Patents

Literature

44results about How to "Meet the requirements of environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite dust suppressant, and preparation method and use method thereof

InactiveCN102703031ADust production process is simpleLow costOther chemical processesPolyvinyl alcoholGlycerol

The invention relates to a composite pulverized coal dust suppressant, and a preparation method and use thereof. The composite pulverized coal dust suppressant comprises calcium chloride and sodium silicate with the ratio of two to one, 0.6 to 1.2% of polyvinyl alcohol, 4 to 6% of glycerol, 0.3 to 0.5% of surface active agent and water in balancing amount. The composite pulverized coal dust suppressant has the advantages as follows: all the chosen materials are common materials, which are nontoxic and harmless and can be naturally degraded, so that no secondary pollution can be caused; the preparation process is simple; after the composite pulverized coal dust suppressant is sprayed on the surface of bulk mineral material, a curing layer can be formed on the surface of bulk mineral material; the curing layer can bond grains on the surface of the bulk mineral material together so as to prevent wind and fix dust; therefore, the composite pulverized coal dust suppressant has certain economical and environmental benefits.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

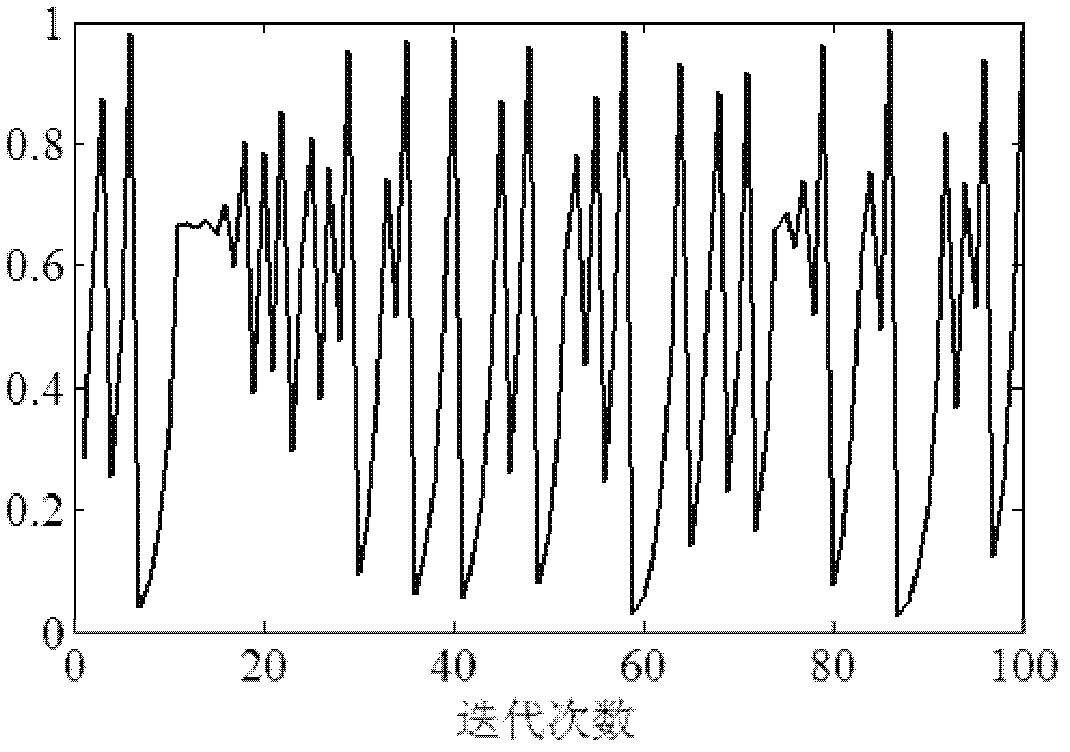

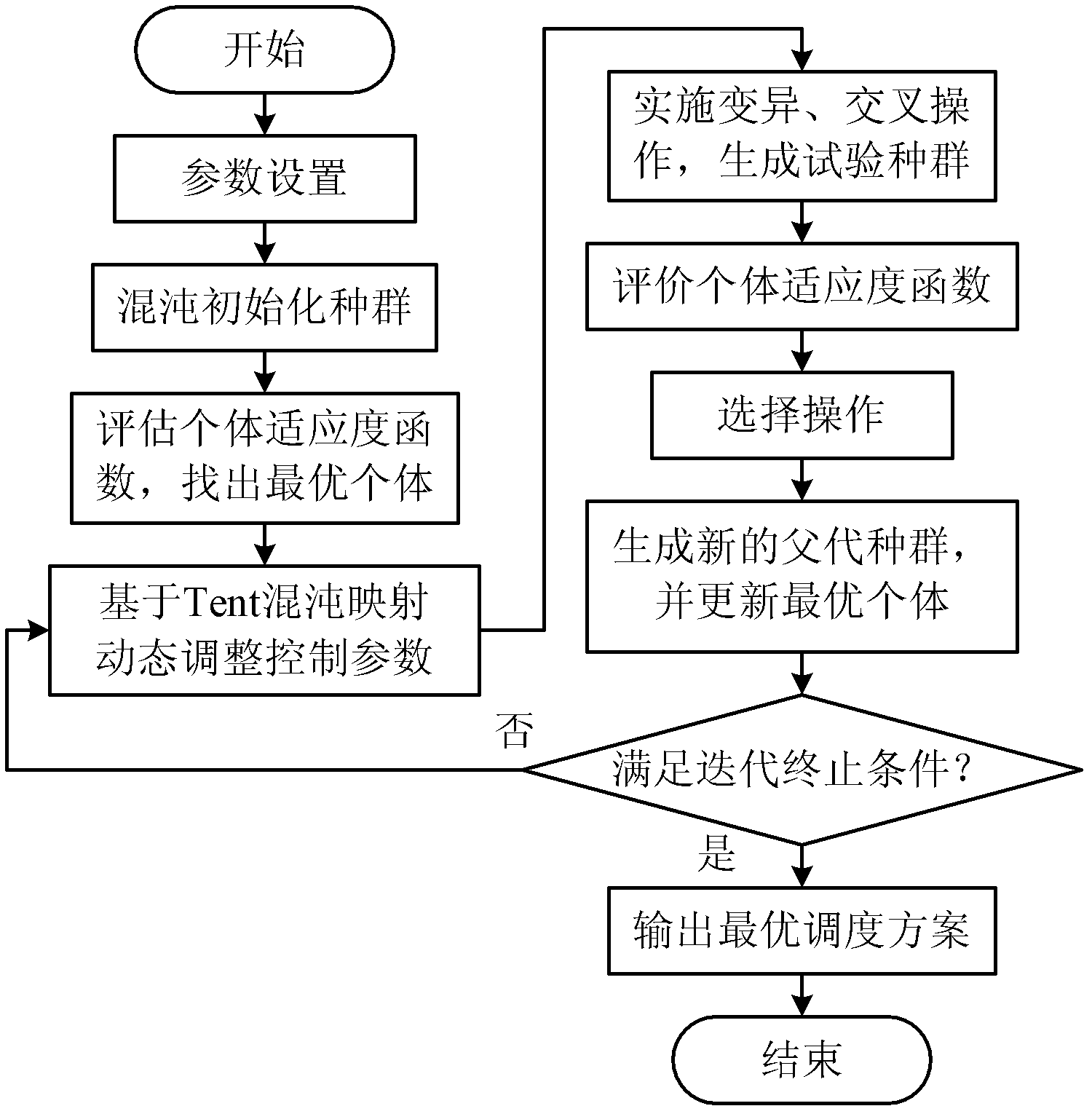

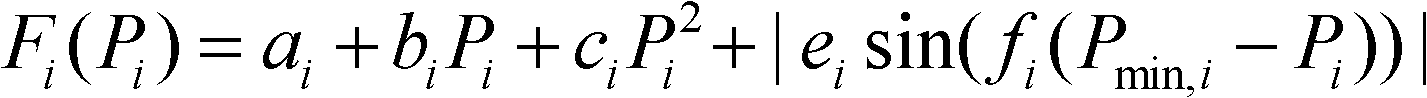

Low-carbon power generation dispatching method for wind farm

InactiveCN102646982AAccurately reflectReliable schedulingComplex mathematical operationsAc network circuit arrangementsFrame basedLow-carbon power

The invention discloses a low-carbon power generation dispatching method for a wind farm, which belongs to the field of operation and control of power systems, and includes the steps: 1) building a low-carbon power generation dispatching model for the wind farm; and 2) solving the low-carbon power generation dispatching model for the wind farm by means of a chaotic differential evolution algorithm. The low-carbon power generation dispatching method for the wind farm has the advantages that 1) actual conditions of the wind farm are more accurately reflected, so that a dispatching scheme formulated on the basis is more reliable; 2) taking CO2 emission restriction into consideration, so that the environment-friendly requirement is met; and 3) taking minimization of fuel cost of a fuel coal fossil power plant as the purpose, so that dispatching economy is guaranteed. The low-carbon power generation dispatching method for the wind frame based on the chaotic differential evolution algorithm can effectively solve the problems of high dimension, non-convexity, nonlinearity and multiple restrictions in power generation dispatching of the power systems, and can overcome the shortcomings of easiness in local convergence and prematurity of a standard differential evolution algorithm.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

