Patents

Literature

33results about How to "Improve antifouling function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

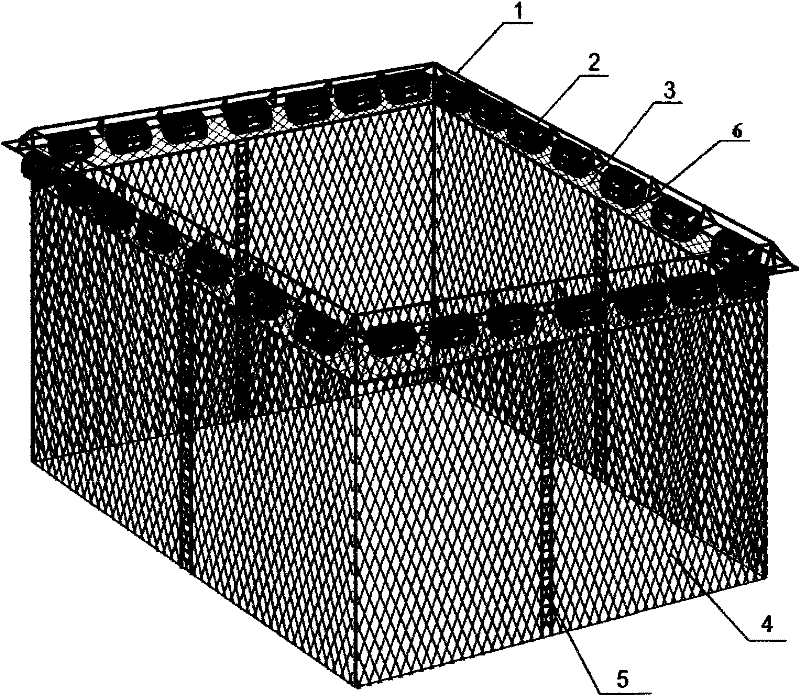

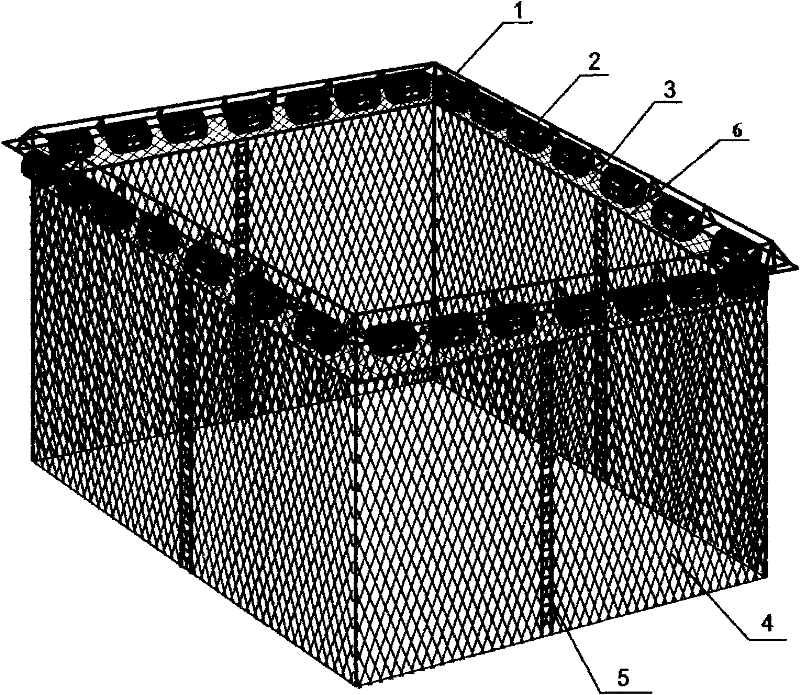

Combined fishnet square net cage used for mariculture

InactiveCN102239817AReduce deformation and volume lossImprove volume retentionClimate change adaptationPisciculture and aquariaDouble rowSeawater

The invention discloses a combined fishnet square net cage used for mariculture, relating to a mariculture net cage. In the combined fishnet square net cage, a cupronickel B10 stretching net, a brass HA177-2 stretching net, a high-strenght single-fast-knot polyethylene fibre net, a high-strength nylon warp knitting net, a fishing high-strength polyethylene monofilament rope, a galvanized iron pipe and a cylindrical foam buoy are adopted. The combined fishnet square net cage is characterized in that a frame system used for the net cage is of a square double-row galvanized iron pipe frame structure. In a fishnet system used for the net cage, a double-layer synthetic fibre fishnet serves as a first fishnet, a combined copper alloy stretching net serves as a second fishnet, and the first fishnet and the second fishnet are in longitudinal semi-soft connection; a square synthetic fibre fishnet is in a combined fishnet form of the fishnets used for the net bottom of the net cage; the combined fishnet used for the net bottom of the net cage is hung on the square double-row galvanized iron pipe frame; and the square double-row galvanized iron pipe frame of the net cage is connected with a float line frame of a mooring system by a mooring rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

