Patents

Literature

32results about How to "Improve nodule strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyformaldehyde resin made composite fiber

InactiveCN1715464AImprove nodule strengthHigh knot strength retentionMelt spinning methodsConjugated synthetic polymer artificial filamentsFiberUltimate tensile strength

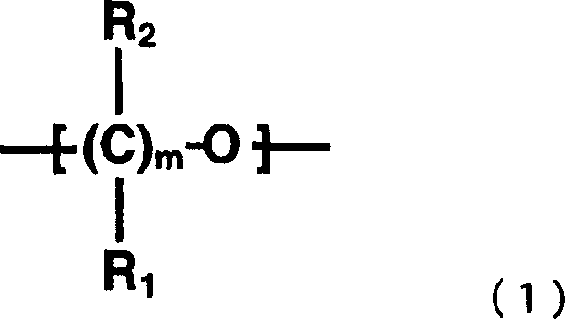

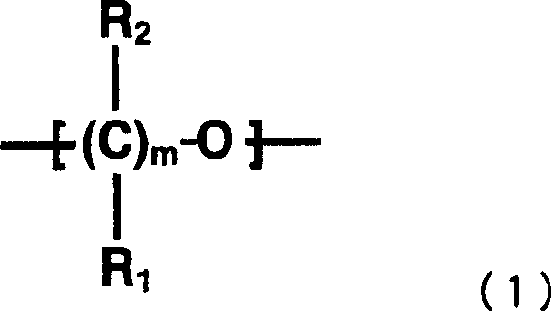

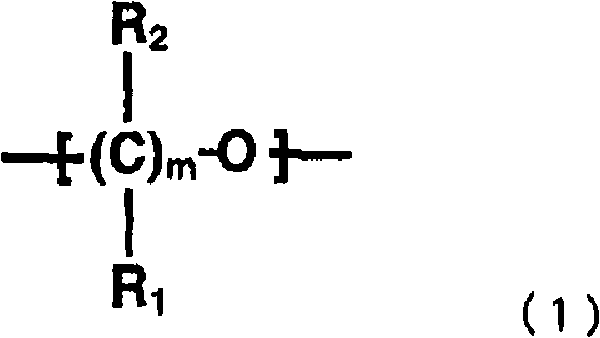

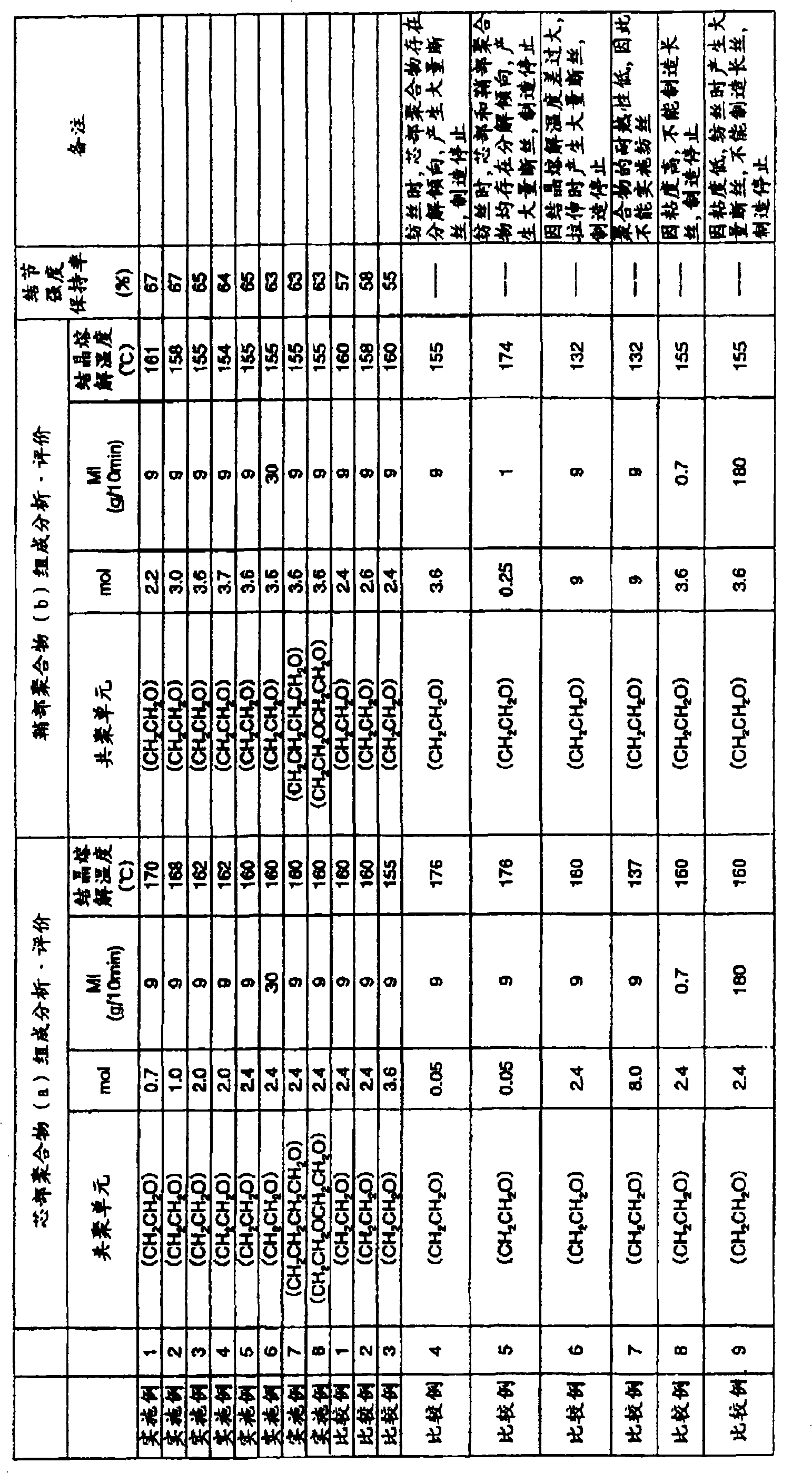

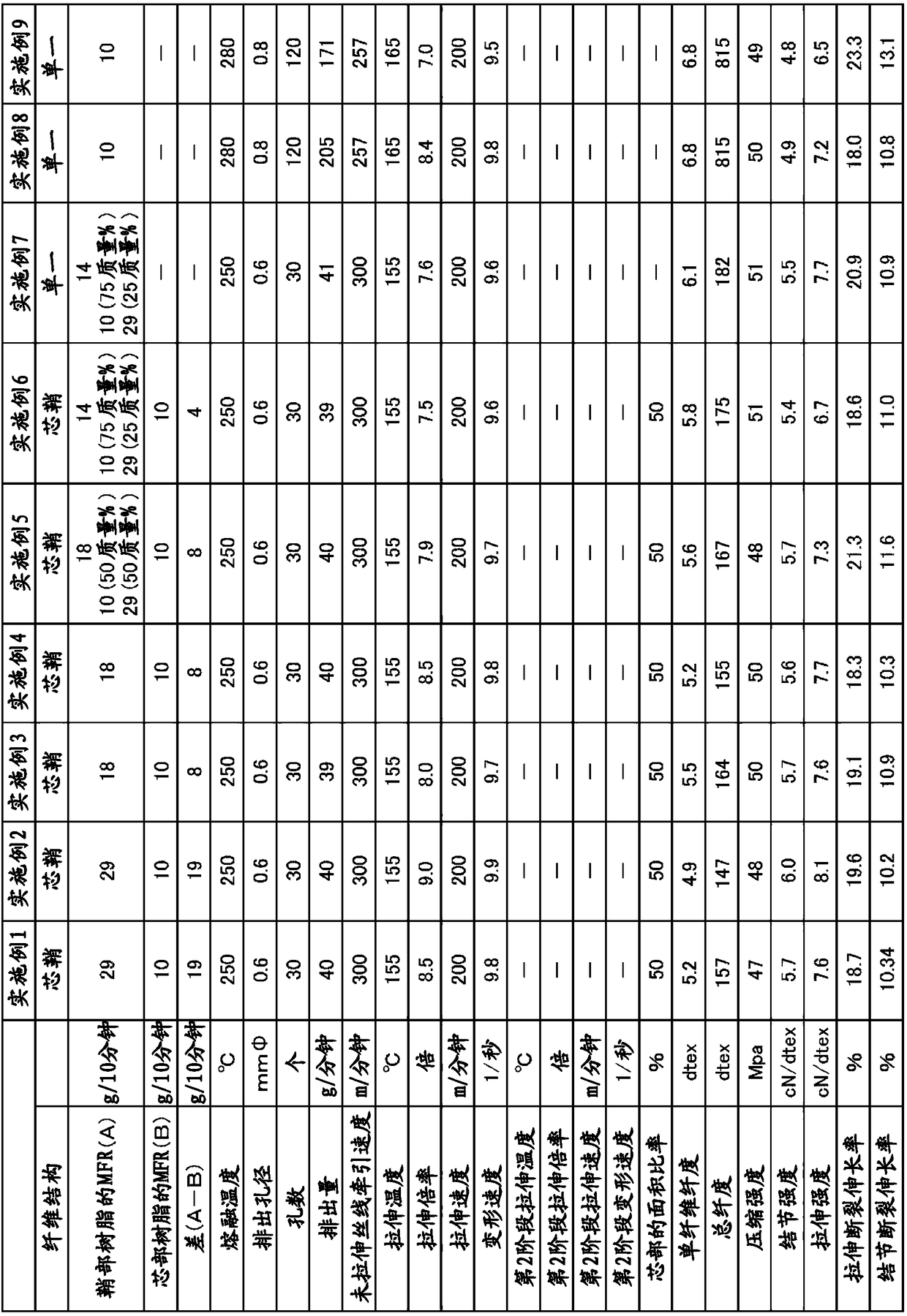

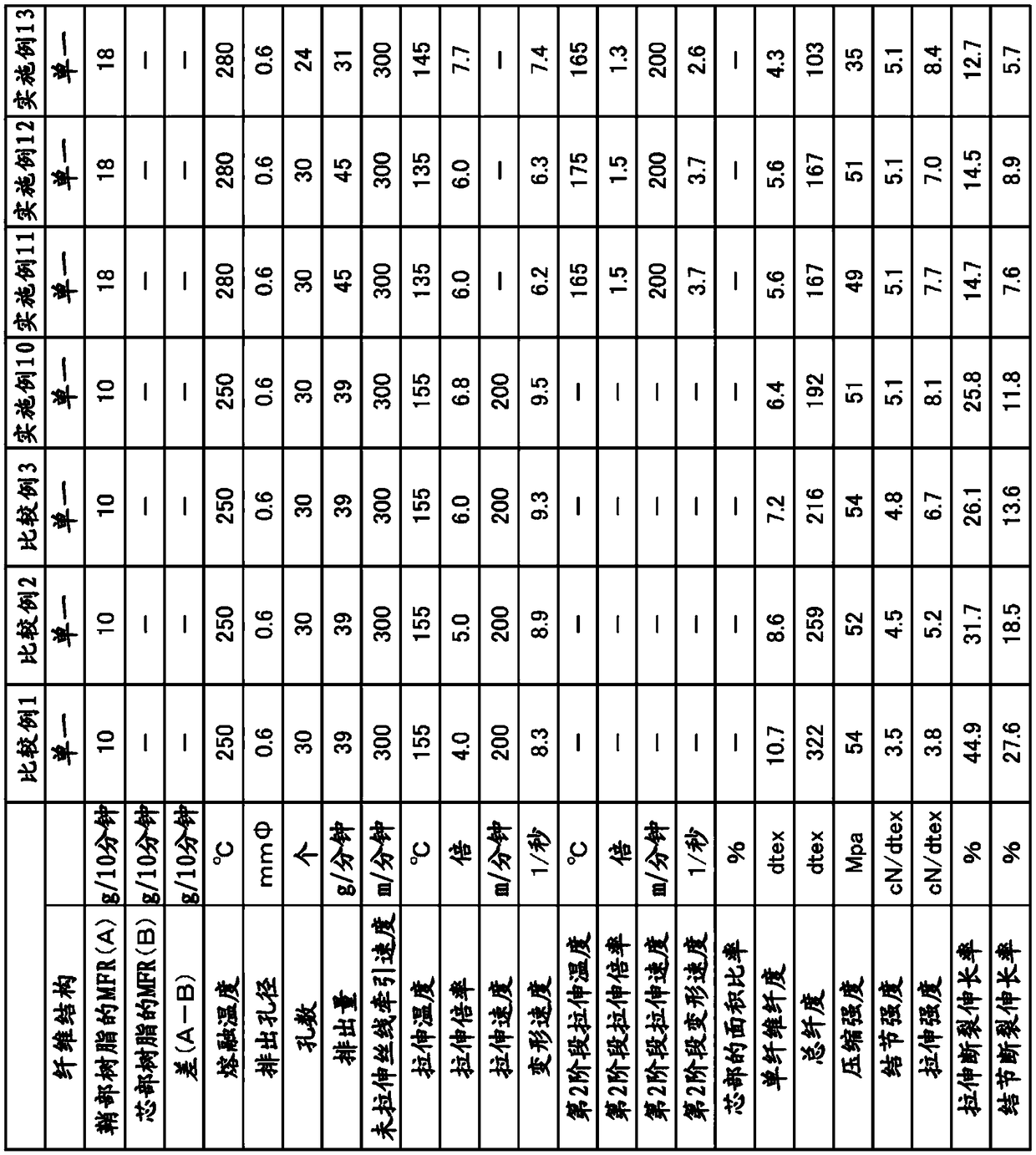

The invention provides a fiber that is provided with a plurality of good properties of pom resin and high retention of knot strength. A composite fiber is formed by a polyoxymethylene copolymer (a) and a polyoxymethylene copolymer (b) that are used as the core and the sheath of the composite fiber. The polyoxymethylene copolymer (a) and the polyoxymethylene copolymer (b) from a polymer chain that consists of formaldehyde repeating units contain a specific amount of specific formaldehyde units and have different crystallization melting temperature.

