Patents

Literature

36results about How to "Drafting smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyester staple fiber double-component assembled oil solution and preparation method

InactiveCN101307564AHigh strengthImprove smoothnessFibre typesSynthetic polymer filament chemical after-treatmentFiberPolyester

The invention discloses a polyester staple fiber two-component composite oil agent and a method for preparing the same. The oil agent is formed by combining a smoothing oil agent No. 4 and an antistatic oil agent No. 2. The components by weight percentage of the smoothing oil agent No. 4 are: 10-20 percent of smoothing agent, 20-25 percent of emulsifier, 1-3 percent of penetrating agent and the balance being water. The components by weight percentage of the antistatic oil agent No. 2 are 24-27 percent of natural fatty alcohol, 6.0-6.5 percent of phosphorus pentoxide, 8-10 percent of potassium hydroxide and the balance being water. The preparation method comprises the following steps of preparing the smoothing oil agent No. 4 in a reaction kettle and preparing the antistatic oil agent No. 2 in an esterification reactor and a neutralization reactor. The oil agent has the advantages of low production cost, good stability, high oil film strength, good gliding property and excellently antistatic property and bundle collection property.

Owner:张金惠

Method for processing high-performance modified polyethylene monofilaments for manufacturing fishing net

InactiveCN101851795AIncrease heat treatment temperatureHigh breaking strengthSpinning head liquid feederFilament manufactureWinding machineElastomer

The invention discloses a method for processing high-performance modified polyethylene monofilaments for manufacturing a fishing net, relates to a method for processing polyethylene monofilaments for manufacturing a fishing net and aims to provide a method for processing the high-performance modified polyethylene monofilaments for manufacturing the fishing net. In the technical scheme of the invention, a stirring machine, a single-screw extruder, a twice-drafting electrical heating drafting machine, a filament winding machine and a filament separating machine are adopted. The method is characterized by comprising the following steps of: mixing a sieved spinning-grade dry HDPE resin, a dry VERSIFYTM 6002 elastomer, white oil or a turpentine aid; uniformly mixing the materials to obtain an HDPE / VERSIFYTM 6002 elastomer blend and fusing and extruding the blend by using the single-screw extruder; cooling and pre-drafting fused and extruded primary filaments, thermally drafting the pre-drafted filaments twice, rapidly cooling the thermally-drafted filaments from which oil is removed with high-pressure air current and winding modified PE monofilaments by using the winding machine; and separating the modified PE monofilaments into the high-performance modified polyethylene monofilaments for manufacturing the fishing net by using the filament separating machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Preparation method of composite monofilament for netting gear manufacture

ActiveCN103147149ASilk is normalDrafting smoothlyMelt spinning methodsMonocomponent polyolefin artificial filamentElectric heatingWinding machine

A preparation method of a composite monofilament for netting gear manufacture. The invention employs a mixer, a double-screw extruder, a single-screw extruder, a secondary drafting electric heating draw machine, a winding machine using a torque motor, a filament splitting machine, a spinning grade drying HDPE resin, nanometer drying Al2O3 and a turpentine assistant for spinning. The preparation method is characterized by comprising the steps of: mixing the spinning grade drying HDPE resin, the nanometer drying Al2O3 and the turpentine assistant for spinning; subjecting the mixture to two times of extrusion granulation by the twin-screw extruder to obtain blend pellets; subjecting the blend pellets to melt extrusion by the single-screw extruder; subjecting the primary composite monofilament obtained from melt extrusion to cooling and a preliminary drafting; subjecting the composite monofilament from preliminary drafting to two times of hot drafting, then high-pressure airflow oil removal and fast cooling; winding the composite monofilament by the winding machine using torque motor; and splitting the composite monofilament by the filament splitting machine into a matrix composite monofilament for low carbon netting gear manufacture.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

