Dynamic-vulcanization thermoplastic polyolefine waterproof roll material and preparation method thereof

A technology of thermoplastic polyolefin and dynamic vulcanization, which is applied in the field of building materials, can solve the problems affecting the application and development of ethylene-propylene-propylene rubber vulcanized coils, the technology of easy migration and exudation of plasticizers, and the limitation of popularization and application, so as to achieve flexible construction methods Convenience, increase market competitiveness, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

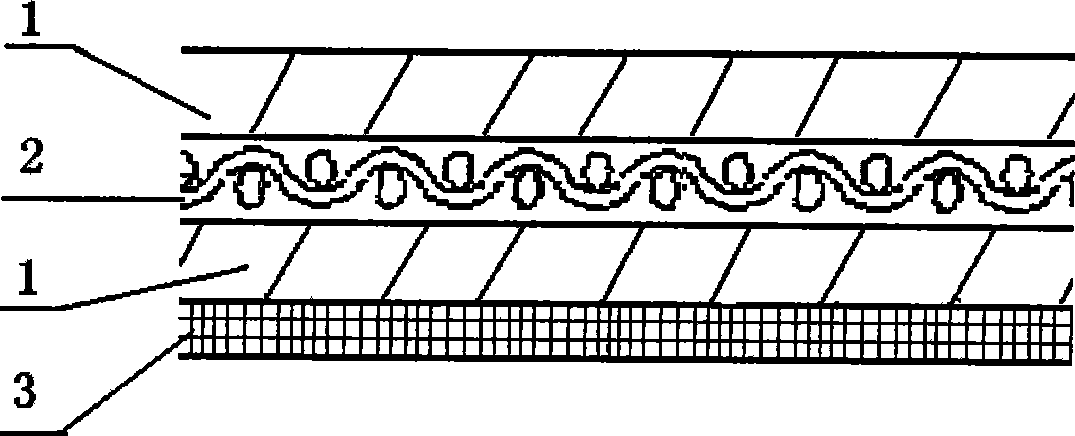

[0027] Example 1 Middle and Surface Backing Double Reinforced Waterproofing Membrane

[0028] exist figure 1 The dynamically vulcanized thermoplastic polyolefin waterproof membrane of the present invention consists of a main body layer 1 , a middle reinforcing layer 2 and a surface backing reinforcing layer 3 .

Embodiment 2

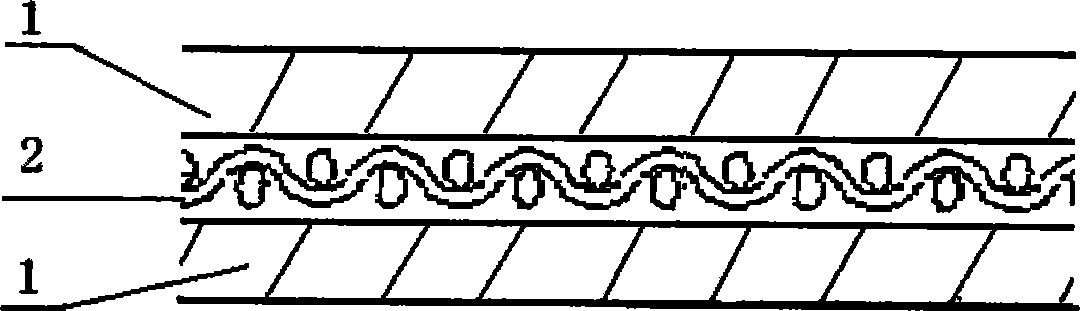

[0029] Example 2 Intermediate reinforced waterproof membrane

[0030] exist figure 2 The dynamically vulcanized thermoplastic polyolefin waterproof membrane of the present invention consists of a main body layer 1 and a middle reinforcement layer 2 .

Embodiment 3

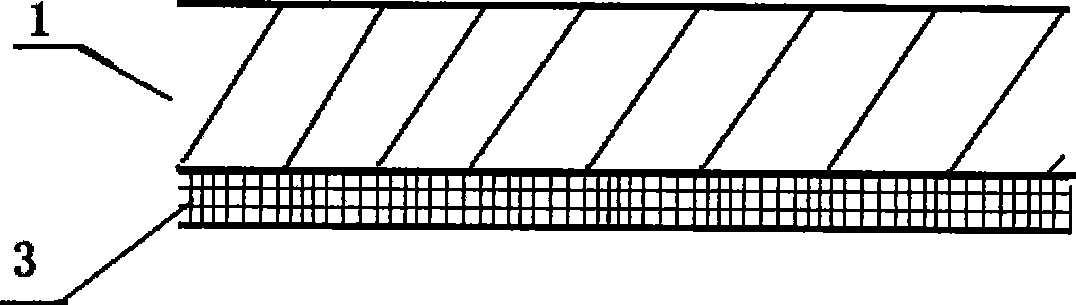

[0031] Example 3 Surface Backing Enhanced Waterproof Membrane

[0032] exist image 3 The dynamically vulcanized thermoplastic polyolefin waterproof membrane of the present invention consists of a main body layer 1 and a surface backing reinforcement layer 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com