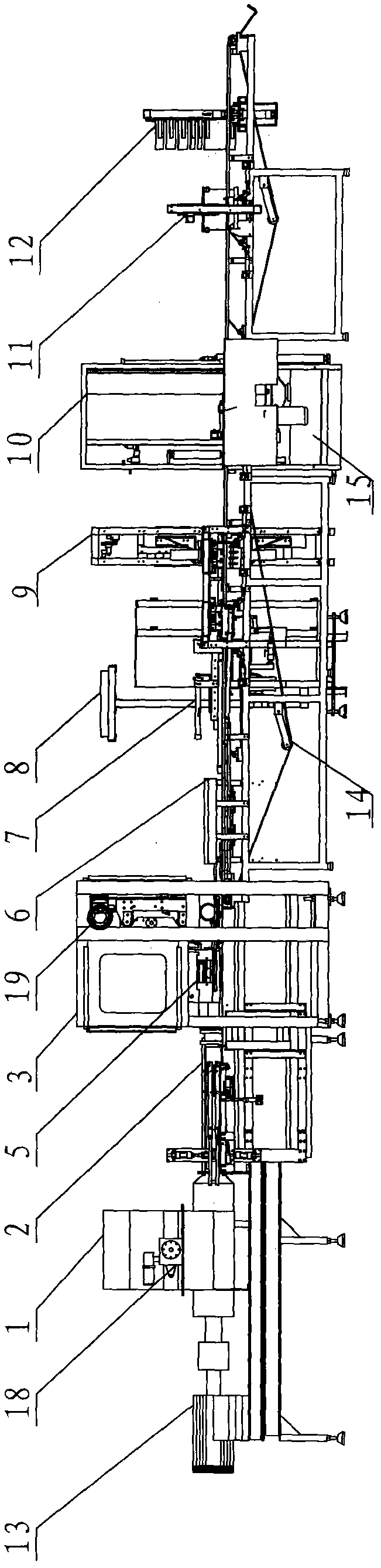

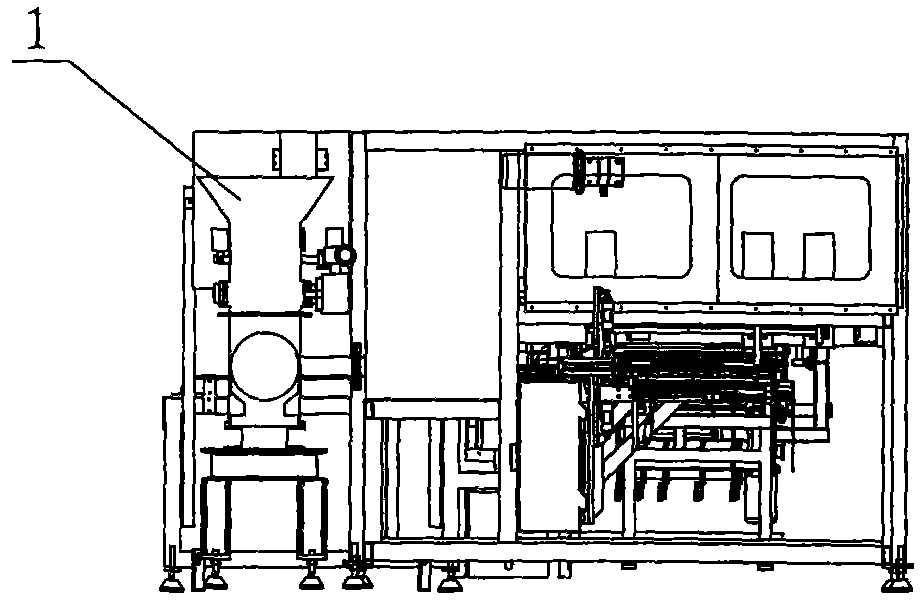

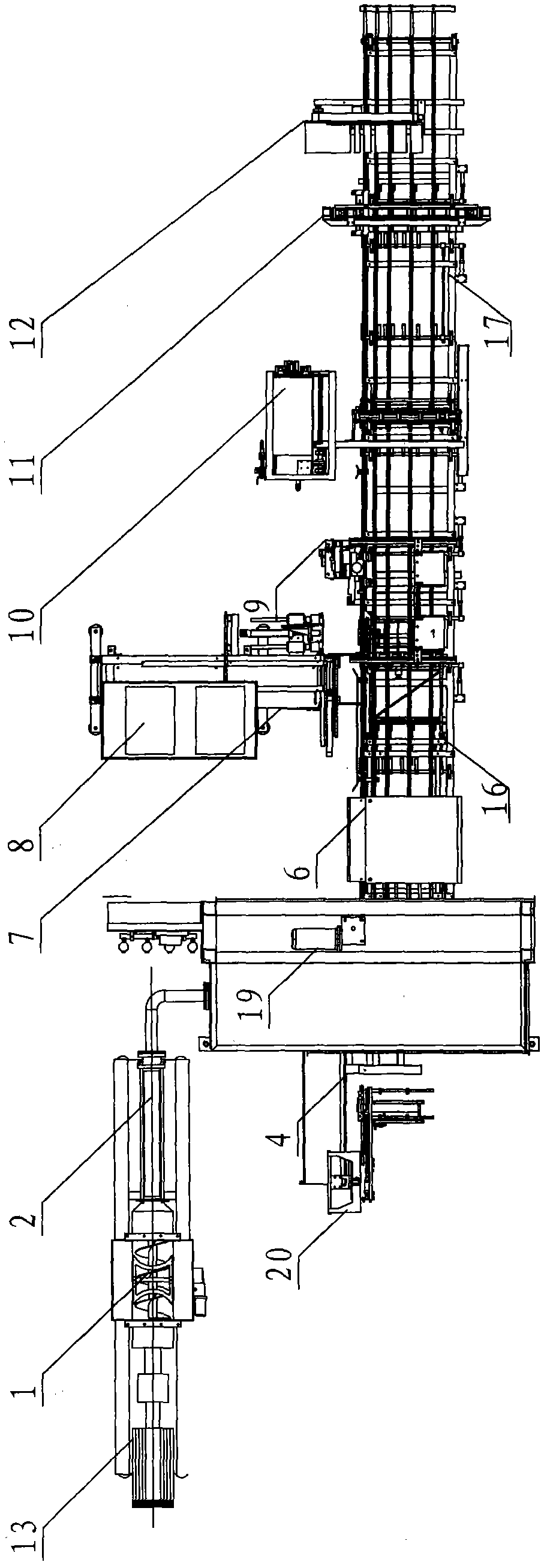

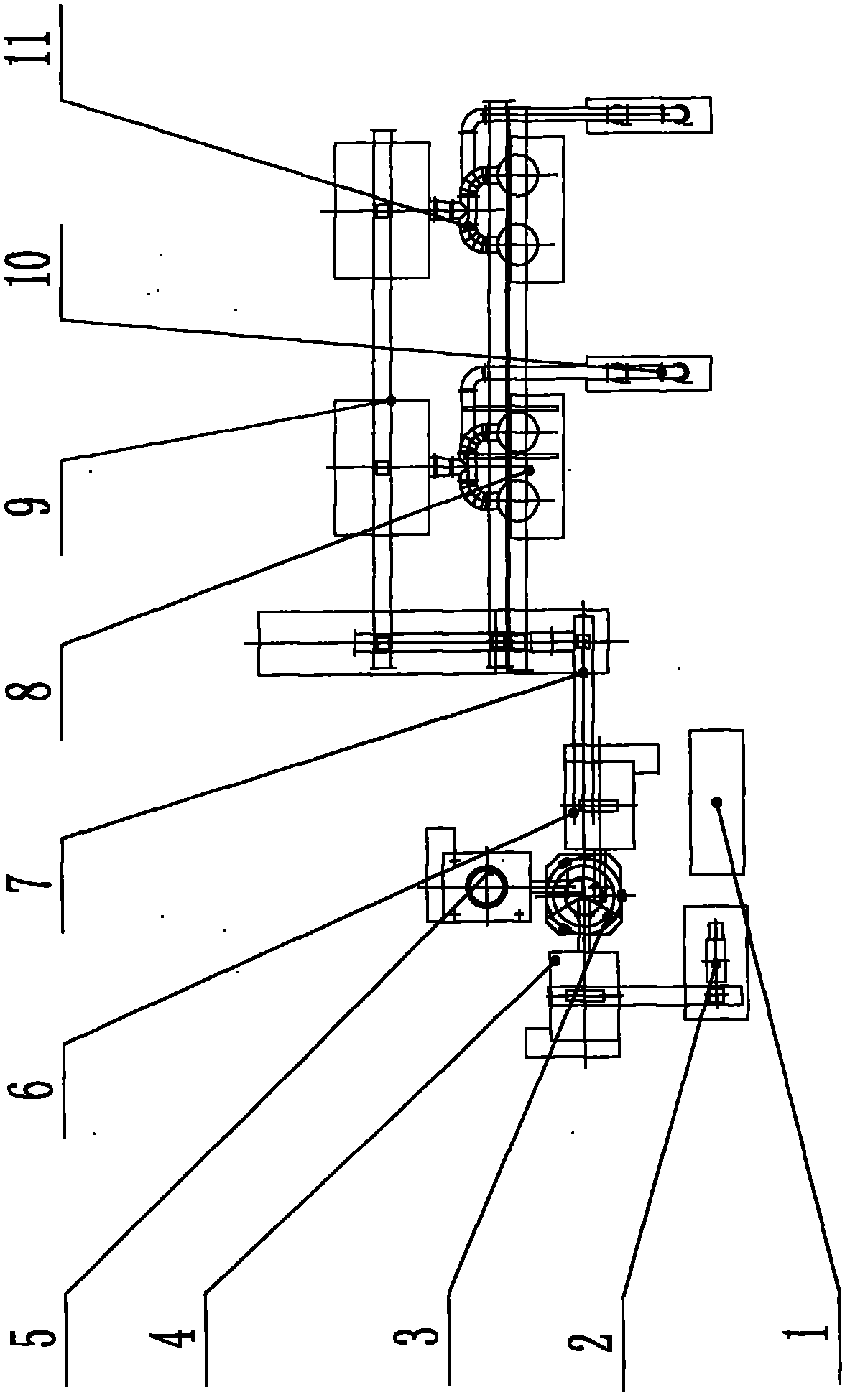

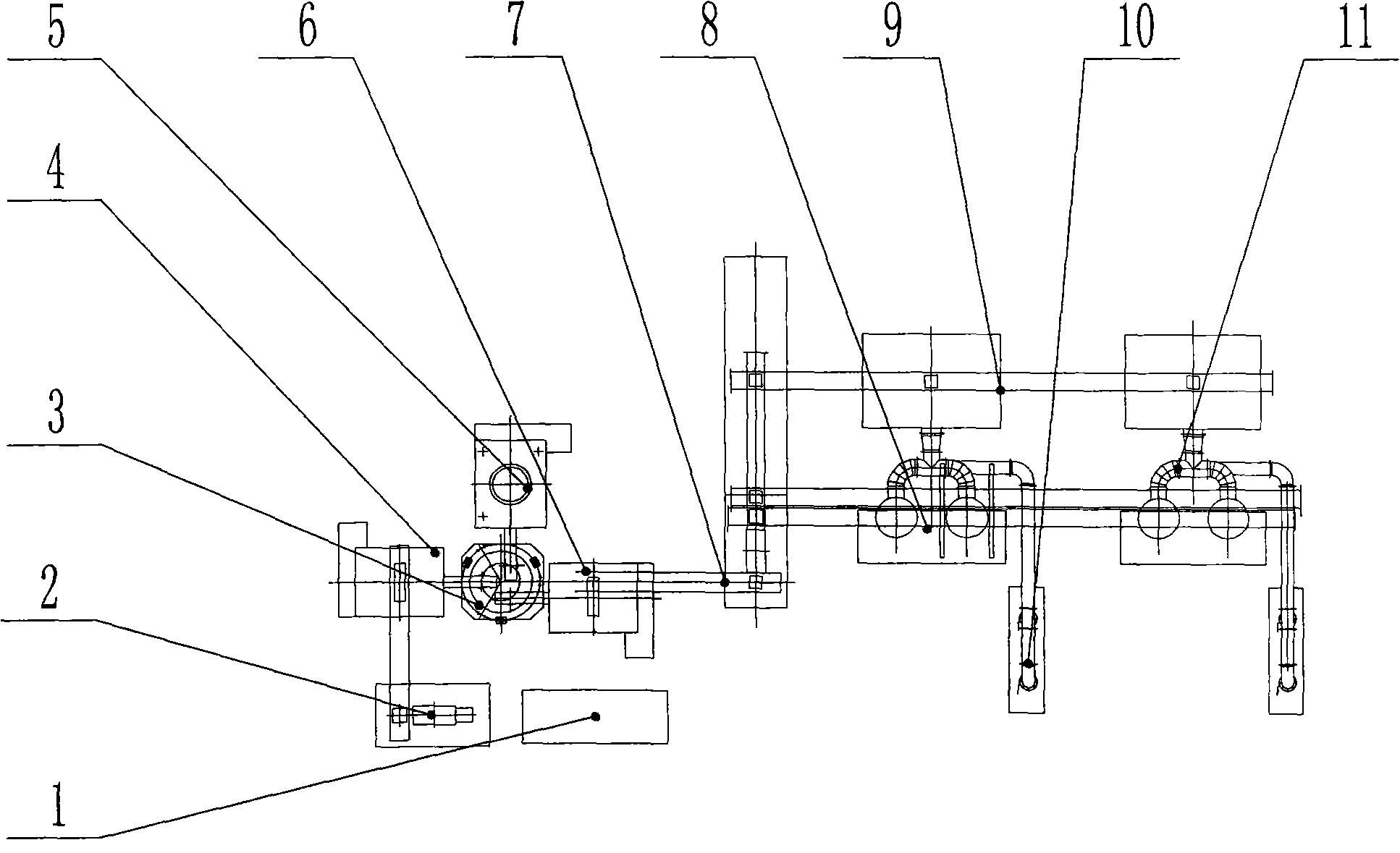

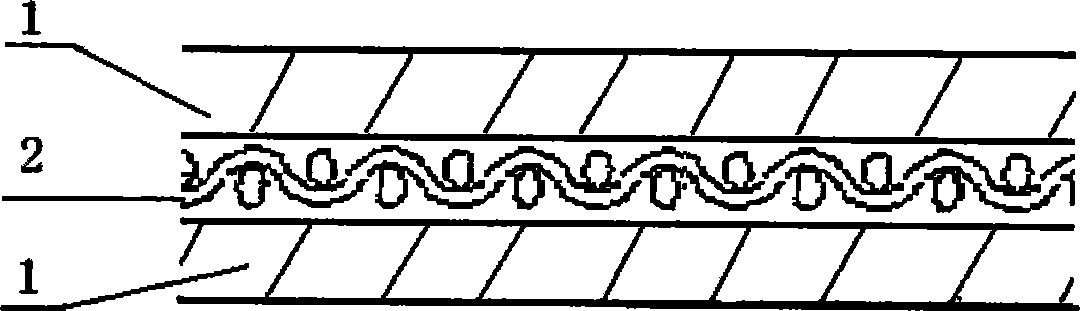

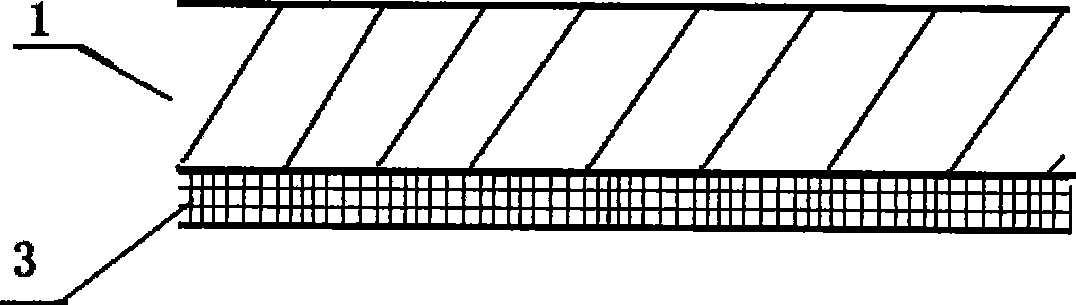

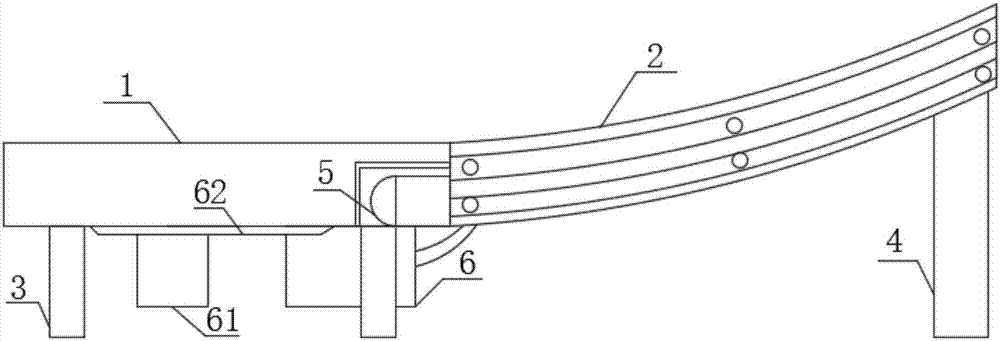

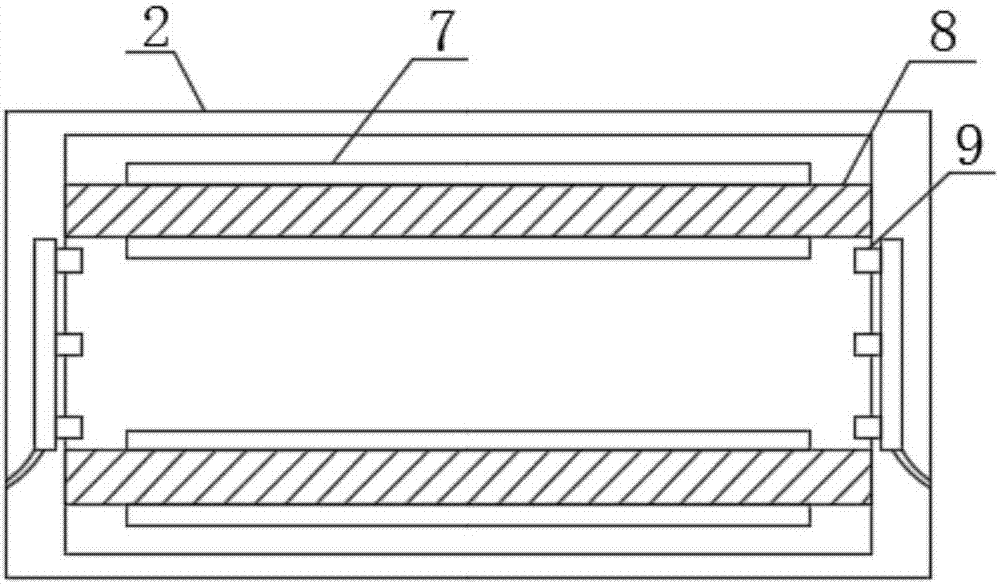

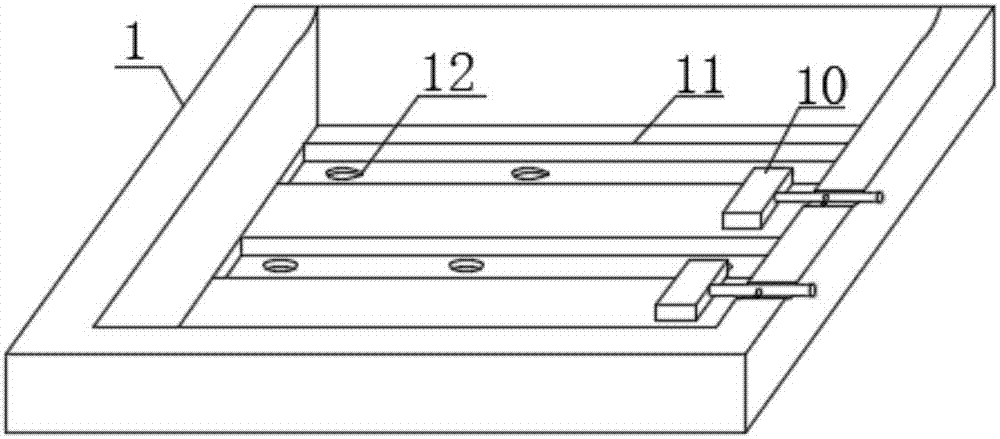

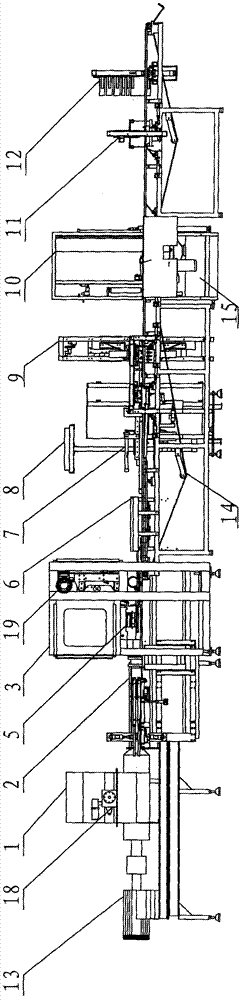

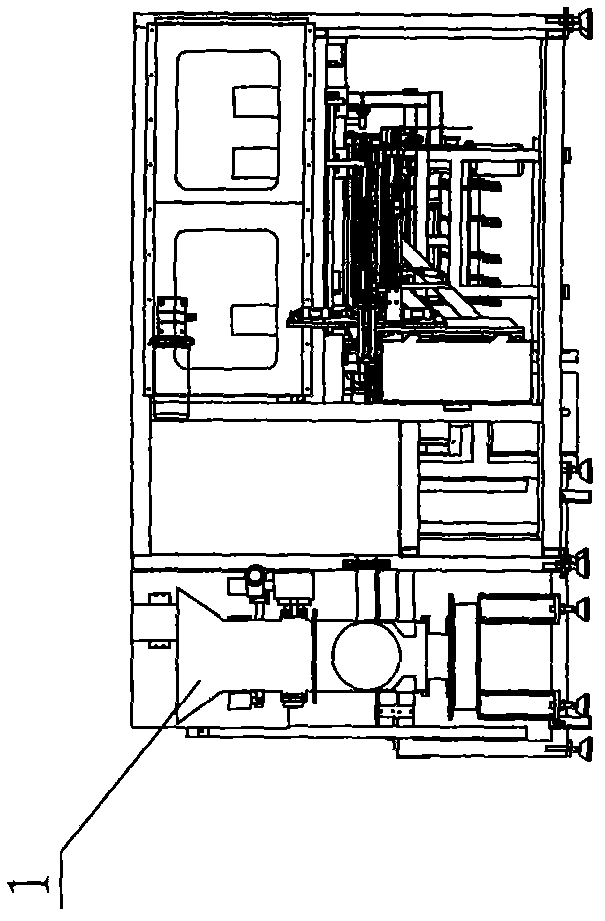

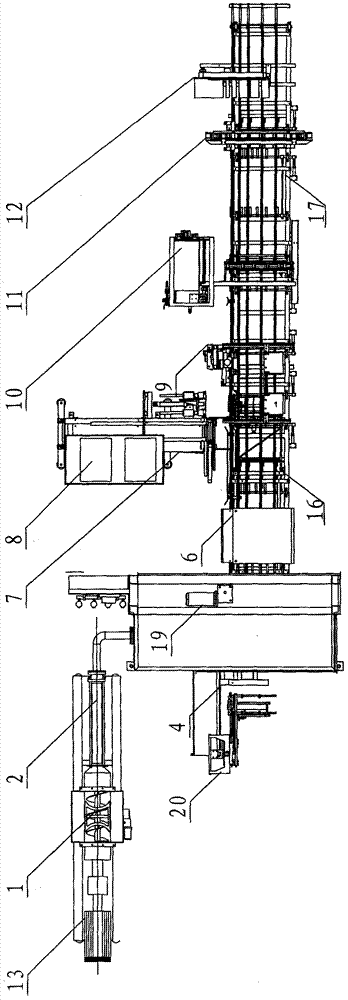

Tube-type slab lattice paste extrusion production line

ActiveCN102136571AGuaranteed performanceAvoid flyingLead-acid accumulator electrodesControl systemUltrasonic welding

The invention relates to a tube-type slab lattice paste extrusion production line. The tube-type slab lattice paste extrusion production line is characterized in that: a lead paste stirring motor is arranged in a paste extrusion bucket; the paste extrusion bucket is arranged on a paste extrusion rack; the lead paste delivery pipe is arranged on the lower part of the paste extrusion bucket and is connected with a paste extrusion head; and a slab lattice clamp device, a sliding table moving device, a primary paste extruding and washing device, a 1# polar plate delivery device, a back cover delivery device, a welding control system, an ultrasonic welding device, a secondary paste extruding and washing device, a 2# polar plate delivery device, a paste weighing device and a waste plate removing device are arranged behind the lead paste delivery pipe in turn. The tube-type slab lattice paste extrusion production line is improved on the basis of an original storage battery tube-type slab lattice which extrudes lead paste directly, and has the characteristics of reliable performance, environment friendliness, and capacity of filling a row gate tube of a storage battery with the lead pasteuniformly and the like.