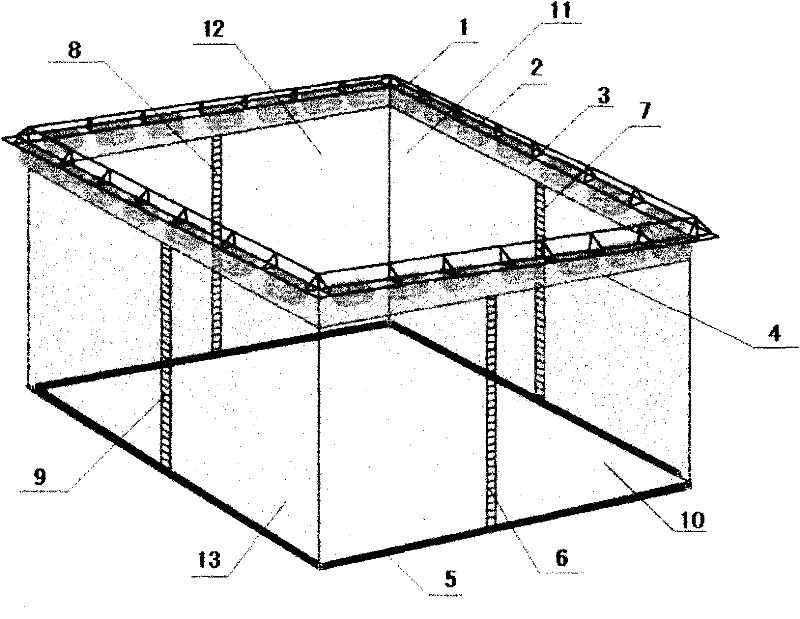

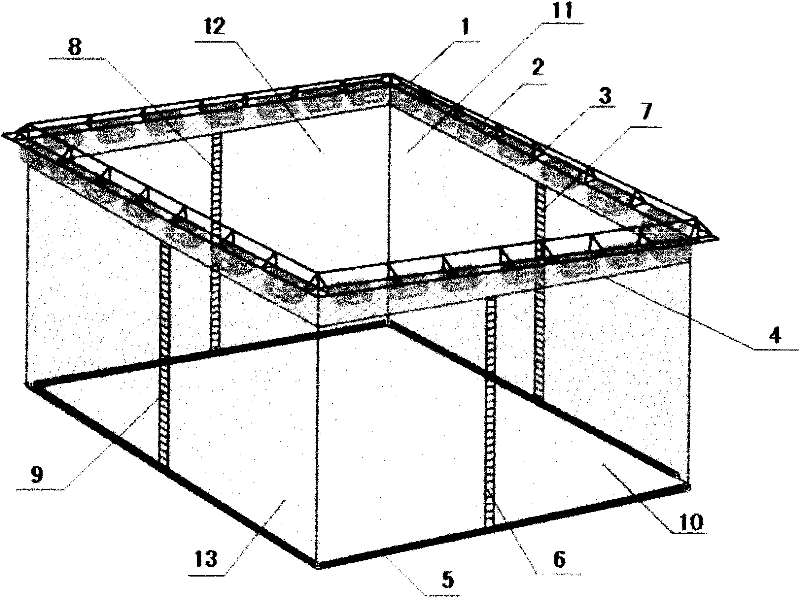

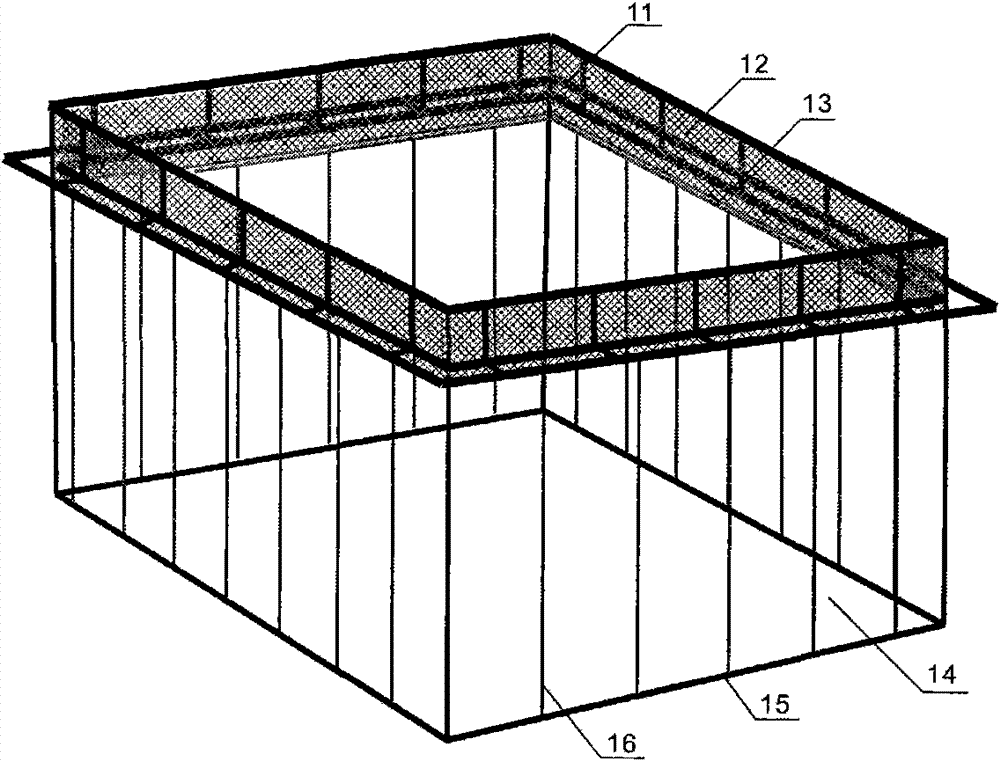

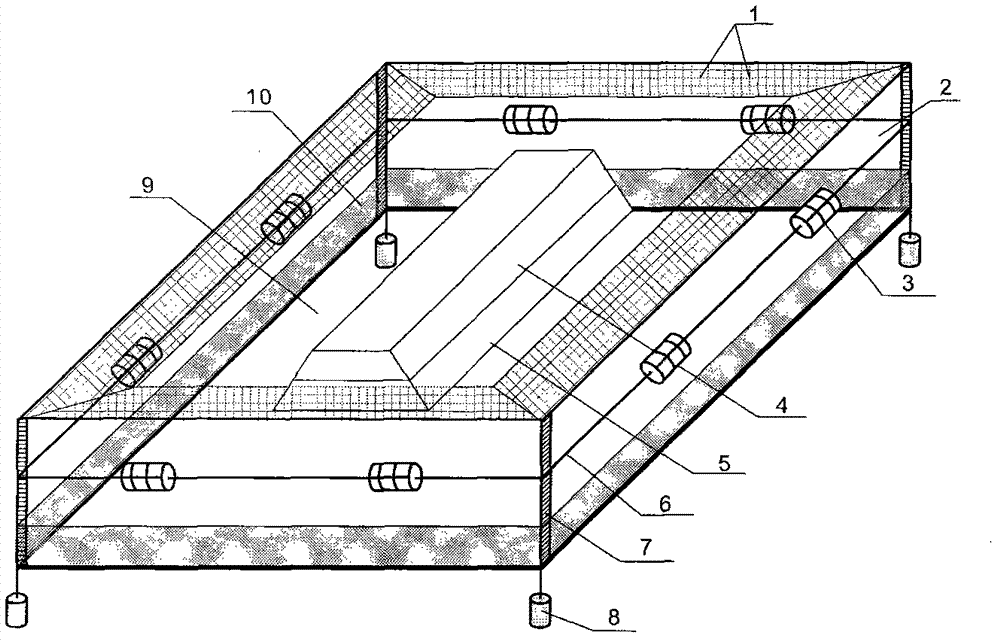

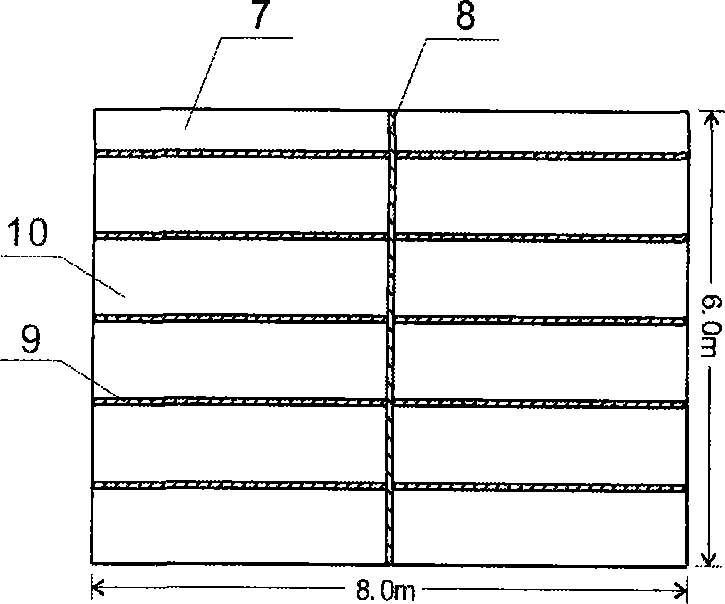

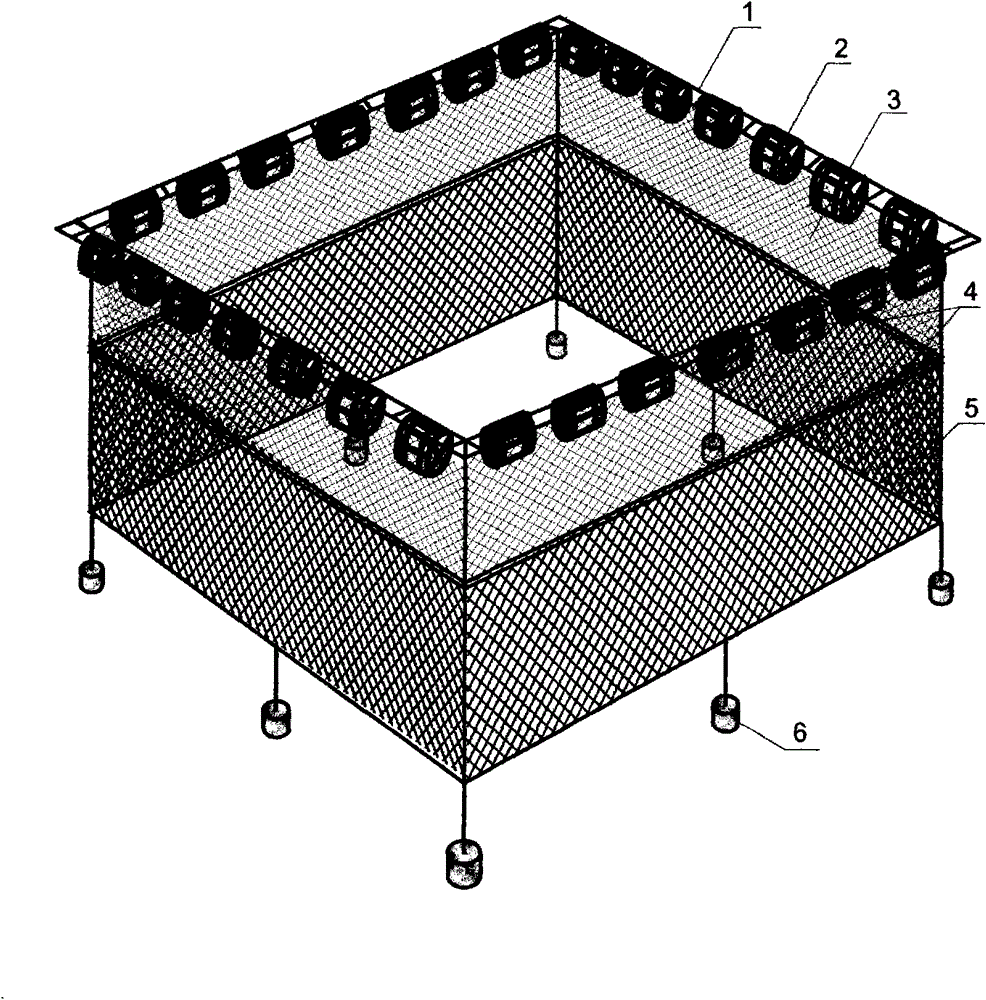

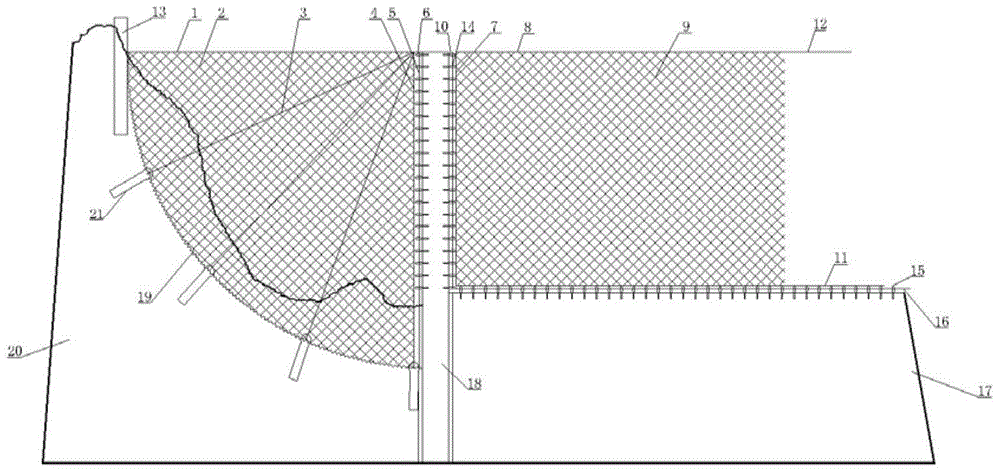

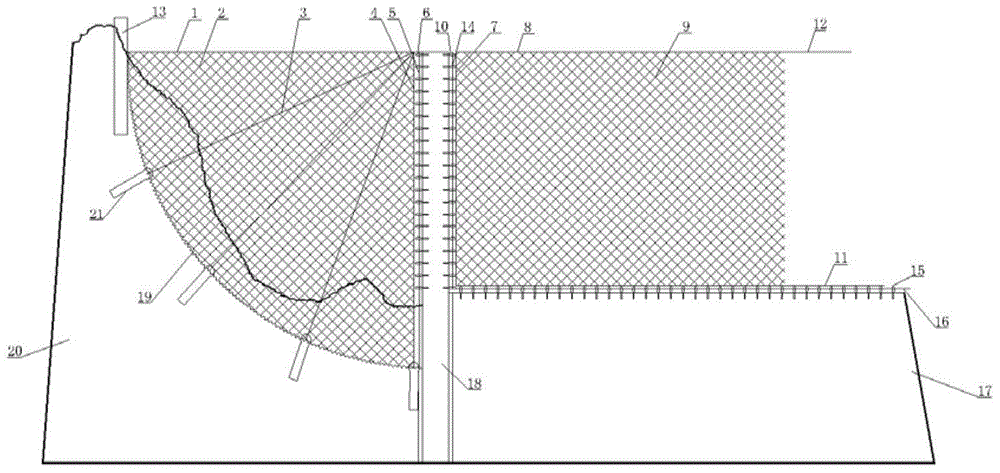

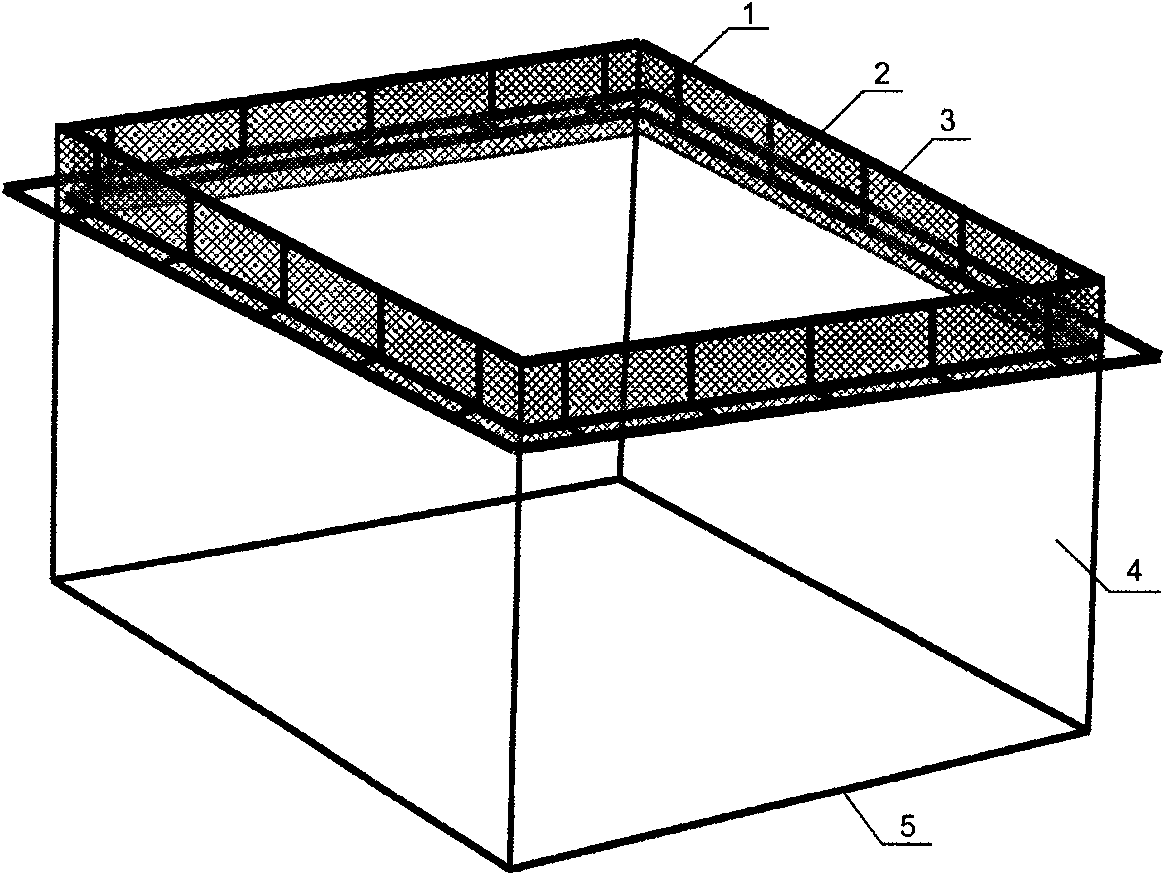

Combined box body system used for floating net cage and mated frame system thereof

ActiveCN102239814AImprove the box volume retention rateImprove antifouling functionClimate change adaptationPisciculture and aquariaPolyamideEngineering

The invention provides a combined box body system used for a floating net cage and a mated frame system thereof, relating to a seawater cultivation floating net cage. A copper alloy inclined square mesh, a copper alloy weaving mesh, high-strength polyamide warp knitting fishnet, ropes, a galvanized iron pipe and foam buoys. The combined box body system is characterized in that a floating net cageframe system comprises two rows of square galvanized iron pipe frames; the foam buoys are distributed below the two rows of galvanized iron pipe frames; the fishnet system of a net cage body combinesa first high-strength polyamide warp knitting fishnet, a second copper alloy inclined square mesh and the copper alloy weaving mesh used for the bottom of the net cage'; the edge installing wire ropeof the fishnet at the bottom of the net cage is assembled on a square high-strength polyamide pipe frame; the high-strength polyamide pipe frame and a horizontal wire rope at the lower edge of the second copper alloy inclined square mesh are connected by an ultrahigh-strength rope; and a vertical force net is installed in the vertical direction of the fishnet and extends to the edge wire rope of the copper alloy weaving mesh used for the bottom of the net cage.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Method for manufacturing antifouling and antibiosis type yellow croaker net cage

InactiveCN102763610AReduce harmImprove survival rateClimate change adaptationPisciculture and aquariaAntibiosisEngineering

The invention discloses a method for manufacturing an antifouling and antibiosis type yellow croaker net cage, which relates to a method for manufacturing a mariculture net cage. According to the invention, the method for manufacturing the antifouling and antibiosis type yellow croaker net cage adopts a buoyancy force system and a netting system, and is characterized in that the buoyancy force system adopts a combination buoyancy force form of 'an anti-aging high-density polyethylene double-floating-pipe cylindrical frame structure + 18 cube cystosepiments with each edge length of 60cm; the netting system adopts a combination structure netting form of 'a first box longitudinal netting + a second box longitudinal netting + a net cage bottom netting; the net cage bottom netting is assembledon a circular high-density polyethylene pipe support which is wrapped with a layer of polyamide multifilament wrap knitting net; and three cross lacing lines are installed at the bottom of the net cage, a polypropylene rope is tied at the cross point of the cross lacing lines, and two foam float bowls which are externally wrapped by double-layer seawater corrosion protection canva and nylon nets are tied at the other end of the polypropylene rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

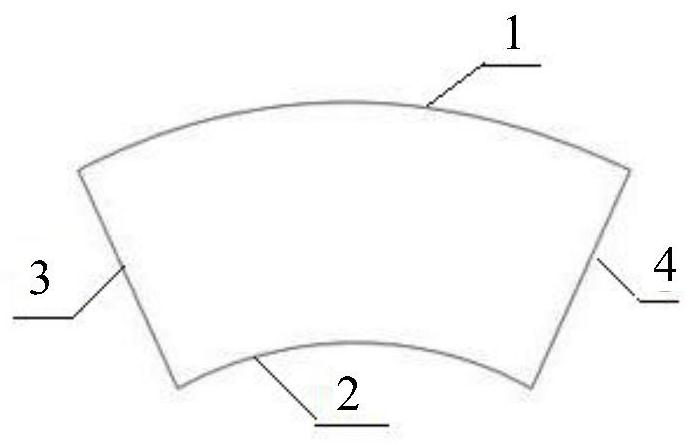

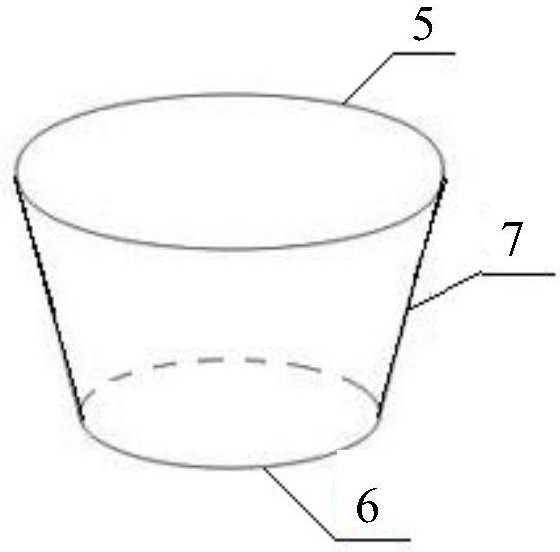

Preparation method of circular truncated cone-shaped side net for semi-submersible aquaculture platform

ActiveCN111642437AUnobstructed exchangeQuality is safe and reliableElectroconductive/antistatic filament manufactureSpinnerette packsNanoparticlePolyethylene glycol

The invention provides a preparation method of a circular truncated cone-shaped side net for a semi-submersible aquaculture platform. The preparation method comprises anti-fouling monofilament bundlepreparation, anti-fouling net sheet preparation, and circular truncated cone-shaped side net preparation. Preparation raw materials comprise PP resin, dioctyl phthalate, polyethylene glycol fatty acidester, cetyl phosphate, a grafted polyguanidine salt / polyethylene granular material, and surface modified copper-nickel alloy nanoparticles. When the anti-fouling net sheet is prepared, first the antifouling monofilament bundle is twisted to obtain an antifouling strand with the Z twist direction, then three antifouling strands with the Z twist direction are processed into an antifouling twistedthread with the S twist direction, then the antifouling twisted thread with the S twist direction is processed into a net sheet with double dead knots, and finally the net sheet is subjected to heat-setting with 0.22 times the longitudinal breaking strength of the net sheet as a pre-tension. When the circular truncated cone-shaped side net is prepared, knotting is performed in a circulation mannerof "single dead knot-single dead knot-double dead knot-double dead knot", then a net sheet is subjected to fan ring-shaped cutting, edge line and net line assembly, and edge strengthening, then mother lines at the left and right side of a fan ring-shaped net sheet are butted and stitched, and double dead knots are knotted at the same distance when butting and stitching are performed.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

