Turbot cultivation net cage having anti-pollution function

A cage and anti-fouling technology, applied in fish farming, application, climate change adaptation, etc., can solve the problem of low tank volume retention rate, low net clothing horizontal drift, synthetic fiber mesh clothing, energy consumption, metal mesh clothing and metal floating frame, metal mesh clothing, etc. Floating racks, affecting the growth and development of turbot and breeding benefits, restricting the popularization and use of metal mesh cages, etc., to improve the anti-fouling and anti-corrosion functions, solve the problems of anti-fouling and anti-corrosion, and reduce the harm of aquaculture fish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings:

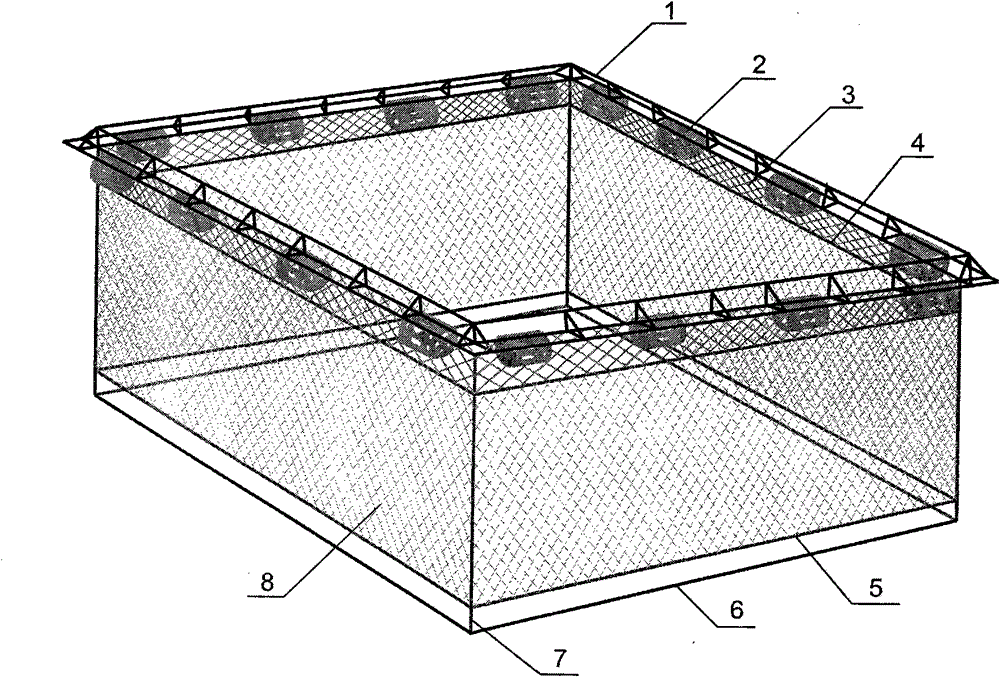

[0008]The invention adopts hot-dip galvanized iron pipe, cylindrical plastic foam floating ball, (super) high-strength single-knot polyethylene net, high-strength nylon warp-knitted net, and UR30 copper alloy orthorhombic net with antifouling function (hereinafter referred to as UR30 orthorhombic net) ), high-strength fishing polyethylene ropes, ultra-high-strength ropes and (ultra) high-strength fishing net lines, floating racks for cages (1 in the figure) each side consists of 3 parallel hot-dip galvanized iron pipes and hot-dip galvanized iron pipes connected to each other It is composed of galvanized iron pipes. The top frame at the top is welded into a circle by 4 hot-dip galvanized iron pipes with a length of 5.0m. The distance between the galvanized iron pipes is 50cm, the inner frame size of the bottom frame of the floating frame is 5.0m×5.0m, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com