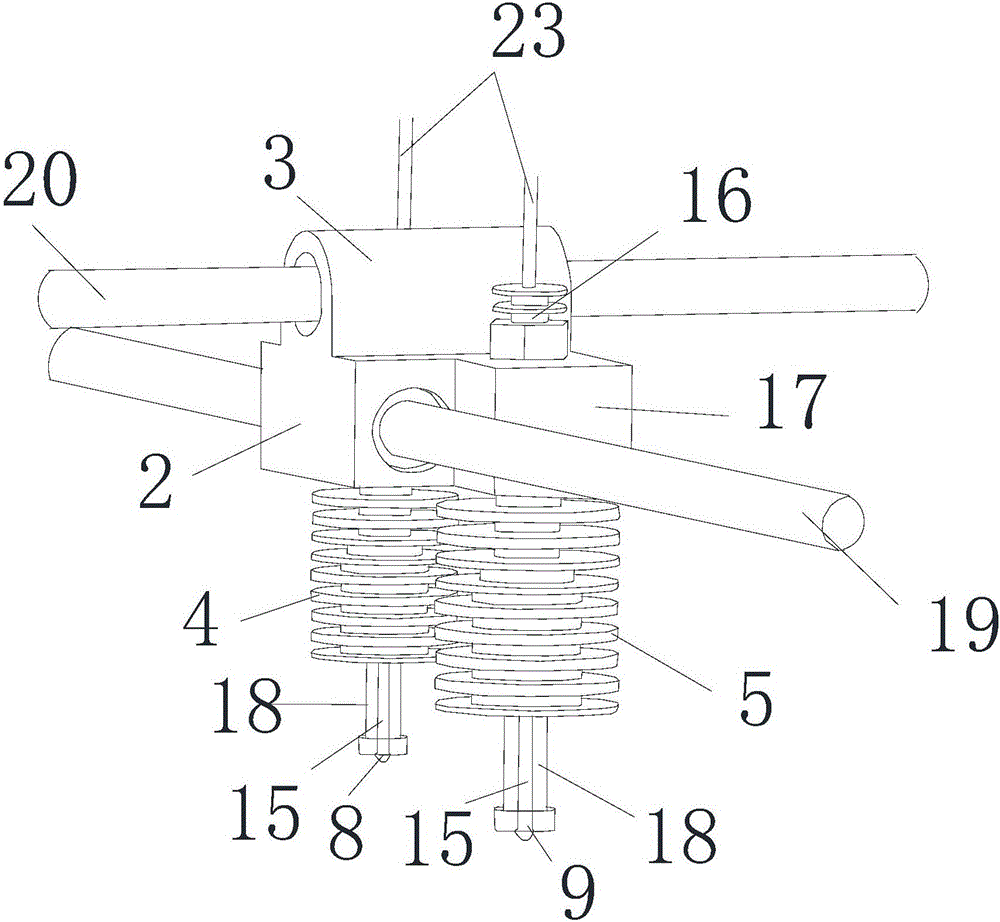

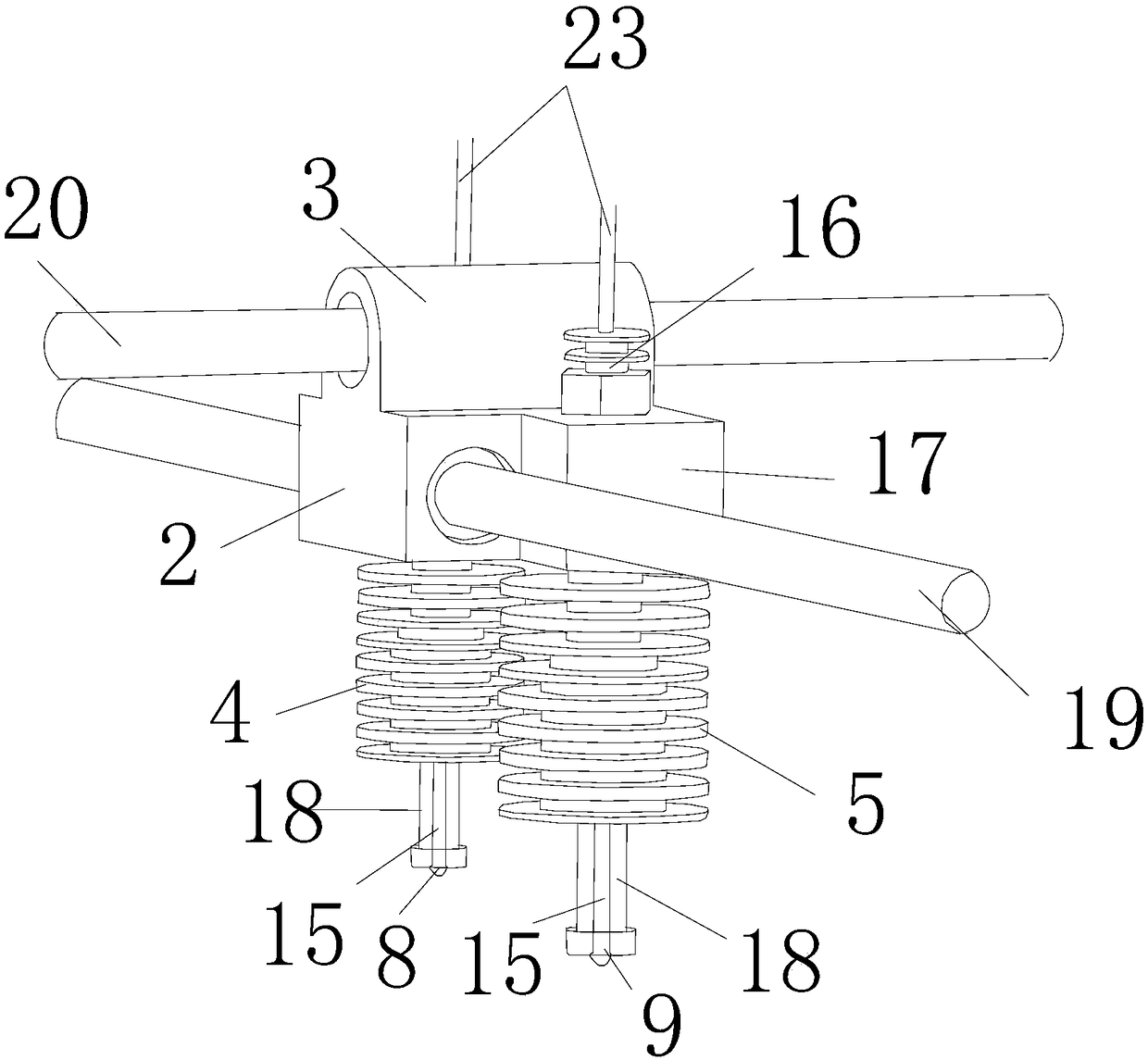

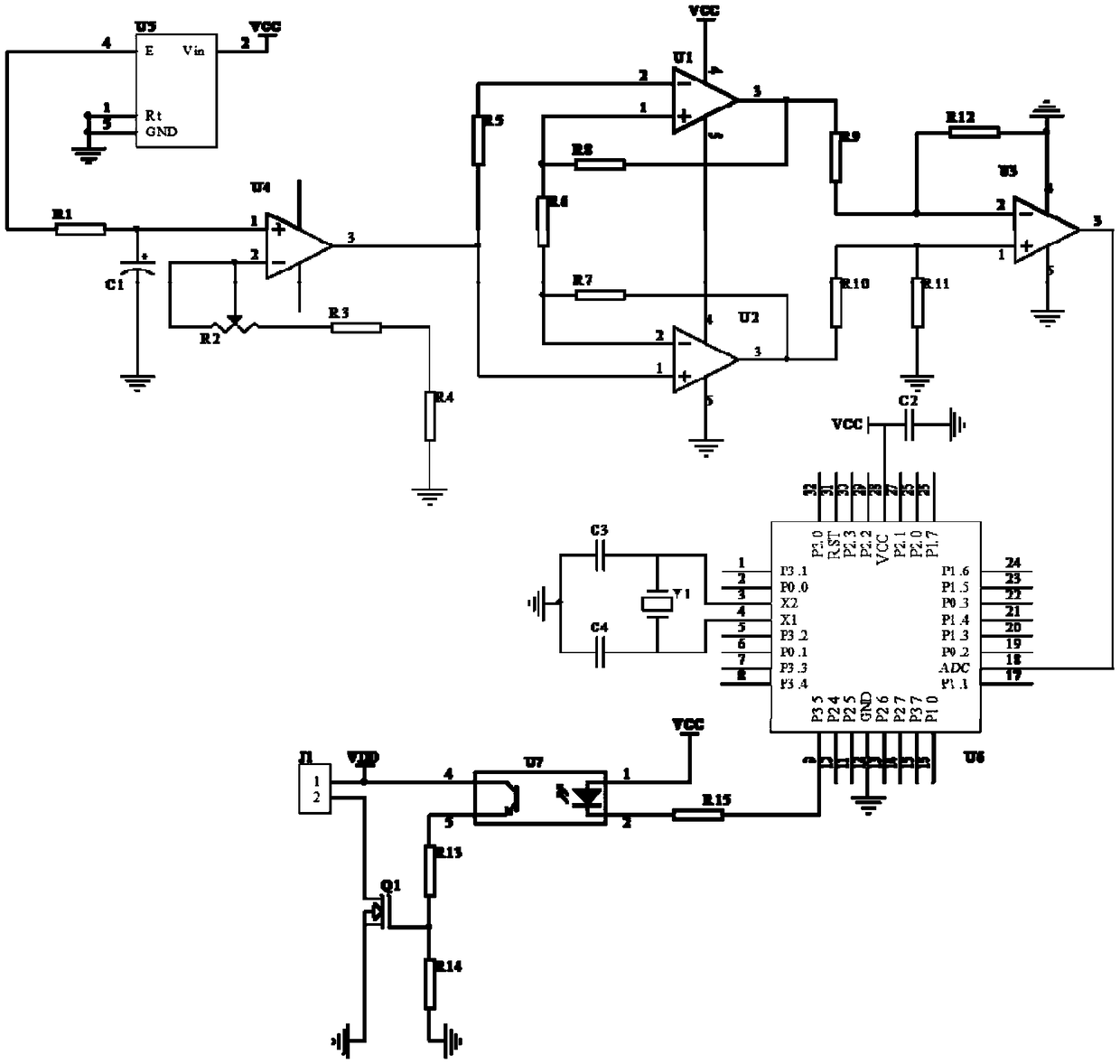

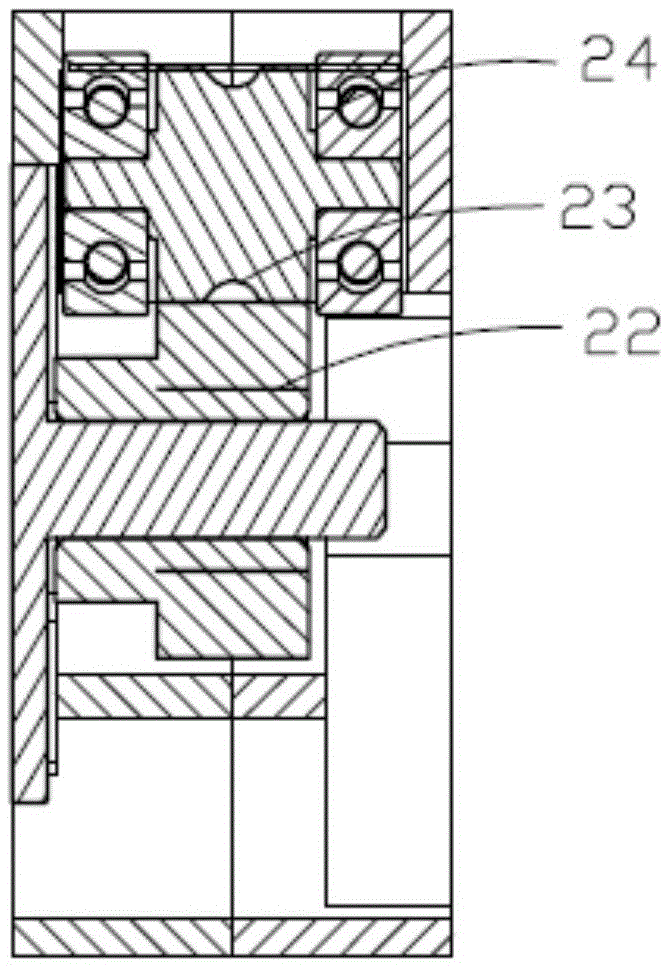

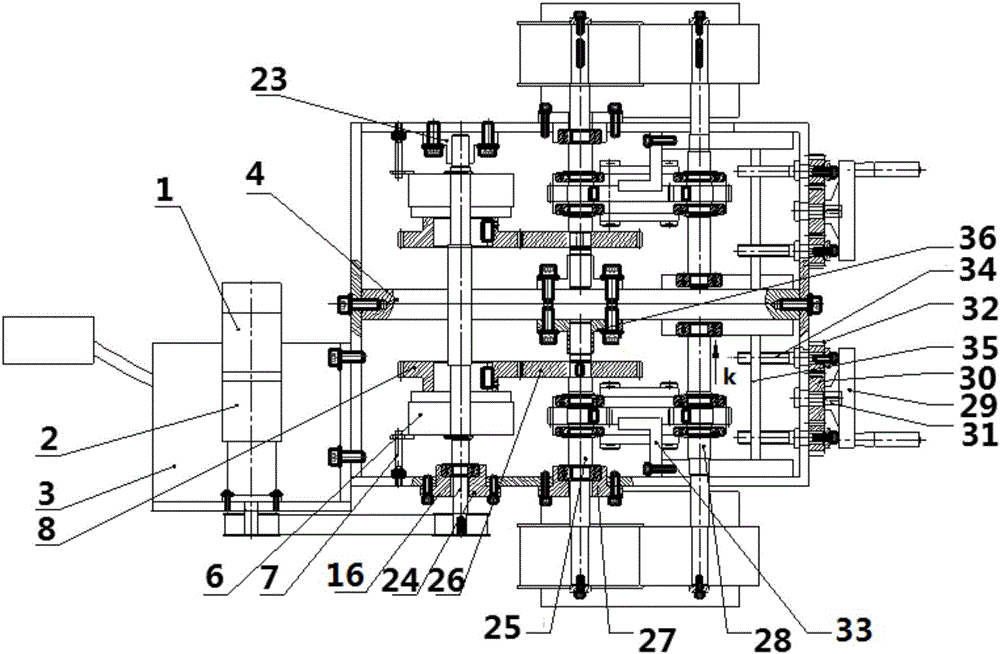

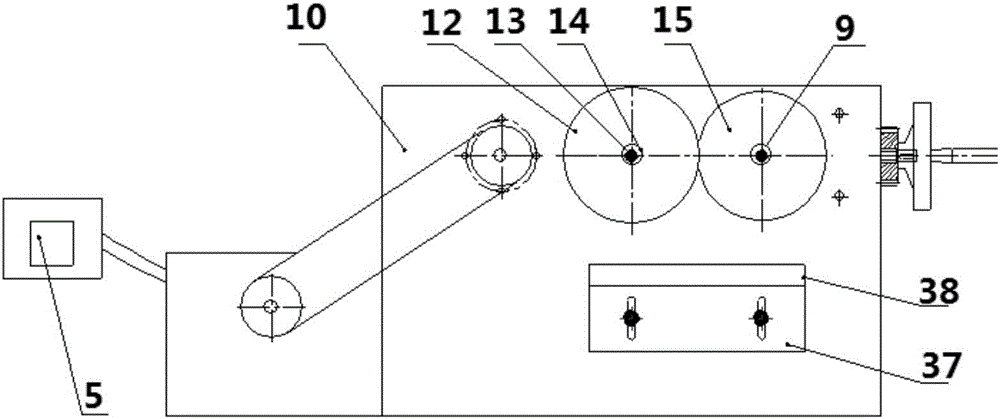

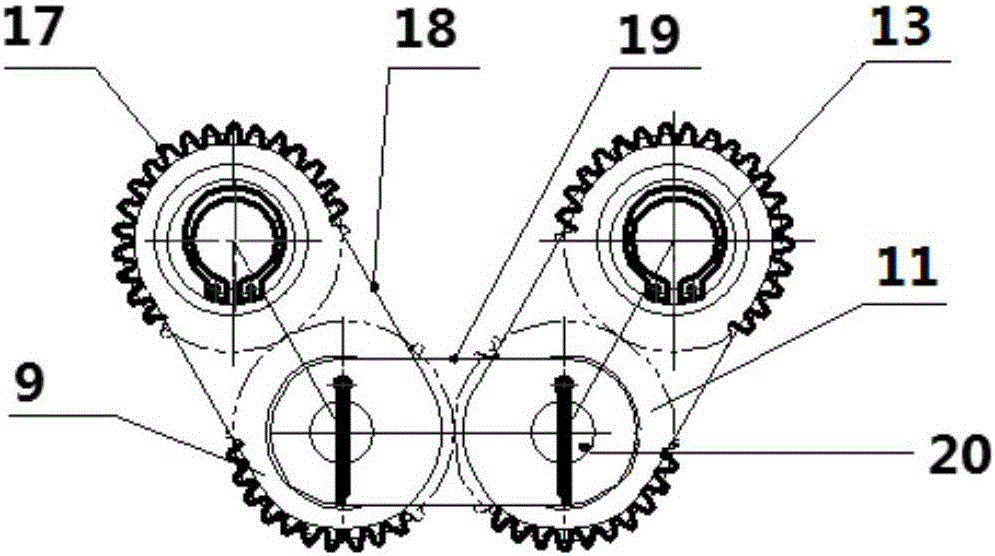

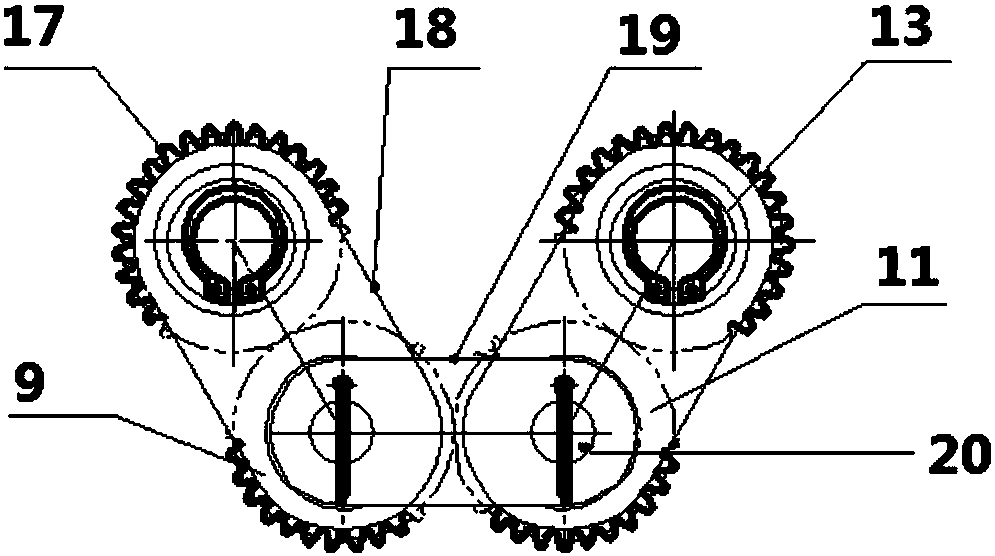

Multi-station automatic-adjustment wheel type gel spinning machine

InactiveCN106498516AAvoid breakingImprove work efficiencyWet spinning methodsYarnElectromagnetic clutch

The invention provides a multi-station automatic-adjustment wheel type gel spinning machine. The multi-station automatic-adjustment wheel type gel spinning machine comprises a spinning box, a power mechanism and a control system, wherein the power system supplies power to the spinning box; two same stations are arranged in the spinning box; the control system selects the station needing to work by controlling connection and disconnection of an electromagnetic clutch; and the control system is connected with the power mechanism and the heating mechanism to realize self-adaptive adjustment of the rotating speeds of a driving rubber roll and a driven rubber roll