Owner:ZIBO XINXU POWER SUPPLY TECH

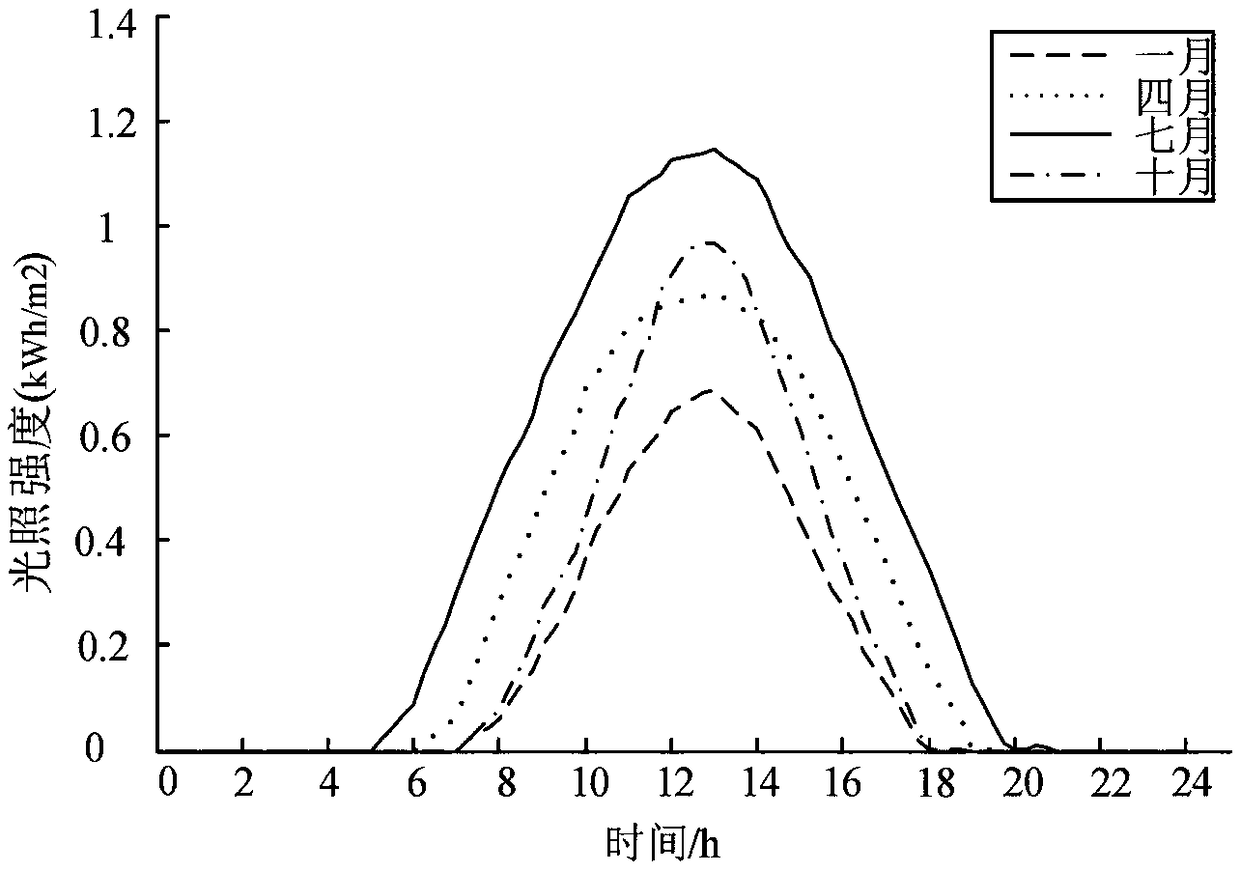

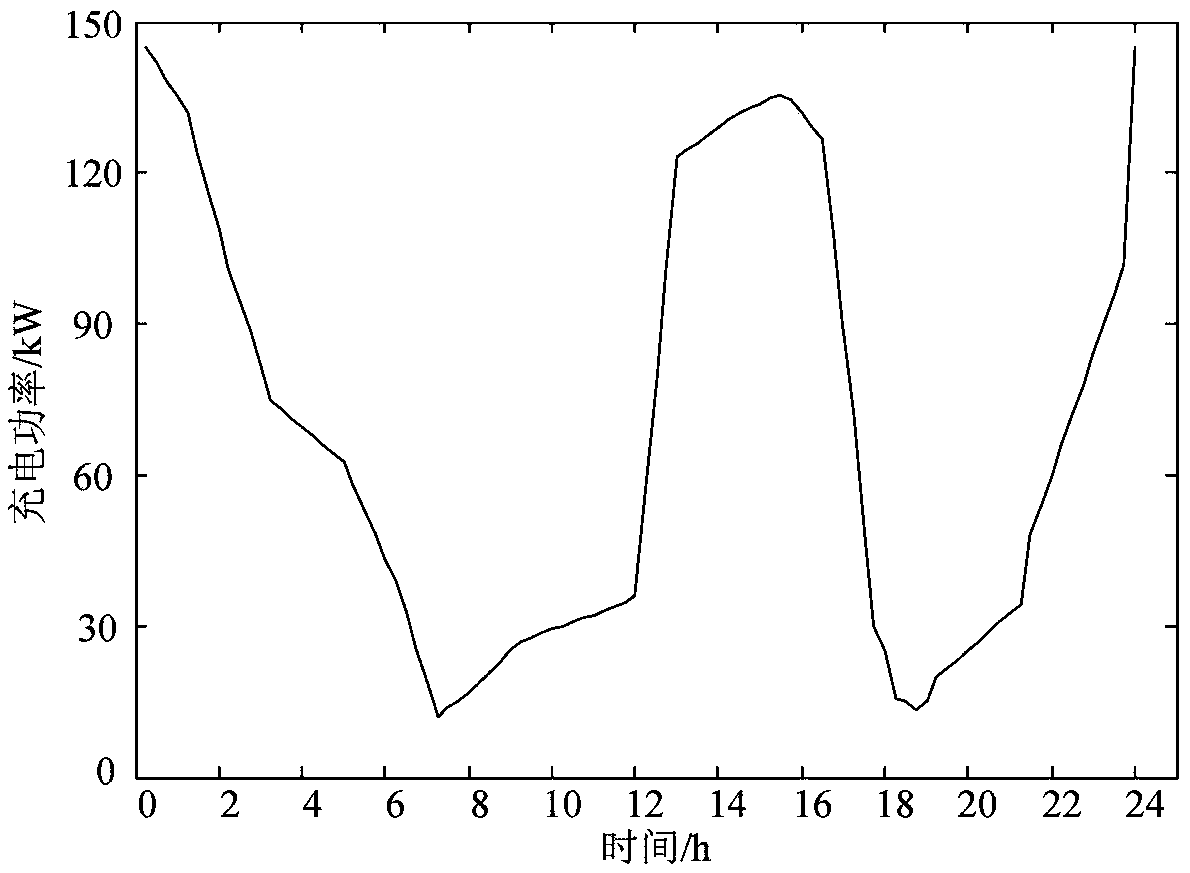

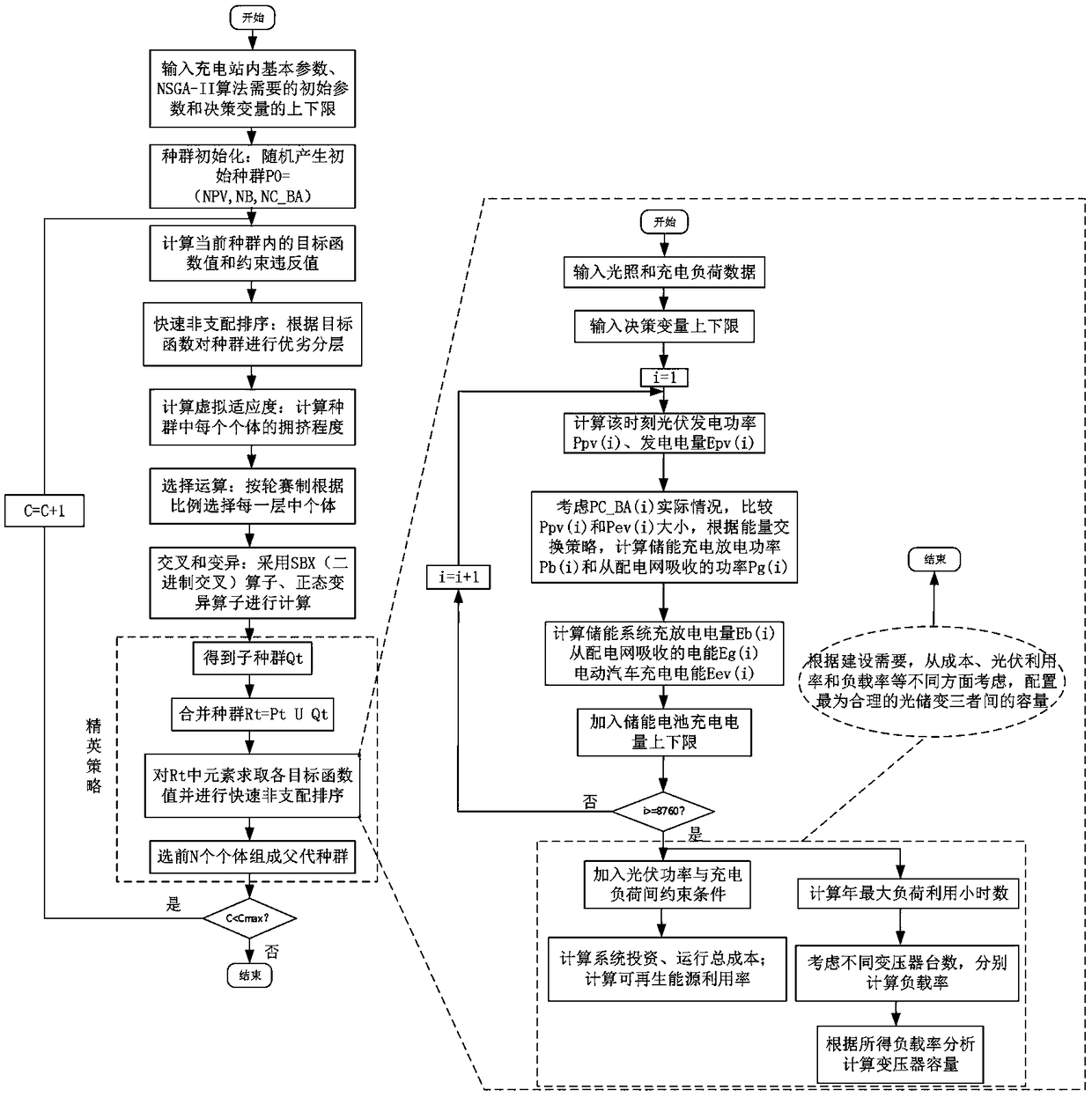

Coordinative optimization configuration method for capacity of photovoltaic array, energy storage device and transformer of photovoltaic charging station

InactiveCN108876000ADiversity guaranteedWill not discardForecastingResourcesTransformerEnergy control

The invention discloses a coordinative optimization configuration method for the capacity of a photovoltaic array, an energy storage device and a transformer of a photovoltaic charging station. The method comprises the following steps: firstly, determining a target function of the photovoltaic charging station, acquiring basic data of the photovoltaic charging station, and determining constraint conditions of the photovoltaic electric automobile charging station; secondly, optimizing the target function by applying an NSGA-II multi-objective genetic algorithm to obtain an optimization result;and finally, selecting the most reasonable construction requirement based on a construction investment budget of a investor according to the optimization result, and performing corresponding hardwarefacility configuration in the photovoltaic electric automobile charging station according to the construction requirement. The coordinative optimization configuration method disclosed by the inventionis applicable to all types of cities with the photovoltaic electric automobile charging station; an energy control strategy-based photovoltaic charging station optimization configuration method for coordinative optimization of the capacity of the photovoltaic array, the energy storage device and the transformer; and a theoretical foundation and a technical support are provided for construction and operation of an electric automobile charging station with a photovoltaic power generation system, so as to guarantee the economy, the environmental friendliness and the reliability of the construction and the operation of the charging station.

Owner:NANJING ELECTRIC POWER ENG DESIGN +3

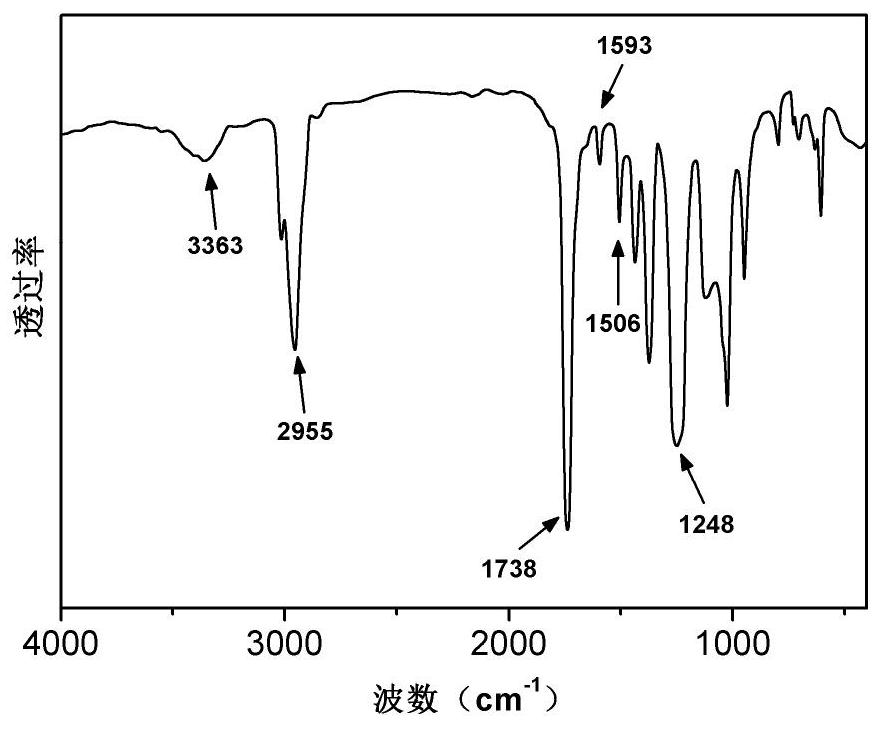

Polyester staple fiber double-component assembled oil solution and preparation method

InactiveCN101307564AHigh strengthImprove smoothnessFibre typesSynthetic polymer filament chemical after-treatmentFiberPolyester

The invention discloses a polyester staple fiber two-component composite oil agent and a method for preparing the same. The oil agent is formed by combining a smoothing oil agent No. 4 and an antistatic oil agent No. 2. The components by weight percentage of the smoothing oil agent No. 4 are: 10-20 percent of smoothing agent, 20-25 percent of emulsifier, 1-3 percent of penetrating agent and the balance being water. The components by weight percentage of the antistatic oil agent No. 2 are 24-27 percent of natural fatty alcohol, 6.0-6.5 percent of phosphorus pentoxide, 8-10 percent of potassium hydroxide and the balance being water. The preparation method comprises the following steps of preparing the smoothing oil agent No. 4 in a reaction kettle and preparing the antistatic oil agent No. 2 in an esterification reactor and a neutralization reactor. The oil agent has the advantages of low production cost, good stability, high oil film strength, good gliding property and excellently antistatic property and bundle collection property.

Owner:张金惠

Fully automatic rapid powder filling system

ActiveCN102136578AGuaranteed powder filling requirementsAvoid flying aroundElectrode carriers/collectorsAutomatic controlProgrammable logic controller

Owner:山东鑫旭集团有限公司

Silk-screen UV glaze printing ink and preparation method thereof

The invention discloses silk-screen UV glaze printing ink and a preparation method thereof, and belongs to the technical field of printing ink and preparation thereof. The printing ink is prepared from 28-32% of epoxy modified acrylate, 18-22% of urethane acrylate, 8-12% of tri(propylene glycol)diacrylate, 18-22% of 1,6-hexamethylene diacrylate, 6-10% of a 184 macroinitiator, 3-7% of an active-amine auxiliary photoinitiator, 0.8-3% of an organosilicone flatting agent, 0.8-3% of an organosilicone antifoaming agent and 3-7% of fumed silica, and is prepared by processes of mixing, stirring at a high speed, grinding, and the like. The preparation method is simple. The printing ink prepared by the method has a transparency effect and a matte effect, thus satisfying a conceive of applying the technical quality of blue and white porcelain and other famous porcelain in history to packaging and printing, and simulating the glaze quality, of the porcelain, that is mild and humid like jade. The printing ink provided by the invention has high environmental protection property. The VOCs smell residue totally reaches requirements of the national standards.

Owner:ZHEJIANG MINONG CENTURY GRP +1

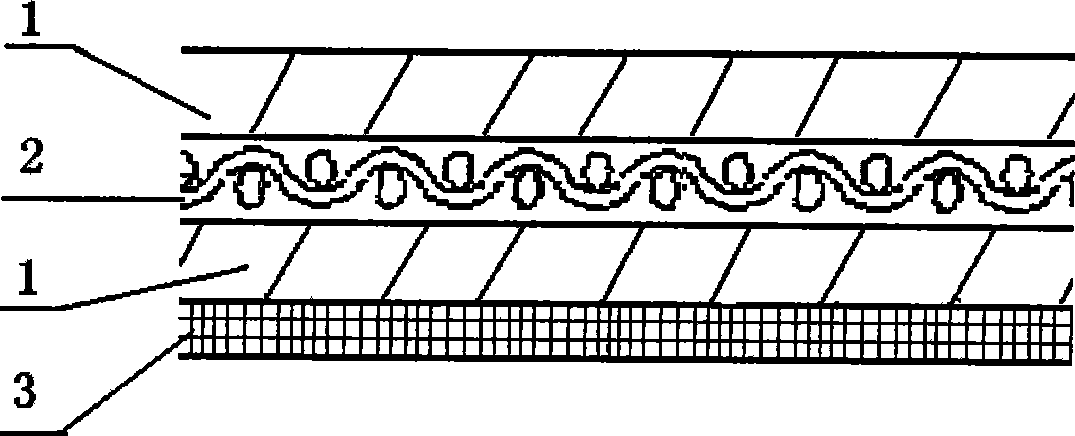

Dynamic-vulcanization thermoplastic polyolefine waterproof roll material and preparation method thereof

InactiveCN101544090AFlexible and convenient construction methodImprove performanceSynthetic resin layered productsThermoplasticElastomer

The invention provides a dynamic-vulcanization thermoplastic polyolefine waterproof roll material and a preparation method thereof. The roll material is characterized by comprising a main body layer and a reinforcing layer arranged according to the need. The main body layer is made of a dynamic-vulcanization thermoplastic polyolefine elastomer. The reinforcing layer comprises a middle reinforcing layer and a surface back-lining layer arranged according to the need. The dynamic-vulcanization thermoplastic polyolefine waterproof roll material has good processing property and excellent mechanical property and has the advantages of great tensile strength, good size stability, strong perforation resistance capability, good ultraviolet resistance and small specific gravity, main body welding seaming realized during the construction, convenient construction, recyclability of corner leftover material, and the like.

