Coil out structure in high voltage in oil immersed type distribution transformer

A technology for distribution transformers and high-voltage outlets, applied in the direction of transformers/inductor coils/windings/connections, etc., can solve problems such as easy-to-crack foreign objects, equipment damage, casualties, etc., to prevent accidents, reduce distances, and ensure safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The high-voltage outlet structure of the oil-immersed distribution transformer of the present invention is particularly suitable for the oil-immersed distribution transformer with a high-voltage rated voltage of 35 kV or below.

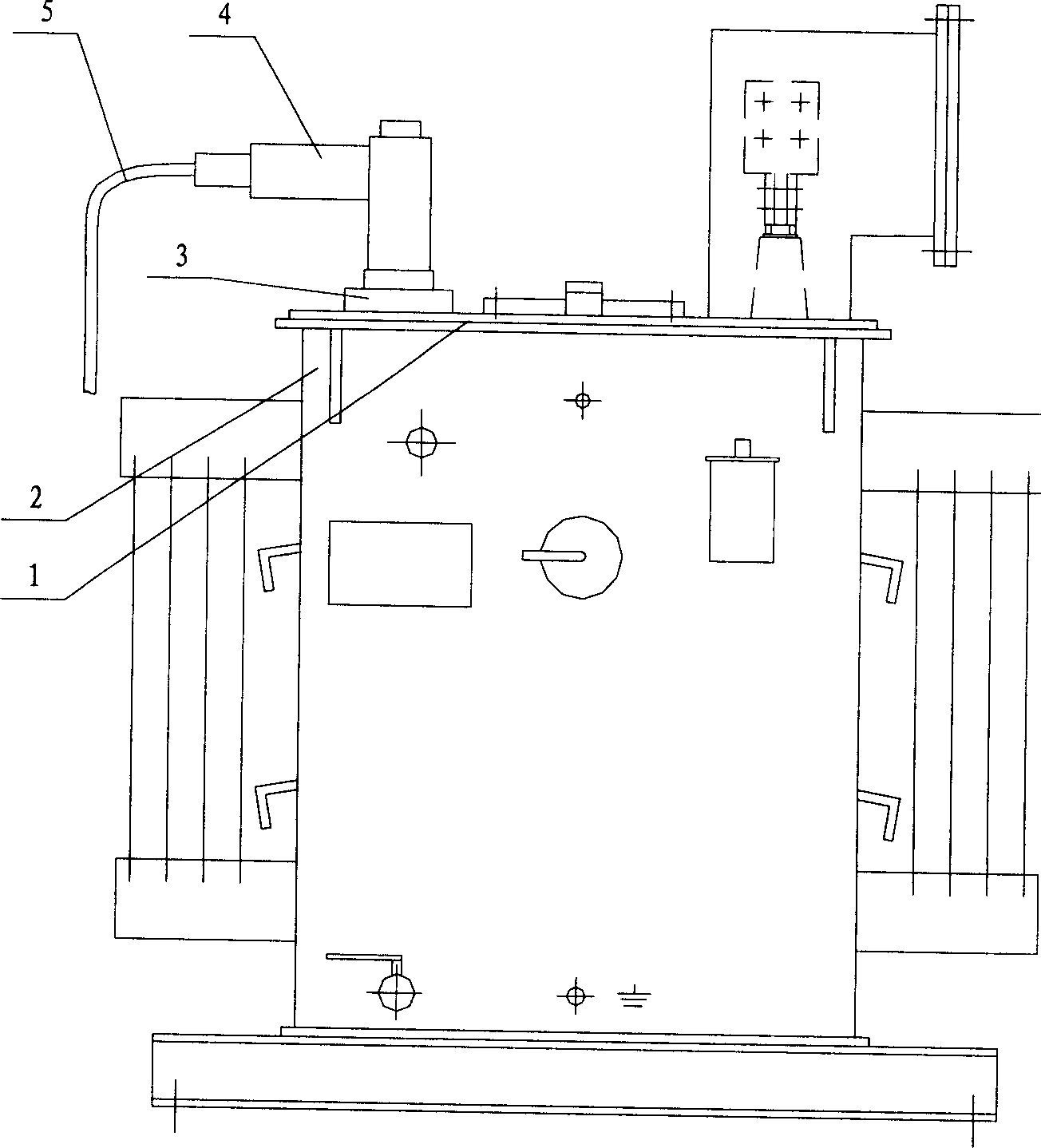

[0012] figure 1 Shown is the structure of the first embodiment of the present invention. The high-voltage outlet structure of the oil-immersed distribution transformer includes a tank cover 1, an oil tank 2, a high-voltage cable 5, a high-voltage bushing seat 3 and an elbow-shaped cable head 4 inserted on the high-voltage bushing seat 3.