Owner:POLYPLASTICS CO LTD

Method for processing high-performance modified polyethylene monofilaments for manufacturing fishing net

InactiveCN101851795AIncrease heat treatment temperatureHigh breaking strengthSpinning head liquid feederFilament manufactureWinding machineElastomer

The invention discloses a method for processing high-performance modified polyethylene monofilaments for manufacturing a fishing net, relates to a method for processing polyethylene monofilaments for manufacturing a fishing net and aims to provide a method for processing the high-performance modified polyethylene monofilaments for manufacturing the fishing net. In the technical scheme of the invention, a stirring machine, a single-screw extruder, a twice-drafting electrical heating drafting machine, a filament winding machine and a filament separating machine are adopted. The method is characterized by comprising the following steps of: mixing a sieved spinning-grade dry HDPE resin, a dry VERSIFYTM 6002 elastomer, white oil or a turpentine aid; uniformly mixing the materials to obtain an HDPE / VERSIFYTM 6002 elastomer blend and fusing and extruding the blend by using the single-screw extruder; cooling and pre-drafting fused and extruded primary filaments, thermally drafting the pre-drafted filaments twice, rapidly cooling the thermally-drafted filaments from which oil is removed with high-pressure air current and winding modified PE monofilaments by using the winding machine; and separating the modified PE monofilaments into the high-performance modified polyethylene monofilaments for manufacturing the fishing net by using the filament separating machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Machining method for steel cable for deep and blue fishery

InactiveCN106087497AGuaranteed performanceImprove liquidityAgriculture tools and machinesFilament forming substance formingHydroxystearic AcidTorque motor

The invention discloses a machining method for a steel cable for deep and blue fishery. The method is characterized in that UHMWPE powder, LLDPE powder, nanometer silver-loaded silicon dioxide antibacterial agent, white oil, silicone powder, hydroxystearic acid, antioxidant 1010, nanoscale kieselguhr, nanoscale wollastonite, antioxidant aid DLTP and ethylene-vinyl acetate copolymer are premixed and then poured into a high-speed kneading pot to be kneaded at a high speed, a UHMWPE composite material is melt and extruded through a twin-screw extruder, the extrudate passes through a metering pump additionally arranged on a twin-screw outlet to be melt and extruded from a spinning orifice, the extruded spun filament is cooled and predrawn, the predrawn filament is subjected to heat drawing, a filament rolling machine of a torque motor is used for rolling melt spinning beams after heat setting, a stranding machine is used for carrying out primary twisting on the melt spinning beam to obtain an S-twisted strand, and a three-strand twisting machine is used for processing three S-twisted strands into the Z-twisted three-strand steel cable for deep and blue fishery. The machining method can also be used in oceanographic engineering and trash holding engineering.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Processing technology of high-strength high-tenacity fishing twine

InactiveCN107200900AImprove usage characteristicsSimple processing technologyConjugated synthetic polymer artificial filamentsArtifical filament manufacturePolymer scienceMicrocrystalline wax

The invention discloses a processing technology of a high-strength high-tenacity fishing twine. The processing technology comprises the following steps: firstly, drying and crushing polypropylene and polyethylene; mixing crushed polypropylene and polyethylene with rubber, glyceryl monostearate, microcrystalline wax, dihydro-quinoline, bisoctadecyl ester and modified nano-zinc oxide; performing granulation; placing the granules in an injection molding machine to be subjected to injection molding; and cooling, drawing and stretching a semi-finished product obtained through molding. Various raw material ingredients are reasonably selected, and meanwhile, the specific processing technology is improved, so that the use features of the end-product fishing twine are effectively improved, the fishing twine is uniform in thickness and stable in overall quality, the breaking strength can be improved by 14-20%, the knot strength can be improved by 10-15%, decrease of the elongation at break is controlled to be within 4% on the basis of strength improvement, besides, the processing yield can reach 99.9% or above, the overall characteristic is excellent and the popularization value is high.

Owner:CHAOHU LOTUS FISHING NET

Preparation method of circular truncated cone-shaped side net for semi-submersible aquaculture platform

ActiveCN111642437AUnobstructed exchangeQuality is safe and reliableElectroconductive/antistatic filament manufactureSpinnerette packsNanoparticlePolyethylene glycol

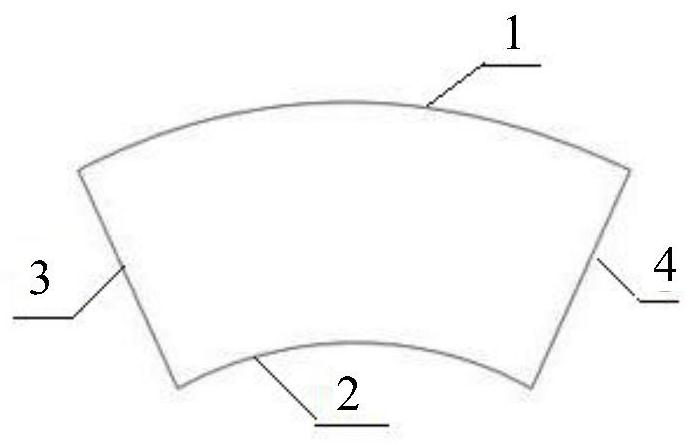

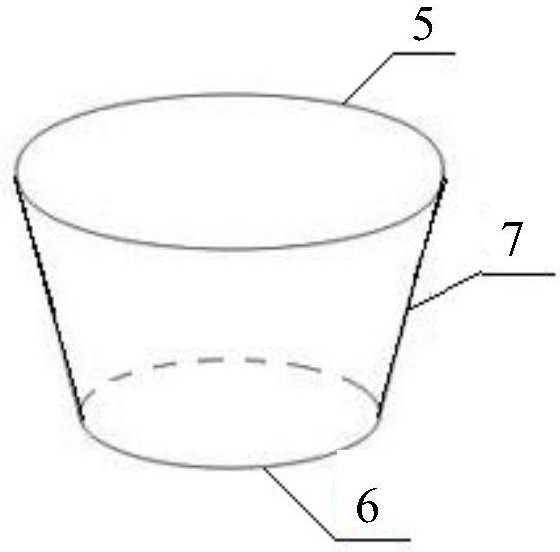

The invention provides a preparation method of a circular truncated cone-shaped side net for a semi-submersible aquaculture platform. The preparation method comprises anti-fouling monofilament bundlepreparation, anti-fouling net sheet preparation, and circular truncated cone-shaped side net preparation. Preparation raw materials comprise PP resin, dioctyl phthalate, polyethylene glycol fatty acidester, cetyl phosphate, a grafted polyguanidine salt / polyethylene granular material, and surface modified copper-nickel alloy nanoparticles. When the anti-fouling net sheet is prepared, first the antifouling monofilament bundle is twisted to obtain an antifouling strand with the Z twist direction, then three antifouling strands with the Z twist direction are processed into an antifouling twistedthread with the S twist direction, then the antifouling twisted thread with the S twist direction is processed into a net sheet with double dead knots, and finally the net sheet is subjected to heat-setting with 0.22 times the longitudinal breaking strength of the net sheet as a pre-tension. When the circular truncated cone-shaped side net is prepared, knotting is performed in a circulation mannerof "single dead knot-single dead knot-double dead knot-double dead knot", then a net sheet is subjected to fan ring-shaped cutting, edge line and net line assembly, and edge strengthening, then mother lines at the left and right side of a fan ring-shaped net sheet are butted and stitched, and double dead knots are knotted at the same distance when butting and stitching are performed.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Manufacturing method of fibers of breeding nets of sea fish