Owner:胜利油田大明新型建筑防水材料有限责任公司

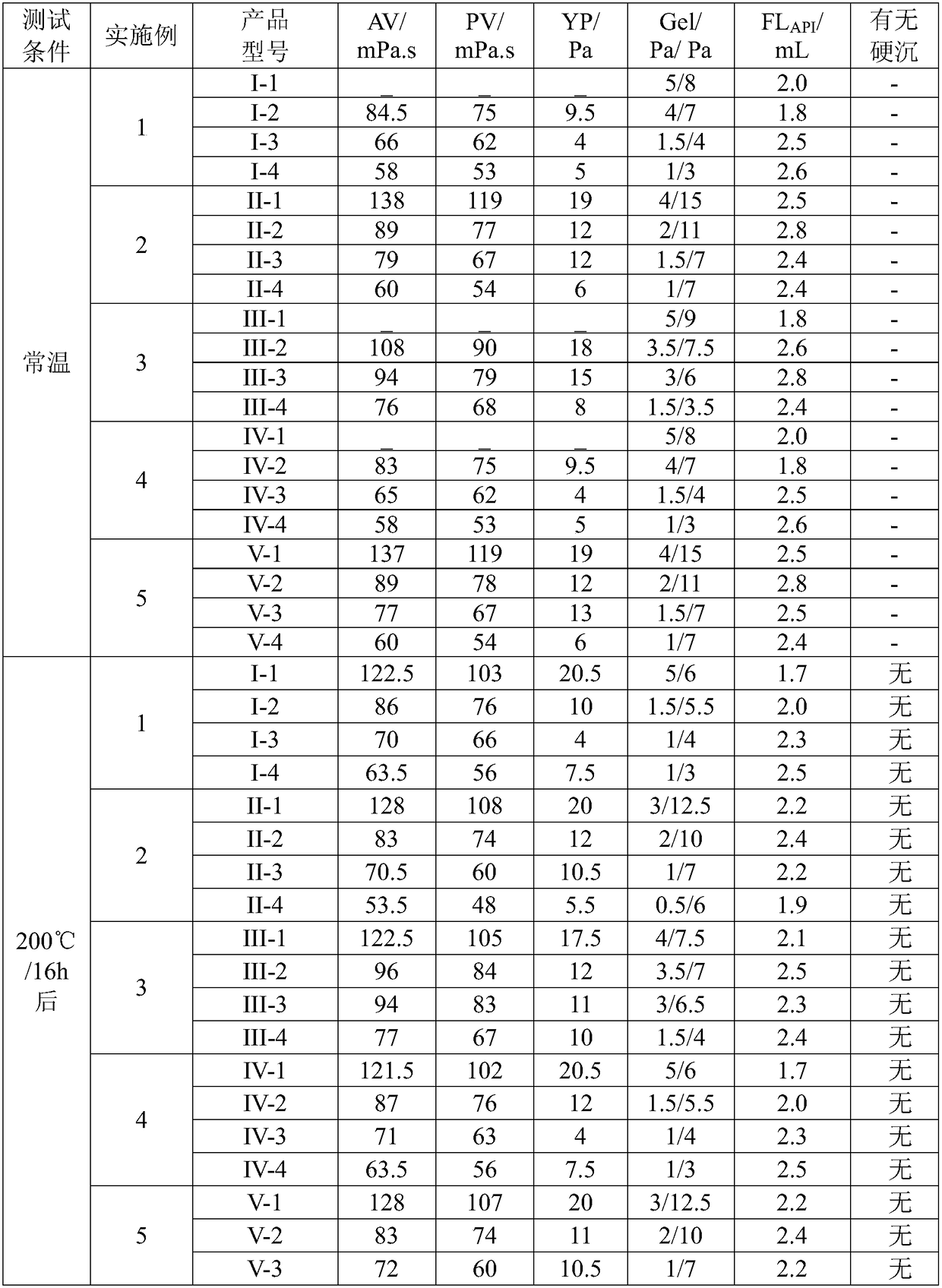

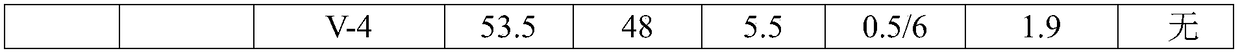

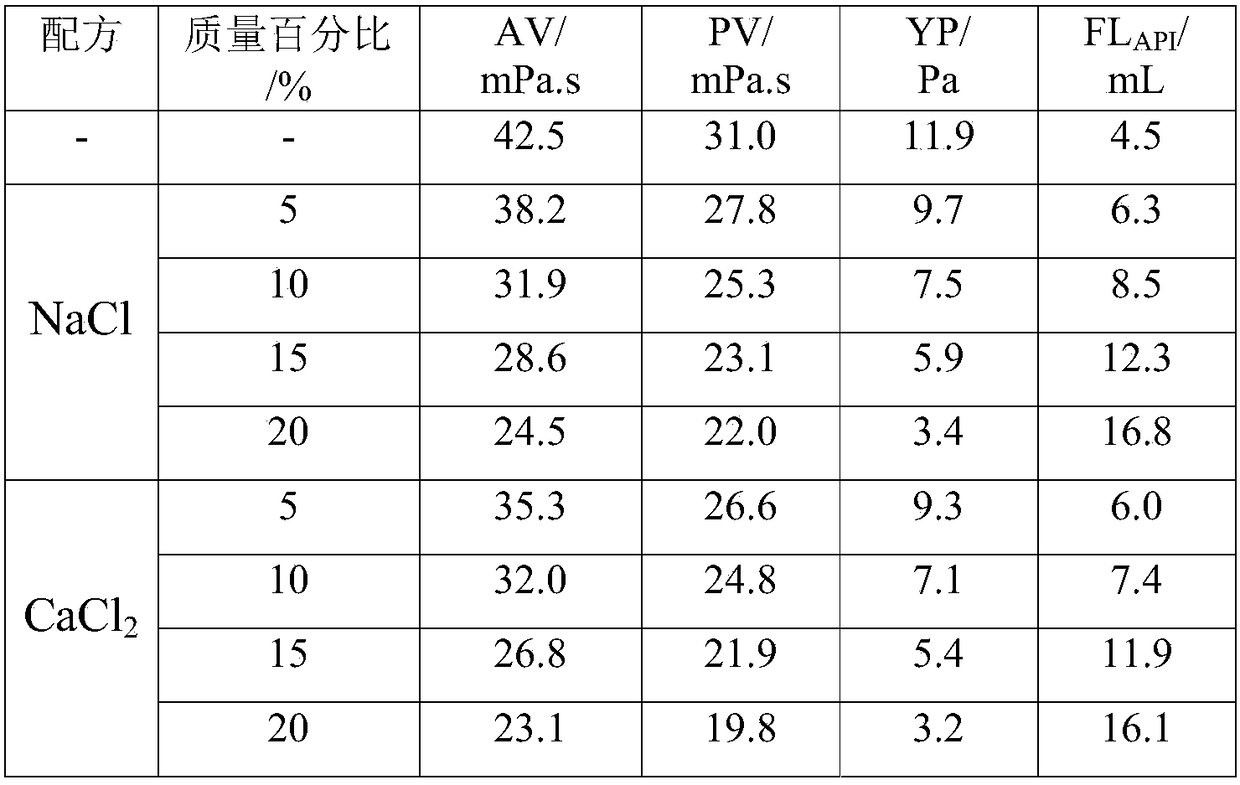

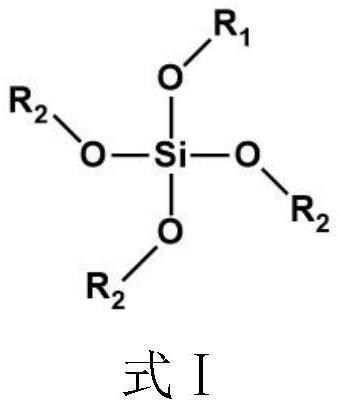

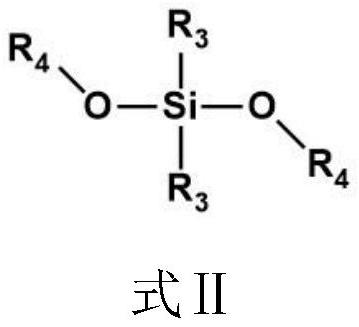

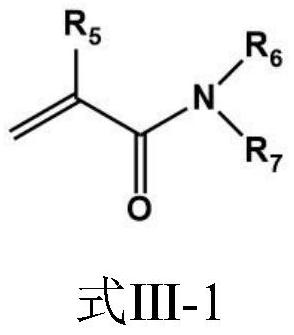

Filtrate reducer for drilling fluid as well as preparation method and application thereof

InactiveCN108774505AStrong filtration wallStrong anti-salt and anti-calcium performanceDrilling compositionBetaineTetrahydrofuran

The invention discloses a filtrate reducer for drilling fluid as well as a preparation method and application thereof. The filtrate reducer disclosed by the invention comprises the following raw material components in parts by weight: 25-30 parts of starch, 3-5 parts of tetrahydrofuran, 0.25-0.5 part of maleic anhydride, 20-30 parts of acrylamide propyl trimethoxysilane, 5-15 parts of 2-acrylamido-2-methylpropane sulfonic acid, 0.3-0.5 part of dimethyl sulfoxide, 5-10 parts of N-benzyl-3-pyrrolidone, 5-10 parts of ammonium persulfate, 5-10 parts of sodium hydrogen sulfite, 10-20 parts of alkyldimethyl betaine and 100 parts of water. The filtrate reducer disclosed by the invention achieves an excellent effect of reducing the filter loss in a clay free phase high-density drilling fluid system, and has excellent salt and calcium resistance and high pollution resistance; the filtrate reducer has an obvious effect of reducing the filter loss, is excellent in temperature and salt resistanteffect and has an excellent suspension effect on the solid phase; and the tackifying amplitude is moderate in the drilling fluid system, and field application requirements are well met.

Owner:张建华

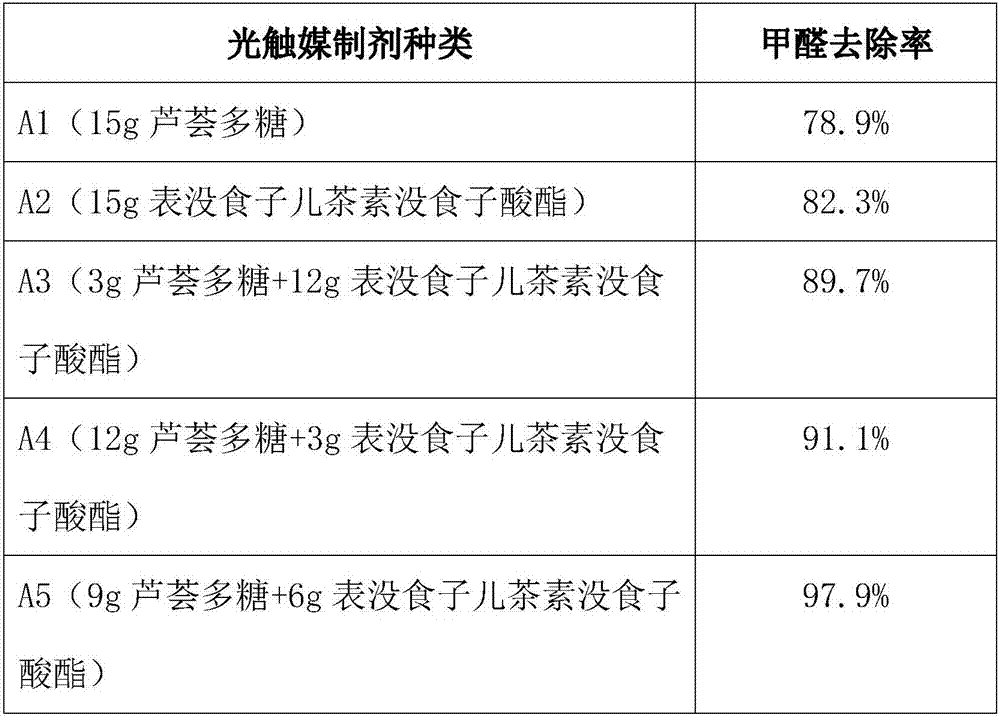

Photocatalyst preparation with function of effectively removing indoor decorative pollution

InactiveCN107876048APowerful catalystStrong ability to oxidize formaldehydeGas treatmentDispersed particle separationPollutionTitanium dioxide

The invention relates to a photocatalyst preparation with a function of effectively removing indoor decorative pollution. The photocatalyst preparation is prepared from components in percentage by weight as follows: 1%-10% of nano titanium dioxide, 0.1%-1% of nano silver, 1%-20% of a synergist and the balance of pure water, wherein the synergist is selected from aloe polysaccharide and / or epigallocatechin gallate. With the adoption of the photocatalyst preparation, formaldehyde can be efficiently removed, and formaldehyde removing property is improved substantially after addition of the synergist; the components are safe and non-toxic, secondary pollution cannot be produced in a using process, and the photocatalyst preparation is safe and reliable and meets requirements of national environmental protection.

Owner:ANHUI ZHONGHONG TECH DEV CO LTD

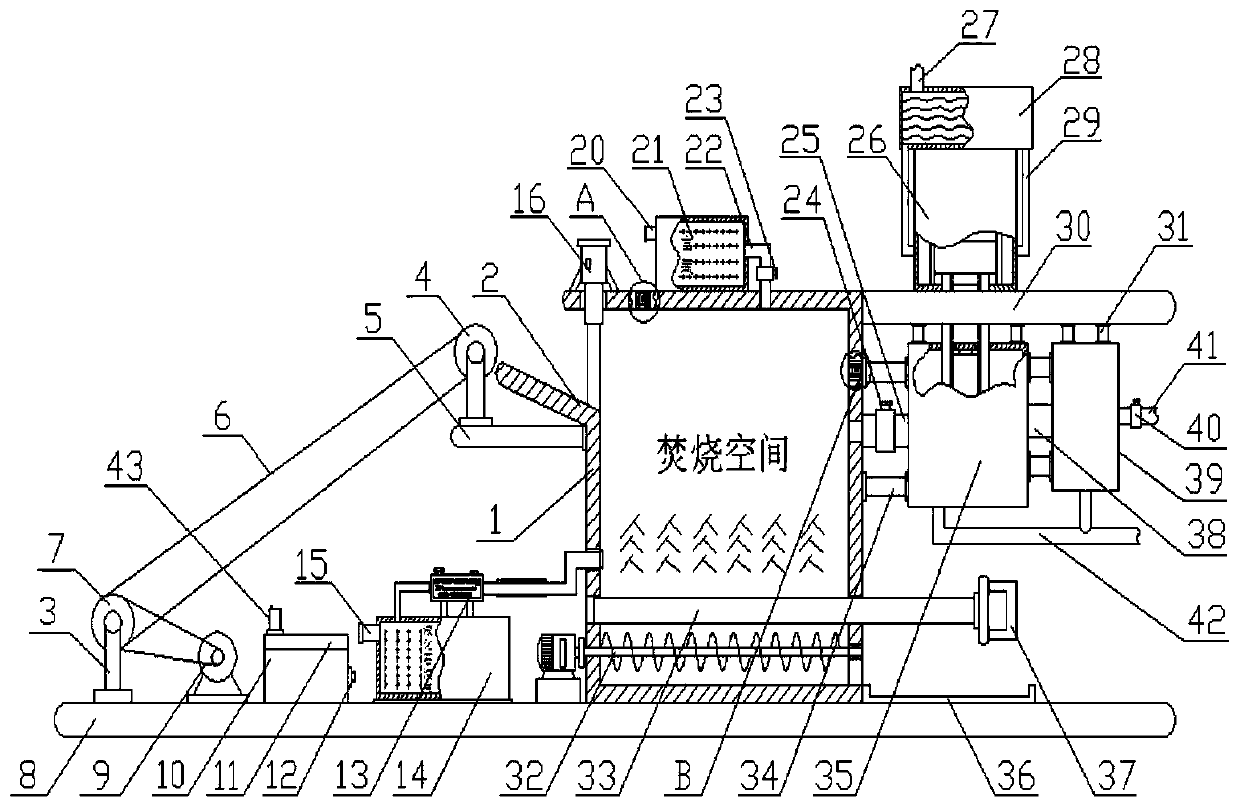

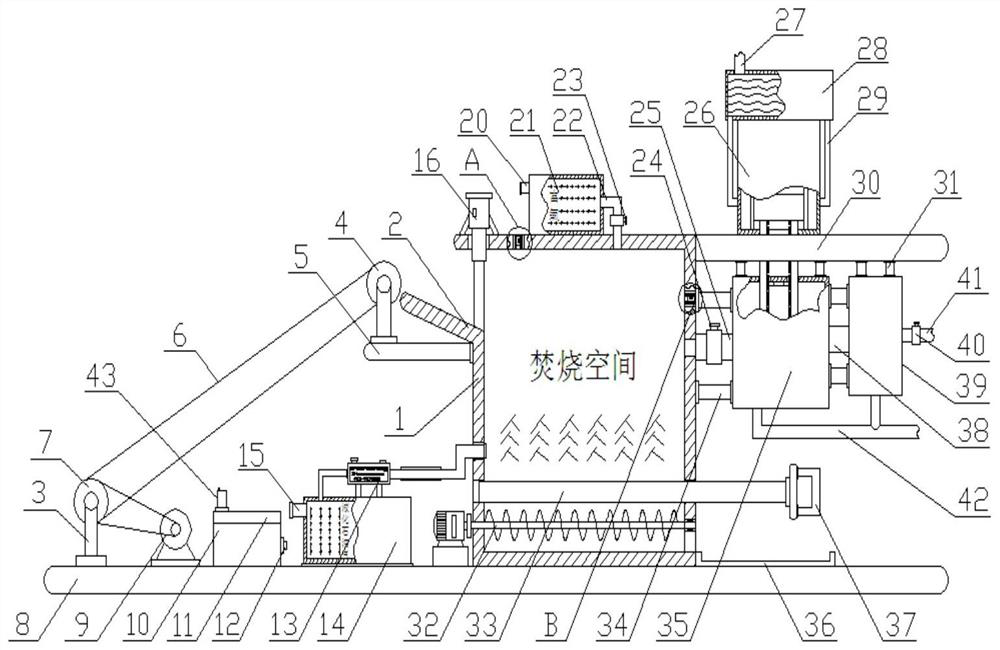

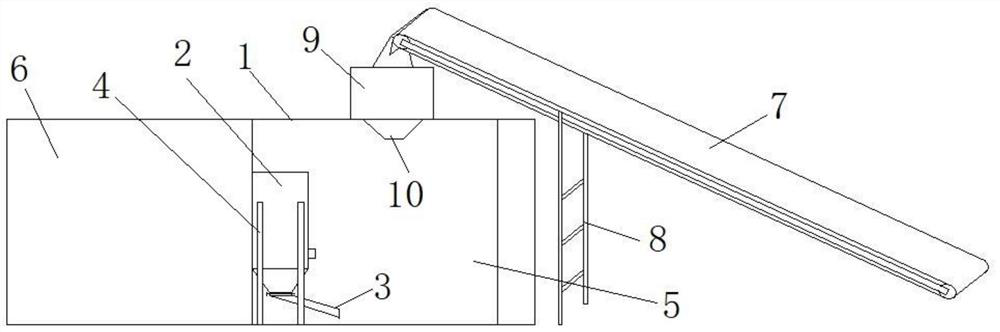

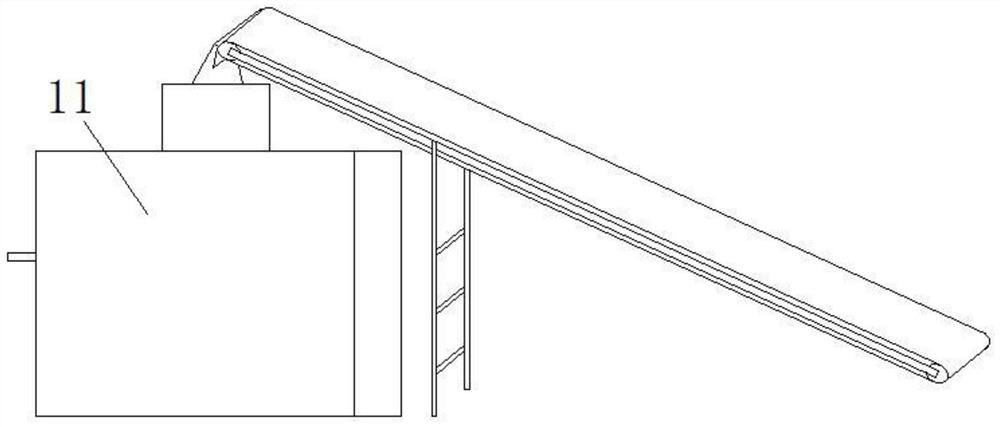

Environment-friendly type dry refuse incineration and waste gas treatment system

ActiveCN110345493ARealize automatic reciprocating movementLabor savingDispersed particle filtrationEmission preventionEnvironmental resistanceEngineering

The invention provides an environment-friendly type dry refuse incineration and waste gas treatment system comprising an incinerator wall, a material guiding inclined plate, supporting frames, a firsttransmission wheel, a support plate, a conveyer belt, a second transmission wheel, a base plate, a material guiding motor and other structures. A reciprocating cleaning mechanism is installed on theupper portion of the installation plate through bolts. A discharging mechanism is installed at the bottom in the incinerator wall and located on the lower side of the incinerator plate. A waste gas filtering box is arranged on the lower portion of the installation plate. The reaction chamber is installed on the lower portion of the installation plate through a stabilizing column and located on oneside of the waste gas filtering box. By means of the reciprocating cleaning mechanism, the filtering mechanism, the waste gas filtering box and a reaction chamber, dry garbage can be effectively incinerated, generated gas is filtered and purified, the filtering portion can be cleaned in a reciprocating manner so as to improve the purifying effect, the national requirements for refuse environmental protection treatment are further met, the incinerated refuse discharging process is environmentally friendly and free of pollution, and the whole system has great environmental protection value.

