Stain-repellent stretch net cage for farming large yellow croaker

A technique for stretching nets and large yellow croakers is applied in the field of cages used for cultivating large yellow croakers at sea, which can solve the problem that the utilization coefficient of bait in large yellow croaker culture cages is low, and the volume retention rate of the cages is low, which affects the growth and development and breeding benefits of large yellow croakers. , synthetic fiber mesh and rope raw materials consumption and other problems, to achieve significant economic and ecological benefits, improve bait utilization coefficient, reduce the effect of breeding large yellow croaker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

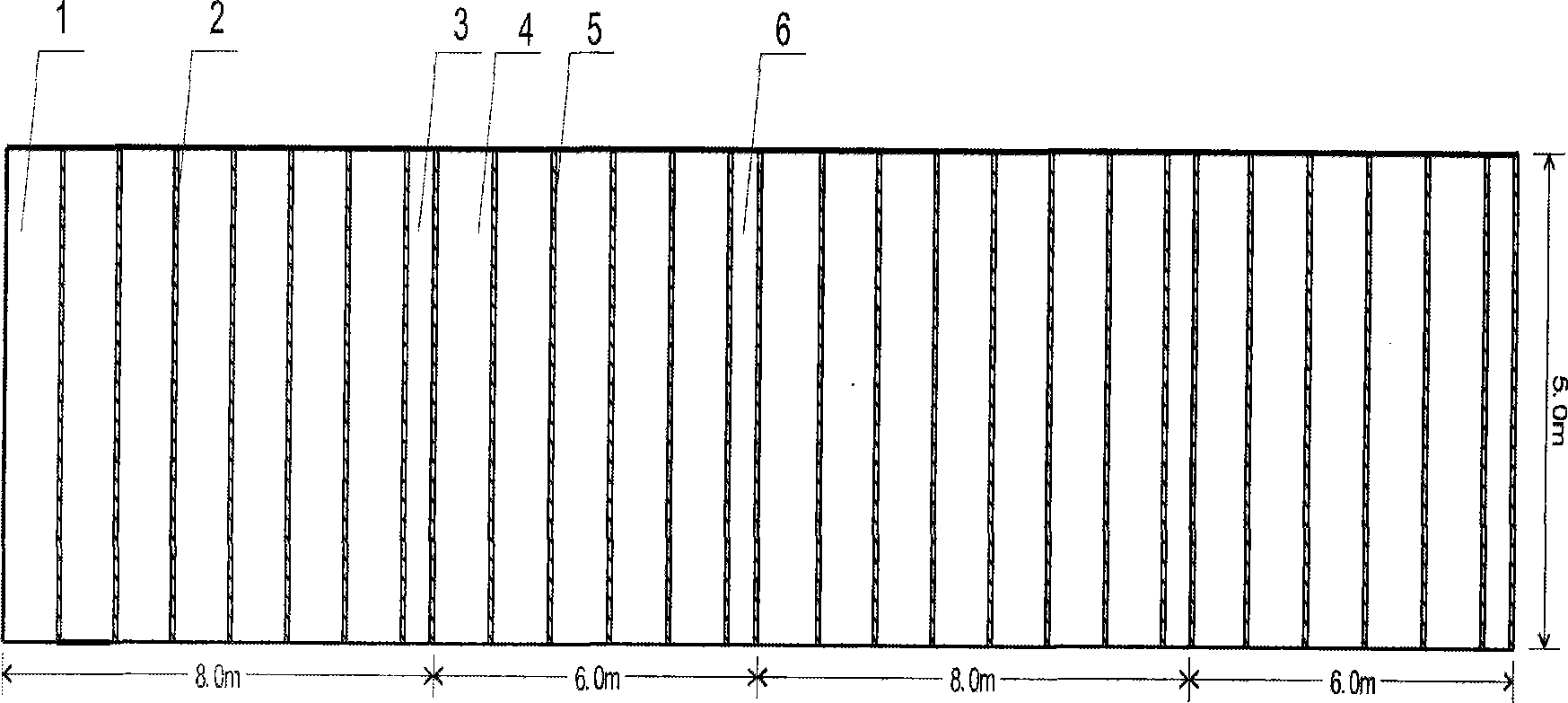

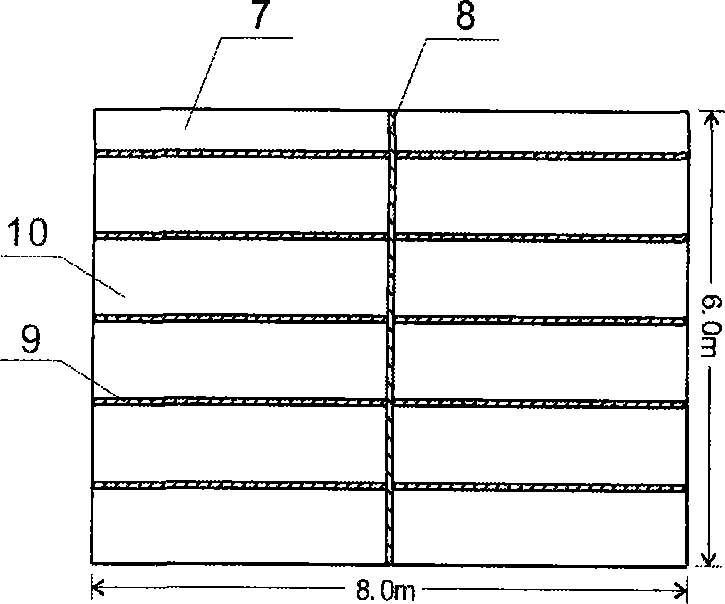

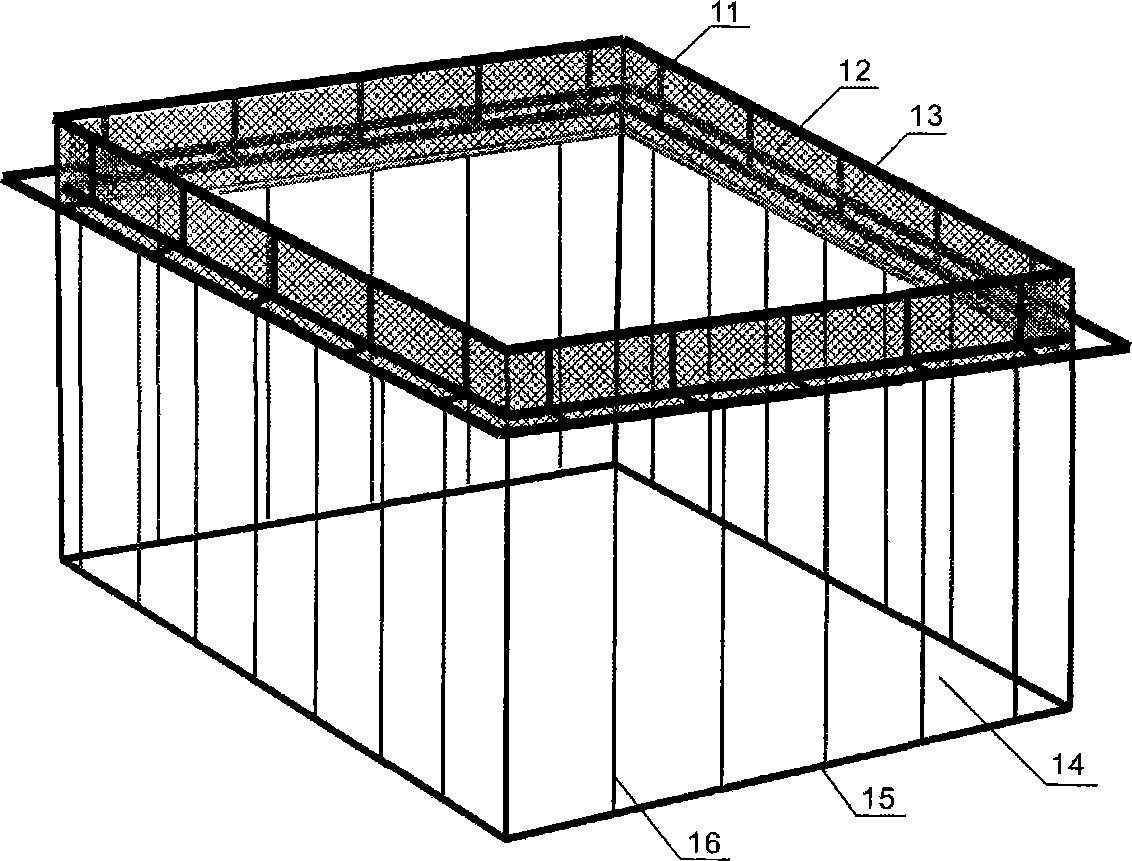

[0009] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings: the buoyancy system of the present invention's antifouling type large yellow croaker culture stretching net cage (hereinafter referred to as net cage) adopts the double floating tube rectangular frame structure of durable high density polyethylene ( image 3 In 11), the frame is made of durable high-density polyethylene double floating tubes with the same outer diameter and the outer diameter ranges from 249mm to 560mm. Two rows of durable high-density polyethylene double floating tubes are assembled in parallel and between adjacent floating tube bodies The vertical spacing between them is controlled at 10cm to 33cm. For example, the vertical spacing between adjacent floating tube bodies is 25cm; two rows of durable high-density polyethylene double floating tubes are made of durable high-density polyethylene floating tubes and their supporting bends. It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com