ActiveCN104562284AImprove performanceReduce consumptionFilament forming substance formingConjugated synthetic polymer artificial filamentsLinear low-density polyethyleneFiber bundle

The invention provides a manufacturing method of fibers of breeding nets of sea fish. The manufacturing method adopts HDPE (high-density polyethylene) resin, an auxiliary agent, metallocene LLDPE (linear low density polyethylene) resin, a stirring machine, a single-screw extrusion machine, a twice-drawing electrical heating drawing machine, a silk collecting machine and a silk dividing machine. The manufacturing method is characterized in that the HDPE resin is sieved; the adding amount of the auxiliary agent is 0.6% of the weight of the HDPE resin; the adding amount of the metallocene LLDPE resin is 10.3% of the weight of the HDPE resin; the materials are stirred by the stirring machine for 19-31 minutes, so that the materials are uniformly stirred, and a mixture of the HDPE resin and the metallocene LLDPE resin is obtained; melt extrusion is performed on the mixture of the HDPE resin and the metallocene LLDPE resin by the single-screw extrusion machine, and primary silk obtained from melt extrusion is cooled and pre-drawn by a cooling water box and a first drawing roller; twice hot drawing is performed on the pre-drawn silk, the drawn silk is degreased by a high-pressure airflow, the degreased silk is rapidly cooled, and fiber bundles are collected and rolled by the silk collecting machine; the fiber bundles are divided into the fibers of the breeding nets of the sea fish by the silk dividing machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Preparation method of cylindrical box body with antifouling property for deep and open sea net cage

ActiveCN111657197AGood antifouling effectAntifouling effectiveElectroconductive/antistatic filament manufactureClimate change adaptationOpen seaHigh density

The invention provides a preparation method of a cylindrical box body with the antifouling property for a deep and open sea net cage. The method comprises the following steps of A, preparing an antifouling netting, which comprises three aspects of preparing a modified high-density polyethylene composite material, preparing an antifouling monofilament bundle and processing the antifouling netting;B, preparing an anti-abrasion netting from a polyamide netting coated with a polyurea coating; and C, preparing the cylindrical box body, which comprises three aspects of side net processing, bottom net processing and cylindrical box body processing. According to the cylindrical box body with the antifouling property for the deep and open sea net cage obtained by the preparation method, the antifouling property of the cylindrical box body can be greatly improved and the water resistance of the cylindrical box body and the attachment area of fouling organisms can be reduced on the premise of keeping the netting strength of a side net unchanged, fouling organism attachment of the cylindrical box body and net breaking fish escape accidents under severe sea conditions can be greatly reduced, and green development and modern construction of the deep and open sea net cage culture industry are realized.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Processing method for antifouling melt spinning for far-reaching-sea net cage or floating-rope surrounding net

ActiveCN106192030AImprove liquidityImprove spinnabilityMelt spinning methodsMonocomponent polyolefin artificial filamentTurpentineHydroxystearic Acid

The invention discloses a processing method for antifouling melt spinning for a far-reaching-sea net cage or a floating-rope surrounding net. The processing method is characterized by including the steps that UHMWPE powder, nanometer Cu powder, HDPE powder, silicone powder, antioxidant B225, assistant antioxidant DLTP, hydroxy stearic acid, nanoscale white carbon black, nanoscale kieselguhr, nanoscale aedelforsite, ethylene-vinyl acetate copolymer and turpentine assistant are weighed in the formula, then premixed to be poured into a high-speed kneading pot and subjected to high-speed kneading, and a blending-modification UHMWPE material is obtained; the blending-modification UHMWPE material is belted and extruded through a double-screw extruder, the extruded substance is metered through a metering pump additionally arranged through a double-screw outlet and belted and extruded through a spinneret hole, the extruded primary raw silk is cooled and pre-drafted, the pre-drafted silk is subjected to heat setting, then tows are winded through a silk winding machine of a torque motor, and are subjected to silk dividing through a silk dividing machine, and the antifouling melt spinning for the far-reaching-sea net cage or the floating-rope surrounding net is obtained.

Owner:威海市宏威塑料有限公司

Method for producing fibers used for twisted threads

InactiveCN104862793AImprove spinnabilityHigh breaking strengthArtificial thread manufacturing machinesSpinning head liquid feederFiberYarn

The invention discloses a method for producing fibers used for twisted threads. According to the method, MMWPE resin, HDPE resin, nanometer SiO2, an auxiliary agent, an agitator, a yarn separating machine, a yarn withdrawal machine, a single screw extruder and a twice-drafting electrical heating drafting machine are adopted, and the method is characterized in that the MMWPE resin, the HDPE resin, the nanometer SiO2 and the auxiliary agent are stirred to be uniform with the agitator, nano-modified compound granules are obtained, the nano-modified compound granules are melt and extruded through the single screw extruder, newly-generated yarn obtained through the extrusion is subjected to cooling and pre-drafting through a cooling water tank and a first drafting roller, pre-drafted yarn is subjected to hot drafting for twice through a high temperature first drafting water bath and a second drafting roller as well as a high temperature second drafting water bath and a third drafting roller, and after the drafting, fiber tows are reeled through the yarn withdrawal machine which uses a moment electric motor; the fiber tows are separated into the fibers used for the twisted threads through the yarn separating machine under the yarn separation tensile force, and the yarn separation tensile force is controlled to be 12%-21% of the fiber breaking force.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Method for making netting twine for euphausiasuperba resource development

InactiveCN104911771AEasy to processRealize energy saving and consumption reductionSpinnerette packsArtificial filament physical treatmentTorque motorEngineering