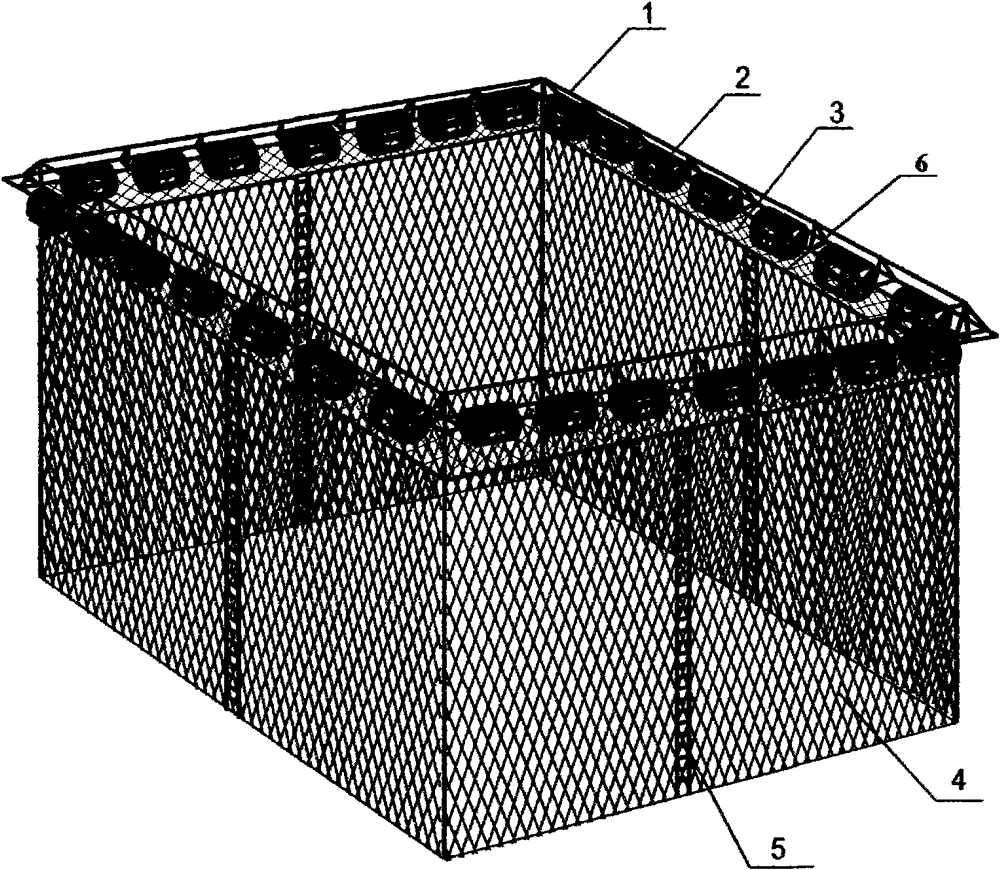

Stain-repellent stretch net cage for farming large yellow croaker

InactiveCN102763611AReduce harmImprove survival rateClimate change adaptationPisciculture and aquariaMaricultureCompound structure

A stain-repellent stretch net cage for farming large yellow croaker relates to a cage for mariculture of the large yellow croaker. The stain-repellent stretch net cage for farming large yellow croaker is provided with a floating system and a net system and is characterized in that the floating system is in a rectangular frame structure with double floating pipes, the net system is in a combined structure of a longitudinal cage upper end net, a longitudinal cage lower end net and a cage bottom net; the cage bottom net is fitted on a frame wrapped with a synthetic fiber mesh, and the frame is connected with lower edge horizontal ropes of the longitudinal cage lower end net; after the longitudinal cage lower end net is connected with the cage bottom net, vertical man ropes longitudinally disposed along the longitudinal cage upper end net from upper horizontal ropes of the longitudinal cage upper end net extends to edge ropes of the cage bottom net; crossing man ropes are added to the bottom of the cage, crossing man ropes are added along diagonals of the bottom of the cage, a high-strength polypropylene rope is tied to an intersection of the two crossing man ropes arranged along the diagonals of the bottom of the cage, and a cylindrical foam float is tied to the other end of the high-strength polypropylene rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Processing method for antifouling melt spinning for far-reaching-sea net cage or floating-rope surrounding net

ActiveCN106192030AImprove liquidityImprove spinnabilityMelt spinning methodsMonocomponent polyolefin artificial filamentTurpentineHydroxystearic Acid

The invention discloses a processing method for antifouling melt spinning for a far-reaching-sea net cage or a floating-rope surrounding net. The processing method is characterized by including the steps that UHMWPE powder, nanometer Cu powder, HDPE powder, silicone powder, antioxidant B225, assistant antioxidant DLTP, hydroxy stearic acid, nanoscale white carbon black, nanoscale kieselguhr, nanoscale aedelforsite, ethylene-vinyl acetate copolymer and turpentine assistant are weighed in the formula, then premixed to be poured into a high-speed kneading pot and subjected to high-speed kneading, and a blending-modification UHMWPE material is obtained; the blending-modification UHMWPE material is belted and extruded through a double-screw extruder, the extruded substance is metered through a metering pump additionally arranged through a double-screw outlet and belted and extruded through a spinneret hole, the extruded primary raw silk is cooled and pre-drafted, the pre-drafted silk is subjected to heat setting, then tows are winded through a silk winding machine of a torque motor, and are subjected to silk dividing through a silk dividing machine, and the antifouling melt spinning for the far-reaching-sea net cage or the floating-rope surrounding net is obtained.

Owner:威海市宏威塑料有限公司

Antifouling and anti-biting cultivation net cage of huangsha (Chinese character) turtle

InactiveCN102763622AEnsure safetyWith anti-fouling functionAnimal husbandryIsosceles trapezoidChinese characters

The invention discloses an antifouling and anti-biting cultivation cage of a huangsha (Chinese character) turtle. The antifouling and anti-biting cultivation net cage comprises a cage body top part, cage sides and a cage bottom. The antifouling and anti-biting cultivation cage is characterized in that the top part of the cage body adopts an anti-biting small-screen ultra-high molecular weight polyethylene net to be sutured into an annular net; the cage side adopts a combined net formed by a copper alloy woven mesh, a netting half-soft state connection, the copper alloy woven mesh, the nettinghalf-soft state connection, the copper alloy woven mesh, the netting half-soft state connection, the copper alloy woven mesh, the netting half-soft state connection and a nylon mesh; a foam floater is arranged on an upper middle line of the copper alloy woven mesh as a buoyancy system; the cage bottom adopts the combined netting of a nylon woven mesh and the copper alloy woven mesh; a cylindricalheavy block is respectively suspended at four corners of the box body for the cage; a back sunning table is arranged inside the cage; the cross section of the back sunning table is an isosceles trapezoid; the distance from an upper bottom to a lower bottom of the isosceles trapezoid is 30cm; and the part of the back sunning table, in the water, is 16-20cm in vertical height, and the cage is fastened on a fixed parking system of an aquaculture area by a connection rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Functional aquaculture net cage for yellow pond turtle

InactiveCN102763621AImprove antifouling functionEnsuring natural habitat and living habitsAnimal husbandryTerrapinMauremys mutica

A functional aquaculture net cage for yellow pond turtle comprises a cage top, a cage side and a cage bottom and is characterized in that the cage top is a circular net sewn with bite-proof small-meshed superhigh molecular weight polyethylene nets, the cage side which is circular is formed by sequentially connecting copper alloy woven meshes in a semi-flexible manner, foam floats disposed on middle ropes of the copper alloy woven meshes forming a ring form a floating system, the cage bottom in a two-layer structure is formed by binding a plastic board and a copper alloy woven mesh, upper ropes of the cage side nets are sewn to an outer circular rope of the cage top net, lower ropes of the cage side nets are sewn to the edge of the cage bottom, four sinkers are hung at four corners of a cage body respectively, a floating rest plate is disposed in the cage, the cross section of the floating rest plate is in the shape of an equilateral trapezium, an upper line of the equilateral trapezium is 30cm away from a lower line, submerged part of the floating rest plate is 5cm-8cm in height, and the middle ropes of the cage are connected with a floating rope frame of a cage mooring system in an aquaculture water through mooring ropes.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Processing method of nanometer copper and nickel synergetic antifouling wires containing grafted polyguanidine salt

ActiveCN111926407AImprove antifouling functionImprove nodule strengthArtificial filament heat treatmentMelt spinning methodsNanoparticleNano copper

The invention provides a processing method of nanometer copper and nickel synergetic antifouling wires containing grafted polyguanidine salt. The method includes the three processes of raw materials compounding, melt-spinning, and stretching and heat forming. With HDPE particles, grafted polyguanidine salt / polyethylene particles and surface modified copper nickel alloy nanoparticles as a main rawmaterial, firstly, a composite material with the synergetic antifouling effect is obtained, and then the synergetic antifouling wires are obtained after a wire drawing technology. The synergetic antifouling wires carry out targeting synergetic antifouling treatment on algae, barnacle and other fouling organisms in the practical breeding production, the fouling organisms are prevented from attaching to the surface of culture and proliferation facility net clothing, the comprehensive and effective synergetic antifouling action can be achieved, the results of sea tests show that the attachment ofthe fouling organisms of the culture and proliferation facility net clothing made of the antifouling wires can be lowered by more than 20%, and the synergetic antifouling effect is very significant.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

A high-strength and high-memory composite polyurethane board with antifouling function and its preparation method

ActiveCN107524131BWith anti-fouling functionHigh strengthArtificial islandsUnderwater structuresFiberVulcanization

A high-strength and high-memory composite polyurethane board with antifouling function and its preparation method. The raw materials of the board include organic silicon, polyurethane resin modified by organic fluorine, wear-resistant materials, reinforcing materials, colorants, light stabilizers, Antioxidant, coupling agent and dispersant are produced through kneading, degassing, molding, vulcanization, aging, and heat sealing process with fiber cloth; the invention has excellent stretch resistance, puncture resistance, weather resistance and wear resistance , corrosion resistance and low surface energy, can effectively prevent biofouling and occasions where antifouling coatings cannot be applied, and is suitable for heavy-attachment areas of marine structures in marine structures; it can be used in conjunction with petrolatum anti-corrosion products to achieve heavy-duty anti-corrosion and anti-fouling Pollution dual function; or add to the outer layer of the existing PTC and other coating anti-corrosion systems, increase the anti-fouling function of PTC and other technologies, broaden the application field of PTC and other coating anti-corrosion technologies, suitable for building materials for manufacturing offshore platforms, and can solve the problem of rivers and rivers Anti-corrosion and anti-fouling and high-strength technical problems for buildings and ship structures in lakes and seas.

Owner:深圳安盾海洋新材料有限公司

Method for manufacturing antifouling and antibiosis type yellow croaker net cage

InactiveCN102763610BReduce harmImprove survival rateClimate change adaptationPisciculture and aquariaAntibiosisEngineering

The invention discloses a method for manufacturing an antifouling and antibiosis type yellow croaker net cage, which relates to a method for manufacturing a mariculture net cage. According to the invention, the method for manufacturing the antifouling and antibiosis type yellow croaker net cage adopts a buoyancy force system and a netting system, and is characterized in that the buoyancy force system adopts a combination buoyancy force form of 'an anti-aging high-density polyethylene double-floating-pipe cylindrical frame structure + 18 cube cystosepiments with each edge length of 60cm; the netting system adopts a combination structure netting form of 'a first box longitudinal netting + a second box longitudinal netting + a net cage bottom netting; the net cage bottom netting is assembledon a circular high-density polyethylene pipe support which is wrapped with a layer of polyamide multifilament wrap knitting net; and three cross lacing lines are installed at the bottom of the net cage, a polypropylene rope is tied at the cross point of the cross lacing lines, and two foam float bowls which are externally wrapped by double-layer seawater corrosion protection canva and nylon nets are tied at the other end of the polypropylene rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Stain-repellent stretch net cage for farming large yellow croaker

InactiveCN102763611BReduce harmImprove farming efficiencyClimate change adaptationPisciculture and aquariaMaricultureCompound structure

A stain-repellent stretch net cage for farming large yellow croaker relates to a cage for mariculture of the large yellow croaker. The stain-repellent stretch net cage for farming large yellow croaker is provided with a floating system and a net system and is characterized in that the floating system is in a rectangular frame structure with double floating pipes, the net system is in a combined structure of a longitudinal cage upper end net, a longitudinal cage lower end net and a cage bottom net; the cage bottom net is fitted on a frame wrapped with a synthetic fiber mesh, and the frame is connected with lower edge horizontal ropes of the longitudinal cage lower end net; after the longitudinal cage lower end net is connected with the cage bottom net, vertical man ropes longitudinally disposed along the longitudinal cage upper end net from upper horizontal ropes of the longitudinal cage upper end net extends to edge ropes of the cage bottom net; crossing man ropes are added to the bottom of the cage, crossing man ropes are added along diagonals of the bottom of the cage, a high-strength polypropylene rope is tied to an intersection of the two crossing man ropes arranged along the diagonals of the bottom of the cage, and a cylindrical foam float is tied to the other end of the high-strength polypropylene rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