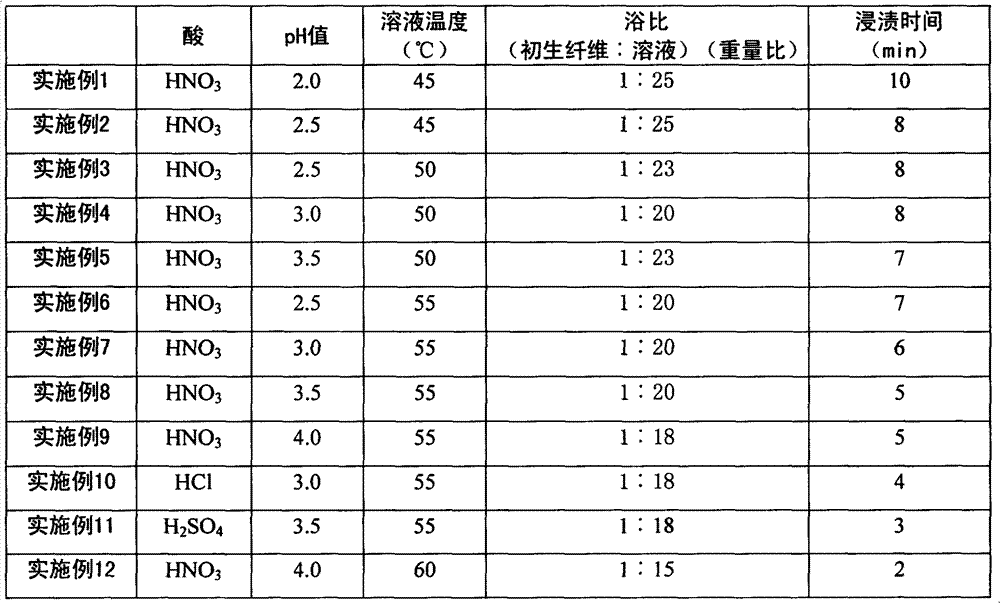

Preparation method for polyacrylonitrile-based carbon fiber

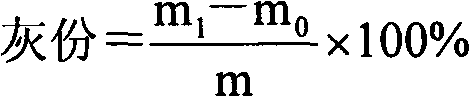

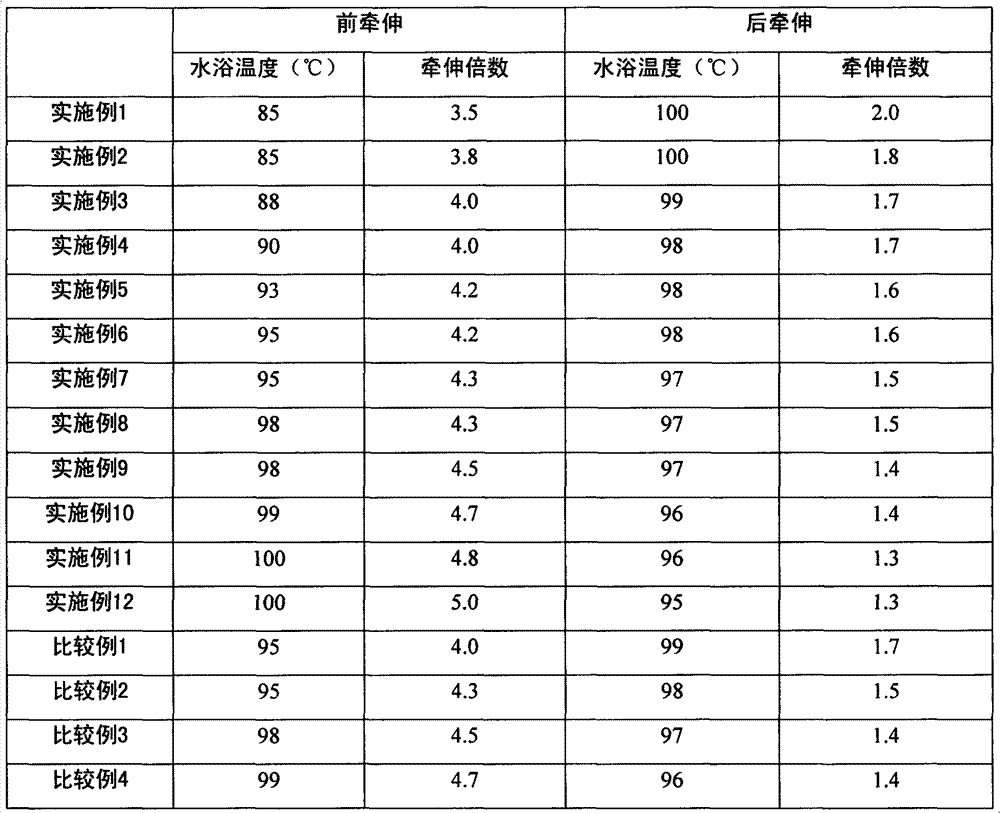

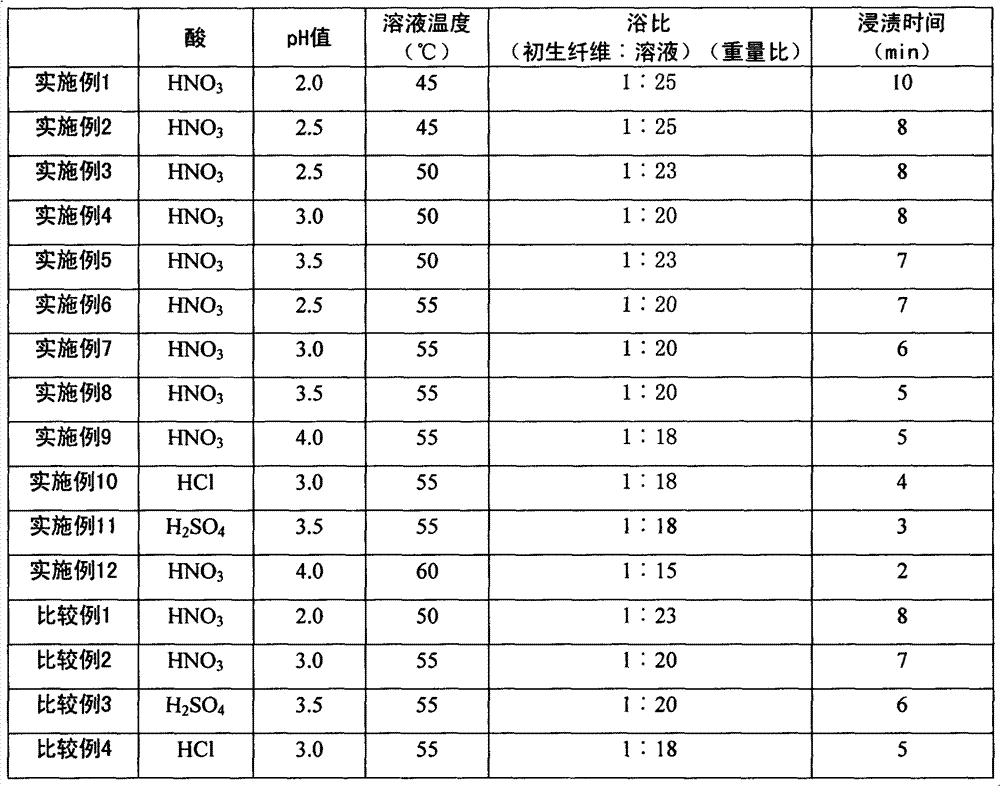

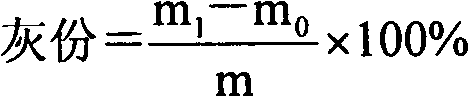

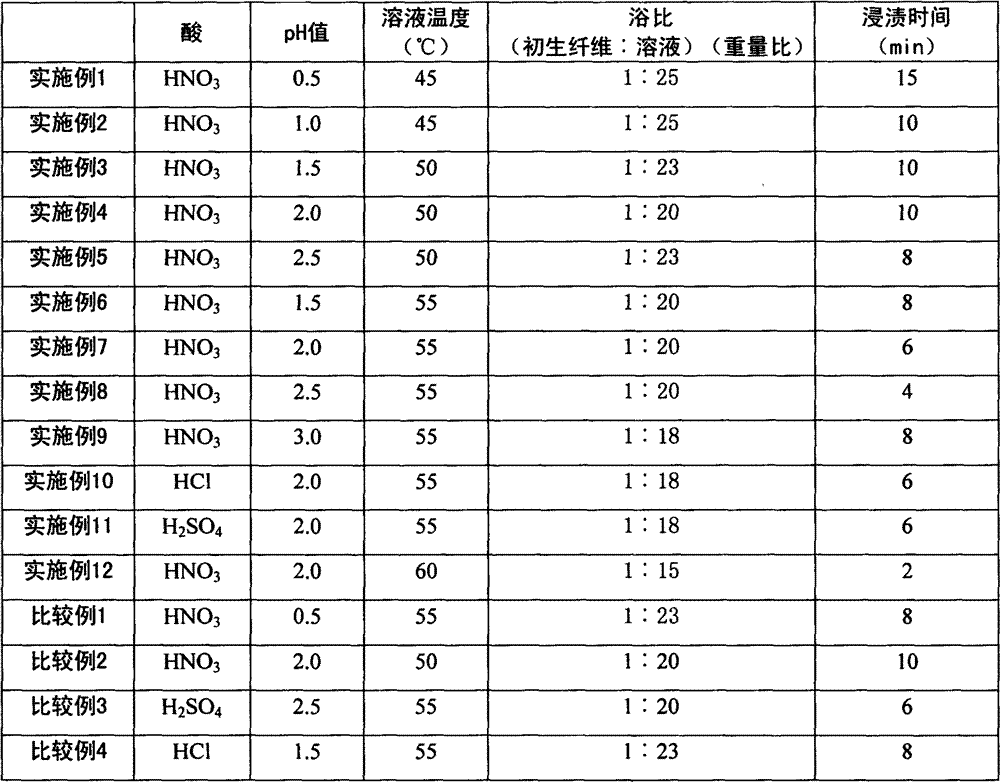

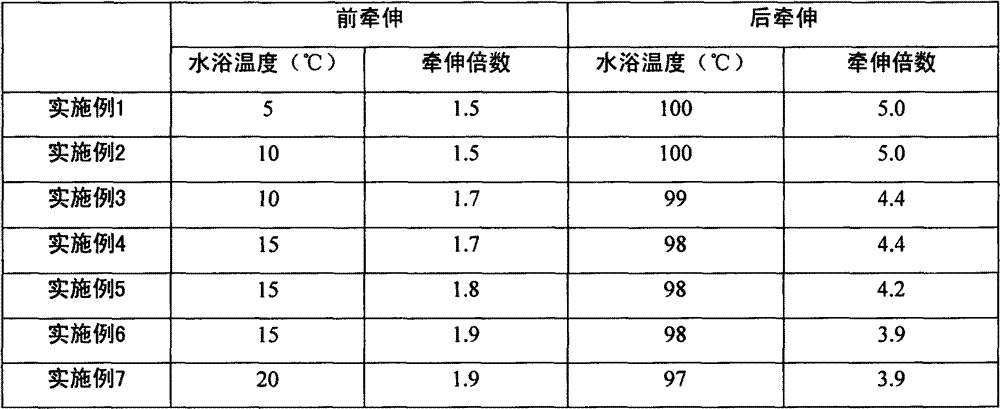

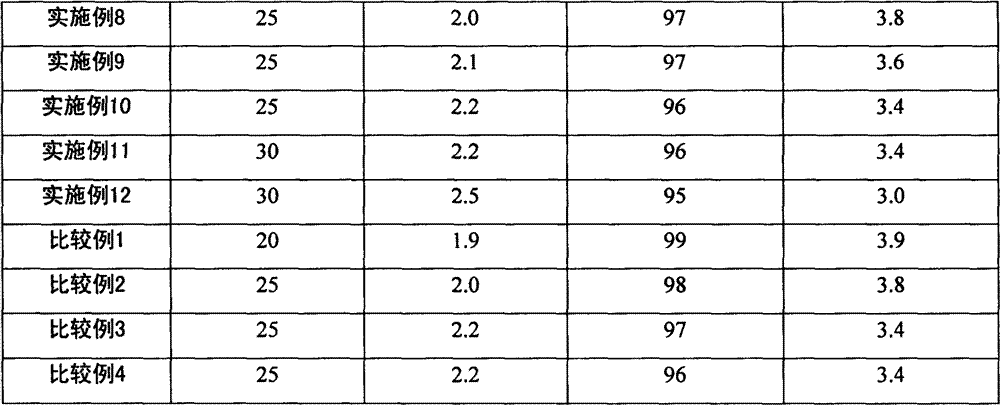

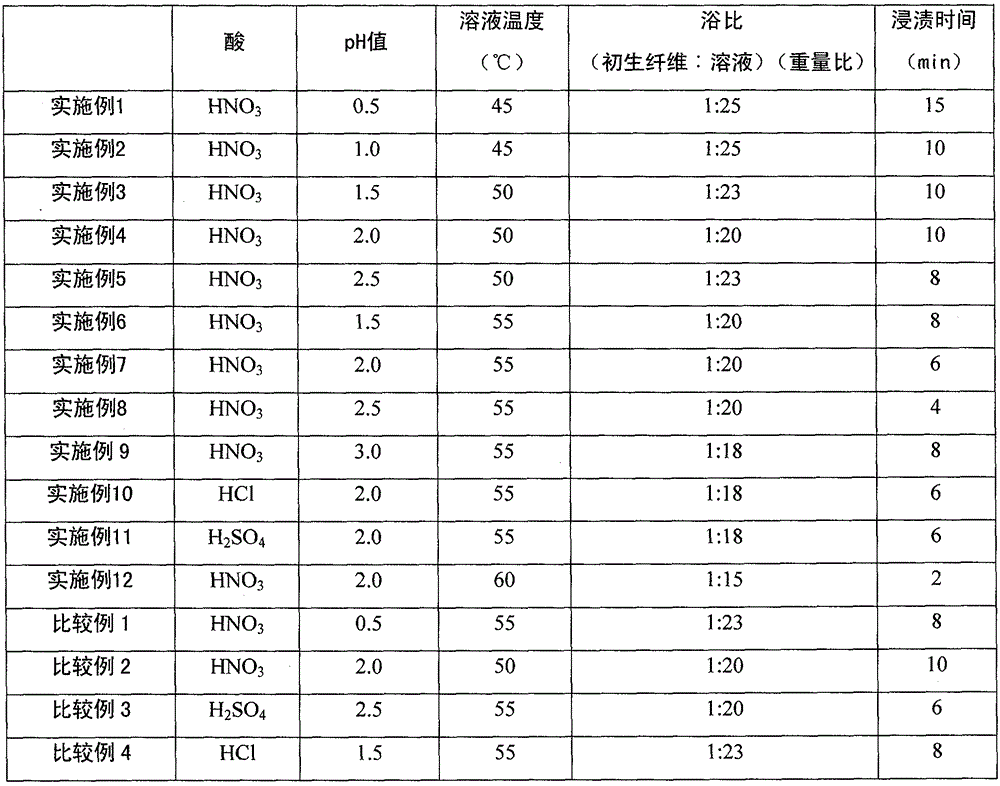

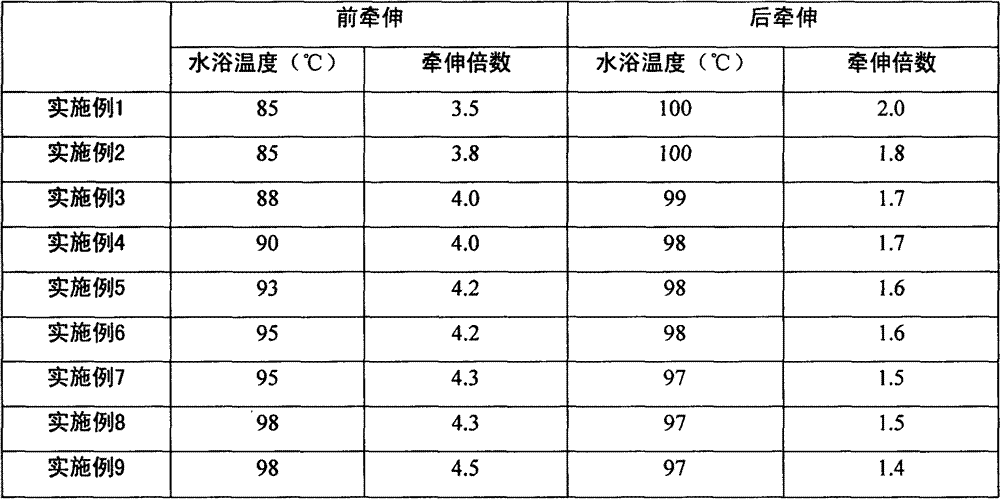

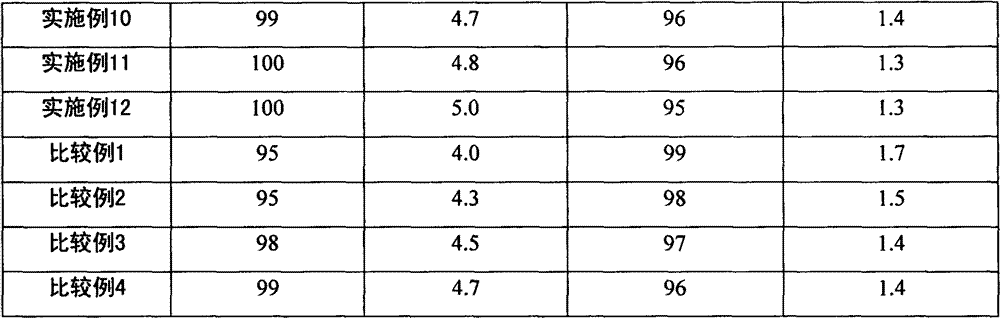

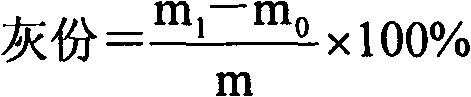

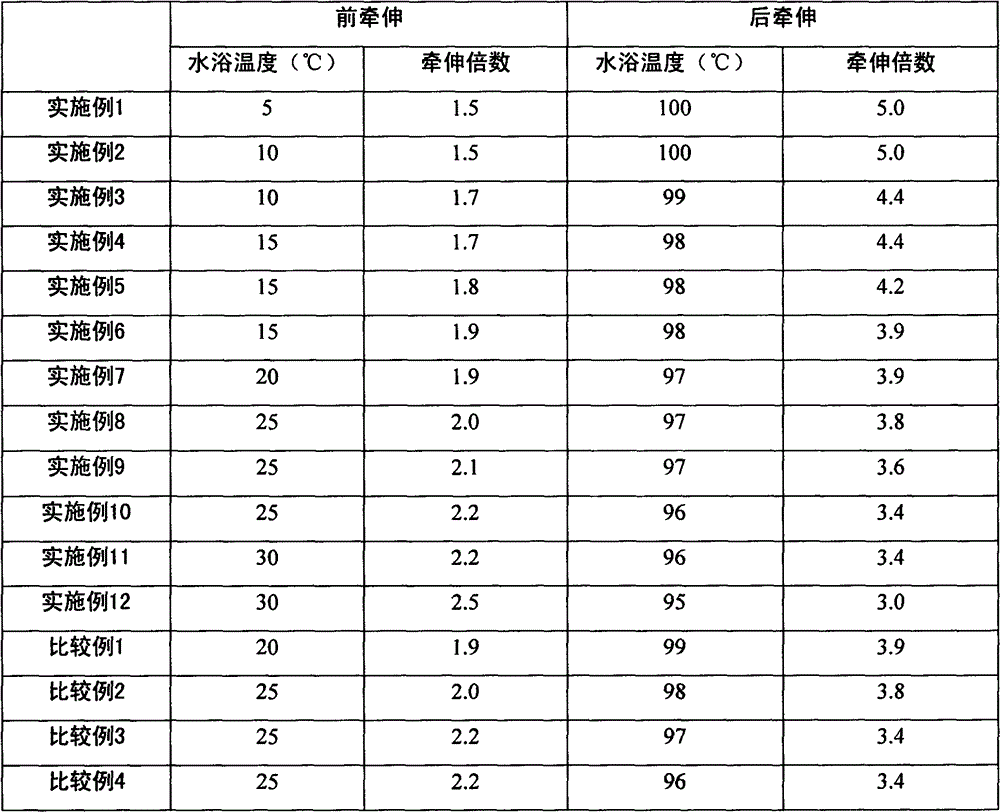

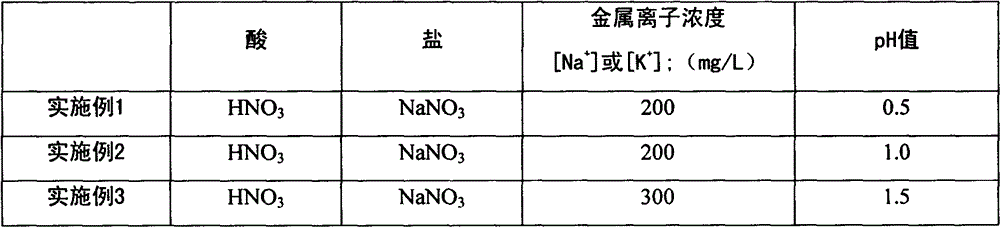

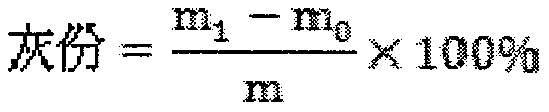

InactiveCN102953151AHigh breaking strengthImprove mechanical propertiesArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentWater bathsCarbon fibers

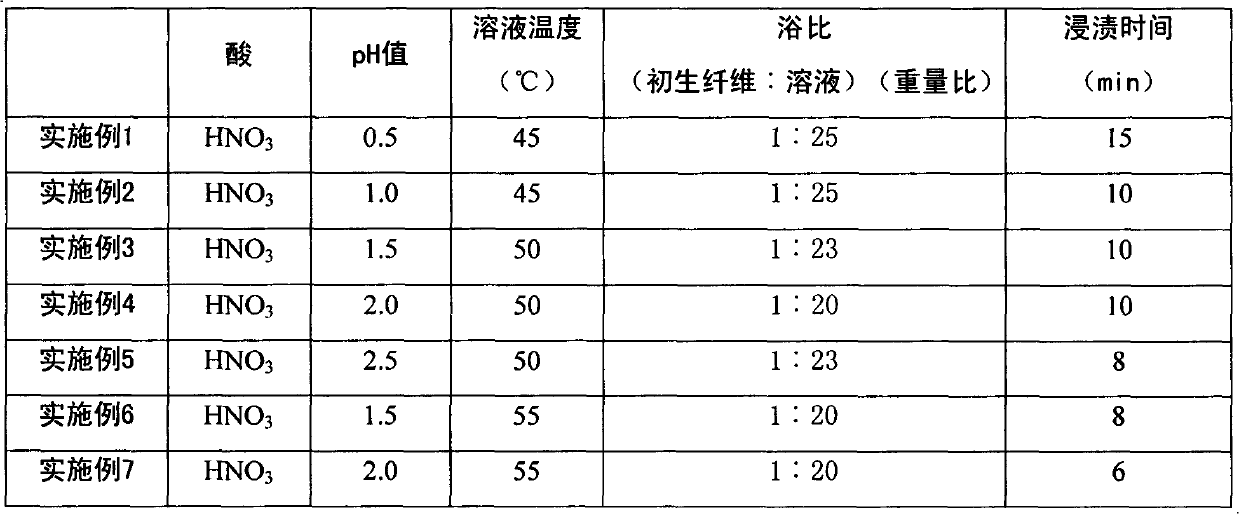

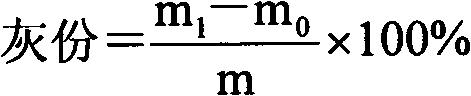

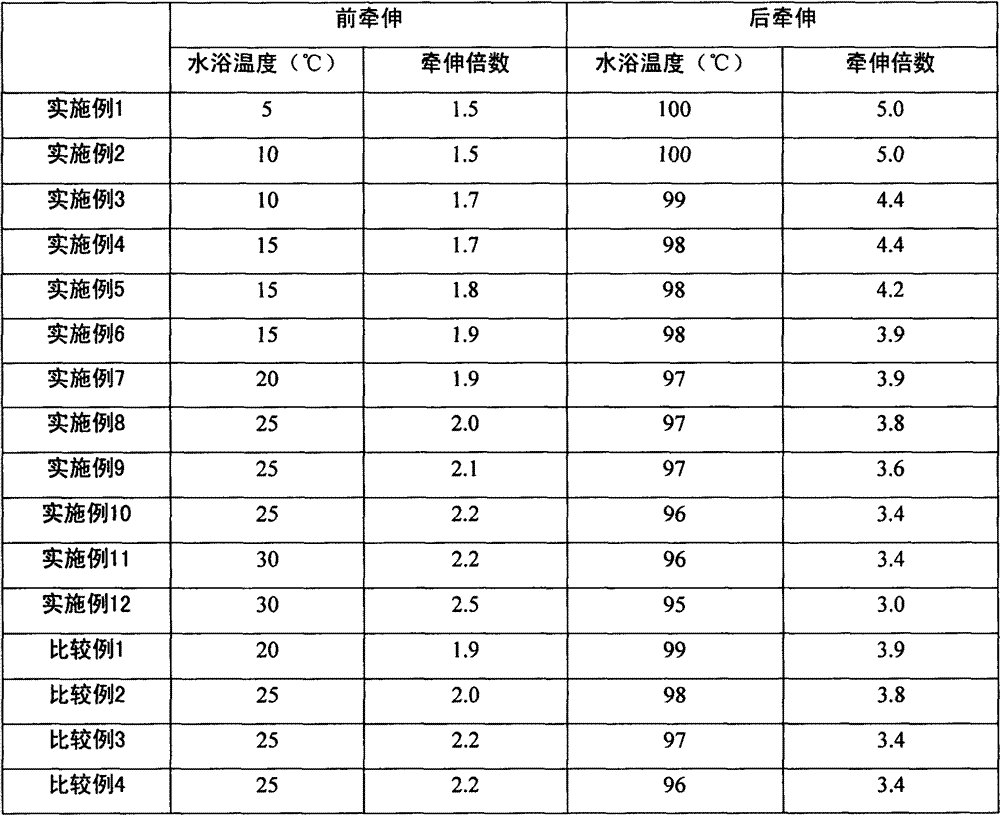

The invention provides a preparation method for a polyacrylonitrile-based carbon fiber. The third monomer of a protofilament spinning raw material, i.e., polyacrylonitrile resin, is itaconic acid; a spinning solution is prepared from the resin by using DMSO or DMAc, and spinning and solidification are carried out so as to prepare a nascent fiber. The nascent fiber successively undergoes the following procedures: drip washing with deionized water; dipping in an acidic aqueous solution for 2 to 10 min; dipping in a sodium hydroxide or potassium hydroxide aqueous solution for 1 to 5 min; water bath drafting in pure water; dipping in the acidic aqueous solution for 2 to 8 min; and hot bath rinsing with deionized water until rinsing liquid is neutral. A carbon fiber protofilament is prepared by subjecting the nascent fiber to post-processing procedures like oiling and dry densification. The protofilament undergoes pre-oxidation in an aerobic atmosphere under the condition of drafting and then undergoes carbonization in an anoxic atmosphere under the condition of drafting so as to obtain a finished product of the polyacrylonitrile-based carbon fiber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of monofilament for net cage body and trawl fishing gear