with the gelation temperature. The multi-station automatic-adjustment wheel type gel spinning machine provided by the invention has the advantages that by controlling the self-adaptive adjustment of the rotating speeds of the rubber rolls and the gelation temperature, spun yarns can reach the nano level; and by adjustment to the gap between the driving rubber roll and the driven rubber roll, uniform silk production and difficult silk breaking are realized; and the two stations can work simultaneously, so that the working efficiency is effectively improved.

Owner:JIANGSU UNIV

A 3D printing smart nozzle

The invention discloses an intelligent nozzle of a 3D (Three-Dimensional) printer. The intelligent nozzle of the 3D printer comprises a fixed bracket, a cover plate, a concave bracket, a heat conduction block and a material guide pipe, wherein the cover plate is mounted at the top of the fixed bracket; the concave bracket is mounted at the bottom of the fixed bracket; the heat conduction block is mounted at the bottom of the concave bracket; an extrusion head is arranged at the front end of the material guide pipe; the material guide pipe is vertically arranged in the fixed bracket; the extrusion head is exposed out of the bottom of the heat conduction block; the intelligent nozzle of the 3D printer also comprises at least one heating part and at least one temperature sensing part; the heating part and the temperature sensing part are mounted in the heat conduction block. The extrusion head of the intelligent nozzle comprises the heating part and the temperature sensing part and is capable of accurately controlling the thread extrusion temperature, guaranteeing the smooth thread extrusion and automatically cleaning the nozzle; all circuit lines are fixed in the nozzle, so that the problem that the circuit lines are abraded, broken and cut out in the process of moving the extrusion head is avoided.

Owner:上海骧远信息科技有限公司

Method for producing ER5356 barreled aluminum alloy welding wires

InactiveCN111151925AQuality assurancePlay the role of tight welding wireFilament handlingWelding/cutting media/materialsEngineeringAluminium alloy

The invention relates to a method for producing ER5356 barreled aluminum alloy welding wires. The method comprises the steps that after wires are released through a pay-off machine, the wires sequentially pass through a tension mechanism, a straightening mechanism and a drawing mechanism to be sent into a wire conveying mechanism, wherein the wires are subjected to two-way straightening after being barreled, so that the straightened welding wires are loose, the diameters of the welding wires tend to infinity, the welding wires are fed along the inner wall of an outer ring of a welding wire barrel through a wire feeding tube, and the diameter of each welding wire ring is controlled to range from 430 mm to 440 mm; and when barreling is conducted, multistage vibration is set, the welding wires fed into the welding wire barrel are tangent to the outer wall of a barrel core and internally tangent to the inner wall of the welding wire barrel, every two adjacent welding wire rings are staggered, and the welding wire rings are evenly distributed to be shaped like a plum blossom. By adopting the method, after each barrel of the welding wires is completely produced, the welding wires are compact and attractive in appearance, the wires can be discharged smoothly in the welding using process, and the stuck and disordered phenomena cannot occur.