A method for making netting twine for euphausiasuperba resource development is characterized in that MMWPE resin, PP resin, EPDM resin and white oil or turpentine auxiliaries are mixed and evenly stirred by a stirrer to obtain blended MMWPE / PP / EPDM granules; the blended MMWPE / PP / EPDM granules are melted and extruded by a single screw extruder, melted and extruded spun filaments are cooled by low-temperature water in a cooling water tank and pre-drafted by a first drafting roller, pre-drafted filaments are subjected to hot drafting through a first drafting water bath and a second drafting roller for the first time and subjected to hot drafting through a second drafting water bath and a third drafting roller for the second time, blended and modified monofilament tows are taken up through a filament take-up machine making use of a torque motor, and bobbin-packaged monofilaments are twisted into one Z-twist single yarn, wherein each tow of the bobbin-packaged monofilaments contains ten blended and modified monofilaments; four Z-twist single yarns are primarily twisted into one S-twist strand; finally, three S-twist strands are twisted into the Z-twist netting twine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Preparation method of ultra-high molecular weight polyethylene monofilament knotted fishing net

ActiveCN103572502BEasy to useRetention strengthNew-spun product collectionLiquid/gas/vapor article treatmentFiberPolymer science

Owner:王庆昭

Polyformaldehyde resin made composite fiber

InactiveCN100529206CImprove nodule strengthHigh knot strength retentionMelt spinning methodsConjugated synthetic polymer artificial filamentsFiberCopolymer

PROBLEM TO BE SOLVED: To provide a fiber having various excellent properties of a polyoxymethylene resin and high knot strength retention. SOLUTION: The conjugate fiber is composed of two kinds of polyoxymethylene copolymers (a) and (b) containing a specific amount of a specific oxymethylene unit in a polymer chain composed mainly of the repetition of oxymethylene units and having different crystal melting temperatures wherein the copolymers (a) and (b) form the core and the sheath of the fiber, respectively.

Owner:POLYPLASTICS CO LTD

Processing method of nanometer copper and nickel synergetic antifouling wires containing grafted polyguanidine salt

ActiveCN111926407AImprove antifouling functionImprove nodule strengthArtificial filament heat treatmentMelt spinning methodsNanoparticleNano copper

The invention provides a processing method of nanometer copper and nickel synergetic antifouling wires containing grafted polyguanidine salt. The method includes the three processes of raw materials compounding, melt-spinning, and stretching and heat forming. With HDPE particles, grafted polyguanidine salt / polyethylene particles and surface modified copper nickel alloy nanoparticles as a main rawmaterial, firstly, a composite material with the synergetic antifouling effect is obtained, and then the synergetic antifouling wires are obtained after a wire drawing technology. The synergetic antifouling wires carry out targeting synergetic antifouling treatment on algae, barnacle and other fouling organisms in the practical breeding production, the fouling organisms are prevented from attaching to the surface of culture and proliferation facility net clothing, the comprehensive and effective synergetic antifouling action can be achieved, the results of sea tests show that the attachment ofthe fouling organisms of the culture and proliferation facility net clothing made of the antifouling wires can be lowered by more than 20%, and the synergetic antifouling effect is very significant.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Polyolefin fiber and method for producing same

ActiveCN109477248AImprove nodule strengthHigh tensile strengthFilament/thread formingMonocomponent polypropylene artificial filamentPolyolefinSingle fiber

The present invention addresses the problem of providing polyolefin fiber that can be easily deformed against stress applied in the direction perpendicular to the fiber axis, has reduced fibrillation,and has excellent knot strength, and in particular, core-sheath composite polypropylene fiber. The problem of the present invention can be solved by having polyolefin fiber with which the compressivestrength, as calculated with formula 1, when compressively deformed by 30% relative to the fiber diameter in the direction perpendicular to the fiber axis in a single fiber is 30 to 51 MPa. St=2P / (Pi*L*d) (Formula 1) St: compressive strength (MPa), P: test force (N), d: single fiber diameter (mm), L: indenter diameter (mm)

Owner:MITSUBISHI CHEM CORP

Polyethylene fishing net thread with good mechanical property

InactiveCN108977914AIncrease the degree of cross-linkingIncrease the number of linker moleculesMonocomponent polyolefin artificial filamentArtifical filament manufactureBreaking strengthEngineering

The invention discloses a polyethylene fishing net thread with good mechanical property, and relates to the technical field of new materials. The polyethylene fishing net thread with good mechanical property contains 1-hydroxybenzotriazole modified polyethylene accounting for 78-85% of the mass of the polyethylene fishing net thread; the polyethylene fishing net thread prepared according to the invention has good breaking strength and knot strength. According to the invention, 1-hydroxybenzotriazole modified polyethylene is adopted, so that the comprehensive mechanical performance of polyethylene is greatly improved, and then the use performance of the fishing net is effectively improved; 1-hydroxybenzotriazole modified polyethylene adopted according to the invention is more significant inthe effect of improving the mechanical performance of polyethylene in comparison with modified polyethylene recorded in the prior art.

Owner:界首市汇珠渔具有限公司

Method for processing wearable blended and modified polypropylene monofilaments for manufacturing fishing rope

InactiveCN101851796BImprove performanceImprove nodule strengthSpinning head liquid feederFilament manufactureWinding machinePulp and paper industry

The invention discloses a method for processing wearable blended and modified polypropylene monofilaments for manufacturing a fishing rope, relates to a method for processing polypropylene monofilaments for a fishing rope and aims to provides a method for processing the wearable blended and modified polypropylene monofilaments for manufacturing the fishing rope. A stirring machine, screw extruders, a drafting machine, a filament winding machine and a filament separating machine are adopted. The method is characterized by comprising the following steps of: mixing a sieved spinning-grade dry T30S type PP resin, a spinning-grade dry PA1010 resin, dry zinc stearate, white oil or a turpentine aid; uniformly mixing the materials, extruding the mixture twice by using a double-screw extruder and pelletizing to obtain poly-blended particles which contain the PP resin, the PA1010 resin and the zinc stearate; fusing and extruding the poly-blended particles by using a single-screw extruder, cooling and pre-drafting the fused and extruded primary filaments, thermally drafting the pre-drafted filaments twice, rapidly cooling the thermally-drafted filaments with high-pressure air current after the two times of thermal drafting and winding monofilaments by using the filament winding machine; and separating the monofilaments by using the filament separating machine to obtain the fishing wearable blended and modified PP monofilaments.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Knotted net for marine fishery

InactiveCN106192199BImprove processing fluidityProcess stabilitySpinnerette packsFilament forming substance formingTurpentineTorque motor

Disclosed is a knotted net for marine fishery. The knotted net for marine fishery is characterized in that UHMWPE powder, HDPE powder, a silver-supported nano-silica antimicrobial agent, hydroxystearic acid, silicone powder, an antioxidant B225, nanoscale white carbon black, an antioxidant aid DLTP, a vinyl-vinyl acetate copolymer, nanoscale diatomite and turpentine are premixed and then poured into a high-speed kneading pot to be subjected to high-speed kneading, and a modified UHMWPE composite is obtained; the modified UHMWPE composite is subjected to melt extrusion through a twin-screw extruder, extrudate is subjected to melt extrusion from spinneret orifices through a metering pump additionally arranged at a twin-screw outlet, extruded spun filaments are cooled and pre-drafted, the pre-drafted filaments are subjected to heat setting, and then melt-spun filament bundles are taken up through a filament take-up machine of a torque motor; the melt-spun filament bundles are subjected to primary twisting through a stranding machine, and then Z-twisting-direction strands are obtained; every three Z-twisting-direction strands are processed into an S-twisting-direction three-strand net line with the twisting pitch of 24 mm through a three-strand rope twisting machine, and the three-strand net lines are knitted into the knotted net for marine fishery through a single-hook netting machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