ActiveCN103147150AGood adaptability for fishingImprove spinnabilityMelt spinning methodsMonocomponent polyolefin artificial filamentWinding machineTorque motor

A preparation method of a monofilament for net cage body and trawl fishing gear. The invention employs a mixer, a double-screw extruder, a single-screw extruder, a secondary drafting electric heating draw machine, a winding machine using a torque motor, a filament splitting machine, a spinning grade drying HDPE resin, nanometer drying ZnO and a turpentine assistant for spinning. The method is characterized by comprising the steps of: mixing the spinning grade drying HDPE resin, the nanometer drying ZnO and the turpentine assistant for spinning; stirring the mixture with a mixer to a uniform state; granulating the thoroughly mixed mixture by the twin-screw extruder to obtain the blend pellets; subjecting the blend pellets to melt extrusion by the single-screw extruder; subjecting the primary monofilament obtained from melt extrusion to cooling and a preliminary drafting; subjecting the composite monofilament from preliminary drafting to two times of hot drafting, then high-pressure airflow oil removal and fast cooling; winding the monofilament by the winding machine using torque motor; and splitting the monofilament by the filament splitting machine into a energy-saving and emission-reducing monofilament for net cage body and trawl fishing gear.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

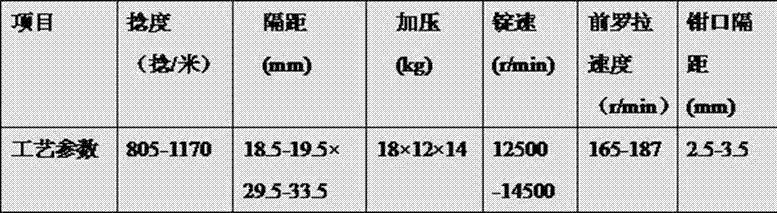

Semi-worsted porous segment color slub yarn and preparation method thereof

The invention relates to a semi-worsted porous segment color slub yarn. The semi-worsted porous segment color slub yarn is prepared from base yarn and decorative yarn, wherein the base yarn is prepared from prolivon fibers, spun silk fibers and wool fibers, and the decorative yarn is prepared from aloe viscose fibers and antibacterial hollow polyester fibers. The slub yarn prepared through the method is colorful, rich in color, changeable in pattern, unique in style, rich in layer change and special in shape, and can generate a flash effect after the fibers in different colors are combined into threads; due to the fact that the yarn is rich in color and diversified in shape change, a fabric manufactured through processing is antibacterial, capable of diminishing inflammation, protecting skin and beautifying the face, good in moisture absorption and good in dyeing property and elasticity, does not generate adverse reactions when making contact with the human body, and is not easy to damage by worms or rot, unique in appearance, good in drapability, good in comfort degree, good in abrasion resistance, natural in color and wide in application range; the processed fabric is strange in style and has the health-care functions of resisting bacteria, protecting the skin, strengthening the body, beautifying the face, moisturizing the skin, being good in comfort degree and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

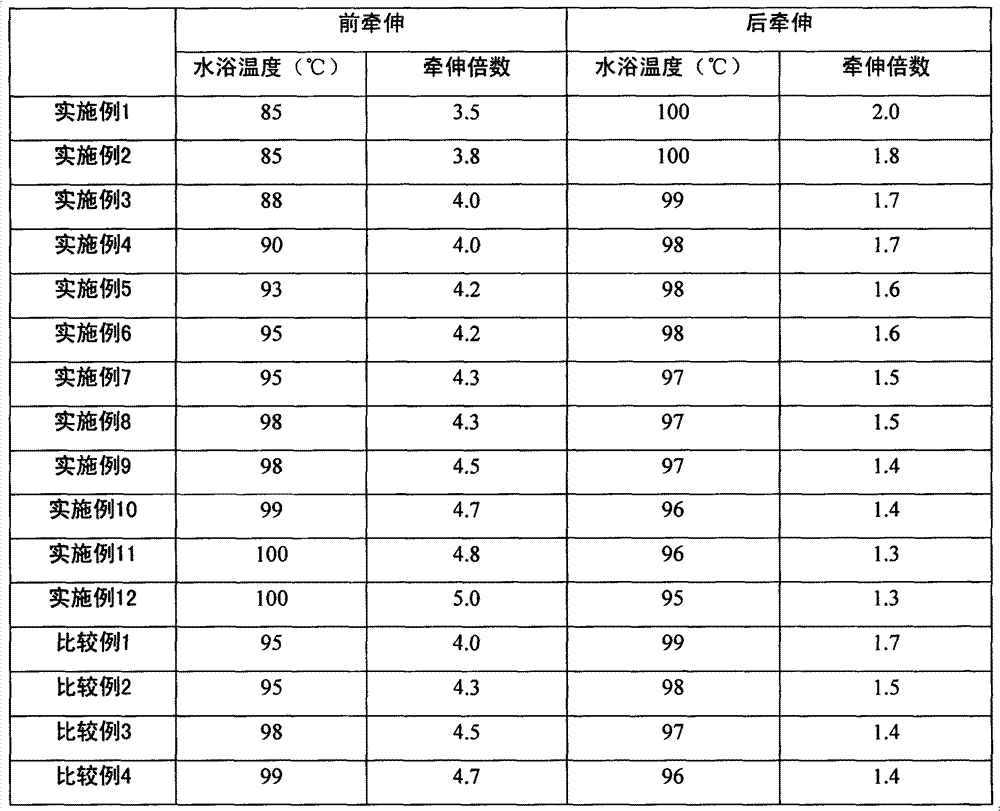

Manufacturing method for polyacrylonitrile-based carbon fiber protofilament

ActiveCN102953138ADrafting smoothlyHigh breaking strengthWet spinning methodsMonocomponent synthetic polymer artificial filamentSolventChemistry

The invention provides a manufacturing method for a polyacrylonitrile-based carbon fiber protofilament. The third monomer of a protofilament spinning raw material polyacrylonitrile resin is itaconic acid. The preparation method comprises the following successive steps: preparing a spinning solution from the resin by using DMSO or DMAc and carrying out spinning and solidification so as to prepare a nascent fiber; placing the nascent fiber in an aqueous solution of the spinning solvent for water bath drafting and carrying out drip washing with deionized water; dipping the nascent fiber in an acidic aqueous solution for 2 to 10 min; then dipping the nascent fiber in a sodium hydroxide or potassium hydroxide aqueous solution for 1 to 5 min; placing the nascent fiber in pure water for water bath drafting; rinsing the nascent fiber with deionized water until rinsing liquid is neutral and sodium or potassium ions cannot be measured, and then continuing rinsing for 5 to 15 min; and carrying out post-processing procedures like oiling and dry densification so as to obtain a product of the polyacrylonitrile-based carbon fiber protofilament. According to the invention, purification of the protofilament is realized through rinsing, and breaking strength of fibers is not affected, so the defects of the prior art are overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacturing method of fibers of breeding nets of sea fish

ActiveCN104562284AImprove performanceReduce consumptionFilament forming substance formingConjugated synthetic polymer artificial filamentsLinear low-density polyethyleneFiber bundle

The invention provides a manufacturing method of fibers of breeding nets of sea fish. The manufacturing method adopts HDPE (high-density polyethylene) resin, an auxiliary agent, metallocene LLDPE (linear low density polyethylene) resin, a stirring machine, a single-screw extrusion machine, a twice-drawing electrical heating drawing machine, a silk collecting machine and a silk dividing machine. The manufacturing method is characterized in that the HDPE resin is sieved; the adding amount of the auxiliary agent is 0.6% of the weight of the HDPE resin; the adding amount of the metallocene LLDPE resin is 10.3% of the weight of the HDPE resin; the materials are stirred by the stirring machine for 19-31 minutes, so that the materials are uniformly stirred, and a mixture of the HDPE resin and the metallocene LLDPE resin is obtained; melt extrusion is performed on the mixture of the HDPE resin and the metallocene LLDPE resin by the single-screw extrusion machine, and primary silk obtained from melt extrusion is cooled and pre-drawn by a cooling water box and a first drawing roller; twice hot drawing is performed on the pre-drawn silk, the drawn silk is degreased by a high-pressure airflow, the degreased silk is rapidly cooled, and fiber bundles are collected and rolled by the silk collecting machine; the fiber bundles are divided into the fibers of the breeding nets of the sea fish by the silk dividing machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Preparation method for polyacrylonitrile-based carbon fiber protofilament

InactiveCN102953144ADrafting smoothlyHigh breaking strengthArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentWater bathsBreaking strength

The invention provides a preparation method for a polyacrylonitrile-based carbon fiber protofilament. The third monomer of a spinning raw material, i.e., polyacrylonitrile resin, is itaconic acid; a spinning solution is prepared from the resin by using DMSO or DMAc, and spinning and solidification are carried out so as to prepare a nascent fiber. The nascent fiber successively undergoes the following procedures: drip washing with deionized water; dipping in an acidic aqueous solution for 2 to 10 min; dipping in a sodium hydroxide or potassium hydroxide aqueous solution for 1 to 5 min; water bath drafting in pure water; dipping in the acidic aqueous solution for 2 to 8 min; and rinsing with deionized water until rinsing liquid is neutral. A carbon fiber protofilament is prepared by subjecting the nascent fiber to post-processing procedures like oiling and dry densification. According to the invention, purification of the protofilament is realized through rinsing, and breaking strength of fibers is not affected, so the defects of the prior art are compensated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of composite filament for netting gear manufacture