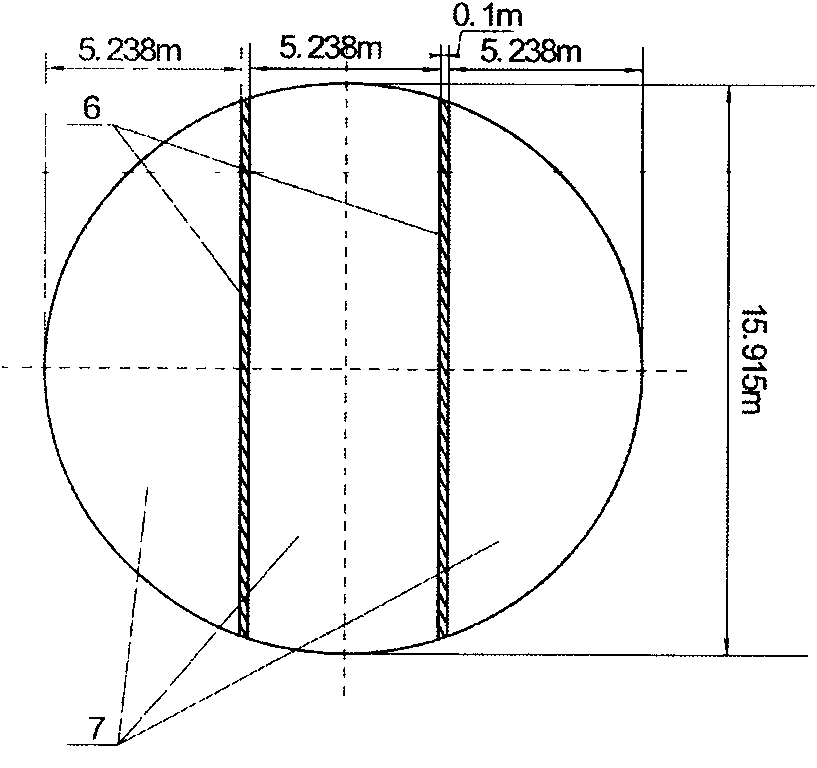

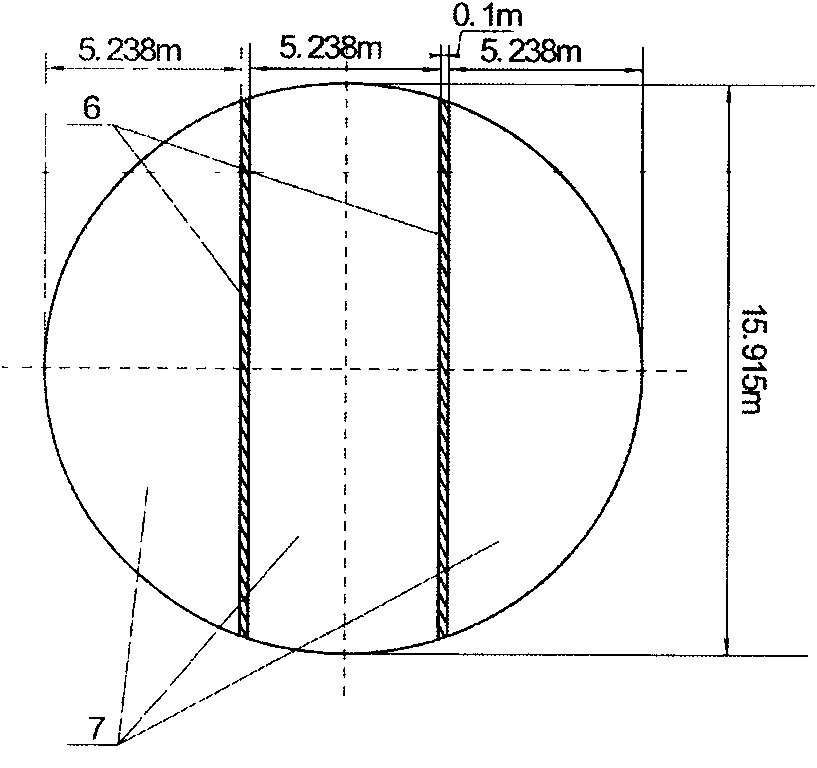

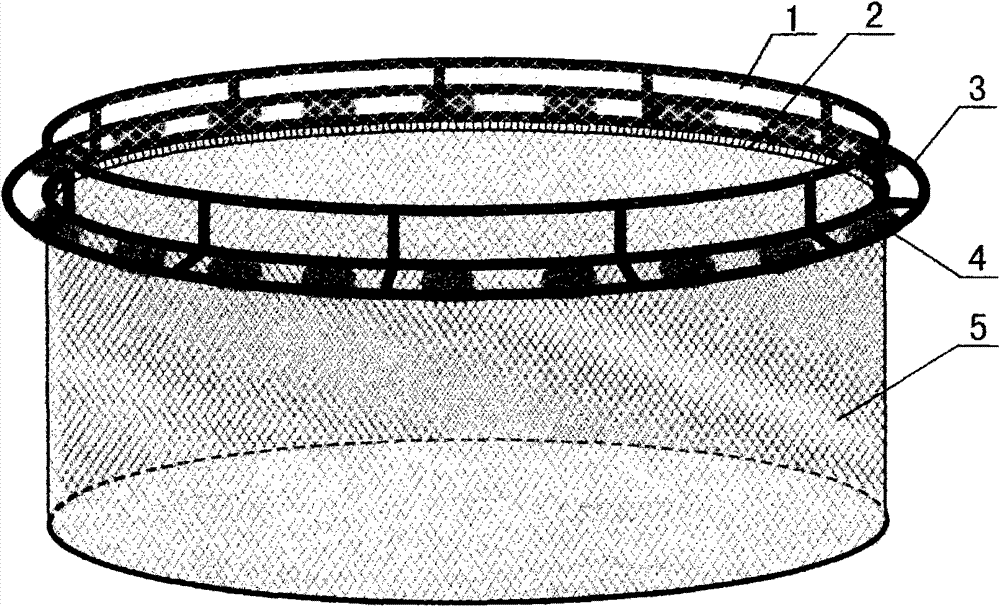

Cylindrical copper-alloy netting net cage for aquaculture

InactiveCN102239816BExtended service lifeImprove the box volume retention rateClimate change adaptationPisciculture and aquariaMooring systemPolyamide

The invention relates to a cylindrical copper-alloy netting net cage for aquaculture. The cylindrical copper-alloy netting net box adopts a high-strength single-dead-knot polyethylene-fiber net, a high-strength polyamide warp knitting net and a copper-alloy rhombic net and is characterized in that a buoyancy system of the net cage is in a combined structure of black high-density polyethylene double floating pipes and cylindrical floaters; a netting system for the net cage consists of a double-layer synthetic-fiber netting as a netting I, a copper-alloy rhombic net as a netting II and a high-strength polyamide warp knitting net as a combined netting for the bottom of a net cage body; the netting I and the netting II of the net cage body are flexibly connected by a longitudinal netting; side bolsh lines and lacing lines are assembled on the netting for the bottom of the net cage body, and horizontal lines and vertical lacing lines are arranged on the netting on the side surface of the net cage body; the combined netting for the net cage body is hung on an armrests and a floating pipe inner frame of a net cage frame; an outer frame of the floating pipe frame is connected with a floating rope frame of a fixed mooring system by mooring ropes, and the fixed mooring system of the net cage is used for fixing the floating rope frame in the sea areas for aquaculture by anchors, wood piles, anchor ropes, floating balls and floating ball connecting ropes.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

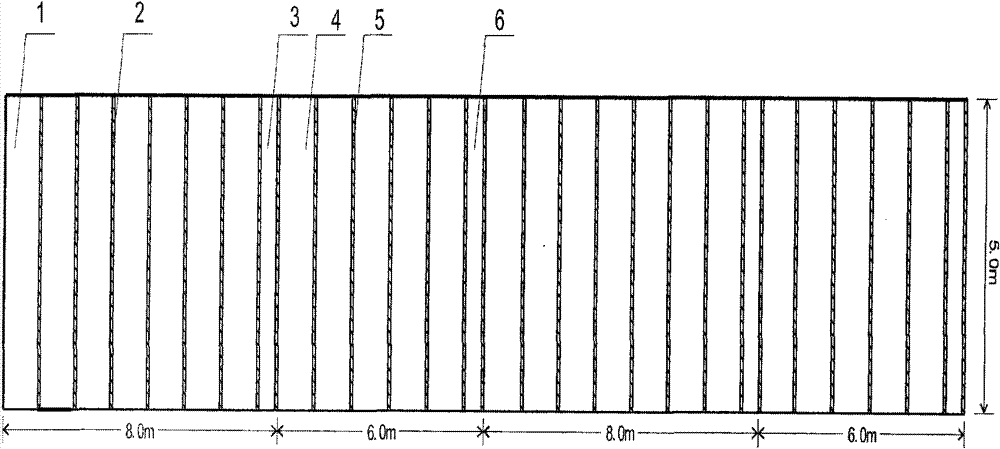

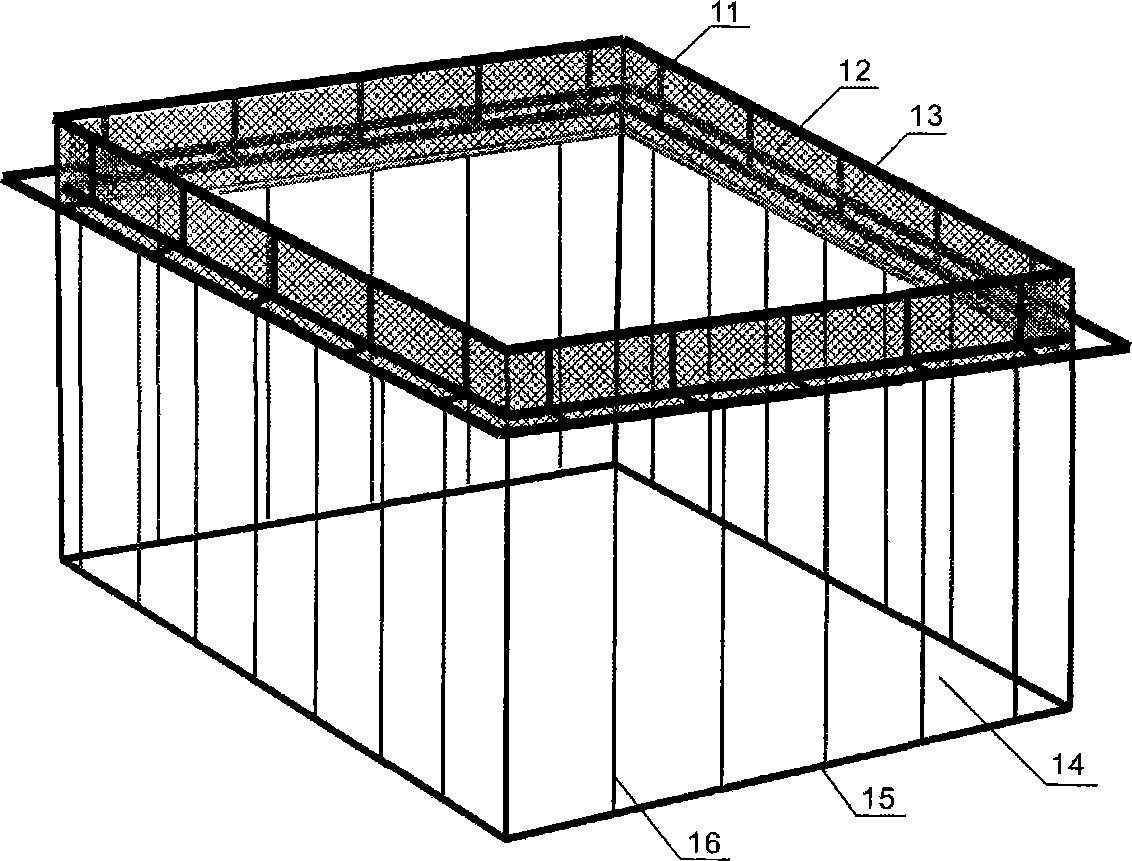

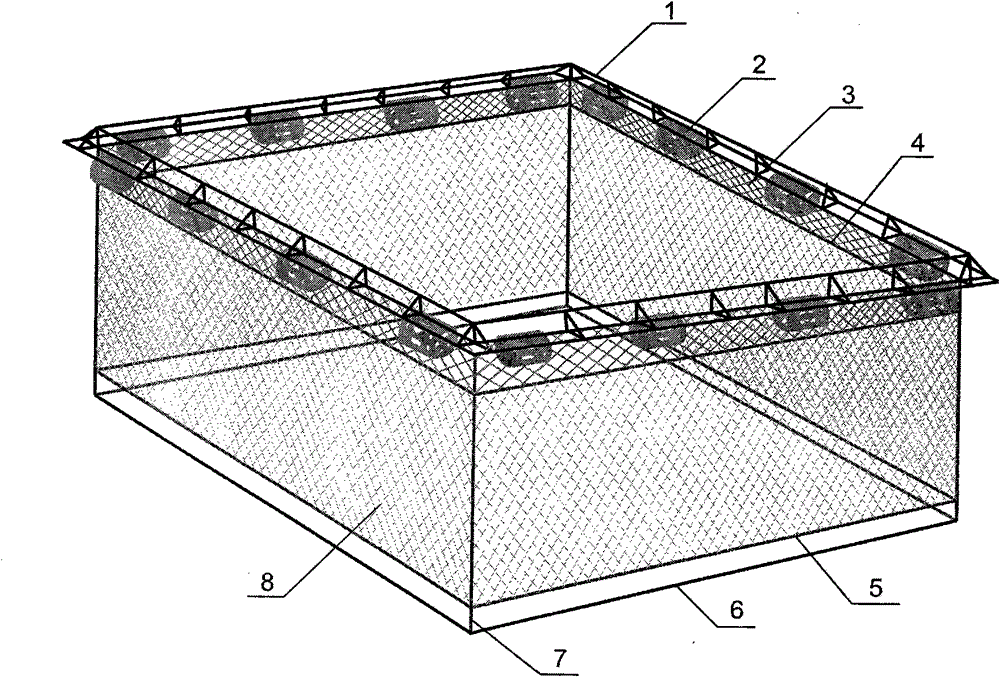

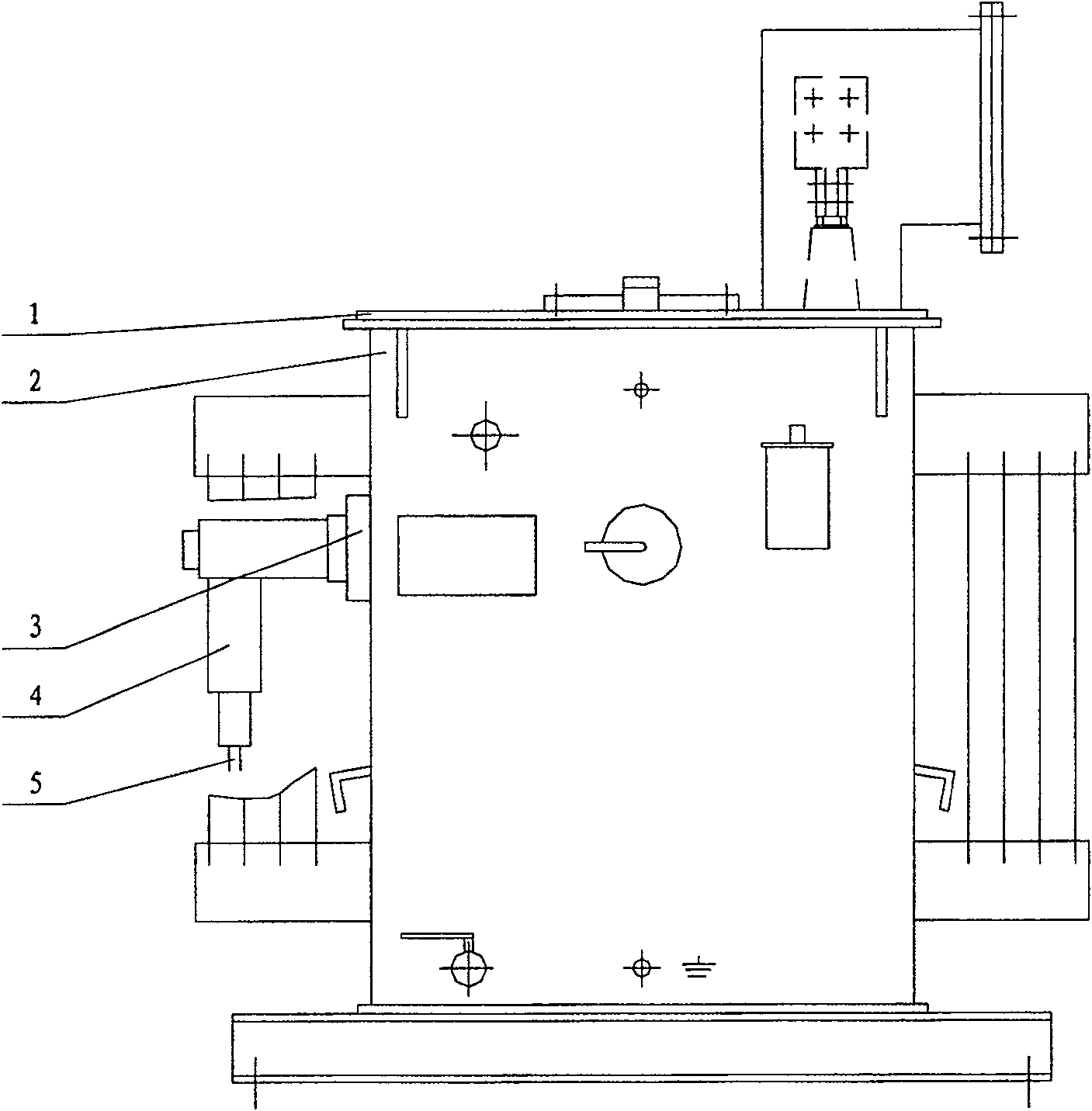

Turbot cultivation net cage having anti-pollution function

InactiveCN102308763BSolve the rustExtended service lifeClimate change adaptationPisciculture and aquariaPollutionMaterials science

