Method for manufacturing antifouling and antibiosis type yellow croaker net cage

A technology for cages and yellow croaker, applied in fish farming, application, climate change adaptation, etc., can solve the problem of yellow croaker cage bait utilization coefficient, low cage volume retention rate, synthetic fiber net clothing and synthetic fiber rope raw material consumption. It will affect the normal growth and development of yellow croaker and the breeding efficiency and other problems, so as to achieve the effect of being beneficial to the exchange of water bodies, improving the anti-fouling function, and reducing the consumption of cage materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

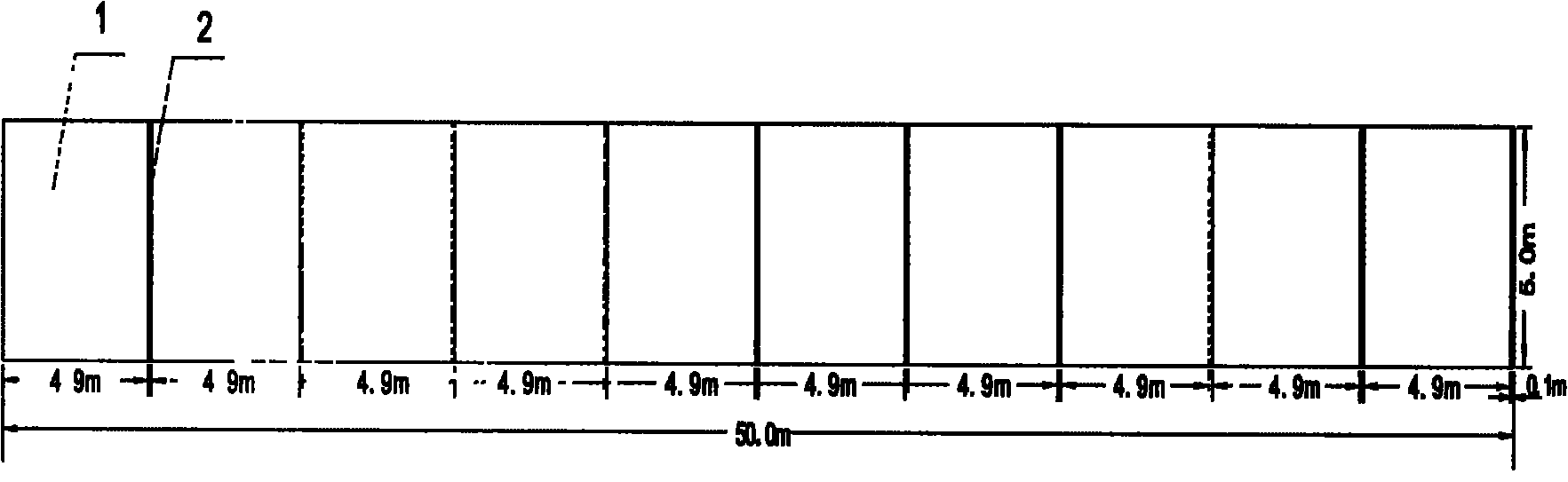

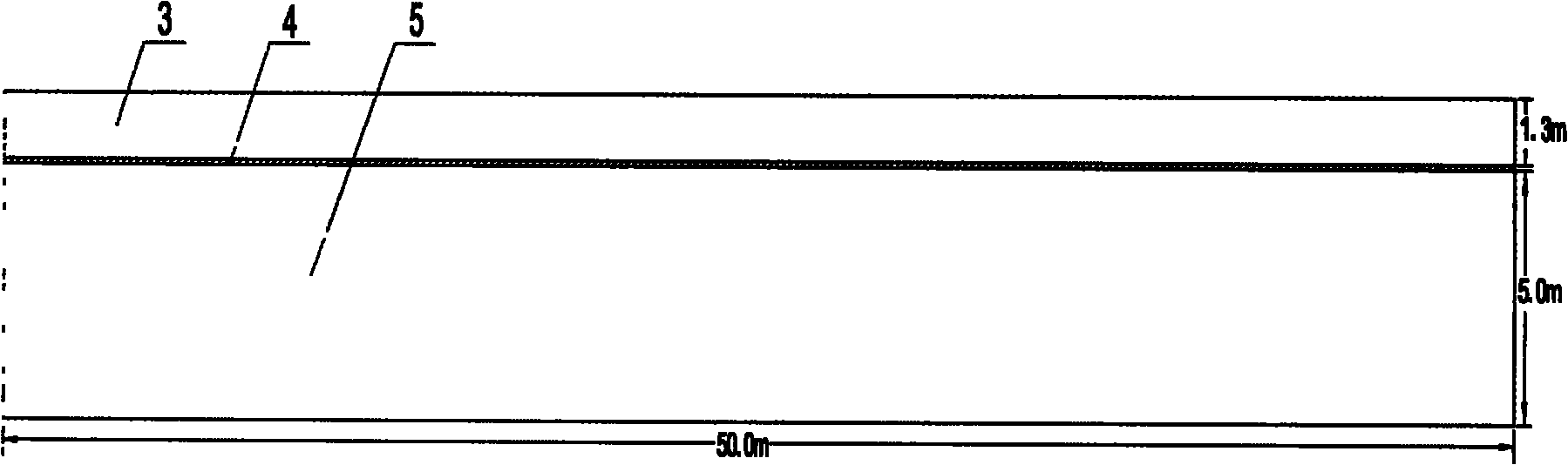

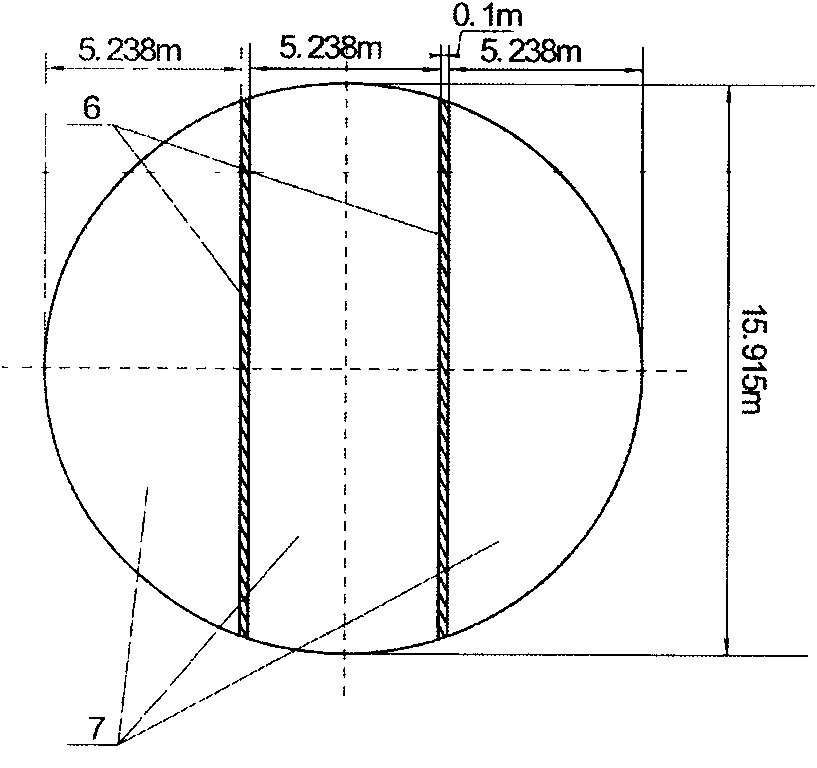

[0010] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings (see accompanying drawings): figure 1 1 in it represents a copper alloy orthorhombic net with a length×height of 4.9m×5m; 2 represents a transverse connection with a width×height of 0.3m×5m; figure 2 3 in the box represents the first net in the longitudinal direction of the box; 4 represents the longitudinal connection between the first and second nets in the longitudinal direction of the box; 5 represents the second net in the longitudinal direction of the box; image 3 6 in the figure represents the horizontal connection for making nets at the bottom of the cage; 7 represents the copper alloy orthorhombic mesh for making the bottom nets of the cages; Figure 4 8 in the box represents the first net in the longitudinal direction of the box; 9 represents the longitudinal connection between the first and second nets in the longitudinal direction of the box; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com