Owner:YUNNAN ALUMINUM

Forging technology for high-strength welding wire

InactiveCN103894761AGuaranteed drawing requirementsPrevent wire breakageWelding/cutting media/materialsSoldering mediaForgeMetal

The invention belongs to the field of welding wires and relates to a forging technology for a high-strength welding wire, in particular to the high-strength welding wires and application of the high-strength welding wires. The high-strength welding wire comprises important metal elements and important alloy elements. The forging temperature range meets preset initial forging temperature and final forging temperature. The forging temperature can be set to guarantee that metal is high in plasticity and small in resistance to deformation within the forging temperature range, and structure and performance temperature values are obtained. Therefore, the quality of a forged blank meets the quality of a follow-up finished product better, and positive effects are directly generated on material forgeability and the structure and performance of the forge piece.

Owner:天津冶金集团天材科技发展有限公司

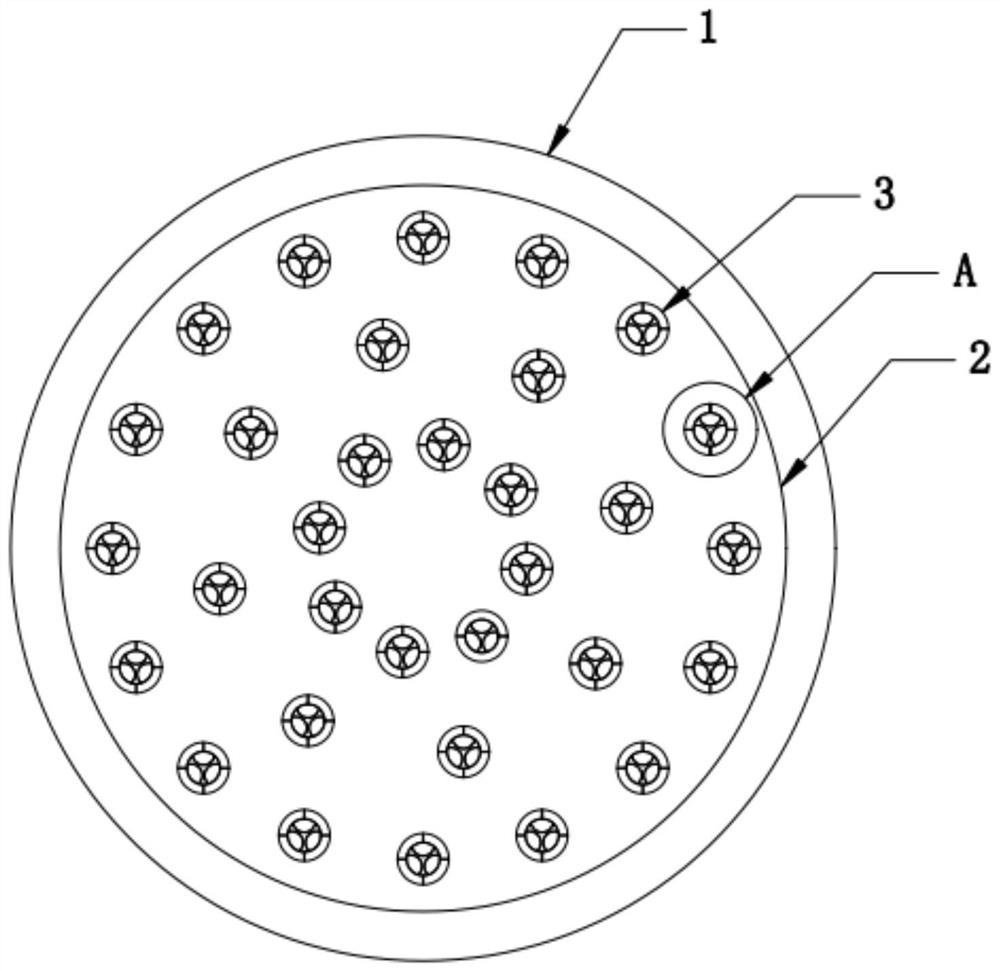

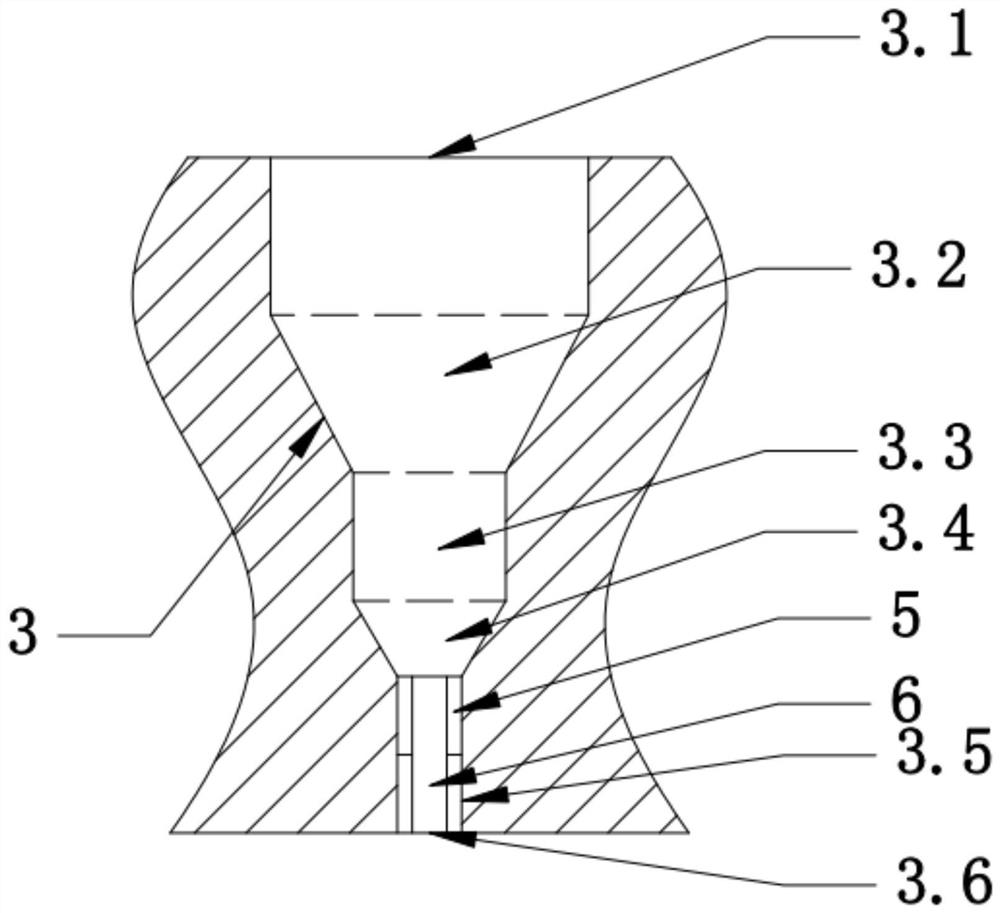

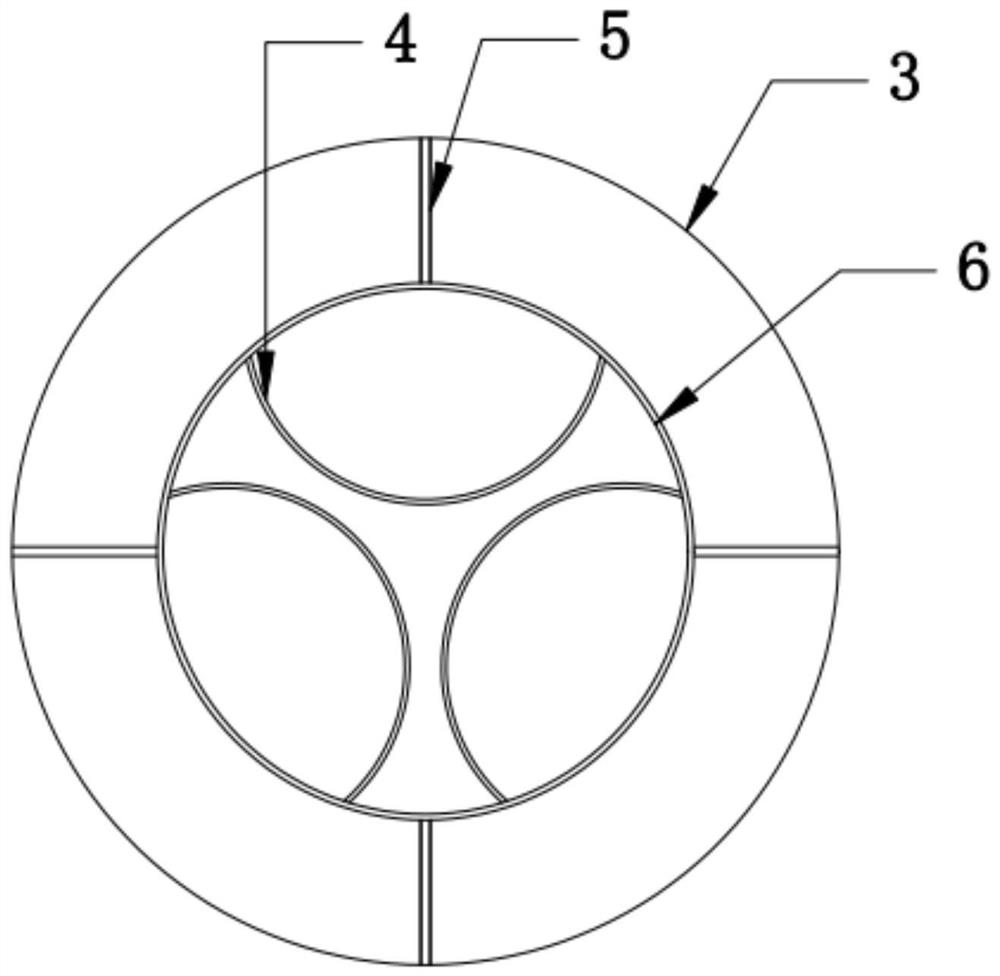

Novel multi-component spinning spinneret plate

PendingCN112962153AImprove usabilityExtended service lifeHollow filament manufactureFilament/thread formingFiberSpinning

The invention discloses a novel multi-component spinning spinneret plate. The spinneret plate comprises a spinneret plate body; the spinneret plate body comprises a feeding plate and a discharging plate; a plurality of spinneret holes are formed in the discharging plate; connecting plates are arranged in the spinneret holes; one end of each connecting plate is connected with an annular baffle; an