Epoxy/ polyester mixed powder coating

A powder coating and hybrid technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of increasing construction difficulty and production cost, unfavorable development of powder coatings, etc., to achieve good dispersion of inorganic pigments, Effect of shortening curing time and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

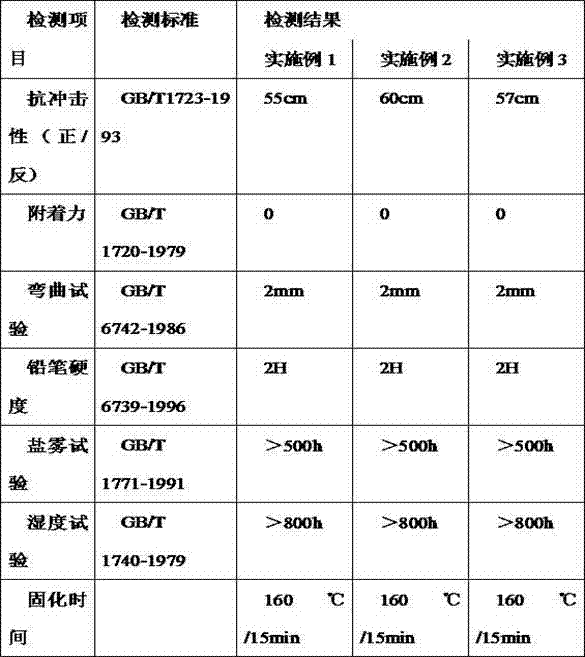

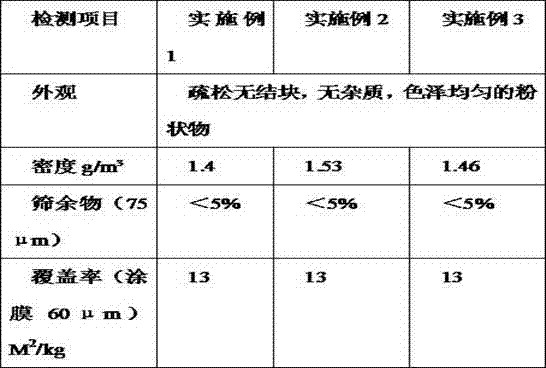

Embodiment 1

[0013] A kind of epoxy / polyester hybrid powder coating, its composition and weight ratio are:

[0014] Epoxy resin E51 18%, polyester tree 899 32%, leveling agent 503 0.5%, brightener TL701 1.2%, titanium dioxide 17%, barium sulfate 30%, additive 0.5%, titanium nickel yellow 0.8%.

Embodiment 2

[0016] A kind of epoxy / polyester hybrid powder coating, its composition and weight ratio are:

[0017] Epoxy resin E51 20%, polyester tree 899 30%, leveling agent 503 1%, brightener TL701 1%, titanium dioxide 20%, barium sulfate 27%, additive 0.3%, molybdenum chrome red 0.7%.

Embodiment 3

[0019] A kind of epoxy / polyester hybrid powder coating, its composition and weight ratio are:

[0020] Epoxy resin E51 23%, polyester tree 899 25%, leveling agent 503 1.3%, brightener TL701 0.7%, titanium dioxide 24%, barium sulfate 25%, additive 0.5%, cobalt green 0.5%.

[0021] Production Process:

[0022] (1) Pre-mixing, pre-mixing barium sulfate and inorganic pigments in proportion to 700rpm for 1min;

[0023] (2) Mixing, add epoxy resin, polyester resin, leveling agent, brightener, titanium dioxide and additives to the pre-mixture in proportion, and mix at 800rpm for 3min;

[0024] (3) Extrusion, melt extrusion through a screw extruder, the temperature control of the three zones of the extruder is: zone one: 50-60°C, zone two: 80-95°C, zone three: 100-120°C;

[0025] (4) Grinding. The molten material is pressed into tablets by a tablet press, and the thickness is controlled at 3 mm. After being crushed, it is sent to a mill for crushing and grading. After passin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com