Hyperbolic double-layer reticulated shell steel structure cooling tower

A steel structure, hyperbolic technology, applied in refrigeration plants, industrial buildings, etc., can solve the problems of large steel consumption, complex structure and construction, and achieve the effect of low steel consumption, simple construction and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

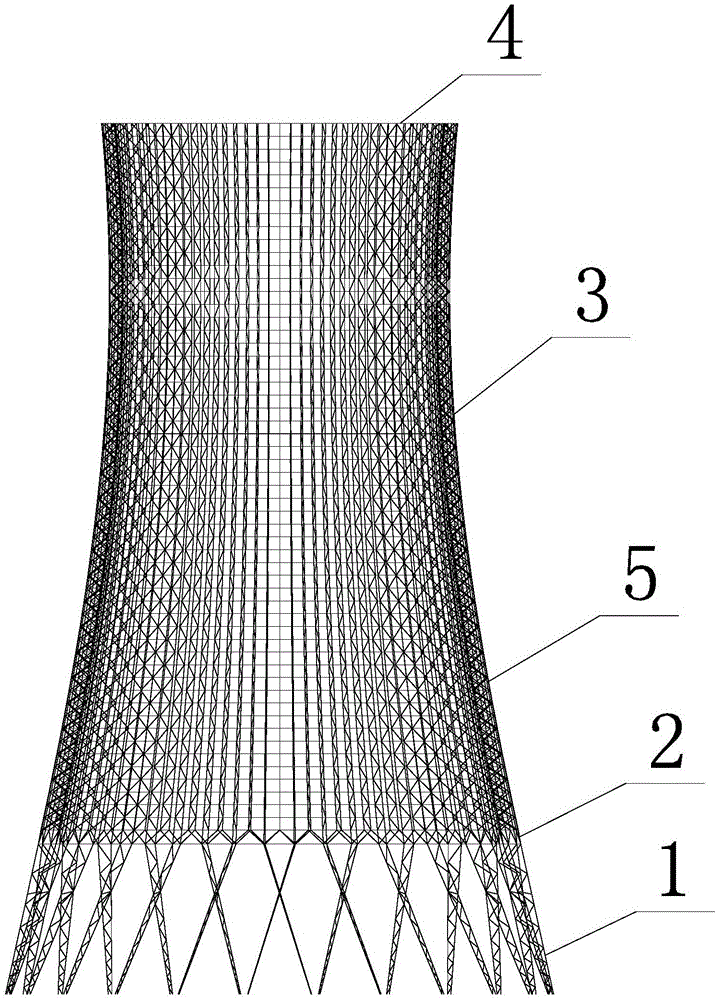

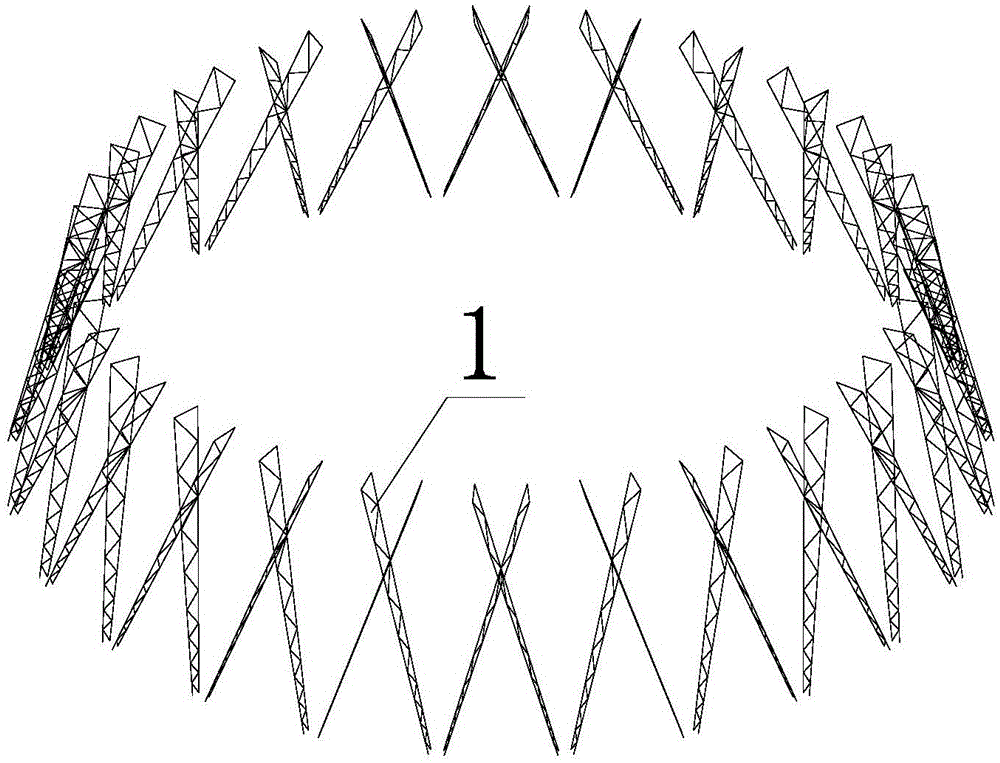

[0029] Embodiment 1 of the present invention: as Figures 1 to 8 As shown, a hyperbolic double-layer reticulated steel structure cooling tower includes a bottom lattice column 1, a conversion truss 2 and an upper tower 3, the conversion truss 2 is installed on the upper part of the bottom lattice column 1, and the upper tower 3 is installed on the The upper part of the conversion truss 2, the upper tower 3 is a double-layer reticulated shell structure.

[0030] The upper tower 3 includes a horizontal plane truss 4 and a vertical plane truss 5 , and the horizontal plane truss 4 and the vertical plane truss 5 are arranged orthogonally.

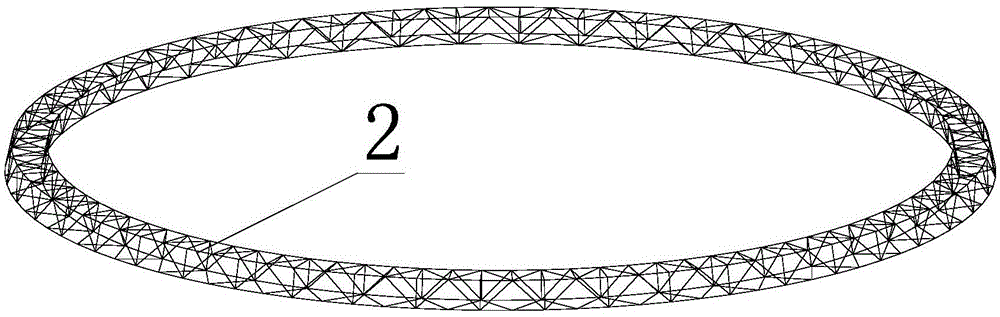

[0031] The horizontal plane truss 4 includes the tower outer ring chord 6, the tower inner ring chord 7 and the first web 8, the tower outer ring chord 6 and the tower inner ring chord 7 are located on the same horizontal plane, the tower outer ring The chord 6 is composed of a plurality of first chords 15 connected end to end through the first...

Embodiment 2

[0038] Embodiment 2: as Figures 1 to 8 As shown, a hyperbolic double-layer reticulated steel structure cooling tower includes a bottom lattice column 1, a conversion truss 2 and an upper tower 3, the conversion truss 2 is installed on the upper part of the bottom lattice column 1, and the upper tower 3 is installed on the The upper part of the conversion truss 2, the upper tower 3 is a double-layer reticulated shell structure.

