Semi-worsted porous segment color slub yarn and preparation method thereof

A slub yarn and semi-worsted spinning technology, applied in the field of yarn, can solve the problems of poor color fastness and poor dimensional stability, and achieve the effects of good dyeability, good dimensional stability and good wrinkle resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

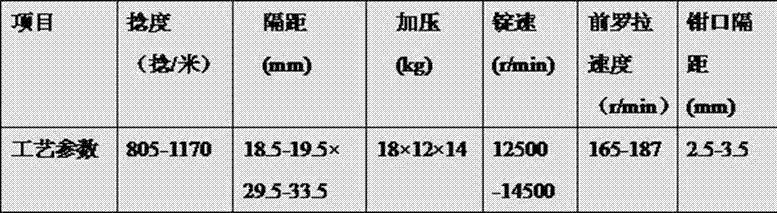

Embodiment 1

[0042] Take colored aloe vera viscose fiber, colored antibacterial hollow polyester fiber, velvet fiber, spun silk fiber and wool fiber semi-worsted porous broken color bamboo knot yarn as an example, among which wool fiber, spun silk fiber and velvet fiber Processed into roving A1 as the main roving, the percentage of blended weight is 40:30:30, while the colored aloe viscose fiber and colored antibacterial hollow polyester fiber are processed into roving B2 as decorative yarn, and the percentage of blended weight is 50: 50, the 18.9tex semi-worsted porous broken color bamboo knot yarn spun through the spinning process flow provided by the present invention, the key technical measures adopted and the spinning process, after testing, its single yarn breaking strength is 16.4cN / tex, The single yarn breaking strength coefficient of variation Cv value is 9.06%, and the evenness uniformity coefficient of variation coefficient Cv value is 16.8%. The antibacterial rate test of the kn...

Embodiment 2

[0044] Take colored aloe vera viscose fiber, colored antibacterial hollow polyester fiber, velvet fiber, spun silk fiber and wool fiber semi-worsted porous broken color bamboo knot yarn as an example, among which wool fiber, spun silk fiber and velvet fiber Processed into roving A1 as the main roving, the percentage of blended weight is 50:25:25, while the colored aloe viscose fiber and colored antibacterial hollow polyester fiber are processed into roving B2 as decorative yarn, and the percentage of blended weight is 45: 55. The 23.9tex semi-worsted porous broken color bamboo knot yarn spun through the spinning process flow provided by the present invention, the key technical measures adopted and the spinning process, after testing, its single yarn breaking strength is 16.7cN / tex, The single yarn breaking strength coefficient of variation Cv value is 10.2%, and the evenness uniformity coefficient of variation coefficient Cv value is 16.4%. The antibacterial rate test of the kn...

Embodiment 3

[0046]Take colored aloe vera viscose fiber, colored antibacterial hollow polyester fiber, velvet fiber, spun silk fiber and wool fiber semi-worsted porous broken color bamboo knot yarn as an example, among which wool fiber, spun silk fiber and velvet fiber Processed into roving A1 as the main roving, the percentage of blended weight is 30:35:35, while the colored aloe viscose fiber and colored antibacterial hollow polyester fiber are processed into roving B2 as decorative yarn, and the percentage of blended weight is 40: 60, the 26.9tex semi-worsted porous broken color bamboo knot yarn spun through the spinning process flow provided by the present invention and the key technical measures adopted and spinning processing, after testing, its single yarn breaking strength is 17.1cN / tex, The single yarn breaking strength coefficient of variation Cv value is 9.12%, and the evenness evenness coefficient of variation coefficient Cv value is 16.1%. The antibacterial rate test of the kni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com