Owner:HEZE UNIV

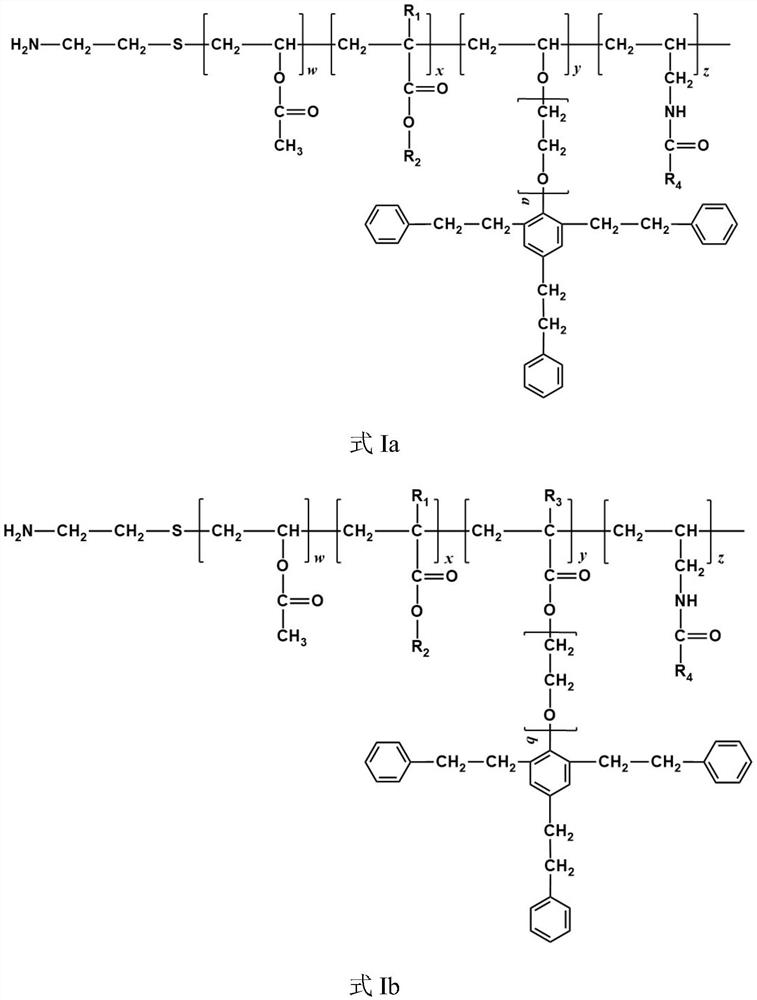

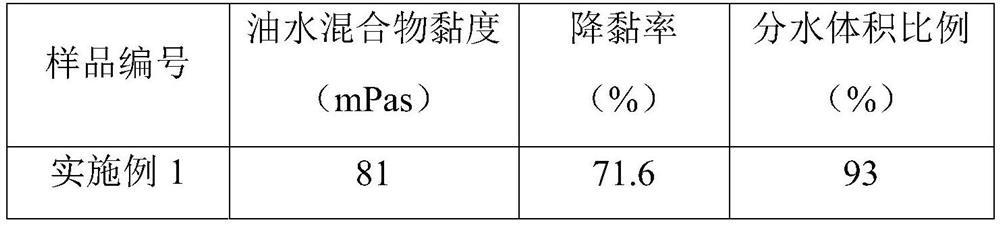

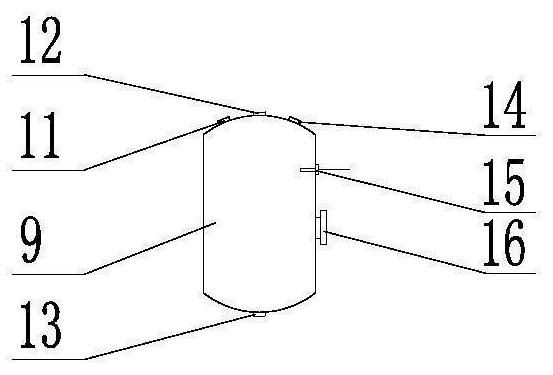

Oil displacement system suitable for high-temperature and high-salinity oil reservoir

The invention discloses an oil displacement system suitable for a high-temperature and high-salinity oil reservoir. The oil displacement system is prepared according to the following method: in an inert atmosphere and in the presence of sodium formate, ethylenediamine tetraacetic acid disodium salt, ferrous sulfate, tetramethylethylenediamine, 4, 4'-azobis (4-cyanovaleric acid), ammonium persulfate and hydrogen peroxide, carrying out a copolymerization reaction among a monomer A, a monomer B, a monomer C, a monomer D and an inorganic component in water to obtain gel; and chopping the gel, adding sodium silicate and sodium pyrophosphate, standing for swelling, drying the swollen gel, and crushing to obtain powder, namely the oil displacement system. Monomer activity (all acryloyloxy monomers) adopted by the invention is high, a high molecular weight product is easy to prepare, and the product is excellent in tackifying performance and small in use amount. The oil displacement system iseasy to store and convenient to transport, and meets the requirements of environmental protection. The method has the advantages of accessible raw materials and favorable preparation technique, and issuitable for industrial production.

Owner:CHINA NATIONAL OFFSHORE OIL (CHINA) CO LTD +1

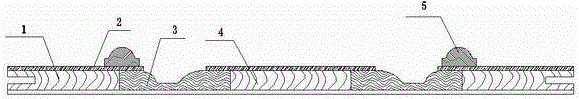

All-wood panel and production process thereof

ActiveCN106193487AReduce usageIncrease profitCovering/liningsDecorative surface effectsPulp and paper industryCarving

The invention protects an all-wood panel and a production process. The all-wood panel comprises a surface veneer layer, internal filling-core wood layers arranged in the surface veneer layer, woods layer adjacent to the internal filling-core wood layers and a hollow filling-core layer adjacent to the wood layer, wherein the internal filling-core wood layers are symmetrically arranged at the two ends of the all-wood panel and sequentially and symmetrically provided with the wood layers, and the hollow filling-core layer is located at the right center of the all-wood panel and filled with filling-core wood. The production process comprises the steps that firstly, internal filling-core wood and high-grade wood are spliced to form boards, wherein the high-grade wood is used at the positions requiring carving; a carving machine with an automatic tool change function is used for carving groove shapes at the carving positions; a surface line frame is assembled, that is, high-grade veneer is used for covering the outer surface, and tidy building is conducted; coating of surface paint is conducted. Through the all-wood panel and the production process, the comprehensive utilization rate is raised, waste of the high-grade wood is reduced, density is high, and strength is high.