arc-shaped baffle is arranged in each annular baffle; a feeding port is formed in the end, close to the feeding plate, of each spinneret hole; a first deceleration cavity is formed in each spinneret hole; a buffer cavity is formed below each first deceleration cavity; and a second deceleration cavity is formed below each buffer cavity. The spinneret plate has the advantages that the spinneret holes are arranged in a staggered manner, so that output filaments of all the spinneret holes can be subjected to excellent solidification; a supported fiber cross section structure can be formed to enhance the overall use characteristics of fibers and prolong the service life of the fibers; and the plurality of deceleration cavities are arranged in the spinneret holes to promote stable flow of melts, ensure uniform output filaments and improve the fiber production quality.

Owner:SUZHOU LONGJIE SPECIAL FIBER

Smelting process for high-strength welding wire

InactiveCN103898392AHigh strengthImprove various performanceWelding/cutting media/materialsSoldering mediaPorosityProportional control

Belonging to the field of welding wire, the invention provides a smelting process for high-strength welding wire, and especially a high strength welding wire and application thereof. The material comprises important metal elements and important alloying elements, and the proportion of the important alloying elements and important metal elements is controlled at a preset value. The steel ingot smelted by the process has more ideal structure, more consistent chemical composition, less impurities, harmful elements and non-metallic inclusions, better consistency of crystal structure, and smaller micro segregation and porosity values, and is more favorable for subsequent forging process.