ActiveCN103147151BSilk is normalImprove wear resistanceFilament forming substance formingMelt spinning methodsWinding machineTorque motor

A processing method of composite filament for netting gear manufacture. The invention employs a mixer, a double-screw extruder, a single-screw extruder, a secondary drafting electric heating draw machine, a winding machine using a torque motor, a filament splitting machine, a spinning grade drying HDPE resin, nanometer drying SiO2 and a turpentine assistant for spinning. The processing method is characterized by comprising the steps of: mixing the spinning grade drying HDPE resin, the nanometer drying SiO2 and the turpentine assistant for spinning; stirring the mixture with a mixer to a uniform state; granulating the thoroughly mixed mixture by the twin-screw extruder to obtain the blend pellets; subjecting the blend pellets to melt extrusion by the single-screw extruder; subjecting the primary composite filament obtained from melt extrusion to cooling and a preliminary drafting; subjecting the composite filament from preliminary drafting to two times of hot drafting, then high-pressure airflow oil removal and fast cooling; winding the composite filament by the winding machine using torque motor; and splitting the composite filament by the filament splitting machine into composite filament for energy-saving and drag-reducing netting gear manufacture.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Manufacturing method for polyacrylonitrile-based carbon fiber

ActiveCN102953158AHigh breaking strengthImprove mechanical propertiesWet spinning methodsFibre chemical featuresWater bathsCarbon fibers

The invention provides a manufacturing method for a polyacrylonitrile-based carbon fiber. The third monomer of a protofilament spinning raw material polyacrylonitrile resin is itaconic acid, a spinning solution is prepared from the resin by using an aqueous solution of NaSCN, and spinning and solidification are carried out so as to prepare a nascent fiber. The nascent fiber successively undergoes the following procedures: water bath drafting in the aqueous solution of NaSCN; drip washing with deionized water; dipping in an acidic aqueous solution; dipping in a sodium hydroxide or potassium hydroxide aqueous solution; water bath drafting in pure water; and rinsing with deionized water until rinsing liquid is neutral and sodium or potassium ions cannot be measured, and continued rinsing for 5 to 15 min. A carbon fiber protofilament is prepared by subjecting the nascent fiber to post-processing procedures like oiling and dry densification. The protofilament undergoes pre-oxidation in an aerobic atmosphere under the condition of drafting and then undergoes carbonization in an anoxic atmosphere under the condition of drafting so as to obtain a finished product of the polyacrylonitrile-based carbon fiber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacturing method for polyacrylonitrile-based carbon fiber

InactiveCN102953156AHigh breaking strengthImprove mechanical propertiesArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentWater bathsCarbon fibers

The invention provides a preparation method for a polyacrylonitrile-based carbon fiber. The third monomer of a protofilament spinning raw material, i.e., polyacrylonitrile resin, is itaconic acid; a spinning solution is prepared from the resin by using an aqueous solution of NaSCN, and spinning and solidification are carried out so as to prepare a nascent fiber. The nascent fiber successively undergoes the following procedures: water bath drafting in the aqueous solution of NaSCN; drip washing with deionized water; dipping in an acidic aqueous solution for 2 to 15 min; dipping in a sodium hydroxide or potassium hydroxide aqueous solution for 1 to 5 min; water bath drafting in pure water; dipping in the acidic aqueous solution for 2 to 8 min; and hot bath rinsing with deionized water until rinsing liquid is neutral. A carbon fiber protofilament is prepared by subjecting the nascent fiber to post-processing procedures like oiling and dry densification. The protofilament undergoes pre-oxidation in an aerobic atmosphere under the condition of drafting and then undergoes carbonization in an anoxic atmosphere under the condition of drafting so as to obtain a finished product of the polyacrylonitrile-based carbon fiber.