Owner:重庆星星套装门(集团)有限责任公司

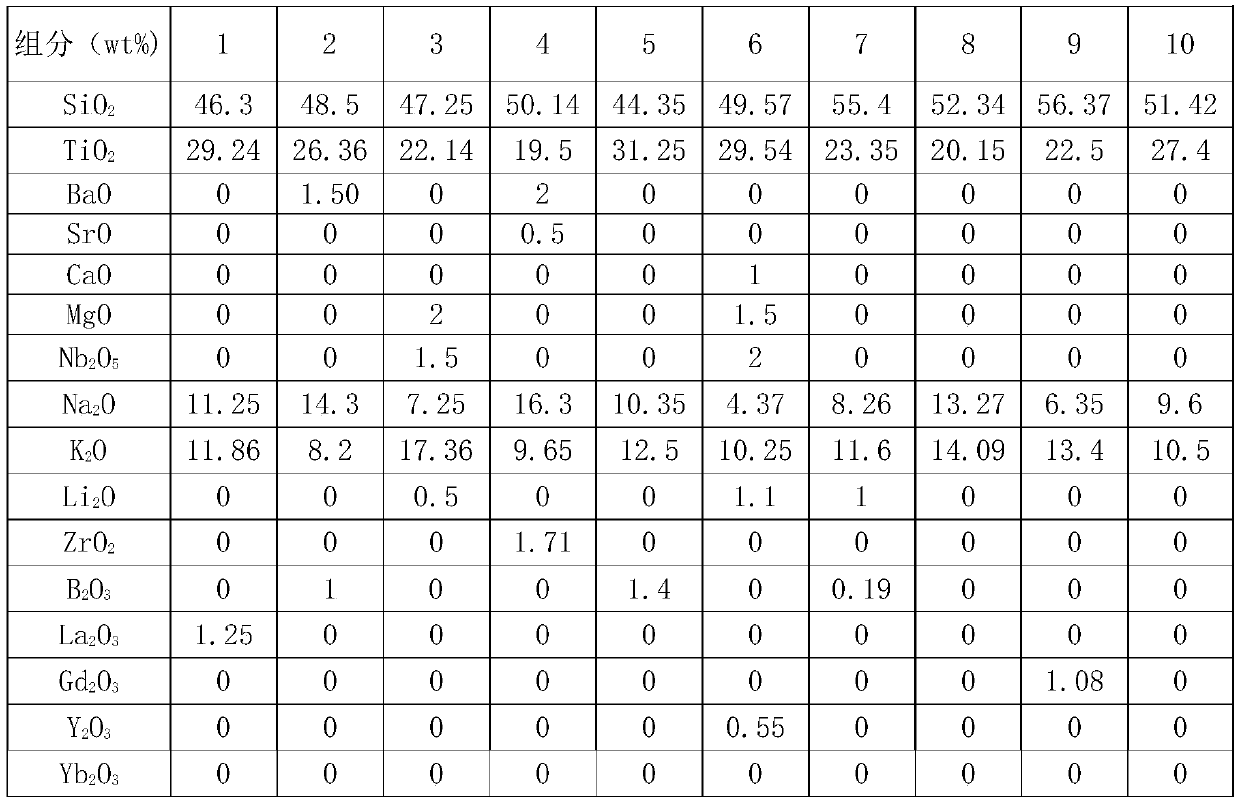

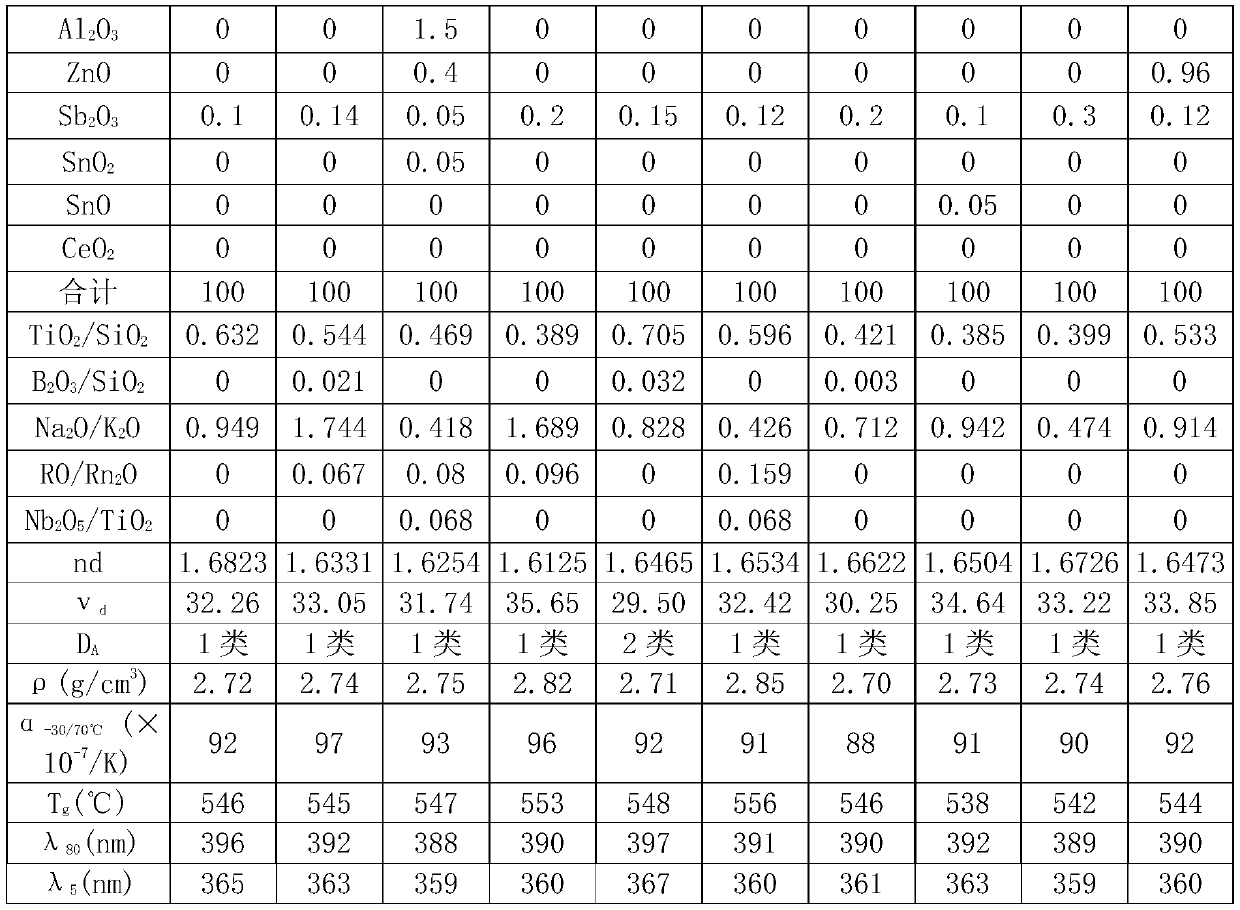

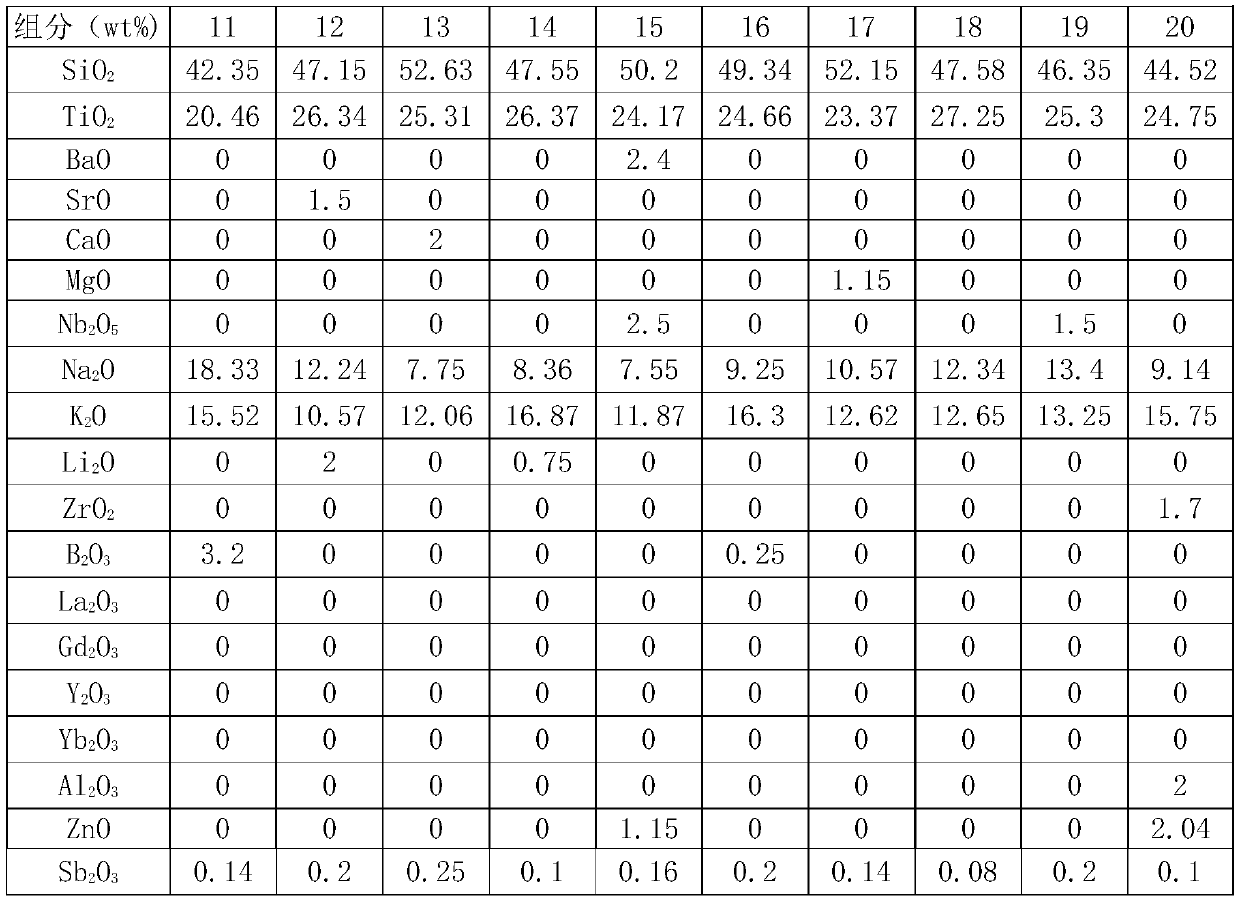

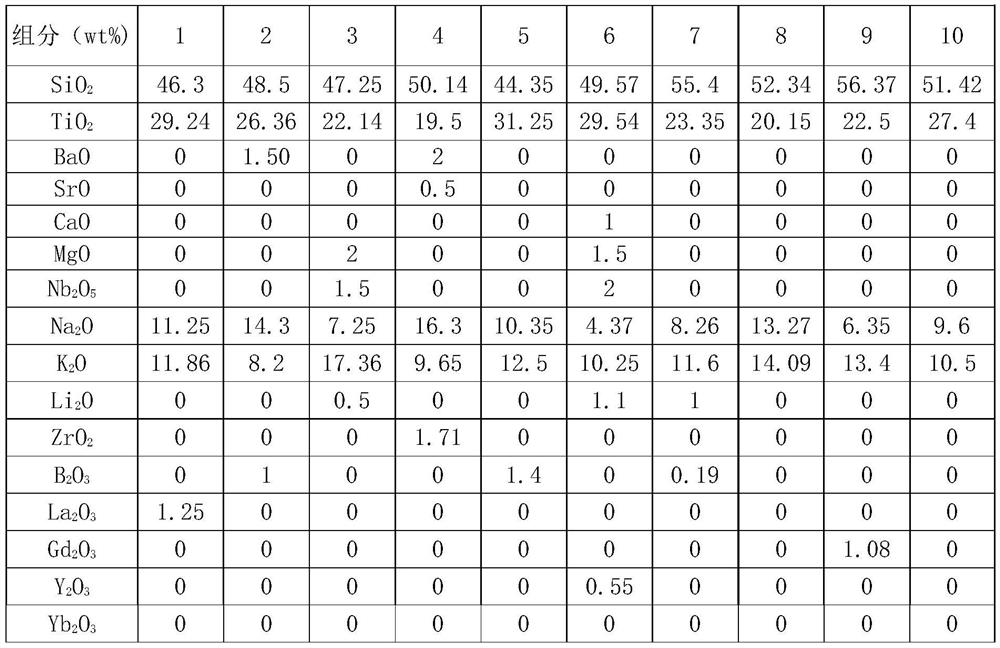

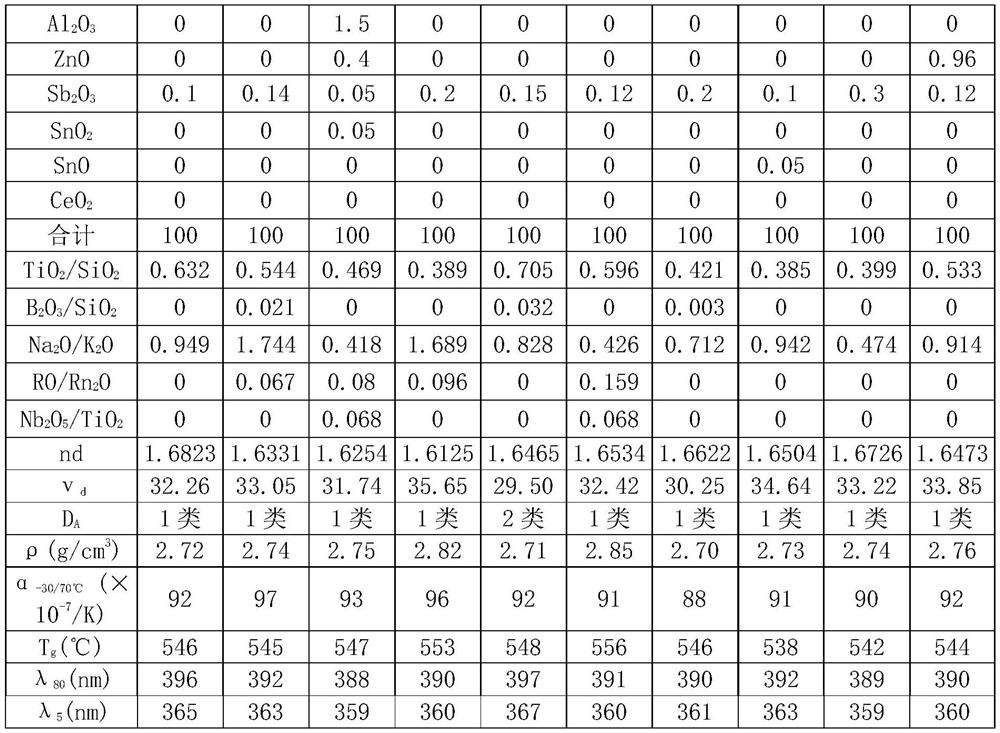

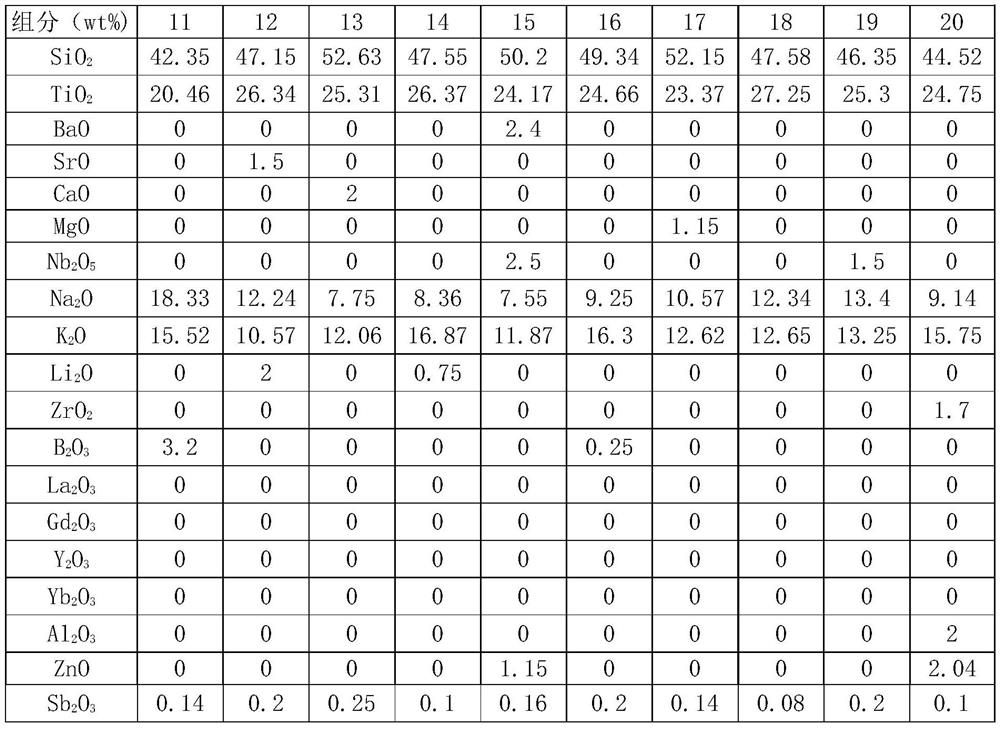

Optical glass

ActiveCN110228946AGood chemical stabilityMeet the requirements of environmental protectionOptical elementsRefractive indexOptical glass

The invention provides optical glass. The optical glass comprises, by weight, 40 to 58% of SiO2, 18 to 32% of TiO2, 3 to 20% of Na2O and 6 to 20% of K2O, wherein a ratio of TiO2 to SiO2 is 0.35 to 0.8. Through reasonable component design and a reasonable component ratio, the optical glass of the invention meets the demands for desired refractive index and Abbe number, has excellent chemical stability, does not contain harmful components like PbO, and satisfies the requirements of environmental protection.

Owner:CDGM OPTICAL GLASS

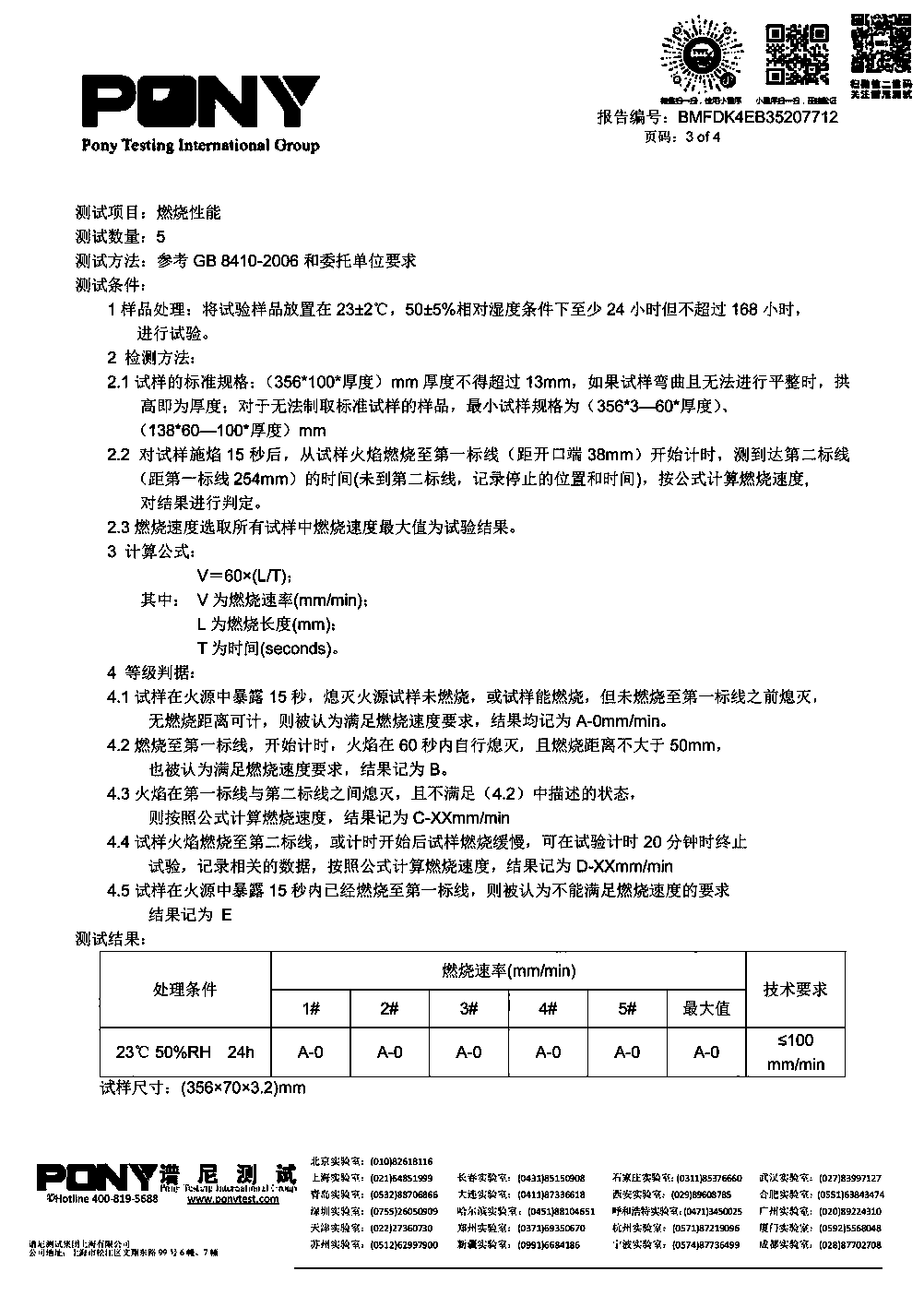

Automobile air duct and preparation method thereof

InactiveCN109705434AImprove flame retardant performanceSmall smellBlow moldingPulp and paper industry

The invention provides an automobile air duct and a preparation method thereof, the automobile air duct comprises the following raw materials in parts by weight: 70-82 parts of PE (polyethylene), 4-8parts of antimonous oxide, 8-16 parts of decabromodiphenyl ethane, 3-10 parts of POE, 0.1-0.3 part of antioxidant 1076, 0.1-0.3 part of antioxidant 168 and 0.1-0.4 part of ultraviolet absorbent UV 944; and an anti-dripping agent accounts for 0.35% of the total weight of the substances. The automobile air duct is formed by blow molding, and the prepared automobile air duct is good in flame retardancy, high in anti-bending strength, high in tensile strength and small in smell.

Owner:ZHENGZHOU BIUCO SAFETY TECH CO LTD

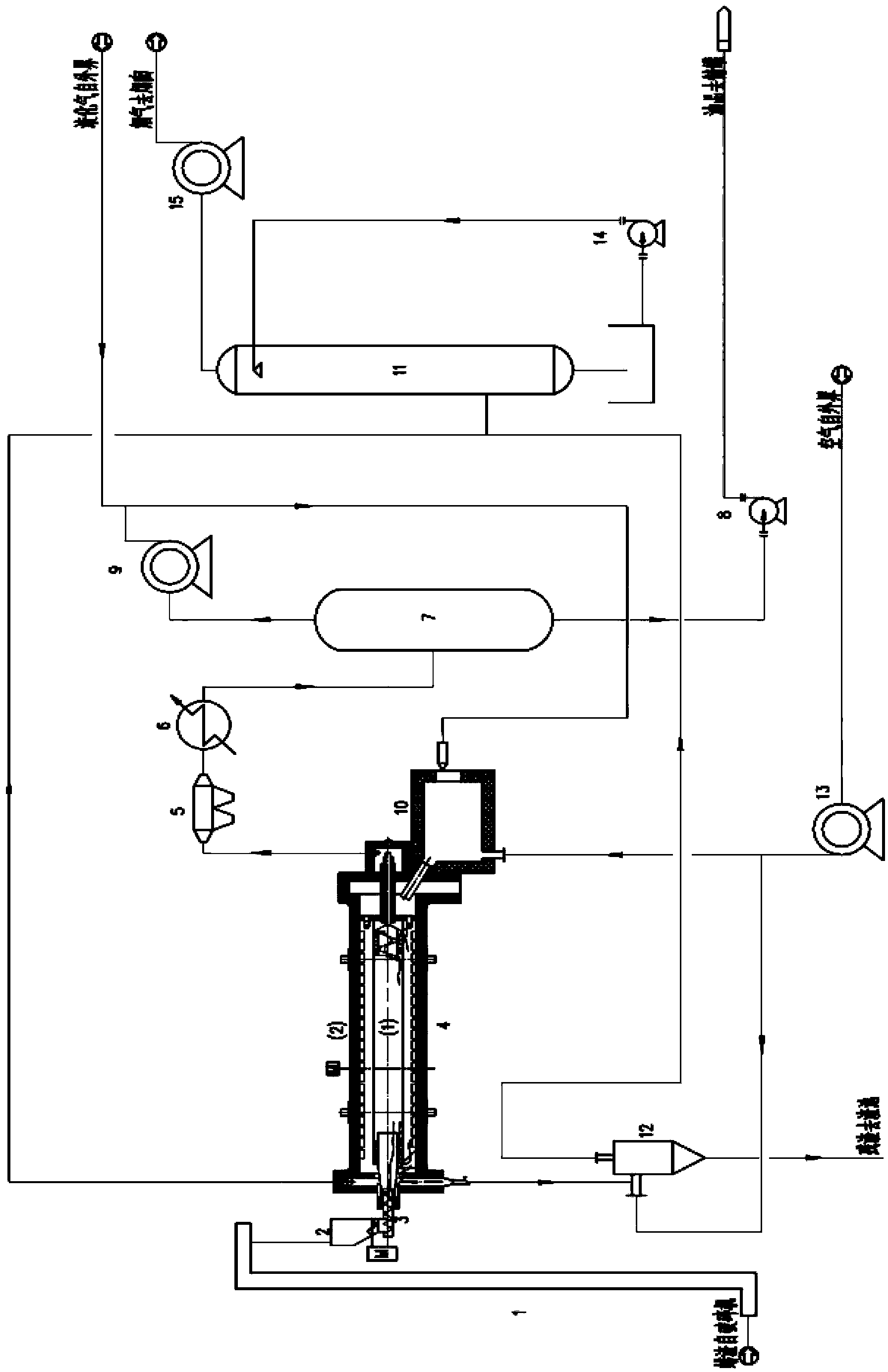

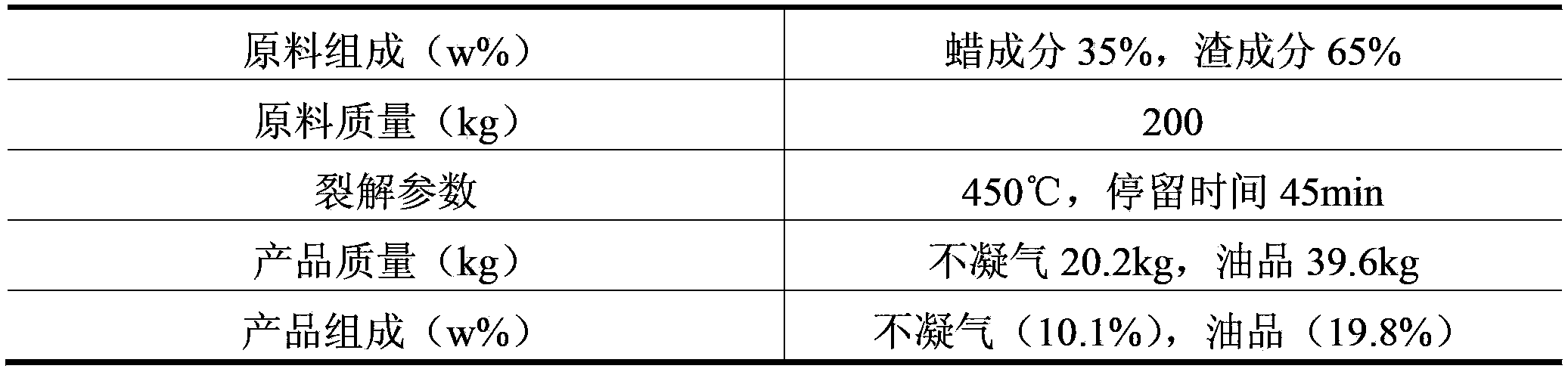

Thermal pyrolysis method for Fischer-Tropsch synthesis reaction wax residue

ActiveCN103173238BCracking temperatureImprove cracking efficiencyLiquid hydrocarbon mixture productionWaxVapor–liquid separator

Owner:SYNFUELS CHINA TECH CO LTD

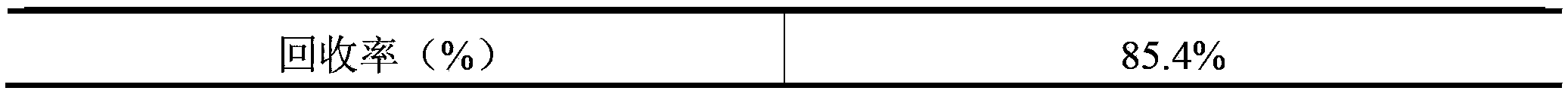

Advanced treatment method of triethylamine salt-containing wastewater

InactiveCN110845051AEfficient removalExtend the life cycleWater contaminantsMultistage water/sewage treatmentPolyacrylamideTriethylamine

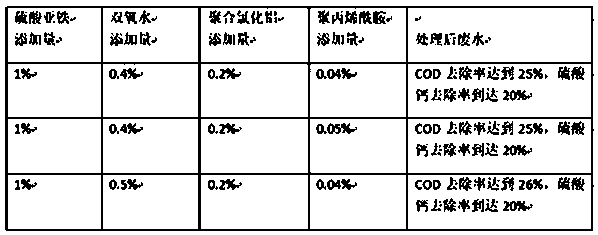

The invention relates to an advanced treatment method of triethylamine salt-containing wastewater in an acesulfame potassium production process. The method comprises the following steps: 1) removing apart of supersaturated precipitated calcium sulfate after pre-precipitation of triethylamine wastewater, 2) adding ferrous sulfate accounting for 1% by weight of each ton of the wastewater and hydrogen peroxide accounting for 0.4-0.5% by weight of each ton of the wastewater to oxidize a part of organic matters in the triethylamine wastewater, and carrying out coagulating sedimentation, and 3) adjusting the pH value of the triethylamine wastewater subjected to coagulating sedimentation to 6-7, and adding 0.2% by weight of polyaluminum chloride and 0.04-0.05% by weight of polyacrylamide into each ton of the wastewater for flocculating sedimentation, thereby reducing the organic matter content and calcium sulfate content of the wastewater. The method has the advantages that the content of organic matters and the concentration of calcium sulfate in the wastewater can be effectively removed, and a part of calcium sulfate and organic matters are removed through pretreatment before the wastewater enters the evaporator, so that the normal service cycle of the evaporator is prolonged, and the triethylamine wastewater treatment capacity is greatly improved.