Owner:天津冶金集团天材科技发展有限公司

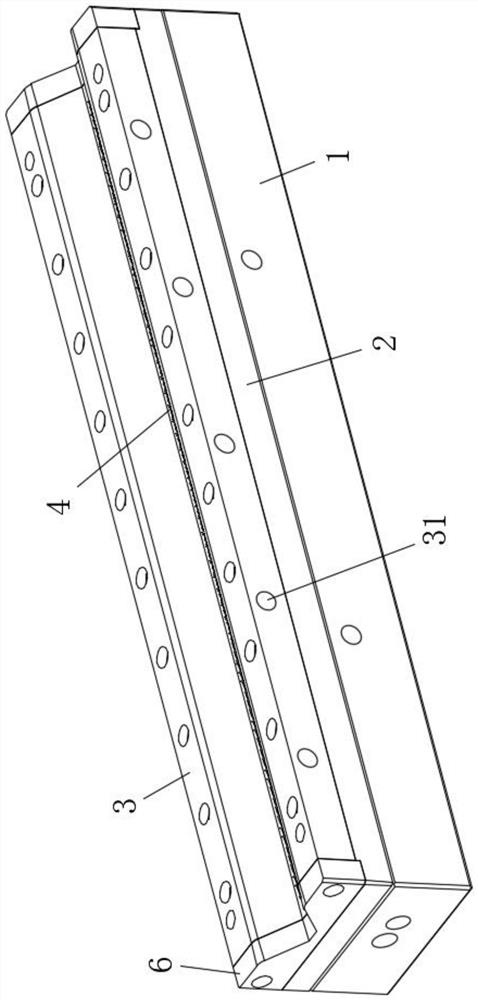

Melt-blown cloth mold with multi-row-hole spray head

PendingCN113373594ANo leaksEasy maintenanceSpinnerette packsNon-woven fabricsEngineeringMechanical engineering

The invention relates to a melt-blown cloth mold with a multi-row-hole spray head. The melt-blown cloth mold comprises a feeding plate, a spinneret plate and an air adjusting plate, wherein the feeding plate is provided with feeding holes, a feeding runner and a material distributing groove which are sequentially communicated; the spinneret plate is internally provided with a material filtering groove, a material distributing cavity and needle mounting holes which are sequentially communicated; the material filtering groove is in butt joint with the material distributing groove; a spinneret needle is mounted in each needle mounting hole; an air conveying pipe connector, an air conveying channel, an air distribution groove and spinneret needle penetrating holes which are sequentially communicated are formed in the air adjusting plate; and an annular air channel surrounding each spinneret needle is formed between the outer side wall of the spinneret needle and the inner side wall of the corresponding spinneret needle penetrating hole. The melt-blown cloth mold with the multi-row-hole spray head has the beneficial effects that even if individual spinneret needles in the same row are blocked, leakage holes are avoided; a single spinneret needle can be replaced, so that the maintenance is convenient, and the cost is low; and the periphery of each spinneret needle is independently blown to perform filament drawing, so that filaments are discharged stably and uniformly.

Owner:广东启新模具有限公司

A wheel-type gel spinning machine with multi-station automatic adjustment

InactiveCN106498516BAvoid breakingImprove work efficiencyWet spinning methodsYarnElectromagnetic clutch

The invention provides a multi-station automatic-adjustment wheel type gel spinning machine. The multi-station automatic-adjustment wheel type gel spinning machine comprises a spinning box, a power mechanism and a control system, wherein the power system supplies power to the spinning box; two same stations are arranged in the spinning box; the control system selects the station needing to work by controlling connection and disconnection of an electromagnetic clutch; and the control system is connected with the power mechanism and the heating mechanism to realize self-adaptive adjustment of the rotating speeds of a driving rubber roll and a driven rubber roll with the gelation temperature. The multi-station automatic-adjustment wheel type gel spinning machine provided by the invention has the advantages that by controlling the self-adaptive adjustment of the rotating speeds of the rubber rolls and the gelation temperature, spun yarns can reach the nano level; and by adjustment to the gap between the driving rubber roll and the driven rubber roll, uniform silk production and difficult silk breaking are realized; and the two stations can work simultaneously, so that the working efficiency is effectively improved.

Owner:JIANGSU UNIV

Method for processing high-performance modified polyethylene monofilaments for manufacturing fishing net

InactiveCN101851795BIncrease heat treatment temperatureHigh breaking strengthSpinning head liquid feederFilament manufactureWinding machineElastomer

The present invention discloses a method for processing high-performance modified polyethylene monofilaments for manufacturing a fishing net, relates to a method for processing polyethylene monofilaments for manufacturing a fishing net and aims to provide a method for processing the high-performance modified polyethylene monofilaments for manufacturing the fishing net. In the technical scheme of the invention, a stirring machine, a single-screw extruder, a twice-drafting electrical heating drafting machine, a filament winding machine and a filament separating machine are adopted. The method is characterized by comprising the following steps of: mixing a sieved spinning-grade dry HDPE resin, a dry VERSIFYTM 6002 elastomer, white oil or a turpentine aid; uniformly mixing the materials to obtain an HDPE / VERSIFYTM 6002 elastomer blend and fusing and extruding the blend by using the single-screw extruder; cooling and pre-drafting fused and extruded primary filaments, thermally drafting the pre-drafted filaments twice, rapidly cooling the thermally-drafted filaments from which oil is removed with high-pressure air current and winding modified PE monofilaments by using the winding machine; and separating the modified PE monofilaments into the high-performance modified polyethylene monofilaments for manufacturing the fishing net by using the filament separating machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