The invention discloses a turbot cultivation net cage having an anti-pollution function, and relates to a turbot cultivation net cage. The turbot cultivation net cage uses a hot-dip galvanized iron pipe, a cylindrical plastic foam floating ball, a high-strength single fast knot polyethylene net, a high-strength nylon warp knitting net, an anti-pollution copper alloy rhombus net, a high-strength fishing polyethylene rope, an ultrahigh-strength rope and high-strength fishing lines and is characterized in that: a net cage floating support is welded into a top frame and a bottom frame by using the hot-dip galvanized iron pipe; the cylinder plastic foam floating ball under the lower surface of the bottom frame of the floating support is coated with waterproof cloth and a small-mesh waste netting; a netting system for the net cage consists of a double-layer synthetic fiber netting serving as a first netting and the anti-pollution copper alloy rhombus net serving as a second netting; the first netting and the second netting are connected in a vertical half-soft mode; the net bottom of the net cage is hung with a square galvanized iron pipe framework with edges of 5.0 meters; and the net cage floating support is connected with a floating rope frame through a cable and tied on a berth fixing system.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Preparation method of rectangular separation net for deep and far sea culture

ActiveCN114775162AImprove antifouling functionNot easy to failTextile selvedgesClimate change adaptationPhosphoric Acid EstersPropanoic acid

The invention provides a preparation method of a rectangular separation net for deep and far sea culture, which comprises the following steps: preparing a blended antifouling composite material, preparing a light blue monofilament bundle, preparing a rectangular separation net, and mixing polypropylene granules, a polyhexamethylene guanidine hydrochloride grafted modified polypropylene antifouling material, nano copper powder, pyrithione copper powder, tetra [beta-(3, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4- 2, 5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, tri (1, 2, 2, 6, 6-pentamethylpiperidinyl) phosphite, phthalocyanine blue pigment, titanium dioxide and turpentine are mixed and uniformly stirred, extrusion granulation is performed 2-3 times through a double-screw extruder to obtain a blended antifouling composite material, light blue monofilament tows are obtained after wire drawing and rolling, and the light blue monofilament tows are used as raw materials. And obtaining the rectangular separation net for deep and far sea culture by using a special rectangular separation net preparation method.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Preparation method of isosceles right triangle deep sea aquaculture protection net

ActiveCN114775075AFast assemblyImprove assembly efficiencyClimate change adaptationHeating/cooling textile fabricsPropanoic acidPolyhexamethylene guanidine

The invention provides a preparation method of an isosceles right triangle deep sea aquaculture protection net. The preparation method comprises the four steps of granule mixing, preparation of wires for a protection net, preparation of net pieces and preparation of the protection net. A phthalocyanine green G pigment, an anti-ultraviolet agent UV-327, a polyhexamethylene guanidine grafted modified polypropylene material, tetrakis [beta-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, a fluorescent yellow pigment, white oil and polypropylene granules are used as raw materials, wire drawing is performed after uniform mixing and stirring, bright yellow wires for the protective net are obtained, then wire making is performed, a net piece is woven, and the protective net is prepared. And a protective net is further prepared to finally form the protective net for deep and far sea culture. According to the technical scheme, the strength, protection, pollution prevention, storm resistance, bite resistance and impact resistance of the product are improved, the color warning function is achieved, and consumption reduction and resistance reduction of deep and far sea culture production, healthy growth of cultured fishes and green development of the deep and far sea culture industry are promoted.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Combined box body system used for floating net cage and mated frame system thereof

ActiveCN102239814BImprove the box volume retention rateImprove antifouling functionClimate change adaptationPisciculture and aquariaPolyamideBuoy

The invention provides a combined box body system used for a floating net cage and a mated frame system thereof, relating to a seawater cultivation floating net cage. A copper alloy inclined square mesh, a copper alloy weaving mesh, high-strength polyamide warp knitting fishnet, ropes, a galvanized iron pipe and foam buoys. The combined box body system is characterized in that a floating net cageframe system comprises two rows of square galvanized iron pipe frames; the foam buoys are distributed below the two rows of galvanized iron pipe frames; the fishnet system of a net cage body combinesa first high-strength polyamide warp knitting fishnet, a second copper alloy inclined square mesh and the copper alloy weaving mesh used for the bottom of the net cage'; the edge installing wire ropeof the fishnet at the bottom of the net cage is assembled on a square high-strength polyamide pipe frame; the high-strength polyamide pipe frame and a horizontal wire rope at the lower edge of the second copper alloy inclined square mesh are connected by an ultrahigh-strength rope; and a vertical force net is installed in the vertical direction of the fishnet and extends to the edge wire rope of the copper alloy weaving mesh used for the bottom of the net cage.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