Owner:ANHUI JINGHE IND

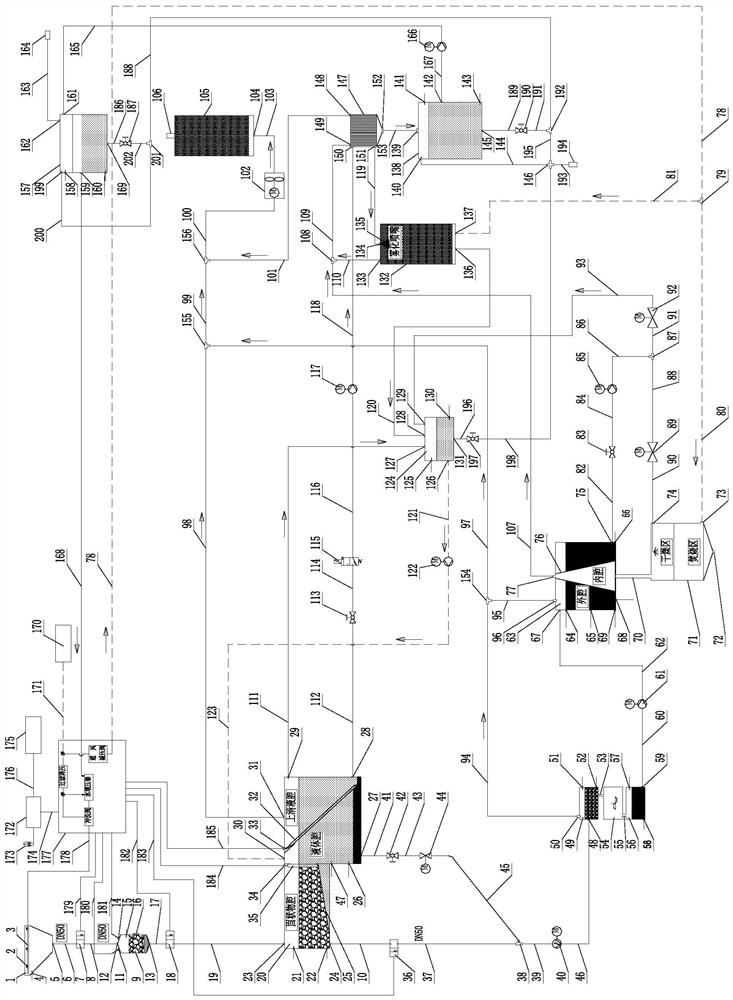

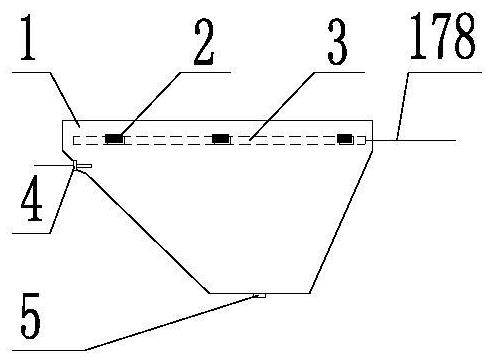

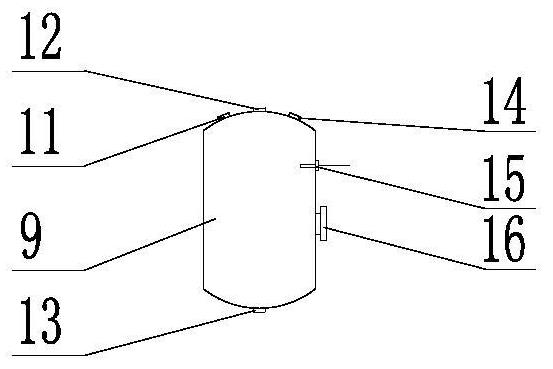

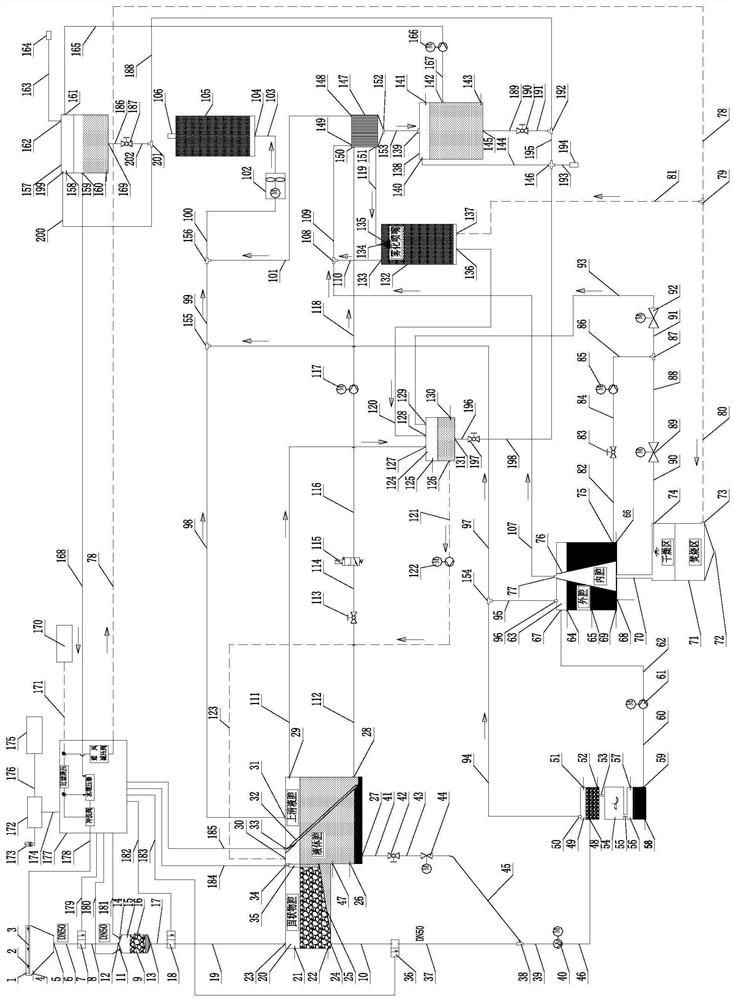

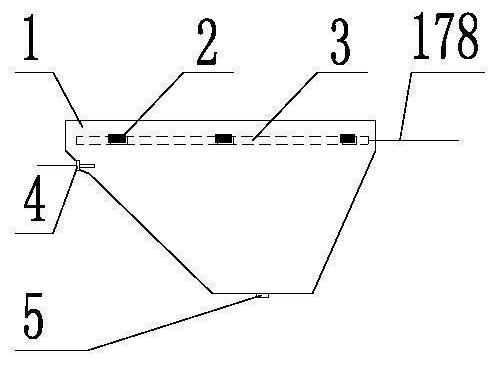

Cleaning and discharging movable multi-toilet-cubicle WC system assembly

PendingCN114000570ASolve pollutionStop breedingWater/sewage treatment by irradiationWater treatment compoundsWater circulationToilet flushing

The invention provides a cleaning and discharging movable multi-toilet-cubicle WC system assembly. The system comprises ten subsystems, namely a toilet cubicle use subsystem, a wind source subsystem, an excrement collection subsystem, a solid-liquid separation subsystem, a microwave incineration subsystem, an electrodeless photocatalysis urine treatment subsystem, an electrodeless photocatalysis waste gas treatment subsystem, a heat exchange subsystem, a reclaimed water recycling toilet flushing subsystem and an intelligent control subsystem. Technical obstacles of human excrement excretion environment, disease transmission, solid and liquid dirt damaging body health, rapid sterilization and incineration treatment of excrement, and sewage treatment and reuse are overcome; a full physical and chemical technology is adopted, excrement collection, microwave incineration, photocatalytic degradation, ultraviolet sterilization, a reclaimed water toilet flushing technology and an intelligent control system are integrated, rapid harmless treatment of human excrement is achieved, the traceless, colorless, odorless and secondary-pollution-free clean emission requirements are met, the convention that a sewer needs to be arranged in a toilet is broken, and all pollutant emission technical indexes meet the requirements specified by the national standard.

Owner:ZHEJIANG JINZI MACHINERY&ELECTRICAL

Energy-saving completely cleaning device for mosaic tiles

InactiveCN106994450AReduce labor intensityAvoid incompletenessCleaning using toolsCleaning using liquidsEnvironmental resistanceSpray nozzle

The invention discloses an energy-saving completely cleaning device for mosaic tiles. The energy-saving completely cleaning device for the mosaic tiles comprises a manual cleaning platform and a mechanical cleaning mechanism. The four ends of the lower side of the manual cleaning platform are supported by a first support. One end of the mechanical cleaning mechanism is fixedly connected with one end of a manual cleaning platform. A motor in a power cavity is connected with a rolling shaft through a bearing. The side wall of a cleaning trough is of a hollow structure. First cleaning spray nozzles are arranged in the middle of the side wall of the cleaning trough at equal intervals. One end of each cleaning spray nozzle penetrates through the side wall of the cleaning trough and is connected with one end of a connecting water pipe through an auxiliary water pipe, and the other end of the connecting water pipe is connected with a clear water tank arranged on the lower side of the manual cleaning platform. The energy-saving completely cleaning device for the mosaic tiles can relieve the labor intensity of workers and avoid that mechanical cleaning is not complete, and the cleaning efficiency is high; and water resources can be circularly utilized, the cleaning cost can be reduced, the environmental protection requirement is met, and the cleaning efficiency and quality can be greatly improved.

Owner:闻斌壹

A kind of flake nanomaterial for oil displacement

ActiveCN112322269BRaw materials are easy to getSafe preparationDrilling compositionSodium bisulfateChemistry

Owner:CHINA NAT OFFSHORE OIL CORP +1

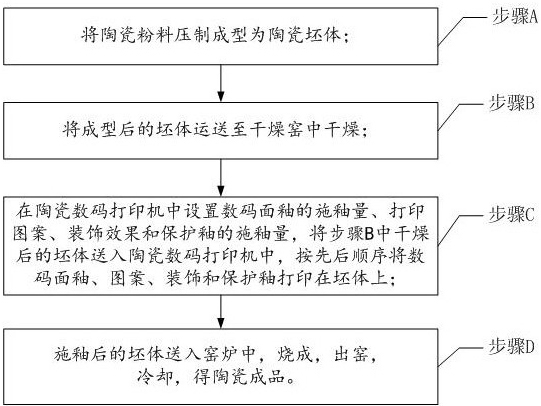

A production process of digitally controlled glazed ceramics

The invention discloses a production technology of ceramic with digital-controlled glazing. The production technology comprises the following steps of after a green body subjected to press forming isdried, surface glazes, patterns, various decorative and protective glazes and the like on the green body are directly printed by a digital printer. The technology can realize simultaneous printing ofthe surface glazes and the protective glazes with different effects on a same ceramic tile, can also perform whole glazing or local glazing to the ceramic tile and can also perform simultaneous printing of various colors, and then high-temperature firing is performed; digital printing glazing is accurate in positioning, the patterns are high in simulation degree, high in definition, strong in stereoscopic sensation and little in glazing amount, so that the production technology reduces waste of glazes, saves the energy, reduces emission, accords with the requirements for environmental protection, avoids the defects of cracking, deformation, glazed pinhole and the like of the green body caused by too much glazing quantity and moisture in the glazes, increases the high-grade rate of productsfrom a kiln, is particularly suitable for production of thin plates in a large specification, is high in production intelligence degree and reduces the manpower cost.

Owner:佛山市华力达材料科技有限公司

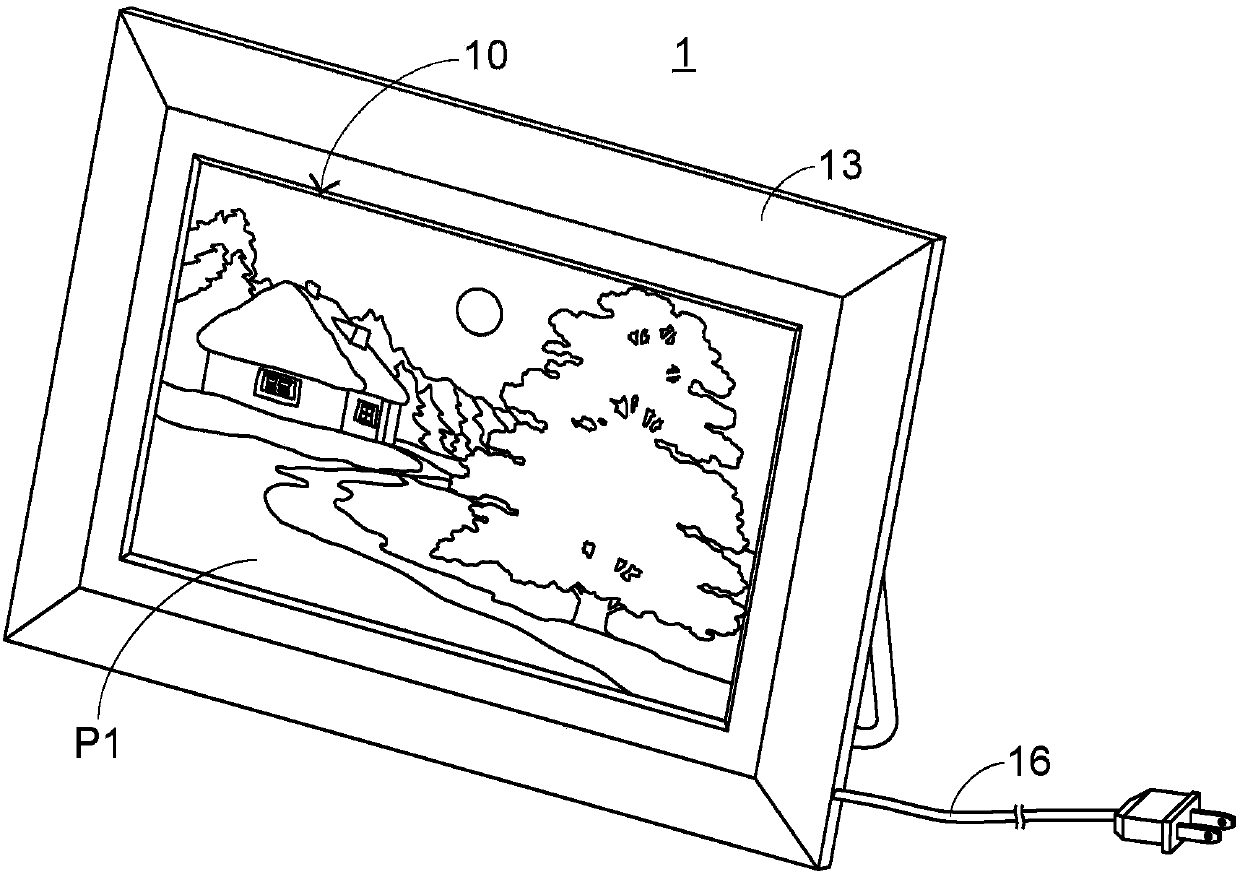

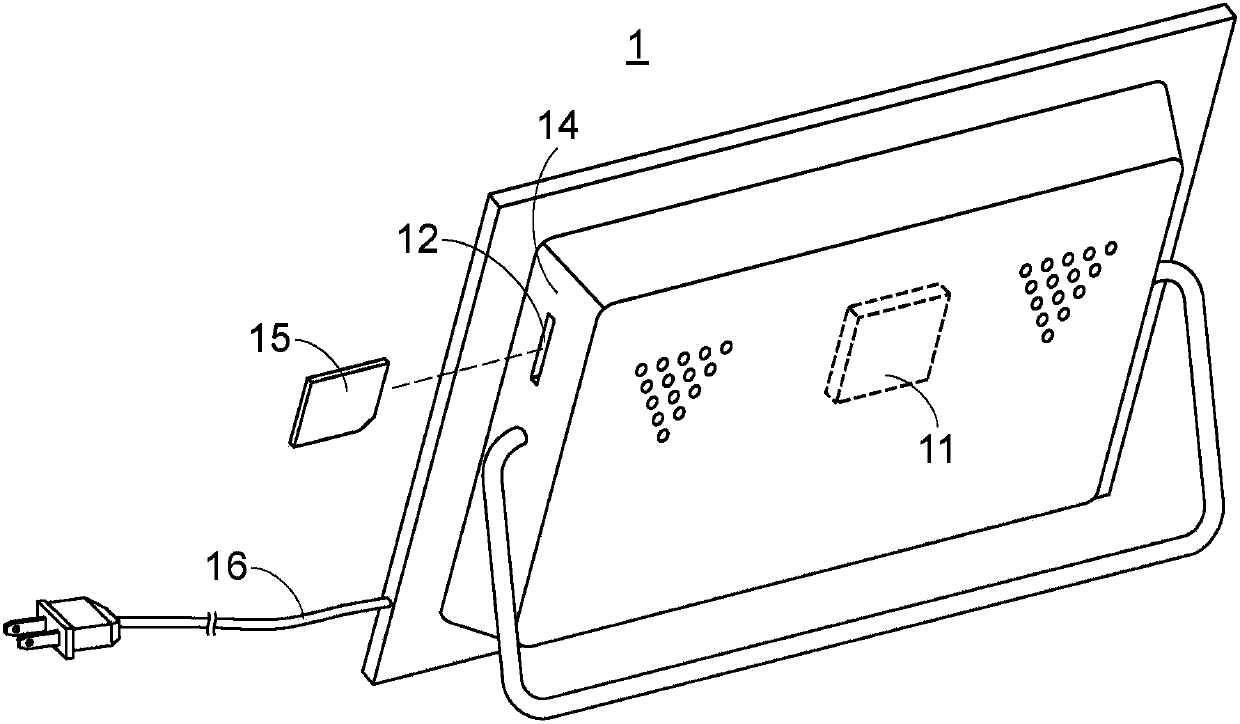

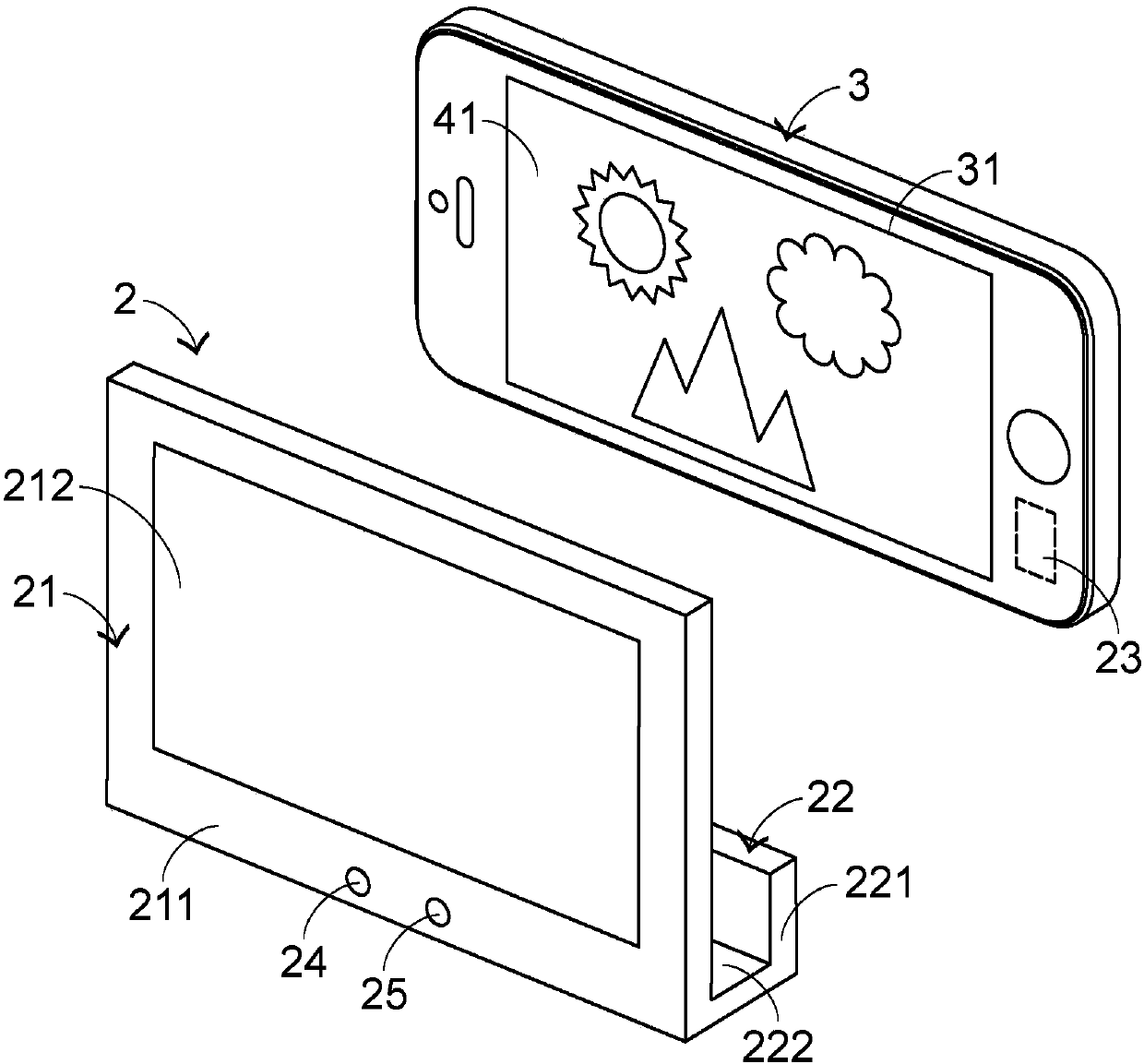

Photo frame module

InactiveCN107610589AMeet the requirements of environmental protectionIdentification meansDisplay deviceTerminal equipment

The invention provides a photo frame module. The photo frame module comprises a display device and a fixing structure, wherein the display device comprises a plurality of sensing units, the fixing structure is used for fixing a terminal device so that a screen of the terminal device is parallel to the display device, and the sensing units are used for sensing an original image shown on the screenof the terminal device after the terminal device is fixed, so that a sensed image corresponding to the original image is shown on the display device.