Owner:CHINA PETROLEUM & CHEM CORP +1

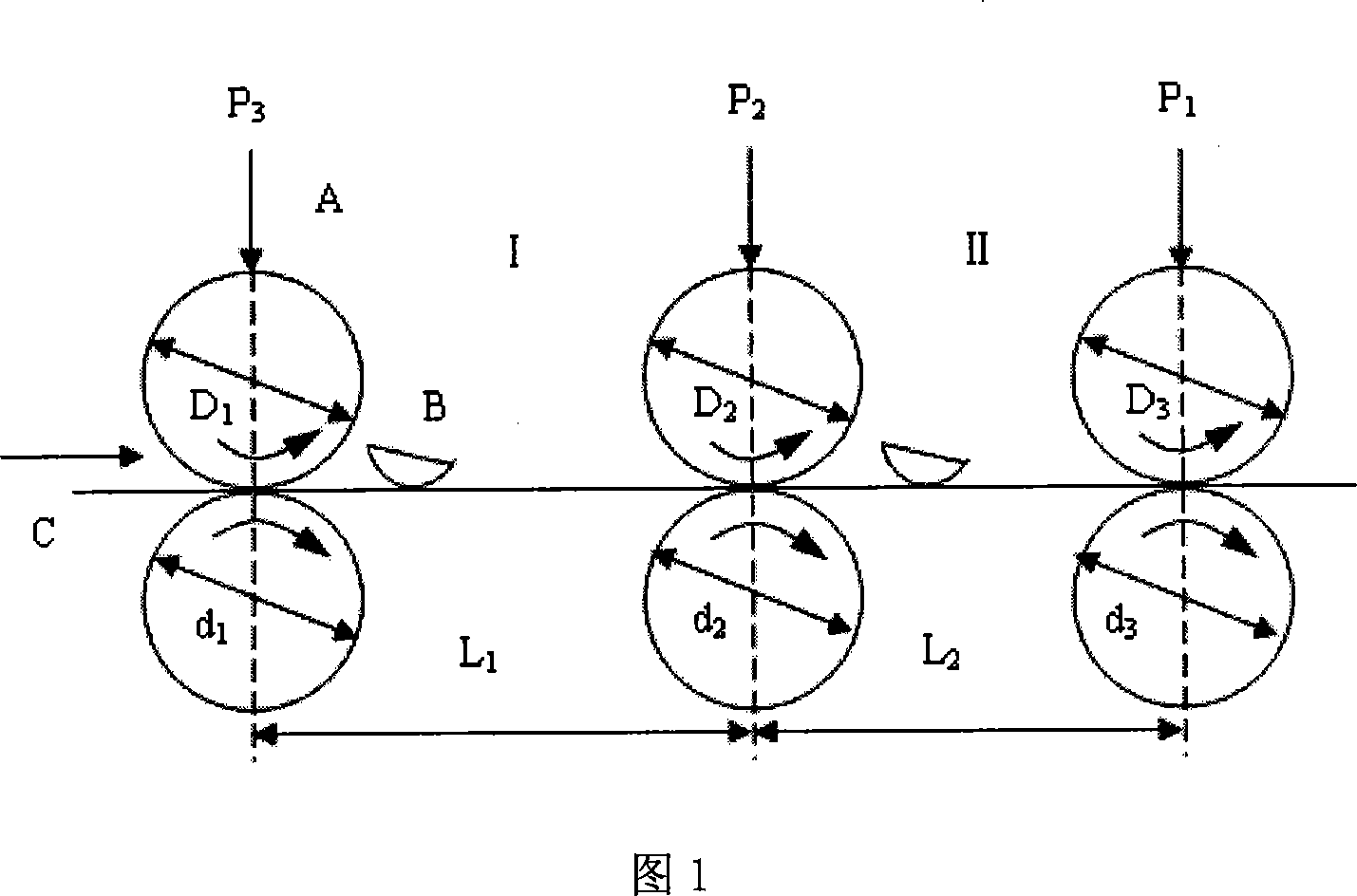

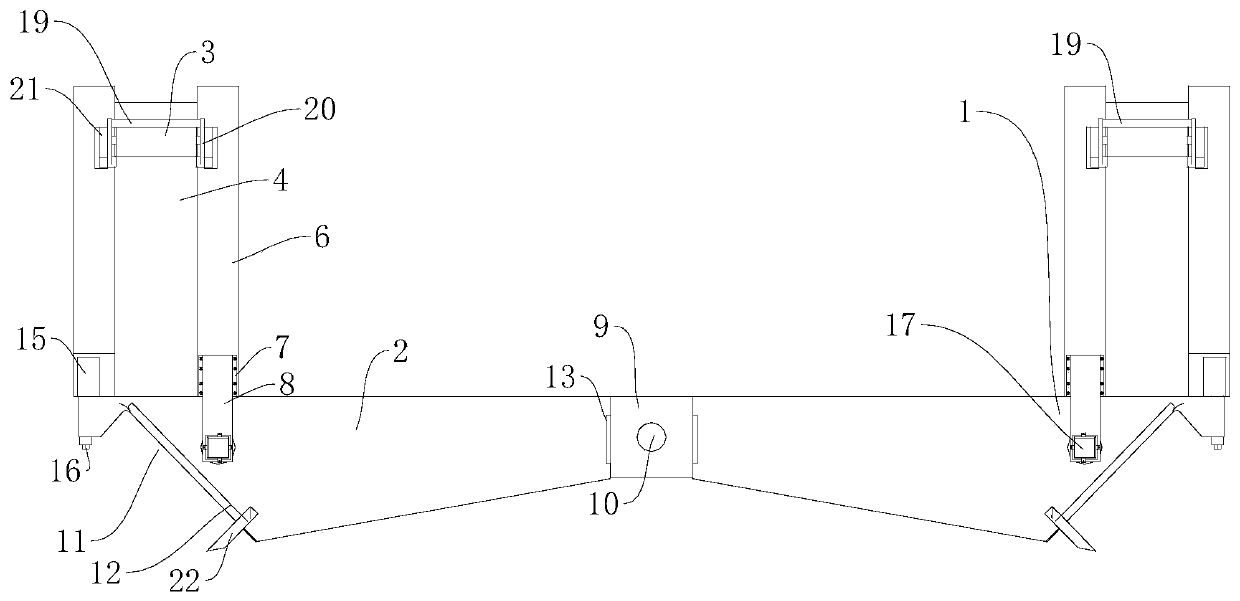

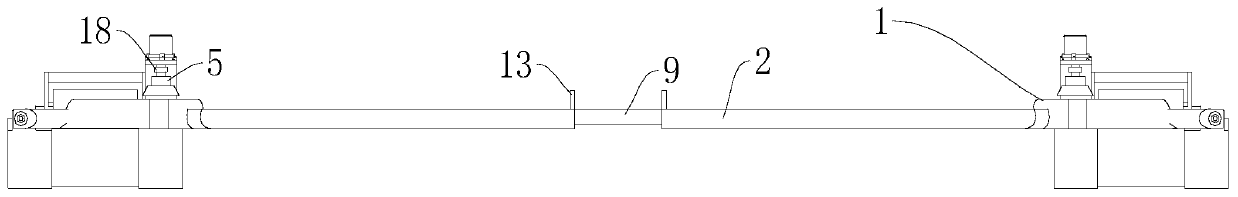

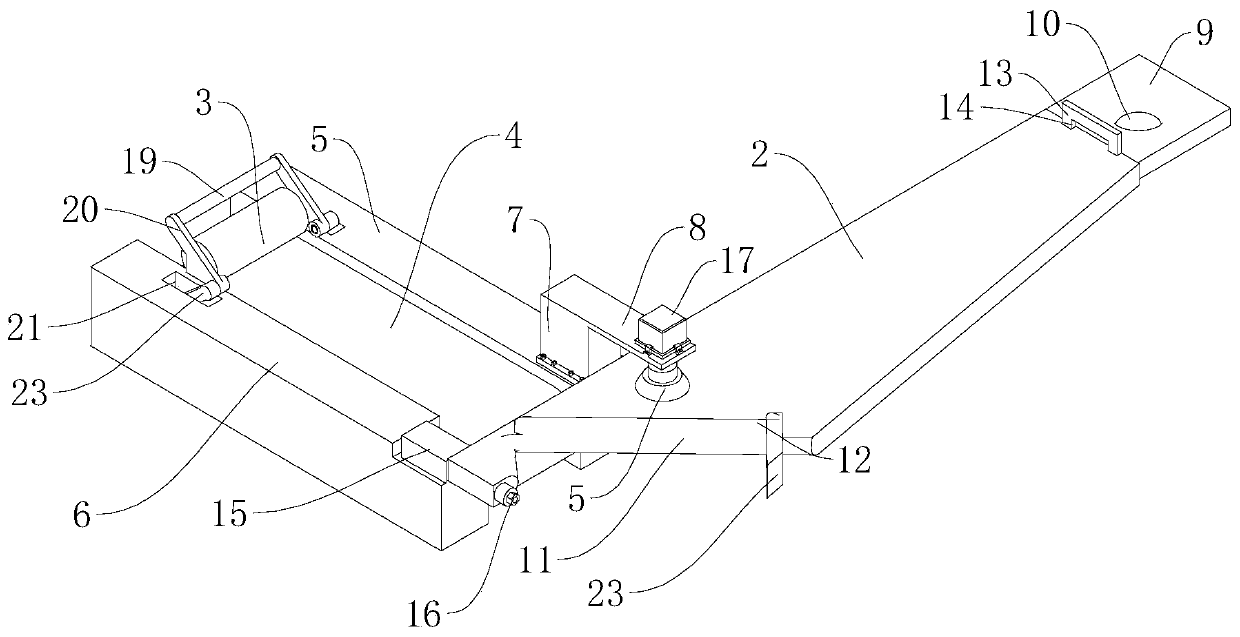

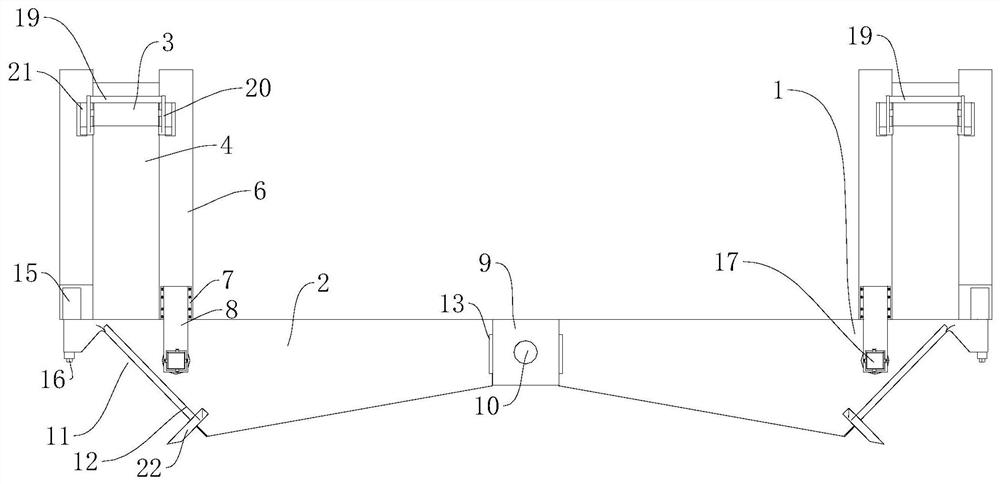

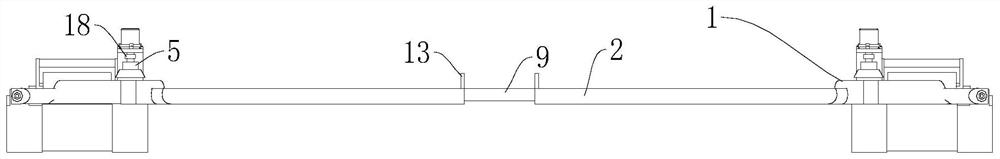

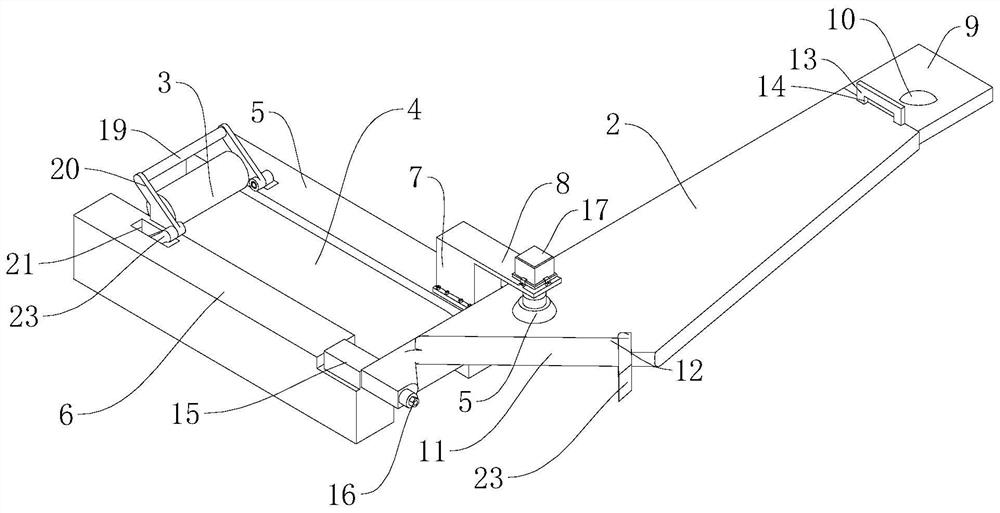

Spinning drawing-out drafting machine

The invention relates to a drawing and drafting mechanism for spinning, comprising a roller drafting device A; wherein the roller drafting device A comprises a drafting area I and a drafting area II, the two drafting areas are composed by three group rollers and rubber rollers. The drawing and drafting mechanism for spinning is characterized in that the drafting mechanism also comprises a press bar B, and doubles the drafting multiple of the back area at least and improves the drafting efficiency, greatly increases the centre distance adjusting range of the rollers in the front area and the back area, ensures successful processing of fur, hemp and silk fiber, and greatly improves the versatility of the equipment; the drawing and drafting mechanism especially considers the usage in the experiment, so the delivery speed can be adjusted between 30m / min to 300m / min, thereby meeting the requirement of parameter adjusting in various processing and experiment, and avoiding the waste of raw material.

Owner:DONGHUA UNIV

Manufacturing method for polyacrylonitrile-based carbon fiber protofilament

ActiveCN102953142ADrafting smoothlyHigh breaking strengthArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentWater bathsBreaking strength

The invention provides a preparation method for a polyacrylonitrile-based carbon fiber protofilament. The third monomer of a spinning raw material polyacrylonitrile resin is itaconic acid. The preparation method comprises the following successive steps: preparing a spinning solution from the resin by using an aqueous solution of NaSCN and carrying out spinning and solidification so as to prepare a nascent fiber; placing the nascent fiber in the aqueous solution of NaSCN for water bath drafting and carrying out drip washing with deionized water; dipping the nascent fiber in an acidic aqueous solution; dipping the nascent fiber in a sodium hydroxide or potassium hydroxide aqueous solution; placing the nascent fiber in pure water for water bath drafting; subjecting the nascent fiber to hot bath rinsing until rinsing liquid is neutral and sodium or potassium ions cannot be measured, and then continuing rinsing for 5 to 15 min; and carrying out post-processing procedures like oiling and dry densification on the nascent fiber so as to obtain a product of the polyacrylonitrile-based carbon fiber protofilament. According to the invention, purification of the protofilament is realized through rinsing, and breaking strength of fibers is not affected, so the defects of the prior art are overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for polyacrylonitrile-based carbon fiber

ActiveCN102953157AHigh breaking strengthImprove mechanical propertiesArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentWater bathsCarbon fibers