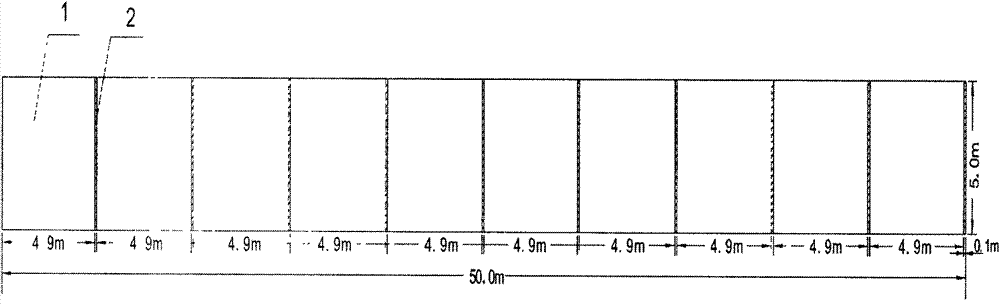

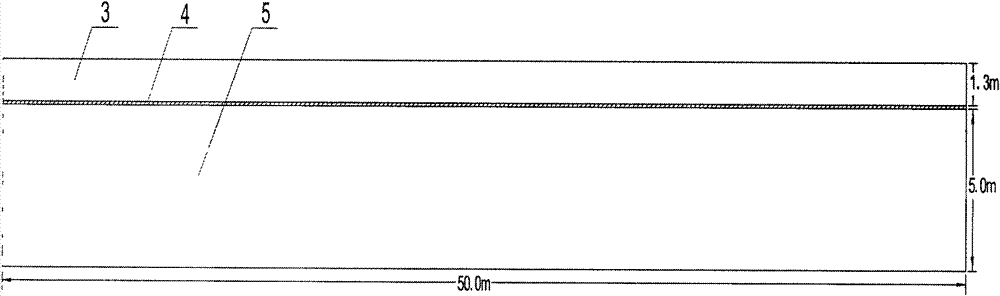

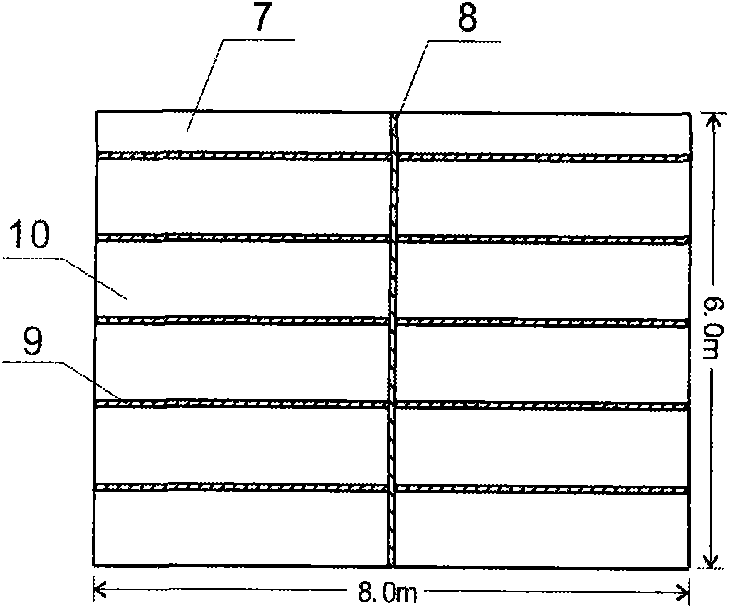

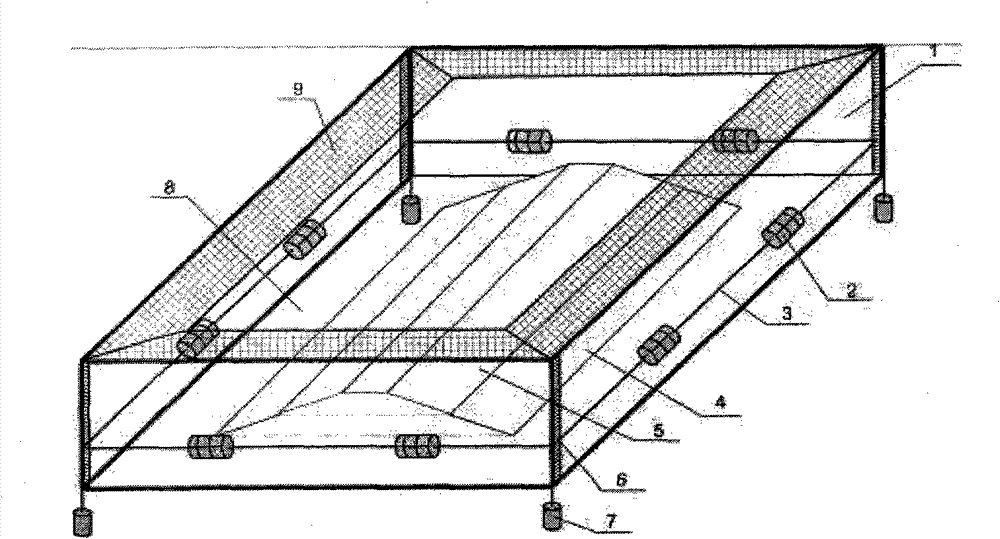

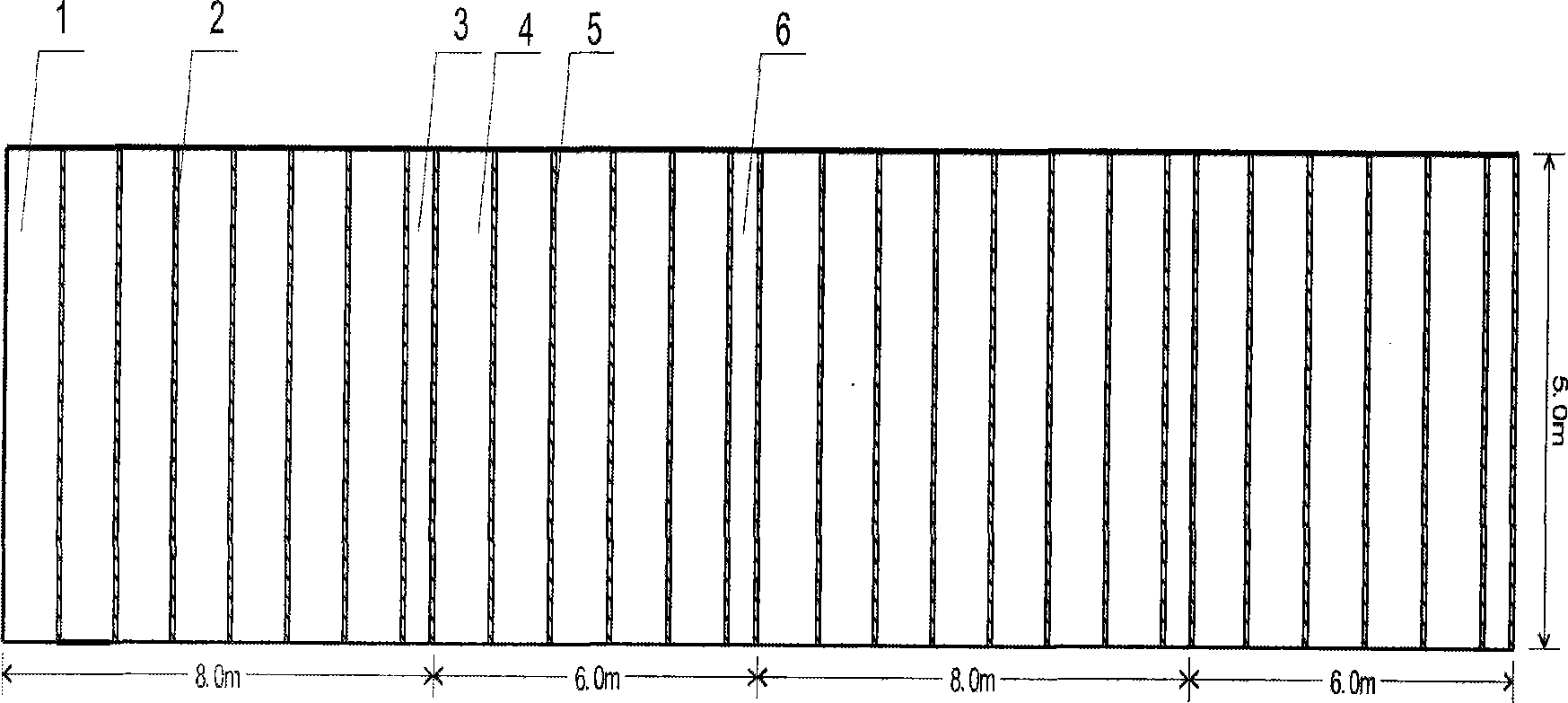

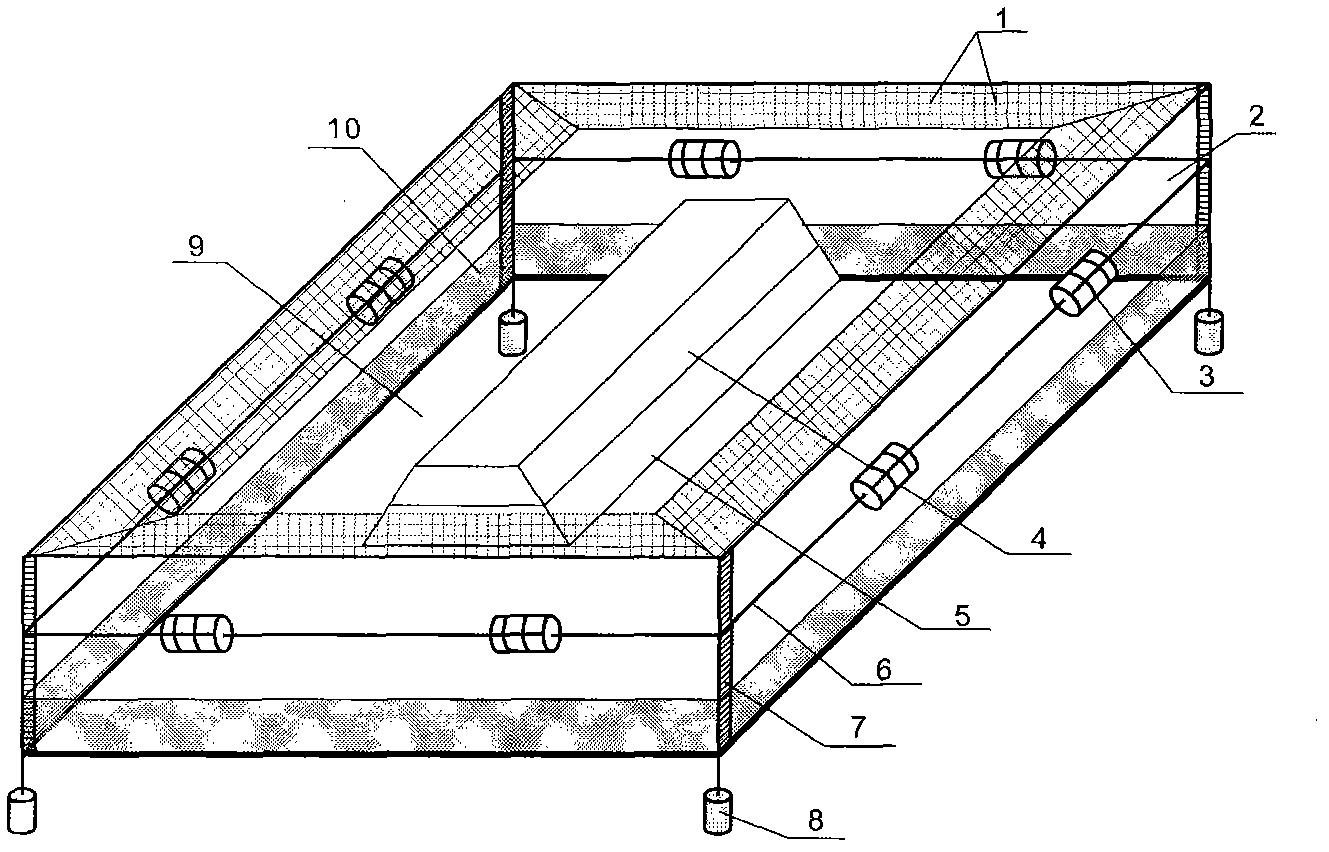

Method for processing net-combined-type neritic square net cage

InactiveCN102239815BSolve the problem of energy saving and consumption reductionReduce energy saving and consumption reductionClimate change adaptationPisciculture and aquariaHigh densityMarine engineering

The invention discloses a method for processing net-combined-type neritic sea square net cages, relates to an aquaculture net cage, and provides a method for processing neritic square net cages. In the invention, a high-strength rope, a high-strength nylon warp knitting net and a copper alloy inclined square net are adopted. The method provided by the invention is characterized in that a double floating tube square frame structure is adopted in a buoyancy system of the net cage; 28 cylindrical foam floaters with the same specification are arranged under the two rows of floating tube frames; the net system of the net cage combines a first high-strength nylon warp knitting net, a second copper alloy inclined square net and a high-strength nylon warp knitting net used for the bottom of the net cage; after being equipped with ropes, the net at the bottom of the net cage is assembled on a high-density polyethylene frame; a vertical force net is longitudinally arranged along the net from the upper horizontal rope of the first high-strength nylon ware knitting net to the bottom of the net cage; 8 sinking blocks are hung on the high-density polyethylene frame used for the bottom of the net bottom evenly, and the weight of each sinking block is 5kg. The method provided by the invention is suitable to be applied to neritic square net cages.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Processing method of antifouling melt-spinning for net cage or floating rope seine in deep sea

ActiveCN106192030BImprove liquidityImprove spinnabilityMelt spinning methodsMonocomponent polyolefin artificial filamentTurpentineHydroxystearic Acid

The invention discloses a processing method for antifouling melt spinning for a far-reaching-sea net cage or a floating-rope surrounding net. The processing method is characterized by including the steps that UHMWPE powder, nanometer Cu powder, HDPE powder, silicone powder, antioxidant B225, assistant antioxidant DLTP, hydroxy stearic acid, nanoscale white carbon black, nanoscale kieselguhr, nanoscale aedelforsite, ethylene-vinyl acetate copolymer and turpentine assistant are weighed in the formula, then premixed to be poured into a high-speed kneading pot and subjected to high-speed kneading, and a blending-modification UHMWPE material is obtained; the blending-modification UHMWPE material is belted and extruded through a double-screw extruder, the extruded substance is metered through a metering pump additionally arranged through a double-screw outlet and belted and extruded through a spinneret hole, the extruded primary raw silk is cooled and pre-drafted, the pre-drafted silk is subjected to heat setting, then tows are winded through a silk winding machine of a torque motor, and are subjected to silk dividing through a silk dividing machine, and the antifouling melt spinning for the far-reaching-sea net cage or the floating-rope surrounding net is obtained.

