Coating liquid capable of reducing fingerprint adhesion, manufacturing method thereof, and products coated with the coating liquid

A coating and liquid technology, applied in the field of products coated with the coating liquid, can solve the problems of weak bonding and degradation of antifouling function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

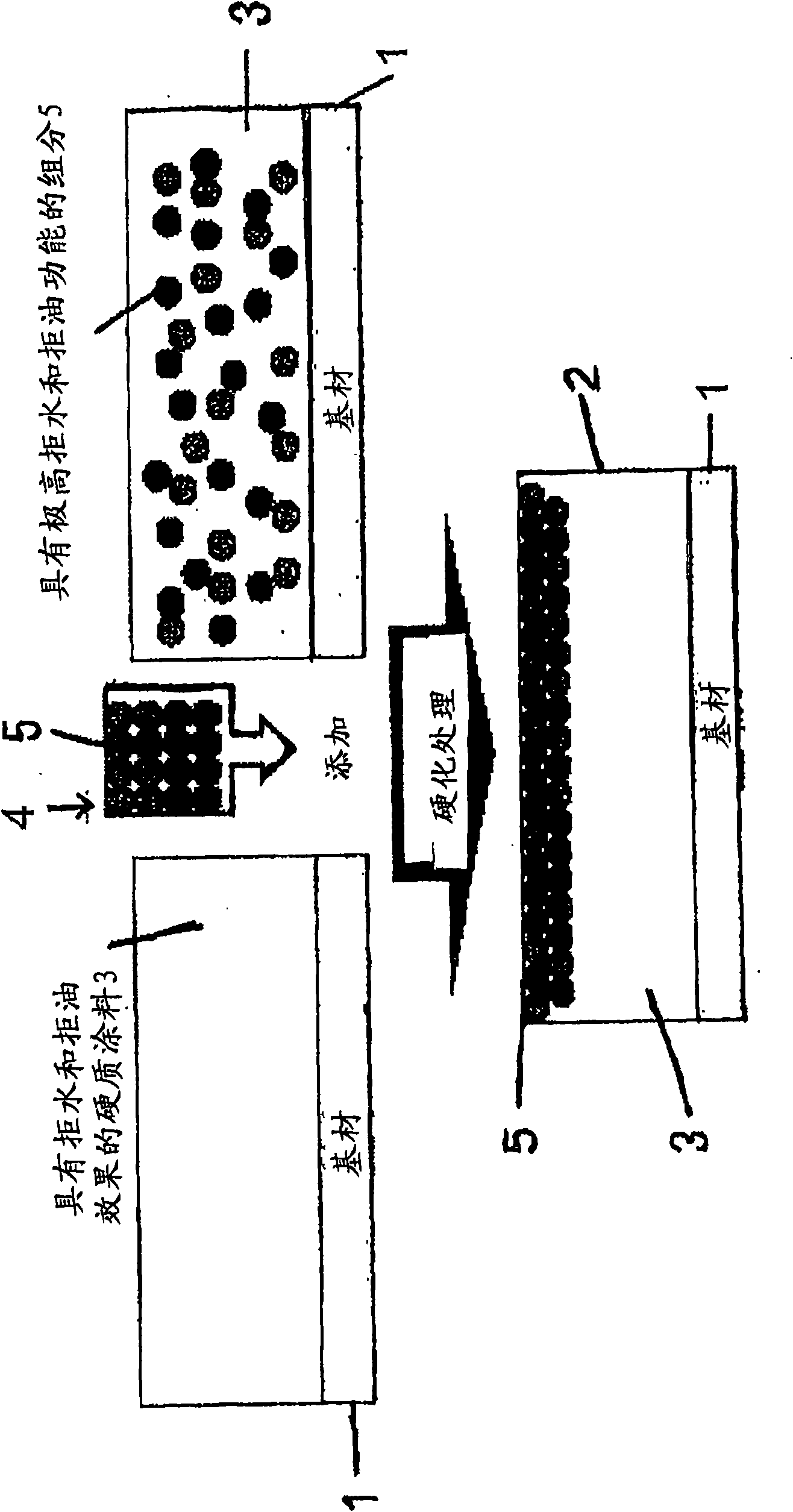

[0027] Embodiments of the present invention will be described below.

[0028] Mixing ratio I

[0029] Organic compound: organic nitrogen compound = 10:30

[0030] 7.5% of an antifouling additive was added based on the amount of solid content of the mixed solution.

[0031] Mixing ratio I I

[0032] Organic compound: organic nitrogen compound = 10:40

[0033] 10.5% of the antifouling additive was added based on the solid content of the mixed solution.

[0034] Mixing ratio III

[0035] Organic compound: organic nitrogen compound = 20:40

[0036] 16.5% of antifouling additive was added based on the solid content of the mixed solution.

[0037] As for the mixed solution actually used, the organic compound was KZ6154, and the organic nitrogen compound was Beam-set 575 CB. The antifouling additive is Optool DAC.

[0038] The organic nitrogen compound and the antifouling additive are propylene glycol monomethyl ether except the organic compound having a ketone group.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com