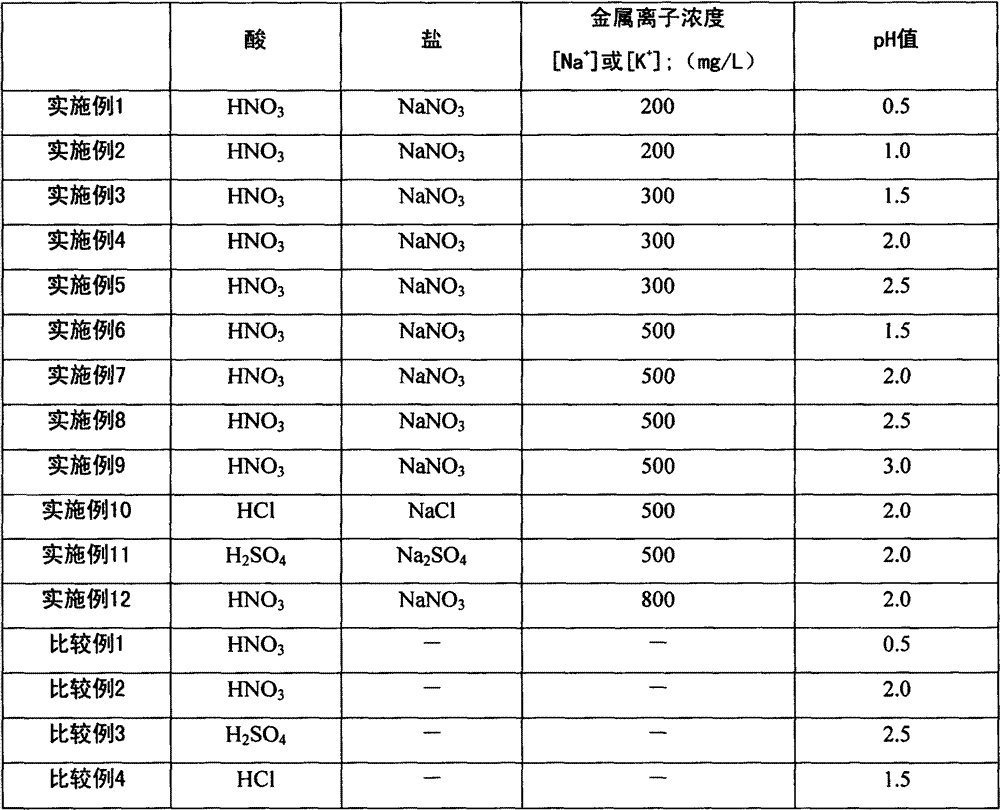

The invention provides a preparation method for a polyacrylonitrile-based carbon fiber. The third monomer of a protofilament spinning raw material polyacrylonitrile resin is itaconic acid, a spinning solution is prepared from the resin by using an aqueous solution of NaSCN as a solvent, and spinning and solidification are carried out so as to prepare a nascent fiber. The nascent fiber successively undergoes the following procedures: water bath drafting in the aqueous solution of NaSCN; drip washing with deionized water; dipping in a buffer solution containing acid A and salt B, wherein A is sulfuric acid, hydrochloric acid or nitric acid, and B is a sodium salt or a sylvite of A; water bath drafting in pure water; dipping in an acidic aqueous solution; and hot bath rinsing with deionized water until rinsing liquid is neutral. A carbon fiber protofilament is prepared by subjecting the nascent fiber to post-processing procedures like oiling and dry densification. The protofilament undergoes pre-oxidation in an aerobic atmosphere under the condition of drafting and then undergoes carbonization in an anoxic atmosphere under the condition of drafting so as to obtain a finished product of the polyacrylonitrile-based carbon fiber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of fiber for euphausia superba net rope

ActiveCN104562283AImprove breaking strength and crystallinityImprove the adaptability and spinnability of temperature difference resistanceArtificial thread manufacturing machinesConjugated synthetic polymer artificial filamentsHigh-density polyethyleneAirflow

The invention discloses a preparation method of fiber for a euphausia superba net rope. According to the preparation method, HDPE (high-density polyethylene) rubber, auxiliaries, metallocene LLDPE (linear low density polyethylene) resin, a stirrer, a single-screw extruder, a two-time drawing electrical heating drawing machine, a fiber winding device and a fiber dividing device. The preparation method is characterized in that the HDPE rubber, the auxiliaries and the metallocene LLDPE resin are mixed and stirred uniformly by the stirrer, a blend is subjected to melt extrusion by a charging barrel of the single-screw extruder, as-spun fiber obtained through melt extrusion is subjected to cooling and preliminary drawing, the fiber after the preliminary drawing is subjected to hot drawing twice, the total drawing multiple is controlled in 12.031 times, after that, airflow at the high pressure of 0.56 MPa-0.63MPa is adopted to remove oil, then the fiber is rapidly cooled, fiber bundles are divided into fiber by the fiber dividing device, and the fiber for the euphausia superba net rope is prepared.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Wool-polyester graphene elastic woolen cloth and production method thereof

ActiveCN110067067AImprove microcirculationRegularize brain wavesProtective fabricsFibre cleaning/openingPolytrimethylene terephthalatePolyethylene glycol

The invention relates to wool-polyester graphene elastic woolen cloth which is made of warps and wefts, wherein the warps are made of 40wt% of 66S wool and 60wt% of a graphene wool type polyester fiber; the wefts are made of 40wt% of 66S wool, 40wt% of the graphene wool type polyester fiber and 20wt% of a PTT (Polytrimethylene Terephthalate) fiber; the yarn count of the warps and the wefts is 72Nm / <2>; and the wool-polyester graphene elastic woolen cloth is made of the warps and the wefts in a blended manner. The invention further discloses a production method of the wool-polyester graphene elastic woolen cloth. The production method comprises steps of dyeing, repeated washing, secondary combing, former combing, yarn fining, warp finishing, drafting and denting, weaving, woolen cloth quantification, blank cloth inspection, crude finishing, aftertreatment, and finished product making. The wool-polyester graphene elastic woolen cloth has the advantages that the product is made of wool, the graphene modified PET (Polyethylene Glycol Terephthalate) fiber and the PTT fiber as main raw materials through procedures of bar dyeing, spinning, weaving and aftertreatment, and through the optimization of repeated combing and spinning and after finishing processes, the uniformity and the product quality of the yarns can be improved, and the product has properties of anti-electrostatic properties, ultraviolet resistance, and the like.

Owner:ZHEJIANG FURUN SILK SPINNING

Blending broken-silk spinning elastic slubby yarn and preparation method thereof

The invention relates to a spinning yarn and in particular to a preparation method and application for a broken-silk spinning elastic slubby yarn with healthcare functions of beautifying and caring skin and resisting an ultraviolet ray. The slubby yarn comprises spandex filaments, anti-pilling polyester fibers, emerald fibers, anti-bacterial deodorized acrylic fibers and wool fibers. Clothes processed by the slubby yarns have the characteristics of skin care, ultraviolet resistance, moisture absorption and ventilation, stiffness and smoothness, good skin-friendliness, antibiosis and deodorization, gentle gloss, light texture, high resilience, good dyeing property, good fullness, soft hand feeling, nobleness and elegance, abundant color, variable pattern, unique style, good comfort, and good abrasive resistance. Untoward effect cannot be produced by contacting with the human body, and a product cannot be easily damaged by worms and decayed, and has the healthcare function of caring skin and exercising body. The use of the product is extensive, and the processed product is dressed lightly and comfortably, and is suitable for producing top-grade fabric, decoration cloth and beddings and so on.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Blended and worsted broken color frame yarn and preparing method thereof

The invention relates to yarn with a healthcare function, in particular to a preparing method and application of blended and worsted broken color frame yarn with the functions of being antimicrobial, deodorizing, moisture-absorbing, sweat-perspiring and health-care. The blended and worsted broken color frame yarn is composed of polyester filament yarn, color moisture-absorbing and sweat-perspiring Cooldry fiber, color aloe fiber, color antimicrobial and deodorizing acrylic fiber and wool fiber. The blended and worsted broken color frame yarn of the polyester filament yarn, the color moisture-absorbing and sweat-perspiring Cooldry fiber, the color aloe fiber, the color antimicrobial and the deodorizing acrylic fiber and wool fiber has the functions of being antimicrobial, deodorizing, moisture-absorbing, sweat-perspiring and the like, processed fabric is stiff and smooth, good in shape maintenance, comfortable to wear, rich in color, bright and natural, good in skin-friendly performance, antimicrobial, deodorizing, moisture-absorbing, sweat-perspiring, breathable, easy to spread and quick to dry, can quickly drain moisture of the human body and is quick to dry, excellent in antistatic effect and friendly to skin and nourishes the skin, when the fabric is in contact with the human skin, microelements can be gradually dissolved out, the effect of preventing the skin from aging is achieved, and the blended and worsted broken color frame yarn is suitable for producing high-end fabric, beddings and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A kind of wool polyester graphene elastic cloth and production method thereof

ActiveCN110067067BImprove microcirculationRegularize brain wavesProtective fabricsFibre cleaning/openingPolyesterPolymer science

The invention relates to a kind of wool polyester graphene elastic cloth, the warp yarn of the wool polyester graphene elastic cloth adopts 40wt% 66S wool and 60wt% graphene wool type polyester fiber, the weft yarn of the wool polyester graphene elastic cloth adopts 40wt% 66S wool, 40wt% graphene wool type polyester fiber and 20wt% PTT fiber, the yarn count of warp and weft is 72Nm / 2, and the wool polyester graphene stretch cloth is blended by warp and weft; also disclosed Its production method includes the following steps: dyeing→rewashing→recombing→pre-spinning→spinning→warping→drawing and reeding→weaving→measurement→grey cloth inspection→raw repair→finishing→finished product. The advantage of the present invention is that the product is made of wool, graphene-modified PET fiber and PTT fiber as main raw materials, processed through processes such as stripe dyeing, spinning, weaving, and finishing, and is processed through combing, spinning, and finishing processes. The optimization of the yarn improves the uniformity of the yarn and the quality of the product, and the product has antistatic and anti-ultraviolet properties.