A preparation method of light sky blue long-acting antifouling net containing grafted polyguanidine salt

ActiveCN111676588BHigh strengthImprove wind and wave resistanceSpinnerette packsHeating/cooling textile fabricsMasterbatchPolymer science

The invention provides a preparation method of a light sky blue long-acting antifouling net containing grafted polyguanidine salt, comprising preparation of light sky blue masterbatch, preparation of light sky blue modified HDPE compound, melt spinning, drawing and heating There are five steps in shaping and preparing long-lasting anti-fouling nets. First, use 5000S high-density polyethylene resin, ultramarine blue pigment and A‑101 titanium dioxide as raw materials to process light sky blue masterbatch; then L501 HDPE resin, grafted polyguanidine salt / polyethylene pellets, stearic acid Zinc, antioxidant KY‑7910, turpentine, and light sky blue masterbatch are mixed and modified, and then drawn to obtain light sky blue long-lasting antifouling tow; finally, light sky blue long-lasting antifouling is obtained through a specific spinning process The light sky blue long-lasting antifouling net containing grafted polyguanidine salt is obtained through a specific net weaving process. The mesh breaking strength of the long-lasting anti-fouling net prepared by the long-lasting anti-fouling mesh meets the qualified product index of GB / T 18673, and is 17.9% higher than the normal PE mesh qualified product.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Preparation method of rectangular separation net for deep and far sea culture

ActiveCN114775162AImprove antifouling functionNot easy to failTextile selvedgesClimate change adaptationPhosphoric Acid EstersPropanoic acid

The invention provides a preparation method of a rectangular separation net for deep and far sea culture, which comprises the following steps: preparing a blended antifouling composite material, preparing a light blue monofilament bundle, preparing a rectangular separation net, and mixing polypropylene granules, a polyhexamethylene guanidine hydrochloride grafted modified polypropylene antifouling material, nano copper powder, pyrithione copper powder, tetra [beta-(3, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4- 2, 5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, tri (1, 2, 2, 6, 6-pentamethylpiperidinyl) phosphite, phthalocyanine blue pigment, titanium dioxide and turpentine are mixed and uniformly stirred, extrusion granulation is performed 2-3 times through a double-screw extruder to obtain a blended antifouling composite material, light blue monofilament tows are obtained after wire drawing and rolling, and the light blue monofilament tows are used as raw materials. And obtaining the rectangular separation net for deep and far sea culture by using a special rectangular separation net preparation method.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Processing method of antifouling melt-spinning for net cage or floating rope seine in deep sea

ActiveCN106192030BImprove liquidityImprove spinnabilityMelt spinning methodsMonocomponent polyolefin artificial filamentTurpentineHydroxystearic Acid

The invention discloses a processing method for antifouling melt spinning for a far-reaching-sea net cage or a floating-rope surrounding net. The processing method is characterized by including the steps that UHMWPE powder, nanometer Cu powder, HDPE powder, silicone powder, antioxidant B225, assistant antioxidant DLTP, hydroxy stearic acid, nanoscale white carbon black, nanoscale kieselguhr, nanoscale aedelforsite, ethylene-vinyl acetate copolymer and turpentine assistant are weighed in the formula, then premixed to be poured into a high-speed kneading pot and subjected to high-speed kneading, and a blending-modification UHMWPE material is obtained; the blending-modification UHMWPE material is belted and extruded through a double-screw extruder, the extruded substance is metered through a metering pump additionally arranged through a double-screw outlet and belted and extruded through a spinneret hole, the extruded primary raw silk is cooled and pre-drafted, the pre-drafted silk is subjected to heat setting, then tows are winded through a silk winding machine of a torque motor, and are subjected to silk dividing through a silk dividing machine, and the antifouling melt spinning for the far-reaching-sea net cage or the floating-rope surrounding net is obtained.

Owner:威海市宏威塑料有限公司

Method for processing high-performance modified polyethylene monofilaments for manufacturing fishing net

InactiveCN101851795BIncrease heat treatment temperatureHigh breaking strengthSpinning head liquid feederFilament manufactureWinding machineElastomer

The present invention discloses a method for processing high-performance modified polyethylene monofilaments for manufacturing a fishing net, relates to a method for processing polyethylene monofilaments for manufacturing a fishing net and aims to provide a method for processing the high-performance modified polyethylene monofilaments for manufacturing the fishing net. In the technical scheme of the invention, a stirring machine, a single-screw extruder, a twice-drafting electrical heating drafting machine, a filament winding machine and a filament separating machine are adopted. The method is characterized by comprising the following steps of: mixing a sieved spinning-grade dry HDPE resin, a dry VERSIFYTM 6002 elastomer, white oil or a turpentine aid; uniformly mixing the materials to obtain an HDPE / VERSIFYTM 6002 elastomer blend and fusing and extruding the blend by using the single-screw extruder; cooling and pre-drafting fused and extruded primary filaments, thermally drafting the pre-drafted filaments twice, rapidly cooling the thermally-drafted filaments from which oil is removed with high-pressure air current and winding modified PE monofilaments by using the winding machine; and separating the modified PE monofilaments into the high-performance modified polyethylene monofilaments for manufacturing the fishing net by using the filament separating machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Preparation method of fiber for seawater fish breeding net clothing

ActiveCN104562284BImprove performanceReduce consumptionFilament forming substance formingConjugated synthetic polymer artificial filamentsLinear low-density polyethyleneFiber bundle

The invention provides a manufacturing method of fibers of breeding nets of sea fish. The manufacturing method adopts HDPE (high-density polyethylene) resin, an auxiliary agent, metallocene LLDPE (linear low density polyethylene) resin, a stirring machine, a single-screw extrusion machine, a twice-drawing electrical heating drawing machine, a silk collecting machine and a silk dividing machine. The manufacturing method is characterized in that the HDPE resin is sieved; the adding amount of the auxiliary agent is 0.6% of the weight of the HDPE resin; the adding amount of the metallocene LLDPE resin is 10.3% of the weight of the HDPE resin; the materials are stirred by the stirring machine for 19-31 minutes, so that the materials are uniformly stirred, and a mixture of the HDPE resin and the metallocene LLDPE resin is obtained; melt extrusion is performed on the mixture of the HDPE resin and the metallocene LLDPE resin by the single-screw extrusion machine, and primary silk obtained from melt extrusion is cooled and pre-drawn by a cooling water box and a first drawing roller; twice hot drawing is performed on the pre-drawn silk, the drawn silk is degreased by a high-pressure airflow, the degreased silk is rapidly cooled, and fiber bundles are collected and rolled by the silk collecting machine; the fiber bundles are divided into the fibers of the breeding nets of the sea fish by the silk dividing machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