Owner:威海市宏威塑料有限公司

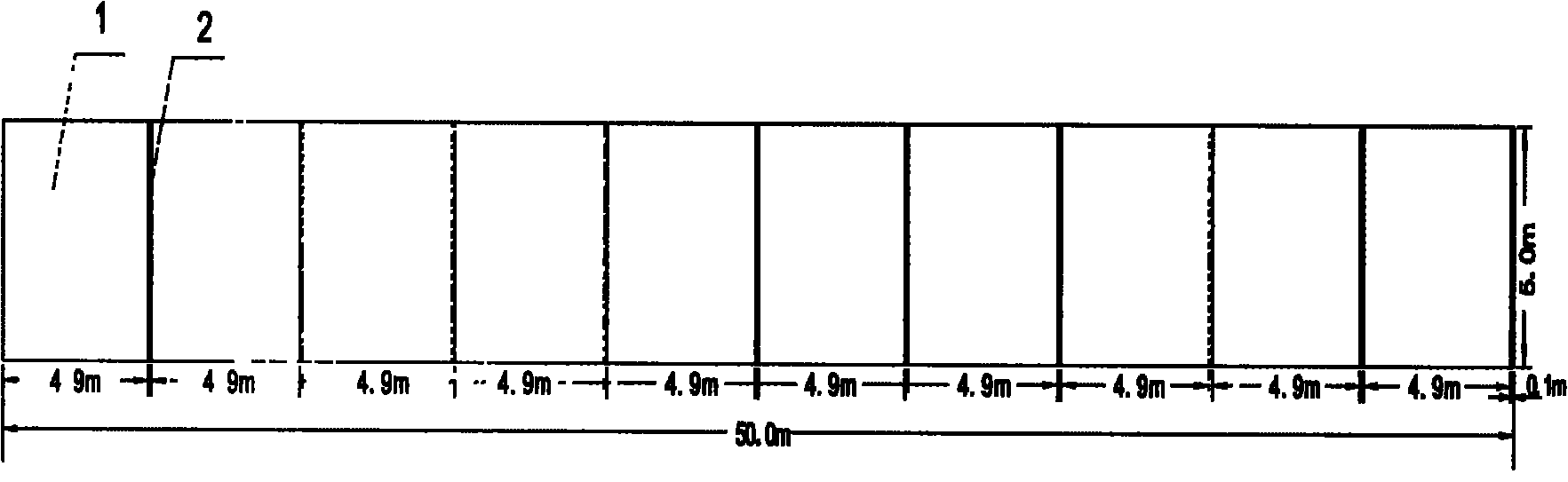

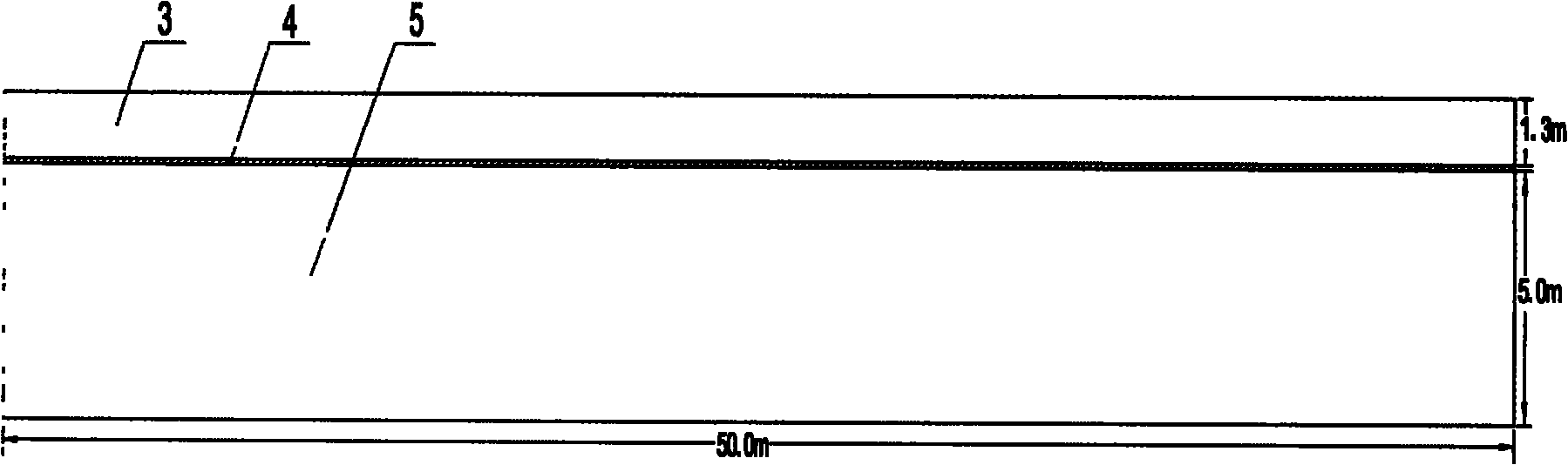

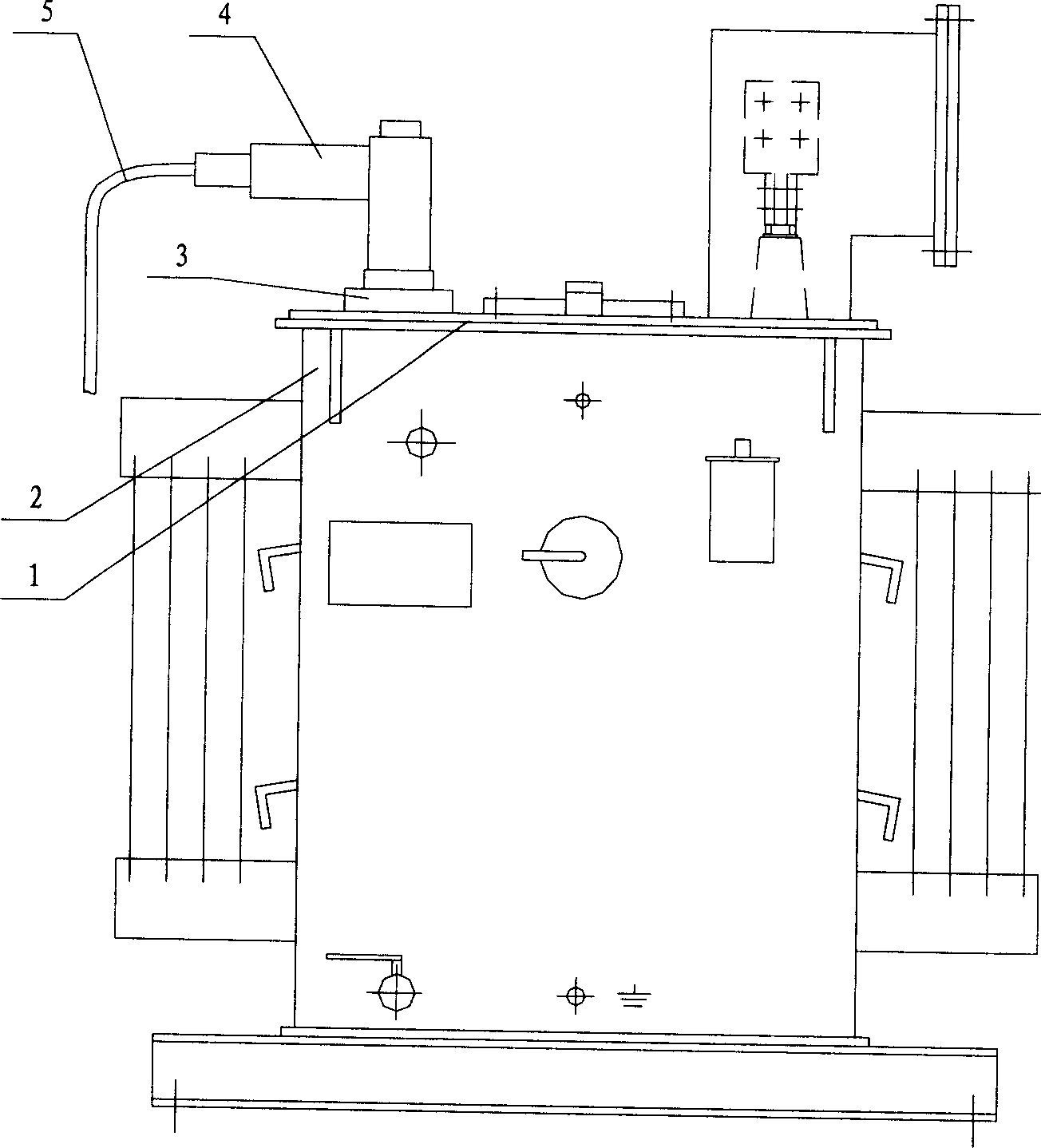

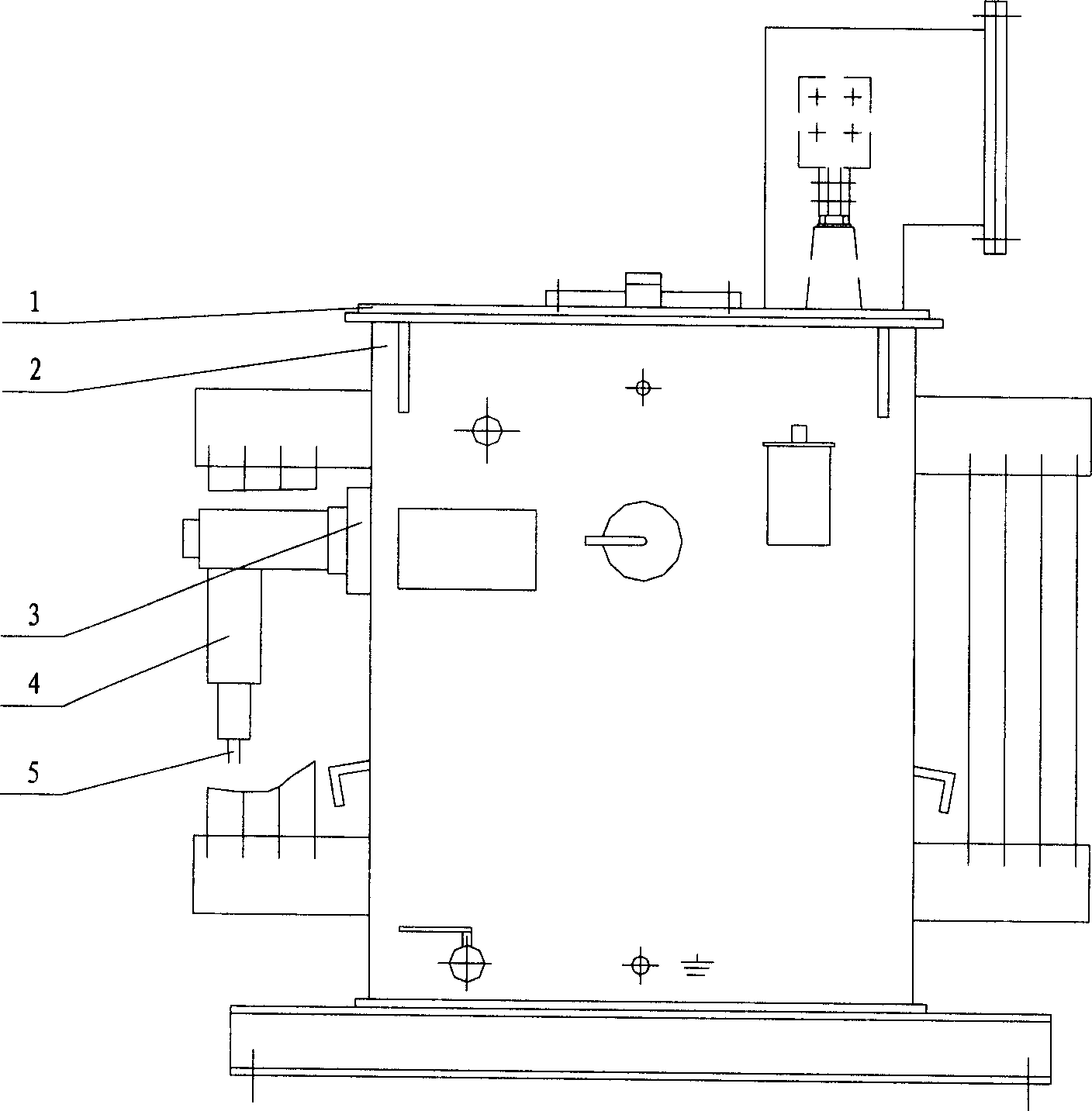

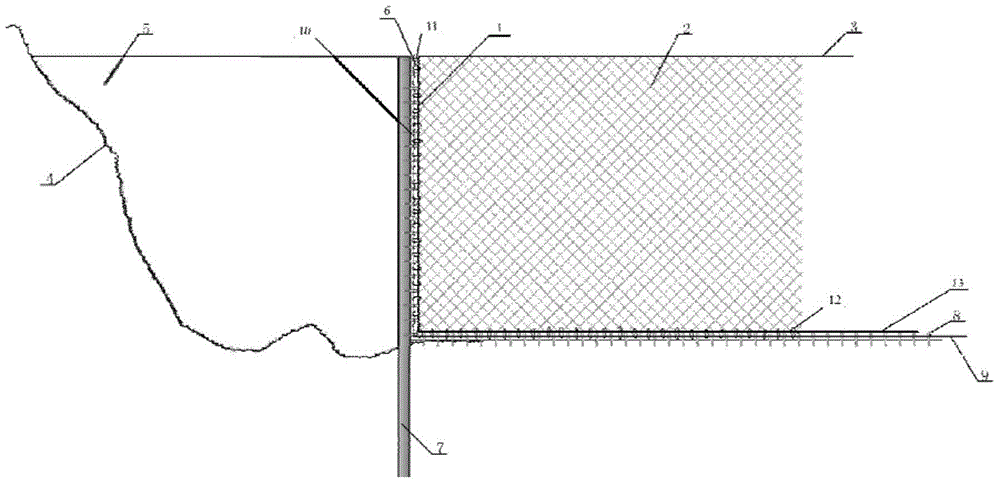

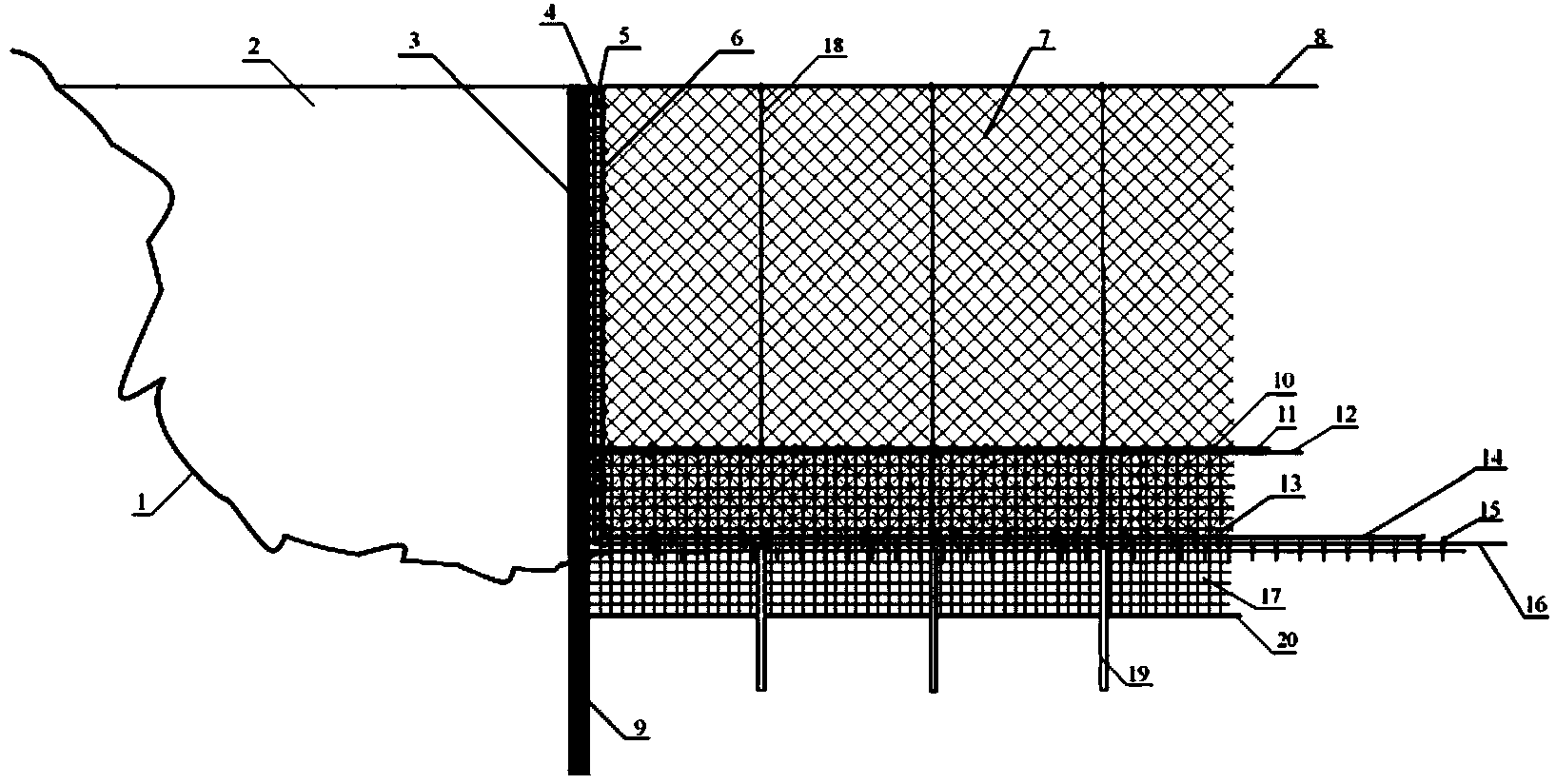

Soft connecting method for coasts and large-scale aquaculture netting

ActiveCN103598128AImprove securityExtended service lifeClimate change adaptationSeaming textilesReinforced concreteEngineering

The invention relates to a soft connecting method for coasts and large-scale aquaculture netting. The method is characterized by including: the antifouling ultra-high molecular weight polyethylene netting is made through warp knitting; a reinforced concrete pile is disposed on each of the left coast and the right coast; a standing reinforced concrete pile is disposed at the joint of each coast and the netting, and a vertical lacing line for hanging the netting is disposed on each standing reinforced concrete pile; one end of each of a left coast soft connecting netting horizontal lacing line and a right coast soft connecting netting horizontal lacing line is connected with the corresponding reinforced concrete pile, the other end each of a left coast soft connecting netting horizontal lacing line and a right coast soft connecting netting horizontal lacing line is fixedly tied to the corresponding standing reinforced concrete pile, and each of a left coast soft connecting netting vertical lacing line and a right coast soft connecting netting vertical lacing line is fixedly tied to the corresponding vertical lacing line, for hanging the netting, of the corresponding standing reinforced concrete pile; the left coast soft connecting netting and the right coast soft connecting netting are connected between the reinforced concrete piles; a reinforced concrete weir is poured between the standing reinforced concrete piles, and net hanging horizontal lacing lines are disposed on the surface of the weir; the edge lacing lines of the netting are fixedly tied to the vertical lacing lines, for hanging the netting, of the standing reinforced concrete piles, the lower lacing lines of the netting are fixedly tied to the net hanging horizontal lacing lines, and the floater lacing lines of the netting are fixedly tied to the standing reinforced concrete piles.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

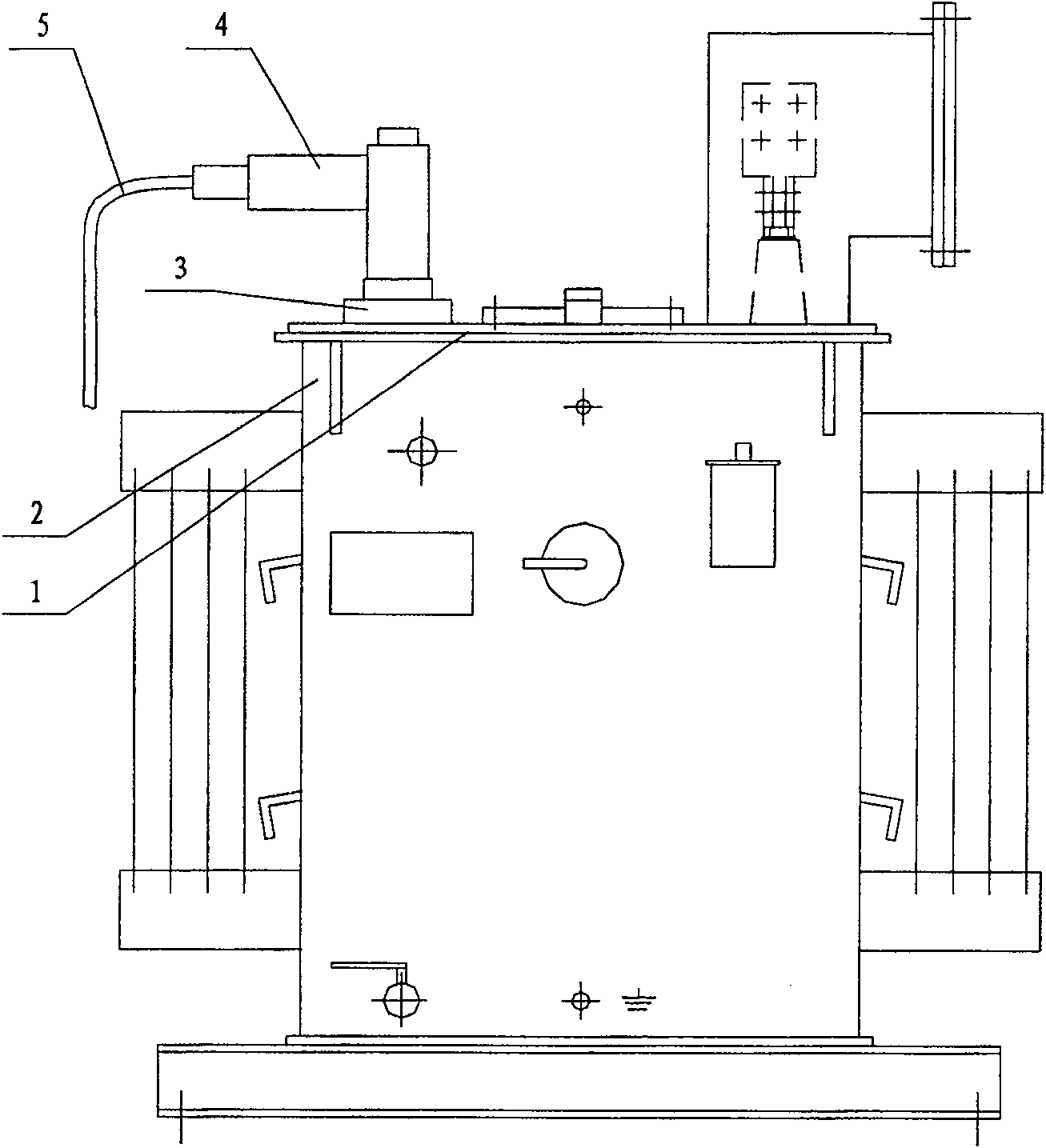

Coil out structure in high voltage in oil immersed type distribution transformer

ActiveCN1797620AImprove antifouling functionReduce distanceTransformers/inductances coils/windings/connectionsEngineeringType distribution

The structure includes tank cap, oil tank, and high voltage cable, sleeve socket of high voltage, and tail current conducting piece of elbow shaped cable head for connecting high voltage cable. Cold pressure welding can be connected in the connection modes. Replacing sleeve of porcelain vase in prior art, cooperation between the sleeve socket of high voltage and the elbow shaped cable head makes transformers have no exposed electrified body at high voltage side so as to prevent accident caused by that small creature climbs to high voltage connection terminal. The elbow shaped cable head and sleeve socket of high voltage are made from macromolecule insulating material, which possesses certain toughness so as to ensure safety performance in procedures of transportation and operation. Furthermore, distances among sleeve sockets of high voltage in three are reduced.

