High strength composite non-prestressed stretching and anchoring construction method

A technology of composite materials and construction methods, applied in building maintenance, construction, building construction, etc., can solve problems such as inconvenience and inability to use, and achieve the effect of expanding the application range, increasing the number of layers, and simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment, further illustrate the present invention.

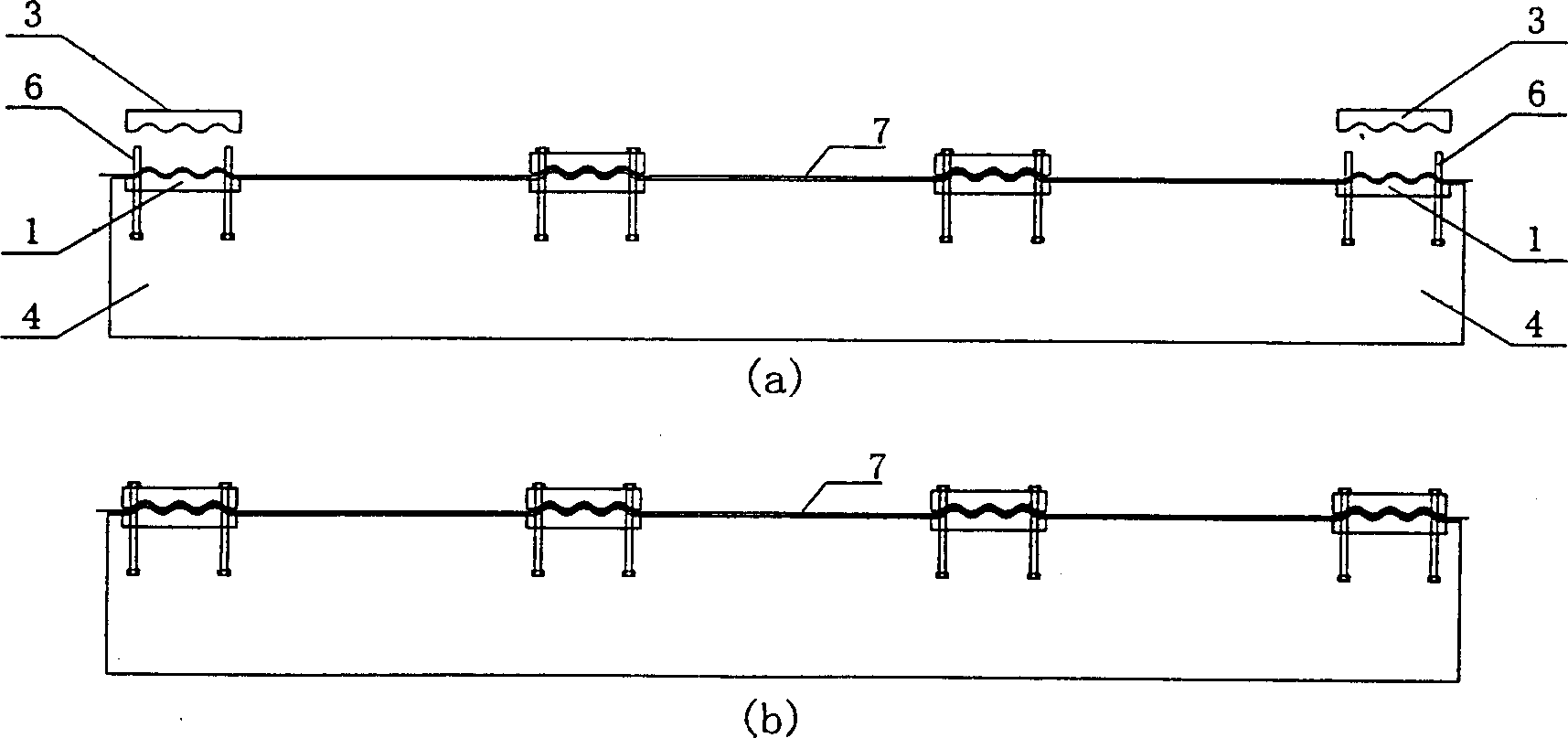

[0022] Such as image 3 As shown, in this embodiment, a reinforced concrete beam with a length of 3.40 meters, a height of 0.32 meters and a width of 0.16 meters is used as the test beam and the comparison beam. The lower corrugated tooth plate 1 of the corrugated tooth fixture anchor is pre-embedded in the test beam, and four corrugated tooth fixture anchors are shared, two of which are located at the two ends of the beam, and the other two are located at the two third points of the beam. A carbon fiber cloth 7 with a thickness of 3×0.111 mm and a width of 100 mm was pasted on the bottom of the test beam, and anchored with four corrugated tooth clamps at the bottom of the beam. In addition, a 3×0.111 mm thick carbon fiber cloth is also pasted on the bottom of the contrast beam, but the wave-tooth clamp is not used for anchoring. In order to facilitate various construction operations, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com