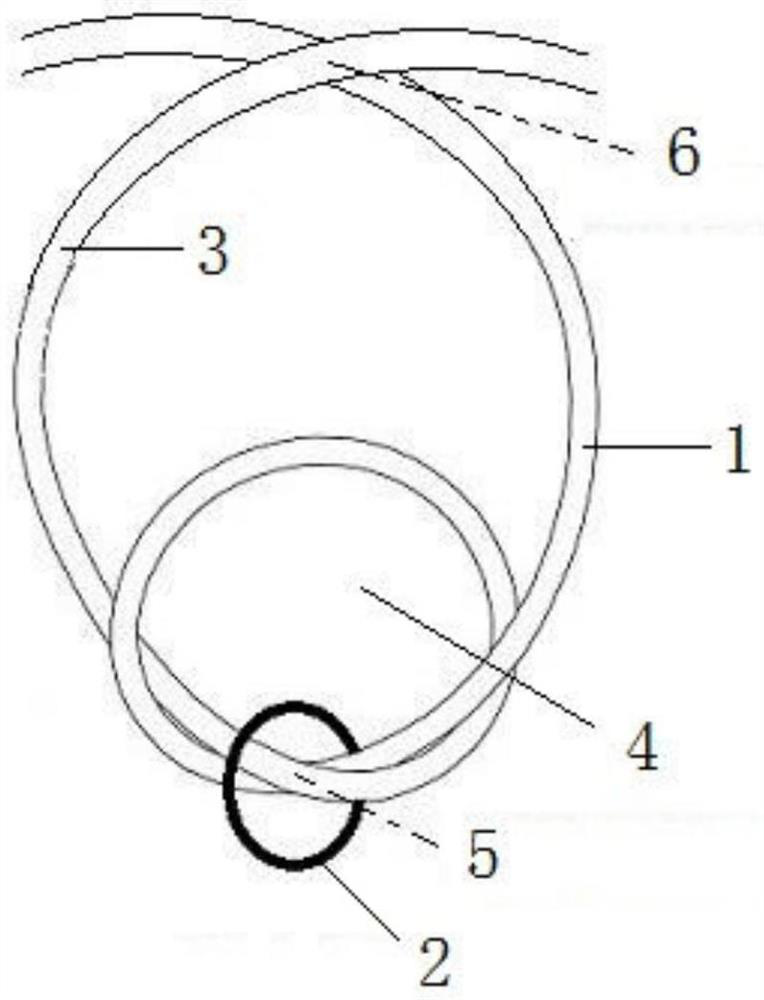

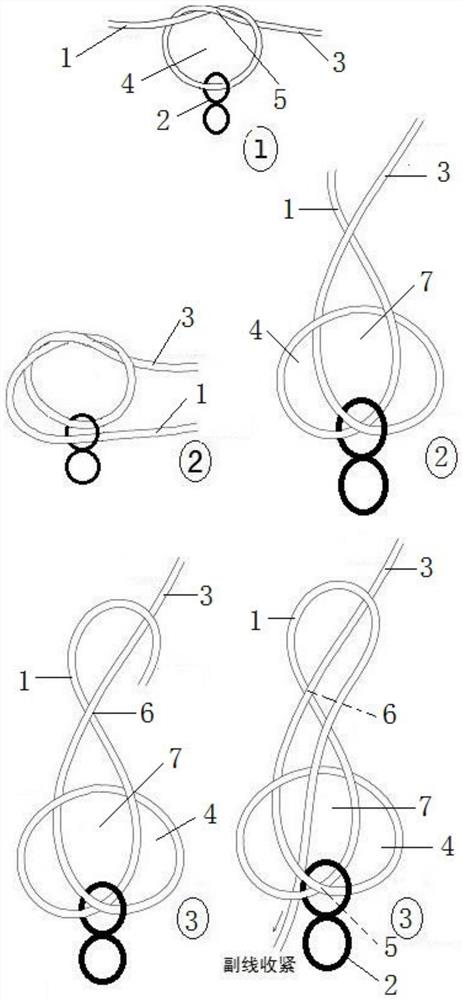

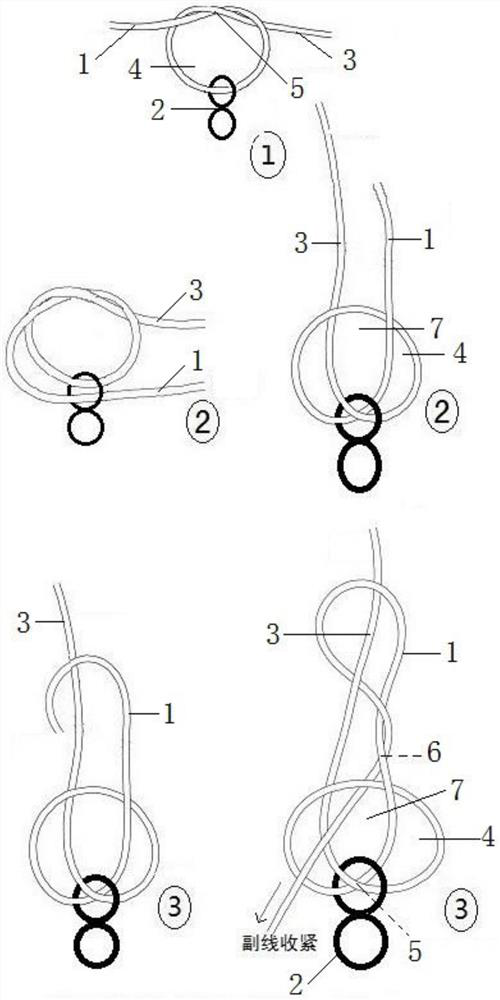

Knotless knotting method of nylon fishing line and connecting ring and main line composite 8-shaped knot knotting method

ActiveCN114190343AImprove nodule strengthEasy to operateClimate change adaptationLinesMarine engineeringPolyamide

The invention discloses a knotless knotting method of a nylon fishing line and a connecting ring and a knotting method of a main line composite 8-shaped knot. According to the knotless knotting method, a sub-line (1) rotates downwards to penetrate through the connecting ring (2) and then intersects with a main line (3) to form a first cross locking point (5), and the sub-line (1) penetrates through the connecting ring (2) and then intersects with the main line (3) or the sub-line (1) to form a second cross locking point (6); when the auxiliary line (1) is tightened, the first cross locking point (5) and the second cross locking point (6) lock and position the main line (3), and the auxiliary line is tightened to complete knotting. According to the knotting method, no tangent knot exists, the main line is not damaged, the knotting method is easy to operate, the knot strength of the nylon (polyamide) fishing line can be improved to the maximum extent, and the phenomenon that fishes escape from the line due to improper knotting is avoided.