[0039] The upper tower 3 includes a horizontal plane truss 4 and a vertical plane truss 5 , and the horizontal plane truss 4 and the vertical plane truss 5 are arranged orthogonally.

[0040] The horizontal plane truss 4 includes the tower outer ring chord 6, the tower inner ring chord 7 and the first web 8, the tower outer ring chord 6 and the tower inner ring chord 7 are located on the same horizontal plane, the tower outer ring The chord 6 is composed of a plurality of first chords 15 connected end to end through the first node 9, the tower inner ...

Embodiment 3

[0047] Embodiment 3: as Figures 1 to 8 As shown, a hyperbolic double-layer reticulated steel structure cooling tower includes a bottom lattice column 1, a conversion truss 2 and an upper tower 3, the conversion truss 2 is installed on the upper part of the bottom lattice column 1, and the upper tower 3 is installed on the The upper part of the conversion truss 2, the upper tower 3 is a double-layer reticulated shell structure.

[0048] The upper tower 3 includes a horizontal plane truss 4 and a vertical plane truss 5 , and the horizontal plane truss 4 and the vertical plane truss 5 are arranged orthogonally.

[0049] The horizontal plane truss 4 includes the tower outer ring chord 6, the tower inner ring chord 7 and the first web 8, the tower outer ring chord 6 and the tower inner ring chord 7 are located on the same horizontal plane, the tower outer ring The chord 6 is composed of a plurality of first chords 15 connected end to end through the first node 9, the tower inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com