Owner:SHANGHAI ZHIXIN INTELLIGENT ELECTRIC CO LTD

Soft connecting method for coasts and large-scale aquaculture netting

ActiveCN103598128BImprove securityExtended service lifeClimate change adaptationSeaming textilesReinforced concreteRebar

The invention relates to a soft connecting method for coasts and large-scale aquaculture netting. The method is characterized by including: the antifouling ultra-high molecular weight polyethylene netting is made through warp knitting; a reinforced concrete pile is disposed on each of the left coast and the right coast; a standing reinforced concrete pile is disposed at the joint of each coast and the netting, and a vertical lacing line for hanging the netting is disposed on each standing reinforced concrete pile; one end of each of a left coast soft connecting netting horizontal lacing line and a right coast soft connecting netting horizontal lacing line is connected with the corresponding reinforced concrete pile, the other end each of a left coast soft connecting netting horizontal lacing line and a right coast soft connecting netting horizontal lacing line is fixedly tied to the corresponding standing reinforced concrete pile, and each of a left coast soft connecting netting vertical lacing line and a right coast soft connecting netting vertical lacing line is fixedly tied to the corresponding vertical lacing line, for hanging the netting, of the corresponding standing reinforced concrete pile; the left coast soft connecting netting and the right coast soft connecting netting are connected between the reinforced concrete piles; a reinforced concrete weir is poured between the standing reinforced concrete piles, and net hanging horizontal lacing lines are disposed on the surface of the weir; the edge lacing lines of the netting are fixedly tied to the vertical lacing lines, for hanging the netting, of the standing reinforced concrete piles, the lower lacing lines of the netting are fixedly tied to the net hanging horizontal lacing lines, and the floater lacing lines of the netting are fixedly tied to the standing reinforced concrete piles.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Energy-conservation and consumption-reduction type obliquely-square net cage for cultivating large yellow croakers

InactiveCN102763612BImprove volume retentionReduce the strength of impacting the cage bodyClimate change adaptationPisciculture and aquariaMaricultureEngineering

The invention discloses an energy-conservation and consumption-reduction type obliquely-square net cage for cultivating large yellow croakers, which is used for mariculture. The technical scheme provided by the invention is that the energy-conservation and consumption-reduction type obliquely-square net cage consists of a buoyancy force system and a netting system, and has the characteristics that the buoyancy force system consists of an inside casing and an outside casing, and the inside casing is connected with a first net cage body longitudinal netting through an ultra high strength dyneema rope; the netting system adopts a combination structure netting form of 'a first box longitudinal netting + a second box longitudinal netting + a net cage bottom netting'; the net cage bottom netting is assembled on a pipe support; micropores are punched in a pipe of the pipe support every 1 meter; after being connected with the net cage bottom netting, the second net cage body longitudinal netting extends to an edge line of the net cage bottom netting along netting longitudinally-installed vertical lines from an upper horizontal line of the box longitudinal first netting; a cross lacing line is additionally arranged at the bottom of the net cage, crossed lacing lines are additionally arranged along the diagonal directions of the bottom of the net cage; and a cross point of the two crossed lacing lines along the diagonal directions of the bottom of the net cage is tied by a rope, and a foam float bowl which is externally wrapped by seawater corrosion protection canva and a nylon net is tied by the other end of the rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

A processing method for synergistic antifouling silk containing grafted polyguanidine salt nano-copper nickel

ActiveCN111926407BImprove antifouling functionImprove nodule strengthArtificial filament heat treatmentMelt spinning methodsEngineeringBiological adhesion

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Connection method for seashore and netting gear net

ActiveCN103609494BExtended service lifeImprove equipment levelClimate change adaptationPisciculture and aquariaHorizontal forceReinforced concrete

The invention discloses a connection method for seashore and a netting gear net. According to the connection method, the netting gear net and reinforced concrete stand columns are used, wherein a cork line, a lower line, a left margin line and a right margin line are mounted on the netting gear net. The connection method is characterized in that a net hanging vertical force line is mounted on each reinforced concrete stand column; the vertical force lines are located on the side far away from the seashore; reinforced concrete dikes are formed by pouring reinforced concrete between the seashore and the reinforced concrete stand columns so that the seashore, the reinforced concrete dikes and the reinforced concrete stand columns can form a closely-connected whole; reinforced concrete horizontal net mounting surfaces are formed in a pouring mode between the reinforced concrete dikes, wherein the reinforced concrete horizontal net mounting surfaces are 4.5m away from the water surface; an ultra-high molecular weight polyethylene stranded rope is mounted on each reinforced concrete horizontal net mounting surface to serve as a net hanging horizontal force line; the margin lines of the netting gear net are fixedly connected with the net hanging vertical force lines on the reinforced concrete stand columns in a binding mod; the lower line of the netting gear net is fixedly connected with the net hanging horizontal force lines in a binding mode; the end portion of the cork line of the netting gear net is fixedly connected with the reinforced concrete stand columns in a binding mode.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

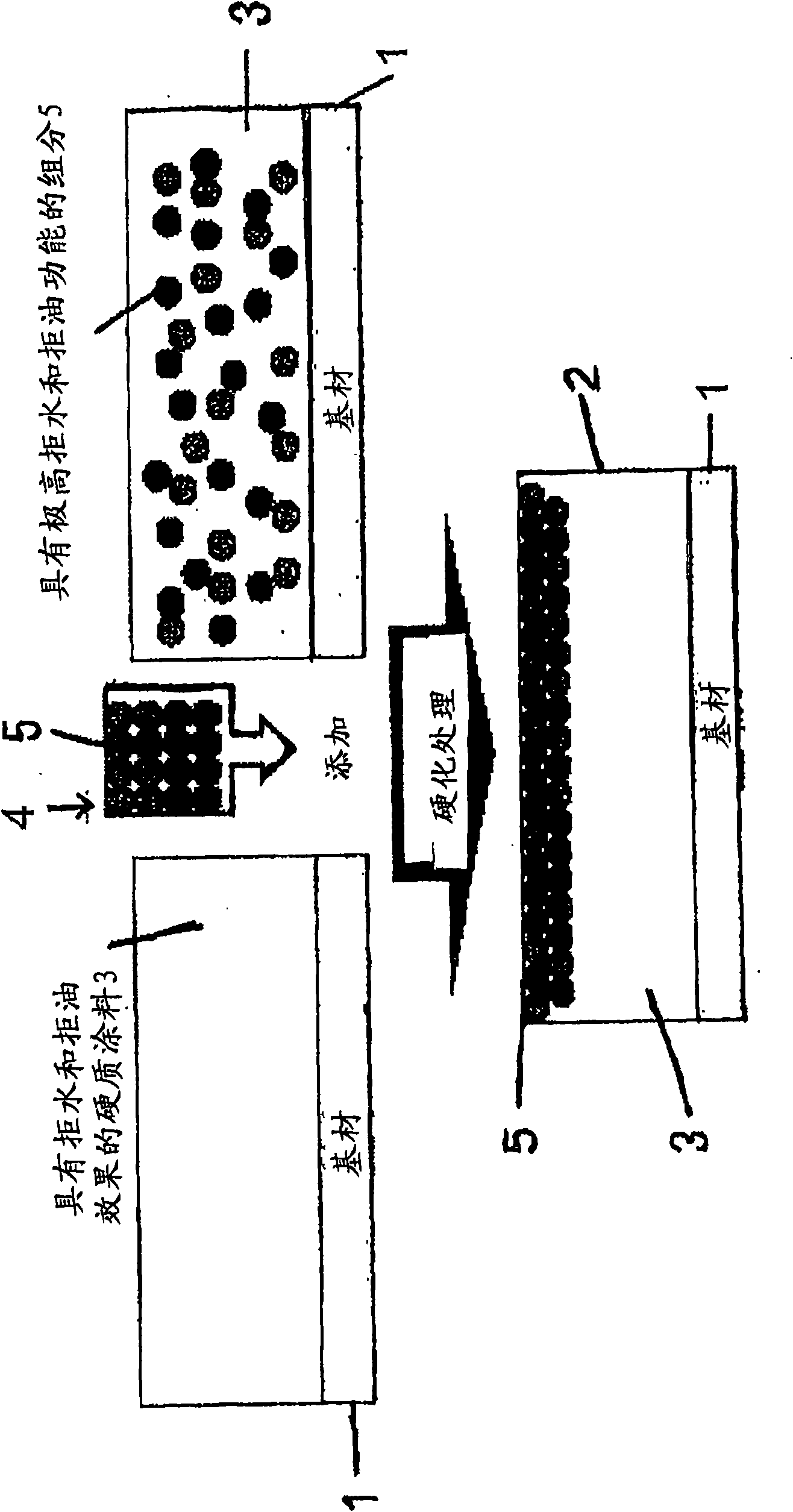

Coating liquid capable of reducing fingerprint adhesion, manufacturing method thereof, and products coated with the coating liquid

InactiveCN101550293AKeep the glossAdhesion barrierAntifouling/underwater paintsPaints with biocidesNitrogenOrganonitrogen compounds

The invention provides a coating liquid capable of reducing fingerprint adhesion and manufacturing method thereof, based on solution total amount by solid content, the organic compound containing ketone group and the organic nitrogen compound are mixed according to 10-40%. 0.1%-20.0% of antifoulant additive is added into the mixture liquid based on the amount of the solid content of the mixture liquid.

Owner:KK TOPCON

Coil out structure in high voltage in oil immersed type distribution transformer

ActiveCN100547702CImprove antifouling functionReduce distanceTransformers/inductances coils/windings/connectionsFuel tankType distribution

A high-voltage outlet structure of an oil-immersed distribution transformer, including a tank cover, an oil tank, a high-voltage cable, a high-voltage bushing seat, and an elbow-shaped cable head plugged into the high-voltage bushing seat, wherein: the high-voltage bushing seat is sealed and installed On the tank cover or on the side wall of the fuel tank, the tail conductive part of the elbow cable head is connected to the high-voltage cable, and the connection method can be cold pressure welding. The present invention uses the high-voltage bushing seat and the elbow-shaped cable head to replace the porcelain bushing in the prior art, so that there is no exposed charged body on the high-voltage side of the transformer, and it can effectively prevent the damage caused by small animals climbing to the high-voltage terminal. The accident, improve the anti-fouling function of the transformer. At the same time, the elbow-shaped cable head and high-voltage bushing seat can be made of polymer insulating material, which has certain toughness, and is not easy to be damaged during the transportation and operation of the transformer, ensuring safety performance. In addition, after adopting the present invention, the distance between the three-phase high-voltage bushing seats can also be reduced.

Owner:SHANGHAI ZHIXIN INTELLIGENT ELECTRIC CO LTD

Method of fitting large fishing tackle net between two shores

ActiveCN103598127BReduce stressPrevent fish escape from the bottomDamsClimate change adaptationReinforced concrete columnEngineering

A method of fitting large fishing tackle net between two shores is characterized in that a reinforced concrete column is driven to 2.5m of the sea bed at an intersection of large fishing tackle net and each of left and right shores, a reinforced concrete dyke is cast between the reinforced concrete column and each of the left and right shores, a reinforced concrete horizontal net weir is cast between the two reinforced concrete dykes, a hanger horizontal lacing line is fixed on the top of the reinforced concrete horizontal net weir, a left side line of the large fishing tackle net is fixedly tied and connected to a hanger vertical lacing line on the left reinforced concrete column, a lower line of the large fishing tackle net is fixedly tied and connected to the hanger horizontal lacing line, a right side line of the large fishing tackle is fixedly tied and connected to a hanger vertical lacing line on the right reinforced concrete column, and finally, the ends of float lines of the large fishing tackle net are fixedly tied and connected to the left and right reinforced concrete columns.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Antifouling and anti-biting cultivation net cage of huangsha (Chinese character) turtle

InactiveCN102763622BEnsure safetyWith anti-fouling functionAnimal husbandryIsosceles trapezoidChinese characters

The invention discloses an antifouling and anti-biting cultivation cage of a huangsha (Chinese character) turtle. The antifouling and anti-biting cultivation net cage comprises a cage body top part, cage sides and a cage bottom. The antifouling and anti-biting cultivation cage is characterized in that the top part of the cage body adopts an anti-biting small-screen ultra-high molecular weight polyethylene net to be sutured into an annular net; the cage side adopts a combined net formed by a copper alloy woven mesh, a netting half-soft state connection, the copper alloy woven mesh, the netting half-soft state connection, the copper alloy woven mesh, the netting half-soft state connection, the copper alloy woven mesh, the netting half-soft state connection and a nylon mesh; a foam floater is arranged on an upper middle line of the copper alloy woven mesh as a buoyancy system; the cage bottom adopts the combined netting of a nylon woven mesh and the copper alloy woven mesh; a cylindrical heavy block is respectively suspended at four corners of the box body for the cage; a back sunning table is arranged inside the cage; the cross section of the back sunning table is an isosceles trapezoid; the distance from an upper bottom to a lower bottom of the isosceles trapezoid is 30cm; and the part of the back sunning table, in the water, is 16-20cm in vertical height, and the cage is fastened on a fixed parking system of an aquaculture area by a connection rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Preparation method of cylindrical hanging cage for preventing seaweed from attaching

ActiveCN111642438BIncrease exchange rateGrow fastClimate change adaptationPisciculture and aquariaPhosphoric Acid EstersSpinning

The invention provides a method for preparing an anti-seaweed adhesion cylindrical hanging cage, which includes the preparation of an outer cover net, including the preparation of an anti-seaweed adhesion composite material, the processing of an anti-seaweed adhesion tow, and the processing of an outer cover net. The spinning raw materials include grafted polymer Guanidine salt / polyethylene pellets, HDPE pellets, dioctyl phthalate, cetyl phosphate, polyethylene glycol fatty acid ester, surface-modified copper-nickel alloy nanoparticles; B, cage assembly, cutting A piece of rectangular outer cover net, and the length of setting this rectangular outer cover net increases 44cm-56cm again than the product of layer height and number of layers, and the width of rectangular outer cover net is 3.142 times of cylindrical hanging cage diameter. The anti-seaweed adhesion cylindrical hanging cage produced by the technical scheme of the present invention can not only greatly improve the anti-seaweed adhesion function of the outer cover net, but also make the water resistance and seaweed and other fouling organisms The reduction of the attachment area can greatly reduce the incidence of algae attachment to the cylindrical hanging cage and the occurrence of cage breaking accidents under severe sea conditions.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com