Connection method for seashore and netting gear net

A connection method and netting technology, which is applied in sea area engineering, water conservancy engineering, climate change adaptation, etc., can solve the problems of shortening the connection time between the coast and netting gear, etc., so as to improve the antifouling function, increase safety, and reduce impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

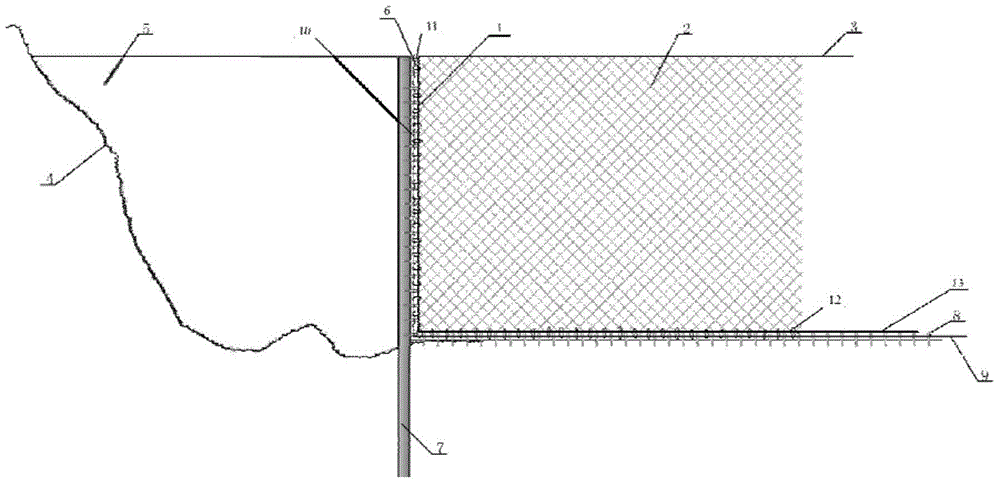

[0007] Embodiment 1: the specific implementation mode of the present invention (referring to accompanying drawing) adopts the net gear net clothes 2 and the reinforced concrete column that floater class 3, lower class 13, left and right edge classes are housed, in net clothes net clothes left edge class 1 and Install a vertical force line every 0.5m between the right edge lines; install a circular polyester rope buckle 11 perpendicular to the axis line of the column every 9cm (about 9cm) of the reinforced concrete column, and penetrate a hanging net into the circular polyester rope buckle The vertical force line 10 is tied and fixed; the lower end of the first reinforced concrete column 7 is driven into the seabed 2.5m at the intersection of the left coast 4 and the netting, and the net hanging on the first reinforced concrete column is ensured. The vertical force line is located on the side away from the left coast; at the intersection of the right coast and the netting, drive...

Embodiment 2

[0008] Embodiment 2: according to the mode described in embodiment 1, except that the nets and nets are equipped in a conventional manner, the preferred nets and nets are "UHMWPE-178tex × 33-44" ultra-high molecular weight polyethylene warp-knitted nets, That is, the ultra-high molecular weight polyethylene fiber yarn with a linear density of 178tex is warped into an ultra-high molecular weight polyethylene fiber yarn with a linear density of 178tex, and then according to the special mesh size of 44mm, "6 loops + 15 weft inserts" Net weaving structure and longitudinal heat setting treatment. 21 ultra-high molecular weight polyethylene fiber yarns with a linear density of 178tex are processed into an ultra-high molecular weight polyethylene warp-knitted net with a specification of "UHMWPE-178tex×33-44" by a warp knitting machine. Then use the antifouling agent for fishing nets to carry out antifouling treatment on the ultra-high molecular weight polyethylene warp knitted net, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com