Manufacturing method of consumption-reducing and resistance-reducing filaments for marine ranch

A marine ranching and manufacturing method technology, which is applied in the direction of rayon manufacturing, melt spinning, stretch spinning, etc., can solve the problems of difficulty in meeting the application requirements of marine ranching, backward new material technology of marine ranching, and low breeding output, and achieve Improve adaptability and comprehensive performance, good spinnability and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

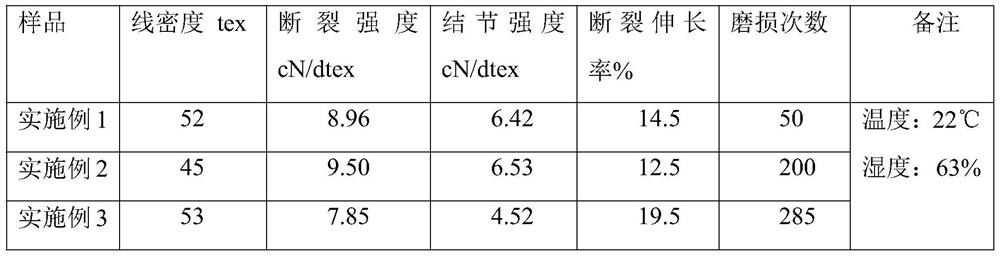

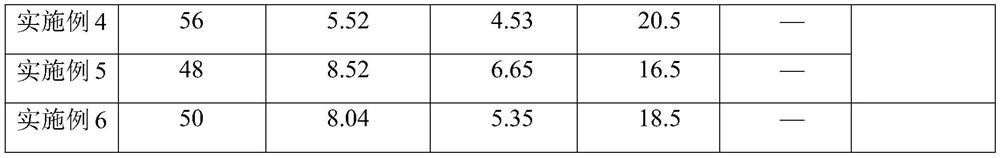

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the examples. However, the following examples should not be considered as limiting the scope of the present invention.

[0028] In this embodiment, a method for manufacturing a consumption-reducing and drag-reducing wire for marine ranching with a linear density of 45 tex is taken as an example to introduce specific implementations of the present invention.

[0029] 1. Raw materials and equipment

[0030] Required raw material and equipment are as follows in the inventive method: polyketone (POK) pellet, zinc stearate, diethylene glycol dibenzoate, silicone powder, antioxidant 1010, white oil raw material and high-speed kneader, Metering pumps, twin-screw extruder equipment.

[0031] The melt index of POK pellets is 6g / 10min-40g / 10min; the amount of zinc stearate added is 0.6%-1.6% of the weight of POK pellets; the organic silicon content of silicone powder is 65%-80%, and the amount added is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com