Owner:贵州垂纶文化科技有限公司

A processing method for synergistic antifouling silk containing grafted polyguanidine salt nano-copper nickel

ActiveCN111926407BImprove antifouling functionImprove nodule strengthArtificial filament heat treatmentMelt spinning methodsEngineeringBiological adhesion

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

A preparation method of a cylindrical box with antifouling performance for deep sea net cages

ActiveCN111657197BGood miscibilityImprove liquidityElectroconductive/antistatic filament manufactureClimate change adaptationHigh densityPolyamide

The invention provides a method for preparing a cylindrical box body for deep-sea net cages with antifouling properties, including A, preparation of antifouling net clothing, including preparation of modified high-density polyethylene composite materials, preparation of antifouling monofilament bundles, and antifouling Three aspects of dirty net processing; B. Anti-friction net preparation, made of polyamide net coated with polyurea coating; C. Cylindrical box preparation, including side net processing, bottom net processing and cylindrical box Three aspects of processing. According to the preparation method of the present invention, the cylindrical box body with antifouling performance for deep-sea net cages can greatly improve the antifouling performance of the cylindrical box body under the premise of keeping the strength of the side nets constant. It can also reduce the water resistance of the cylindrical box and the area of fouling organisms, which can greatly reduce the fouling of the cylindrical box and the fish escape accidents caused by broken nets under harsh sea conditions. Green development and modernization.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

A kind of steel rope processing method for dark blue fishery

InactiveCN106087497BGuaranteed performanceImprove liquidityAgriculture tools and machinesFilament forming substance formingHydroxystearic AcidTorque motor

The invention discloses a machining method for a steel cable for deep and blue fishery. The method is characterized in that UHMWPE powder, LLDPE powder, nanometer silver-loaded silicon dioxide antibacterial agent, white oil, silicone powder, hydroxystearic acid, antioxidant 1010, nanoscale kieselguhr, nanoscale wollastonite, antioxidant aid DLTP and ethylene-vinyl acetate copolymer are premixed and then poured into a high-speed kneading pot to be kneaded at a high speed, a UHMWPE composite material is melt and extruded through a twin-screw extruder, the extrudate passes through a metering pump additionally arranged on a twin-screw outlet to be melt and extruded from a spinning orifice, the extruded spun filament is cooled and predrawn, the predrawn filament is subjected to heat drawing, a filament rolling machine of a torque motor is used for rolling melt spinning beams after heat setting, a stranding machine is used for carrying out primary twisting on the melt spinning beam to obtain an S-twisted strand, and a three-strand twisting machine is used for processing three S-twisted strands into the Z-twisted three-strand steel cable for deep and blue fishery. The machining method can also be used in oceanographic engineering and trash holding engineering.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Manufacturing method of consumption-reducing and resistance-reducing filaments for marine ranch

ActiveCN111647960AImprove roundnessImprove liquidityArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentProcess engineeringStearic acid

The invention provides a manufacturing method of consumption-reducing and resistance-reducing filaments for a marine ranch. The manufacturing method comprises three steps of raw material compounding,melt spinning and stretching and heat setting. The manufacturing method comprises the following specific steps: by taking POK granules, zinc stearate, silicone powder, an antioxidant and white oil asraw materials, acquiring a POK compound material first; and then carrying out extrusion by a twin-screw extruder, and performing spinning, stretching, heat setting and filament separating to obtain POK fibers. The POK fibers prepared by the manufacturing method of the consumption-reducing and resistance-reducing filaments for the marine ranch have excellent performance of surface smoothness, highstrength, wear resistance and the like. The manufacturing method is simple, low in carbon and friendly to environment in preparation process, and can lower the production cost obviously.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Manufacturing method of super antibacterial melt-spinning yarn for krill fishery or breeding seine

ActiveCN106192065BImprove performanceSolving Melt Fracture ProblemsSpinnerette packsFilament forming substance formingHydroxystearic AcidTorque motor

The invention relates to a manufacturing method of superstrong-bacterium-inhibiting melt-spun filaments for krill fishery or aquaculture purse seines. The manufacturing method is characterized by including: premixing UHMWPE powder, HDPE powder, nano titanium dioxide silver-loaded antibacterial agent, nano titanium dioxide, hydroxy stearic acid, ethylene-vinyl acetate copolymer, silicone powder, antioxidant 1010, nanoscale diatomite, nanoscale white carbon black, assistant antioxidant DLTP and white oil weighed according to the formula, and pouring into a high-speed kneading pot to perform high-speed kneading to obtain a UHMWPE composite material; extruding the UHMWPE composite material with a double-screw extruder in a melt manner, using a measuring pump mounted at the a double-screw outlet to measure the extruded material, extruding the measured material from a spinneret orifice in a melt manner, cooling and pre-drafting the extruded spun filaments, subjecting the pre-drafted filaments to thermoforming, using a filament collecting machine using a torque motor to wind melt-spun tows; separating the melt-spun tows with a filament separator to obtain the superstrong-bacterium-inhibiting melt-spun filaments for the krill fishery or aquaculture purse seines.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Preparation method of cylindrical hanging cage for preventing seaweed from attaching

ActiveCN111642438BIncrease exchange rateGrow fastClimate change adaptationPisciculture and aquariaPhosphoric Acid EstersSpinning

The invention provides a method for preparing an anti-seaweed adhesion cylindrical hanging cage, which includes the preparation of an outer cover net, including the preparation of an anti-seaweed adhesion composite material, the processing of an anti-seaweed adhesion tow, and the processing of an outer cover net. The spinning raw materials include grafted polymer Guanidine salt / polyethylene pellets, HDPE pellets, dioctyl phthalate, cetyl phosphate, polyethylene glycol fatty acid ester, surface-modified copper-nickel alloy nanoparticles; B, cage assembly, cutting A piece of rectangular outer cover net, and the length of setting this rectangular outer cover net increases 44cm-56cm again than the product of layer height and number of layers, and the width of rectangular outer cover net is 3.142 times of cylindrical hanging cage diameter. The anti-seaweed adhesion cylindrical hanging cage produced by the technical scheme of the present invention can not only greatly improve the anti-seaweed adhesion function of the outer cover net, but also make the water resistance and seaweed and other fouling organisms The reduction of the attachment area can greatly reduce the incidence of algae attachment to the cylindrical hanging cage and the occurrence of cage breaking accidents under severe sea conditions.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

A method for manufacturing a consumption-reducing and drag-reducing wire for marine ranching

ActiveCN111647960BImprove surface smoothnessHigh strengthArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentYarnEngineering

The invention provides a method for manufacturing consumption-reducing and drag-reducing yarns for marine pastures, including three processes of raw material compounding, melt spinning, stretching and heat setting, and POK pellets, zinc stearate, silicone powder, antioxidant , white oil as raw material, first obtain POK composite material, and then through twin-screw extruder extrusion, spinning, drafting, heat setting and splitting, to obtain POK fiber. The POK fiber prepared by the manufacturing method of the consumption-reducing and drag-reducing yarn for ocean ranching has excellent properties such as smooth surface, high strength and wear resistance. The manufacturing method of the invention is simple, the preparation process is low-carbon and environment-friendly, and the production cost can be significantly reduced.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com