[0013] The high-voltage bushing seat 3 is hermetically installed on the case cover 1 .

[0014] The connection between the tail conductive part of the elbow cable head 4 and the high voltage cable 5 is connected by cold pressure welding.

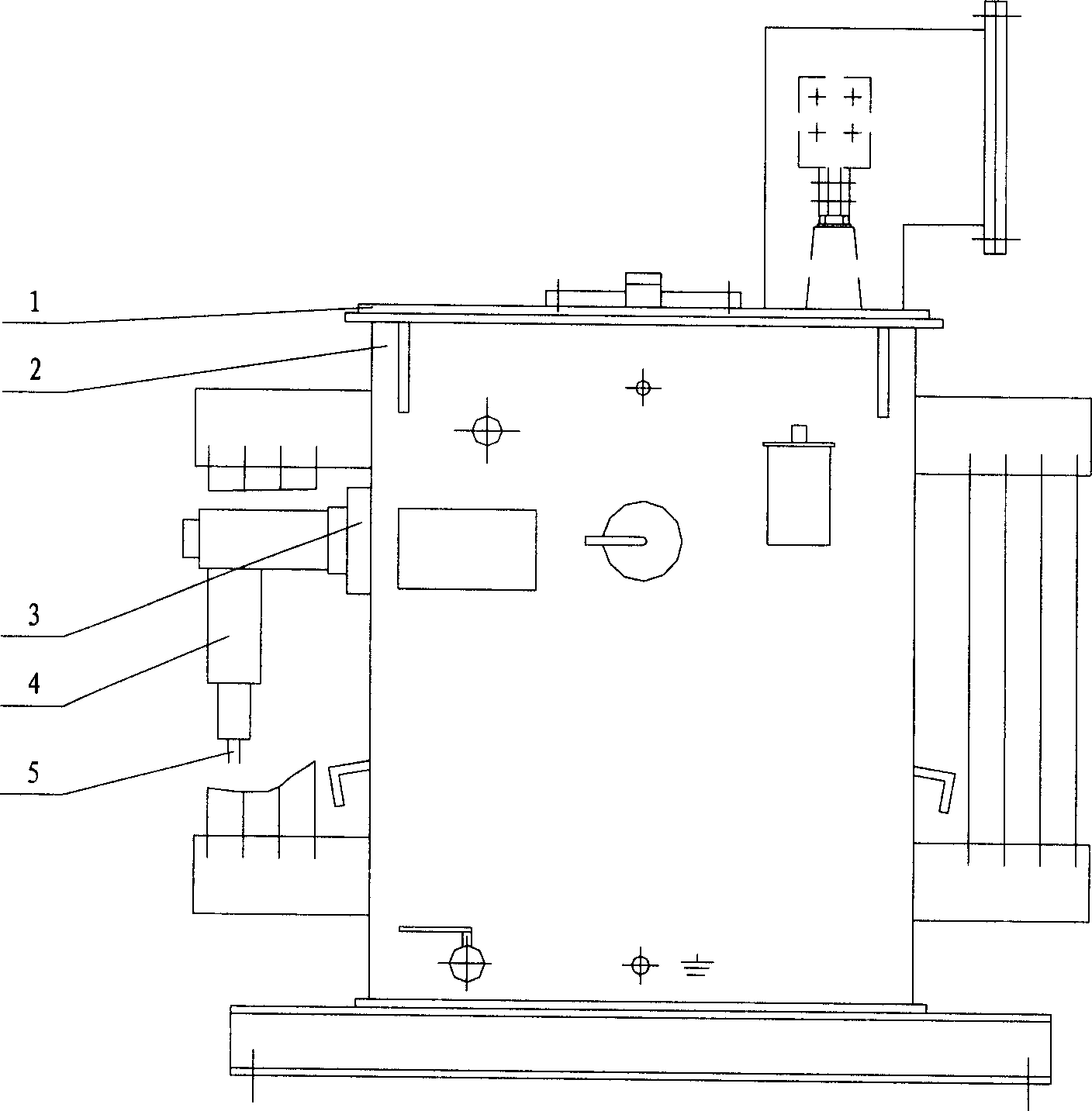

[0015] figure 2 Shown is the structure of the second embodiment of the present invention. The high-voltage outlet structure of the oil-immersed distribution transforme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com