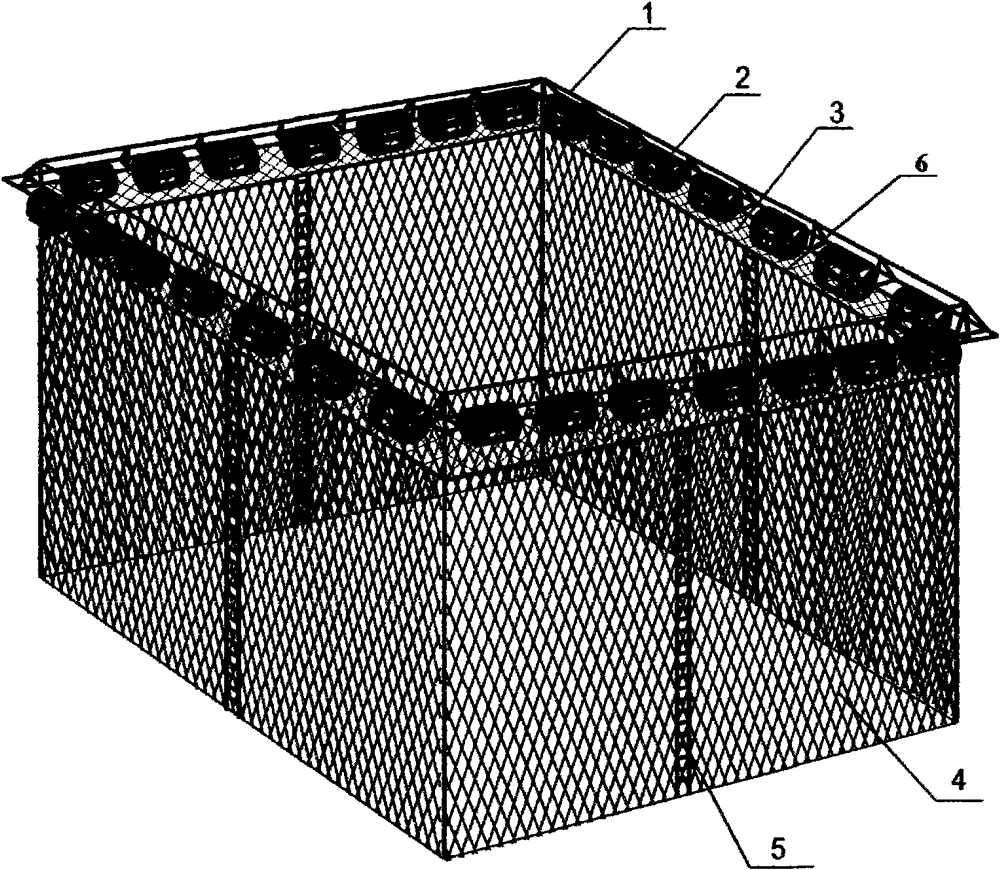

Combined box body system used for floating net cage and mated frame system thereof

A framework system and cage technology, applied in application, fish farming, climate change adaptation, etc., to improve the anti-fouling function, facilitate operation and maintenance, and reduce the number of net changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings:

[0008]The present invention adopts copper alloy orthorhombic mesh, copper alloy woven mesh, high-strength polyamide warp-knitted mesh clothing, ropes, galvanized iron pipes and foam buoys, and the buoyancy system of the cage adopts a square double-row galvanized iron pipe frame structure (1 in the figure), Two rows of galvanized iron pipes are assembled in parallel and the vertical distance between them is controlled at 20-36cm, for example, it can be controlled at 30cm. The inner frame size of the square double-row galvanized iron pipe frame is 10m×10m. The first nets are connected with ultra-high-strength polyethylene ropes; 28 cylindrical foam buoys of the same specification (2 in the figure) are arranged under the double-row galvanized iron pipe frame to provide buoyancy. The specifications of the cylindrical foam buoys are: 60cm (diameter) × 105cm (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com