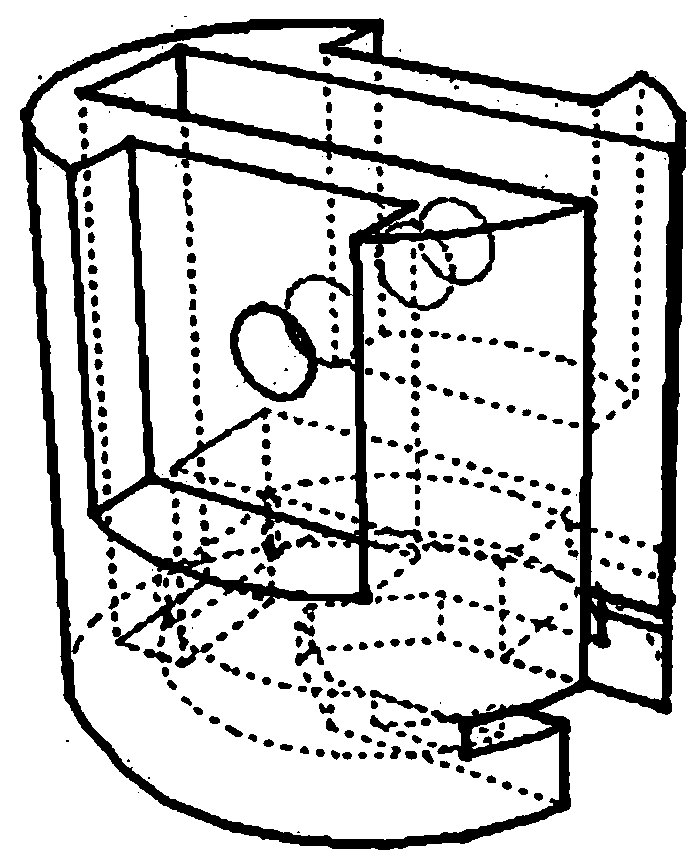

A 3D printing clay extrusion device

ActiveCN107214809BEasy to refuelAdjustable speedAdditive manufacturing apparatusCeramic shaping apparatusEngineeringPiston

The invention discloses a 3D printing clay extruding device. The 3D printing clay extruding device comprises a supporting base. A needle cylinder penetrates through the middle of the supporting base. A clay material is contained in the needle cylinder. A cylinder body of the needle cylinder is fixed to the supporting base. A piston moving vertically is arranged in the needle cylinder. A piston neck is fixed to the upper portion of the piston and connected with a synchronous belt. The synchronous belt extrudes the piston neck through an extruding linkage mechanism so that the piston can move downwards. The 3D printing clay extruding device is simple in structure, materials can be replaced, clay wires are output smoothly, and printing forming is stable.

Owner:HOHAI UNIV CHANGZHOU

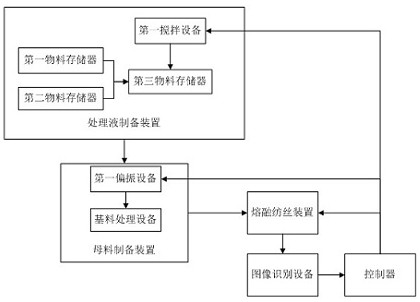

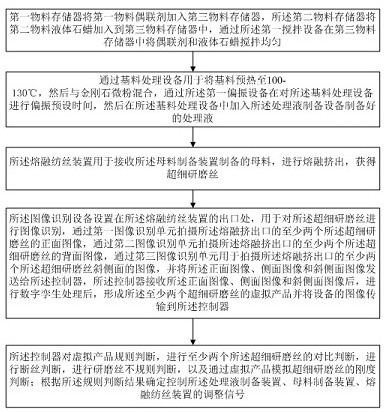

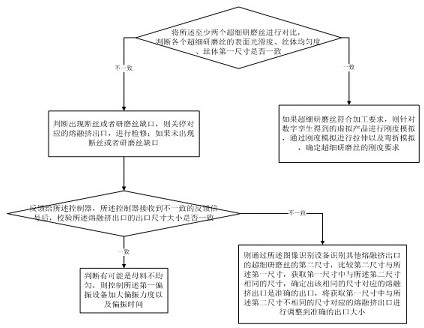

A kind of processing system and processing method of ultrafine grinding wire

ActiveCN114193344BGuaranteed stiffnessSmooth silkImage analysisMaterial strength using tensile/compressive forcesProcess engineeringMelt extrusion

The invention relates to a processing system and a processing method for ultra-fine grinding filaments, comprising: a treatment liquid preparation device, a master batch preparation device, a melt spinning device, an image recognition device and a controller, and the treatment liquid preparation device is used for preparing treatment The master batch preparation device is used for processing the master batch; the melt spinning device is used to receive the master batch prepared by the master batch preparation device, and perform melt extrusion to obtain ultra-fine grinding filaments; the image recognition equipment is set At the outlet of the melt spinning device, it is used for image recognition of the ultra-fine grinding filaments, and the image of the device is transmitted to the controller, and the controller performs digital twin processing after receiving the image. , determine the processing effect of the ultra-fine grinding wire, and generate an adjustment signal according to the processing effect, and control the treatment liquid preparation device, the master batch preparation device, and the melt spinning device. The invention can improve the processing and production efficiency of the ultra-fine grinding wire, and can perform processing adjustment in time.

Owner:广东佳硕尼龙丝科技有限公司

High-strength welding wire and purpose thereof

InactiveCN103894753AGuaranteed drawing requirementsPrevent wire breakageWelding/cutting media/materialsWelding/soldering/cutting articlesChemical compositionWeld seam

The invention belongs to the field of welding wires and relates to a high-strength welding wire and the purpose of the high-strength welding wire, in particular to the high-strength welding wires and application of the high-strength welding wires. The high-strength welding wire comprises important alloy elements with shrunk austenite phase fields, and the important alloy elements comprise refined steel microcosmic crystalline grains to achieve a refined crystalline strengthening effect. Therefore, after formed new alloy is used for manufacturing the high-strength welding wire, the strength is significantly improved. Chemical components of the high-strength welding wire has important influences on corrosion resistance of welded seams and shall be similar to chemical components of parent metal, in this way, welded seam metal and the parent metal are similar in chemical component, and the high-strength welding wire is generally supposed to achieve the optimal corrosion resistance. According to the scheme, the parent metal is more suitable for heavy and large-scale special vehicles.

Owner:天津冶金集团天材科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com