Owner:ZHEJIANG FURUN SILK SPINNING

A method of manufacturing polyacrylonitrile-based carbon fiber

ActiveCN102953158BHigh breaking strengthImprove mechanical propertiesFibre chemical featuresWet spinning methodsWater bathsCarbon fibers

The invention provides a manufacturing method for a polyacrylonitrile-based carbon fiber. The third monomer of a protofilament spinning raw material polyacrylonitrile resin is itaconic acid, a spinning solution is prepared from the resin by using an aqueous solution of NaSCN, and spinning and solidification are carried out so as to prepare a nascent fiber. The nascent fiber successively undergoes the following procedures: water bath drafting in the aqueous solution of NaSCN; drip washing with deionized water; dipping in an acidic aqueous solution; dipping in a sodium hydroxide or potassium hydroxide aqueous solution; water bath drafting in pure water; and rinsing with deionized water until rinsing liquid is neutral and sodium or potassium ions cannot be measured, and continued rinsing for 5 to 15 min. A carbon fiber protofilament is prepared by subjecting the nascent fiber to post-processing procedures like oiling and dry densification. The protofilament undergoes pre-oxidation in an aerobic atmosphere under the condition of drafting and then undergoes carbonization in an anoxic atmosphere under the condition of drafting so as to obtain a finished product of the polyacrylonitrile-based carbon fiber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for polyacrylonitrile-based carbon fiber

ActiveCN102953152AGood purification effectImprove mechanical propertiesArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentSolventChemistry

The invention provides a preparation method for a polyacrylonitrile-based carbon fiber. The third monomer of a protofilament spinning raw material, i.e., polyacrylonitrile resin, is itaconic acid; a spinning solution is prepared from the resin by using DMSO or DMAc, and spinning and solidification are carried out so as to prepare a nascent fiber. The nascent fiber successively undergoes the following procedures: water bath drafting in an aqueous solution of a spinning solvent; drip washing with deionized water; dipping in a buffer solution containing acid A and salt B, wherein A is sulfuric acid, hydrochloric acid or nitric acid, and B is a sodium salt or a sylvite of A; water bath drafting in pure water; dipping in an acidic aqueous solution; and hot bath rinsing with deionized water until rinsing liquid is neutral. A carbon fiber protofilament is prepared by subjecting the nascent fiber to post-processing procedures like oiling and dry densification. The protofilament undergoes pre-oxidation in an aerobic atmosphere under the condition of drafting and then undergoes carbonization in an anoxic atmosphere under the condition of drafting so as to obtain a finished product of the polyacrylonitrile-based carbon fiber.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of polyacrylonitrile base carbon fiber

ActiveCN102953153BHigh breaking strengthImprove mechanical propertiesWet spinning methodsFibre chemical featuresCarbon fibersSpinning

The invention provides a preparation method for a polyacrylonitrile-based carbon fiber. The third monomer of a spinning raw material of a carbon fiber protofilament, i.e., polyacrylonitrile resin, is itaconic acid; a spinning solution is prepared from the resin by using an aqueous solution of NaSCN, and spinning and solidification are carried out so as to prepare a nascent fiber. The nascent fiber successively undergoes the following procedures: water bath drafting in the aqueous solution of NaSCN; drip washing with deionized water; dipping in a buffer solution containing acid A and salt B, wherein A is sulfuric acid, hydrochloric acid or nitric acid, and B is a sodium salt or a sylvite of A; water bath drafting in pure water; and hot bath rinsing with deionized water until rinsing liquid is neutral and sodium or potassium ions cannot be measured, and continued rinsing for 5 to 15 min. The carbon fiber protofilament is prepared by subjecting the nascent fiber to post-processing procedures like oiling and dry densification. The protofilament undergoes pre-oxidation in an aerobic atmosphere under the condition of drafting and then undergoes carbonization in an anoxic atmosphere under the condition of drafting so as to obtain a finished product of the polyacrylonitrile-based carbon fiber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of composite monofilament for netting gear manufacture

ActiveCN103147149BGood adaptability for fishingSilk is normalMelt spinning methodsMonocomponent polyolefin artificial filamentWinding machineTorque motor

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Preparation method of monofilament for net cage body and trawl fishing gear

ActiveCN103147150BGood adaptability for fishingImprove spinnabilityMelt spinning methodsMonocomponent polyolefin artificial filamentWinding machineTorque motor

A preparation method of a monofilament for net cage body and trawl fishing gear. The invention employs a mixer, a double-screw extruder, a single-screw extruder, a secondary drafting electric heating draw machine, a winding machine using a torque motor, a filament splitting machine, a spinning grade drying HDPE resin, nanometer drying ZnO and a turpentine assistant for spinning. The method is characterized by comprising the steps of: mixing the spinning grade drying HDPE resin, the nanometer drying ZnO and the turpentine assistant for spinning; stirring the mixture with a mixer to a uniform state; granulating the thoroughly mixed mixture by the twin-screw extruder to obtain the blend pellets; subjecting the blend pellets to melt extrusion by the single-screw extruder; subjecting the primary monofilament obtained from melt extrusion to cooling and a preliminary drafting; subjecting the composite monofilament from preliminary drafting to two times of hot drafting, then high-pressure airflow oil removal and fast cooling; winding the monofilament by the winding machine using torque motor; and splitting the monofilament by the filament splitting machine into a energy-saving and emission-reducing monofilament for net cage body and trawl fishing gear.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Preparation method of rectangular separation net for deep and far sea culture

ActiveCN114775162AImprove antifouling functionNot easy to failTextile selvedgesClimate change adaptationPhosphoric Acid EstersPropanoic acid

The invention provides a preparation method of a rectangular separation net for deep and far sea culture, which comprises the following steps: preparing a blended antifouling composite material, preparing a light blue monofilament bundle, preparing a rectangular separation net, and mixing polypropylene granules, a polyhexamethylene guanidine hydrochloride grafted modified polypropylene antifouling material, nano copper powder, pyrithione copper powder, tetra [beta-(3, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4-trimethyl-1, 3, 4- 2, 5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, tri (1, 2, 2, 6, 6-pentamethylpiperidinyl) phosphite, phthalocyanine blue pigment, titanium dioxide and turpentine are mixed and uniformly stirred, extrusion granulation is performed 2-3 times through a double-screw extruder to obtain a blended antifouling composite material, light blue monofilament tows are obtained after wire drawing and rolling, and the light blue monofilament tows are used as raw materials. And obtaining the rectangular separation net for deep and far sea culture by using a special rectangular separation net preparation method.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

A kind of manufacture method of polyacrylonitrile-based carbon fiber

ActiveCN102953154BHigh breaking strengthImprove mechanical propertiesArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentWater bathsCarbon fibers

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for making round wire for processing grouper breeding net

ActiveCN104562237BWith wear resistanceEnsure industrialized processing and productionMelt spinning methodsWinding machineLinear low-density polyethylene

Disclosed is a fabrication method for round filaments for producing grouper culture nets. Auxiliaries, high-density polyethylene (HDPE) resins, metallocene linear low density polyethylene (LLDPE) resins, a stirring machine, a single-screw extruder, a twice-drawing electrical heating drawing machine, a filament winding machine and a filament split machine. The method is characterized in that the auxiliary adding amount is 0.36% to 0.47% of the weight of the HDPE resins, the HDPE resin melt index should meet 0.8 grams / 10minutes to 1.3 grams / 10minutes, and the metallocene LLDPE resin adding amount is 14.3% to 15.7% of the weight of the HDPE resins. The auxiliaries, the HDPE resins and the metallocene LLDPE resins are mixed and stirred uniformly to obtain HDPE / metallocene LLDPE resin mixtures which are fused extruded through the single-screw extruder, the fused extruded primary filaments are cooled and pre-drawn, the pre-drawn filaments are subjected to twice thermal drawing and are wound into round filament beams after un-oiled through high-pressure air flows. The round filament beams are split into round filaments for producing grouper culture nets by the filament split machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Method for processing high-performance modified polyethylene monofilaments for manufacturing fishing net

InactiveCN101851795BIncrease heat treatment temperatureHigh breaking strengthSpinning head liquid feederFilament manufactureWinding machineElastomer

The present invention discloses a method for processing high-performance modified polyethylene monofilaments for manufacturing a fishing net, relates to a method for processing polyethylene monofilaments for manufacturing a fishing net and aims to provide a method for processing the high-performance modified polyethylene monofilaments for manufacturing the fishing net. In the technical scheme of the invention, a stirring machine, a single-screw extruder, a twice-drafting electrical heating drafting machine, a filament winding machine and a filament separating machine are adopted. The method is characterized by comprising the following steps of: mixing a sieved spinning-grade dry HDPE resin, a dry VERSIFYTM 6002 elastomer, white oil or a turpentine aid; uniformly mixing the materials to obtain an HDPE / VERSIFYTM 6002 elastomer blend and fusing and extruding the blend by using the single-screw extruder; cooling and pre-drafting fused and extruded primary filaments, thermally drafting the pre-drafted filaments twice, rapidly cooling the thermally-drafted filaments from which oil is removed with high-pressure air current and winding modified PE monofilaments by using the winding machine; and separating the modified PE monofilaments into the high-performance modified polyethylene monofilaments for manufacturing the fishing net by using the filament separating machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Preparation method of fiber for seawater fish breeding net clothing

ActiveCN104562284BImprove performanceReduce consumptionFilament forming substance formingConjugated synthetic polymer artificial filamentsLinear low-density polyethyleneFiber bundle

The invention provides a manufacturing method of fibers of breeding nets of sea fish. The manufacturing method adopts HDPE (high-density polyethylene) resin, an auxiliary agent, metallocene LLDPE (linear low density polyethylene) resin, a stirring machine, a single-screw extrusion machine, a twice-drawing electrical heating drawing machine, a silk collecting machine and a silk dividing machine. The manufacturing method is characterized in that the HDPE resin is sieved; the adding amount of the auxiliary agent is 0.6% of the weight of the HDPE resin; the adding amount of the metallocene LLDPE resin is 10.3% of the weight of the HDPE resin; the materials are stirred by the stirring machine for 19-31 minutes, so that the materials are uniformly stirred, and a mixture of the HDPE resin and the metallocene LLDPE resin is obtained; melt extrusion is performed on the mixture of the HDPE resin and the metallocene LLDPE resin by the single-screw extrusion machine, and primary silk obtained from melt extrusion is cooled and pre-drawn by a cooling water box and a first drawing roller; twice hot drawing is performed on the pre-drawn silk, the drawn silk is degreased by a high-pressure airflow, the degreased silk is rapidly cooled, and fiber bundles are collected and rolled by the silk collecting machine; the fiber bundles are divided into the fibers of the breeding nets of the sea fish by the silk dividing machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com