Owner:PRIMAX ELECTRONICS LTD

Multi-toilet-cubicle mobile intelligent purifying and discharging WC system assembly and sewage treatment method thereof

InactiveCN112609787AImprove acceptabilityReduce volumeWater/sewage treatment by irradiationWater treatment compoundsPhotocatalytic degradationWater circulation

The invention provides a multi-toilet-cubicle mobile intelligent purifying and discharging WC system assembly. The system assembly comprises ten subsystems including a toilet cubicle use subsystem, an air source subsystem, an excrement collection subsystem, a solid-liquid separation subsystem, a microwave incineration subsystem, an electrodeless photocatalytic treatment urine treatment subsystem, an electrodeless photocatalytic treatment waste gas treatment subsystem, a heat exchange system, a reclaimed water recycling toilet flushing subsystem and an intelligent control subsystem. Meanwhile, the invention further provides a sewage treatment method based on the system assembly. Technical obstacles of rapid sterilization, incineration treatment and sewage treatment and recycling of solid-liquid dirt and excrement which are harmful to human excrement excretion environment, disease transmission and body health are overcome. A full physicochemical technology is adopted, excrement collection, microwave incineration, photocatalytic degradation, ultraviolet sterilization, a reclaimed water toilet flushing technology and an intelligent control system are integrated, rapid harmless treatment of human excrement is achieved, the colorless, odorless and secondary-pollution-free up-to-standard emission requirements are met, and all pollutant emission technical indexes reach the national standard.

Owner:浙江金字机械电器股份有限公司

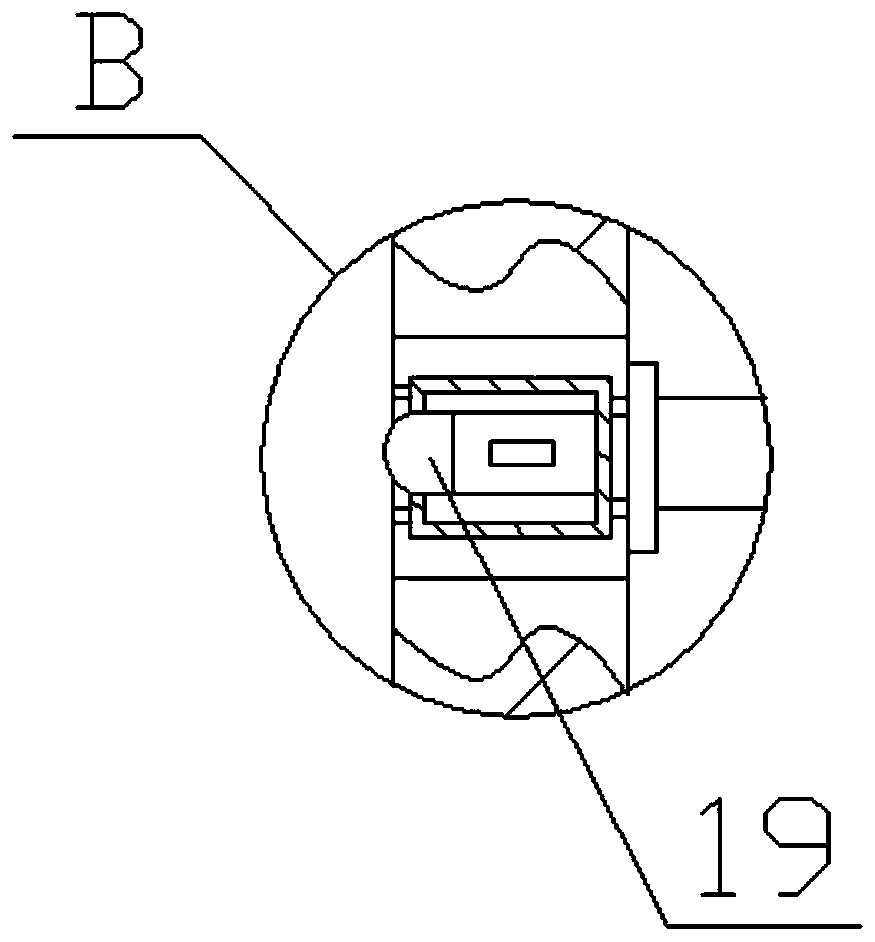

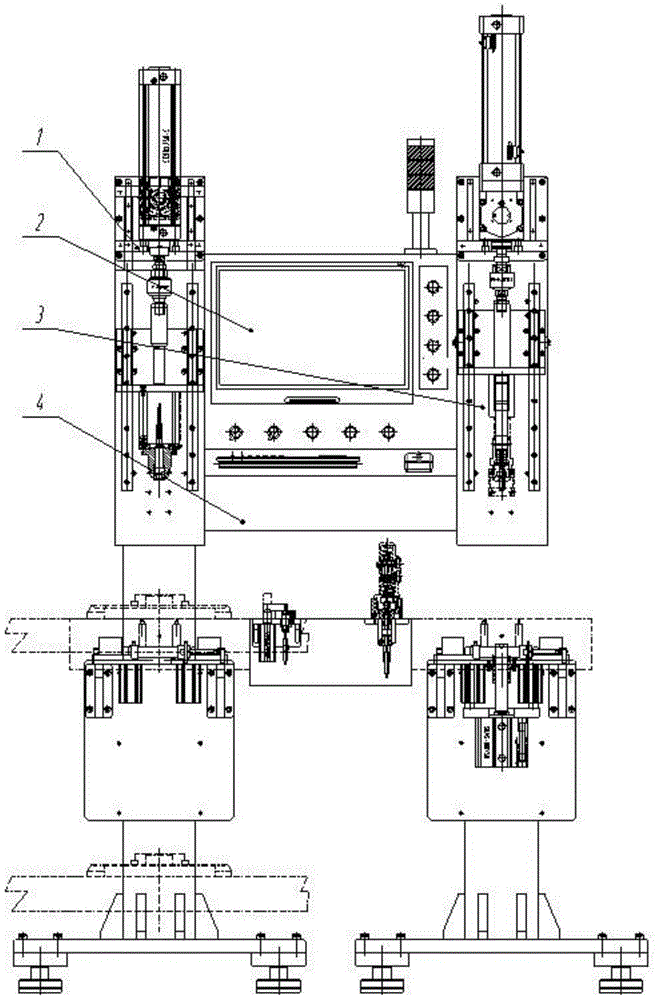

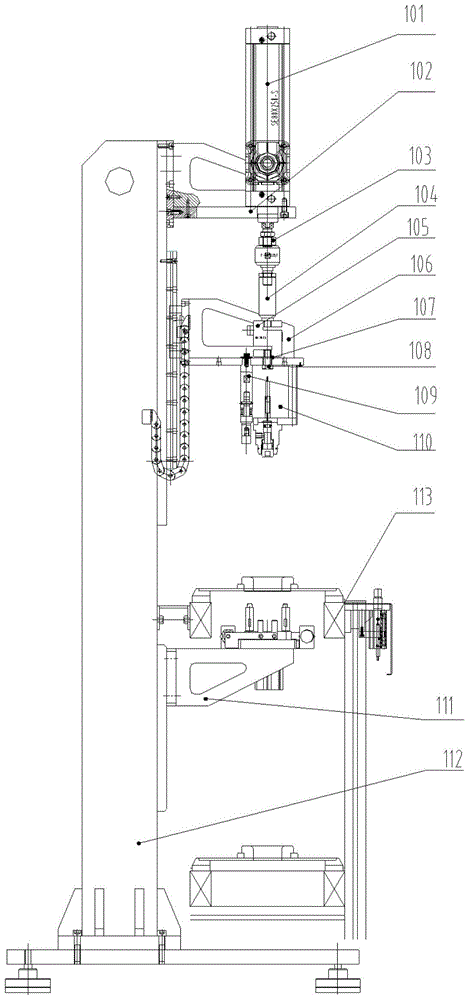

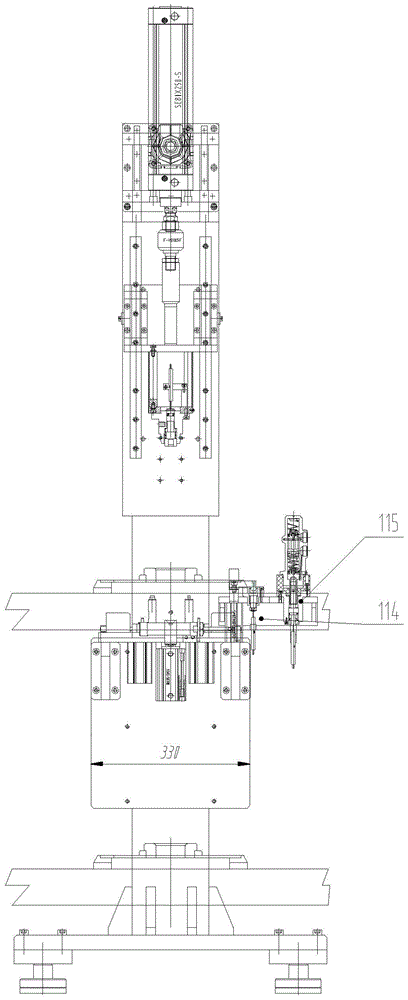

An ejector head adjustment press-fit detection device in a vacuum booster assembly line

ActiveCN104551645BStable and reliable safety protection measuresGood photoelectric isolation functionMeasurement devicesMetal working apparatusAutomatic controlData acquisition

The invention discloses an adjusting and press fitting detecting device for an ejector pin head in a vacuum booster assembling line. The adjusting and press fitting detecting device comprises an ejector pin head adjusting device, an automatic control device, a push rod head press fitting detecting device, a material box and a gas circuit control device, wherein the automatic control device is disposed between the ejector pin head adjusting device and the push rod head press fitting detecting device, and the material box is disposed below the automatic control device; the automatic control device comprises a data collecting control part, a PC and a PCI bus, the PC is connected with the data collecting control part through the PCI bus, the data collecting control part controls the gas circuit control device through the instructions of the PC, and accordingly the operation of the first air cylinder and the first jacking mechanism of the ejector pin head adjusting device and the second air cylinder and the second jacking mechanism of the push rod head press fitting detecting device is controlled. The adjusting and press fitting detecting device is high in automation level, stable and reliable in operation, and capable of guaranteeing ejector pin head detecting accuracy and monitoring data accuracy.

Owner:HANGZHOU WOLEI INTELLIGENT TECH

Tube-type slab lattice paste extrusion production line

ActiveCN102136571BGuaranteed performanceAvoid flyingLead-acid accumulator electrodesProduction lineControl system

The invention relates to a tube-type slab lattice paste extrusion production line. The tube-type slab lattice paste extrusion production line is characterized in that: a lead paste stirring motor is arranged in a paste extrusion bucket; the paste extrusion bucket is arranged on a paste extrusion rack; the lead paste delivery pipe is arranged on the lower part of the paste extrusion bucket and is connected with a paste extrusion head; and a slab lattice clamp device, a sliding table moving device, a primary paste extruding and washing device, a 1# polar plate delivery device, a back cover delivery device, a welding control system, an ultrasonic welding device, a secondary paste extruding and washing device, a 2# polar plate delivery device, a paste weighing device and a waste plate removing device are arranged behind the lead paste delivery pipe in turn. The tube-type slab lattice paste extrusion production line is improved on the basis of an original storage battery tube-type slab lattice which extrudes lead paste directly, and has the characteristics of reliable performance, environment friendliness, and capacity of filling a row gate tube of a storage battery with the lead paste uniformly and the like.

Owner:ZIBO XINXU POWER SUPPLY TECH

An environment-friendly dry waste incineration and waste gas treatment system

ActiveCN110345493BRealize automatic reciprocating movementLabor savingDispersed particle filtrationEmission preventionDrive wheelExhaust fumes

The invention provides an environment-friendly dry garbage incineration system and its exhaust gas treatment system, which includes an incinerator wall, a material guide inclined plate, a support frame, a No. 1 drive wheel, a support plate, a conveyor belt, a No. 2 drive wheel, a bottom plate, and a material guide motor. and other structures, the reciprocating cleaning mechanism is installed on the upper part of the installation plate through bolts; the discharge mechanism is installed on the inner bottom of the incinerator wall and below the furnace plate; the waste gas filter box is arranged on the lower part of the installation plate; The reaction chamber is installed on the lower part of the mounting plate through a stabilizing column and is located on one side of the exhaust gas filter box. The arrangement of the reciprocating cleaning mechanism, the discharging mechanism, the exhaust gas filter box and the reaction chamber of the present invention can effectively incinerate the dry garbage, and the generated gas can be filtered and purified, and the filter parts can be reciprocally cleaned to improve the purification effect, and further It meets the country's requirements for environmental protection of garbage, and the discharge process of waste after incineration is environmentally friendly and pollution-free. The whole system has great environmental protection value.

Owner:HEZE UNIV

Optical glass

ActiveCN110228946BGood chemical stabilityMeet the requirements of environmental protectionOptical elementsRefractive indexOptical glass

The invention provides an optical glass, the components of which are represented by weight percentage, containing: SiO 2 : 40~58%; TiO 2 : 18~32%; Na 2 O: 3-20%; K 2 O: 6~20%, of which TiO 2 / SiO 2 0.35 to 0.8. Through reasonable component design and proportioning, the optical glass of the present invention not only satisfies the expected refractive index and Abbe number, but also has excellent chemical stability, does not contain harmful components such as PbO, and meets the requirements of environmental protection.

Owner:CDGM OPTICAL GLASS

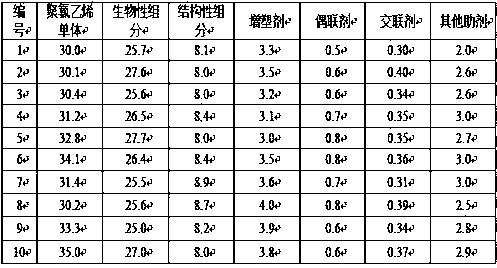

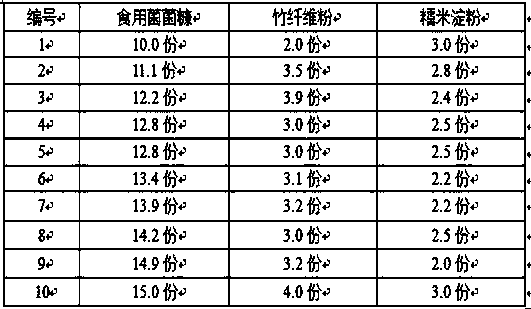

Preparation method of easily-degradable environmentally-friendly plastic

The invention discloses a preparation method of an easily-degradable environmentally-friendly plastic, and the preparation method comprises the following steps: S01, ultrasonically sterilizing a biological component; S02, mixing a polyvinyl chloride monomer with a plasticizer and other auxiliary agents, dispersing, adding the biological component, uniformly dispersing, adding a structural component, grinding and dispersing; S03, adding a coupling agent and a crosslinking agent into a mixture obtained in the S02, and using a planet type grinding machine for grinding and dispersing for 5-8min at300 to 400 r / min to obtain a desired mixed raw material; S04, using a twin-screw extruder for granulating the mixed raw material obtained in the S03 at the extrusion rate of 3.5-4.5 kg / hand the melting temperature of 205-210 DEG C to obtain the easily-degradable environmentally-friendly plastic. The easily-degradable environmentally-friendly plastic can be used for a long time under the conditionof daily use, and has stable storage property. Compared with plastic products in the prior art, the strength and toughness of the easily-degradable environmentally-friendly plastic are basically thesame as that of the plastic products in the prior art, and after being discarded, the easily-degradable environmentally-friendly plastic can be slowly broken and completely degraded in a hot and humidenvironment, has no pollution to the environment and the human body, and meets the requirements of environmental protection.

Owner:FOSHAN RICH FIELD COMMODITIES CO LTD

Method for absorbing paint mist by utilizing nanometer calcium carbonate

ActiveCN104028409AReduce usageImprove adsorption capacityLiquid surface applicatorsSpraying apparatusLacquerNanometre

The invention relates to a method for absorbing paint mist by utilizing nanometer calcium carbonate. The method comprises the following steps: firstly preparing the nanometer calcium carbonate into a required nanometer calcium carbonate forming body; then placing nanometer calcium carbonate forming body in the paint mist environment after the nanometer calcium carbonate forming body is sealed, placing a concentration meter in the paint mist environment at the same time and measuring the initial concentration of the paint mist; opening the sealed forming body, observing the read number of the concentration meter during the opening period and judging whether the absorption of the paint mist by the nanometer calcium carbonate has reached saturation or not or whether the nanometer calcium carbonate forming body needs to be replaced or not according to the read number of the concentration meter. The method has the advantages that the huge specific surface area and the excellent absorption capability of the nanometer calcium carbonate are fully utilized to capture the paint mist; meanwhile, after being retreated, the nanometer calcium carbonate after absorbing the paint mist can be taken as an additive to be applied to coating, so that the cost is greatly saved; the nanometer calcium carbonate has good long-term sustainability, and the shape of the nanometer calcium carbonate is easy to process when the nanometer calcium carbonate is used as the forming body, therefore, the nanometer calcium carbonate is suitable for mass production and application.

Owner:陈曦

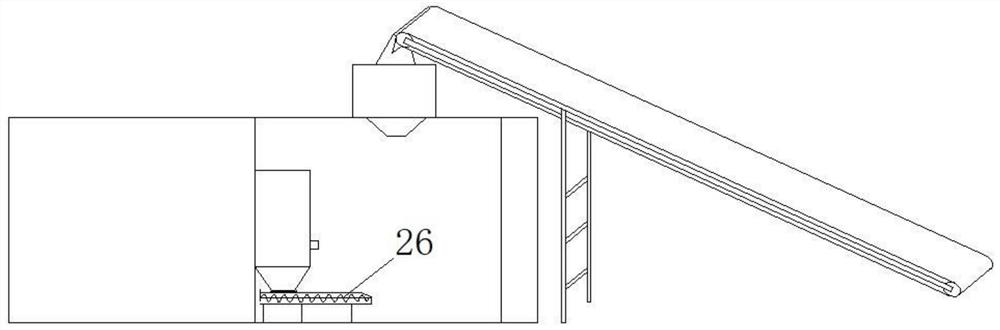

Cullet crushing dust recovery device

PendingCN112676008AReduce labor intensityImprove the operating environmentDispersed particle filtrationGlass recyclingDust controlEnvironmental engineering

The invention provides a cullet crushing dust recovery device. The cullet crushing dust recovery device comprises a powder bin, a crushing mechanism is arranged on the powder bin, a discharging port of the crushing mechanism extends into the powder bin, the cullet crushing dust recovery device further comprises a feeding conveying mechanism used for conveying glass to a feeding port of the crushing mechanism, and a dust removal mechanism used for sucking in broken glass dust for treatment is arranged in the powder bin. The device can effectively eliminate the flying dust generated when cullet is broken, reduce the labor intensity of workers, improve the operation environment of the workers and meet the requirement for environmental protection treatment.

Owner:信和光能(安徽)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com