Magnetic levitation track structure

A technology of maglev track and steel structure, which is applied in the directions of tracks, roads, buildings, etc., can solve the problems of high assembly difficulty of maglev track, difficult manufacture of F-shaped rails, and high manufacturing cost, so as to facilitate rapid assembly and replacement, and save manufacturing and installation. Cost, effect of increased maintainability and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

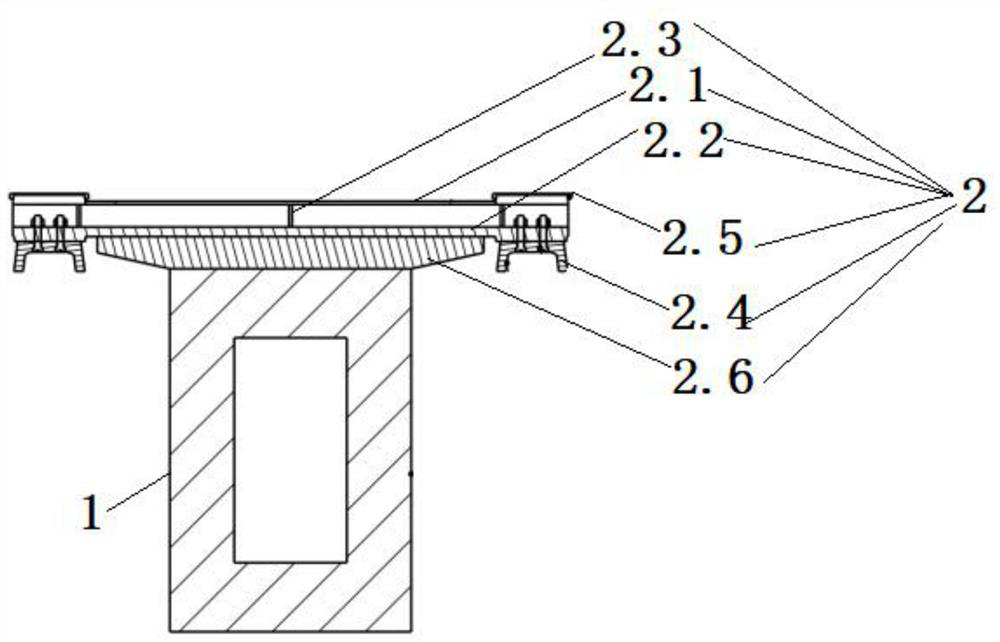

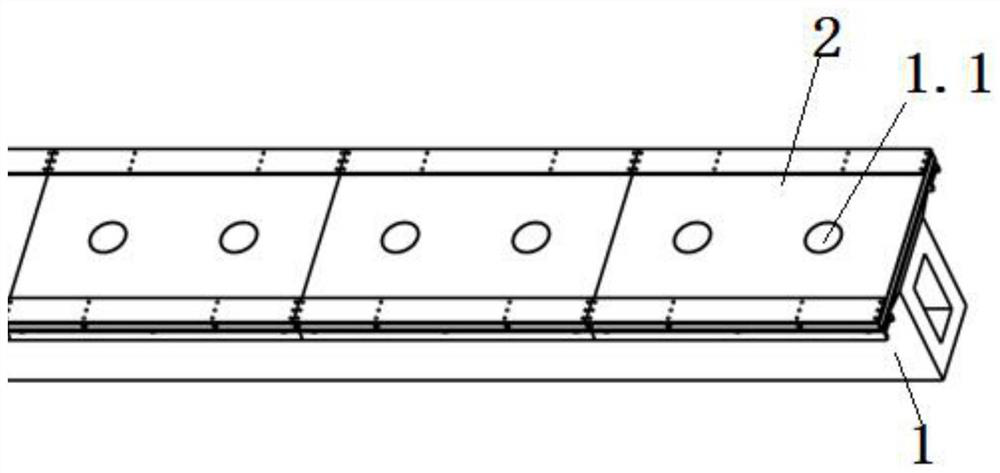

[0036] A magnetic levitation track structure, including a concrete main body 1 and a steel structure component 2, such as Figure 1-3 As shown, the details are as follows:

[0037] like figure 2 As shown, the concrete main body 1 is provided with through grooves along the length direction of the magnetic levitation track, which is convenient for cost reduction, and the top surface of the concrete main body 1 is provided with multiple sets of positioning columns 1.1 at equal intervals along the length direction of the magnetic levitation track, and the positioning columns 1.1 are used for steel Positioning and installation of structural components 2.

[0038] like figure 2 As shown, there are multiple sets of steel structure components 2, and multiple sets of steel structure components 2 are arranged on the top surface of the concrete main body 1 along the length direction of the maglev track;

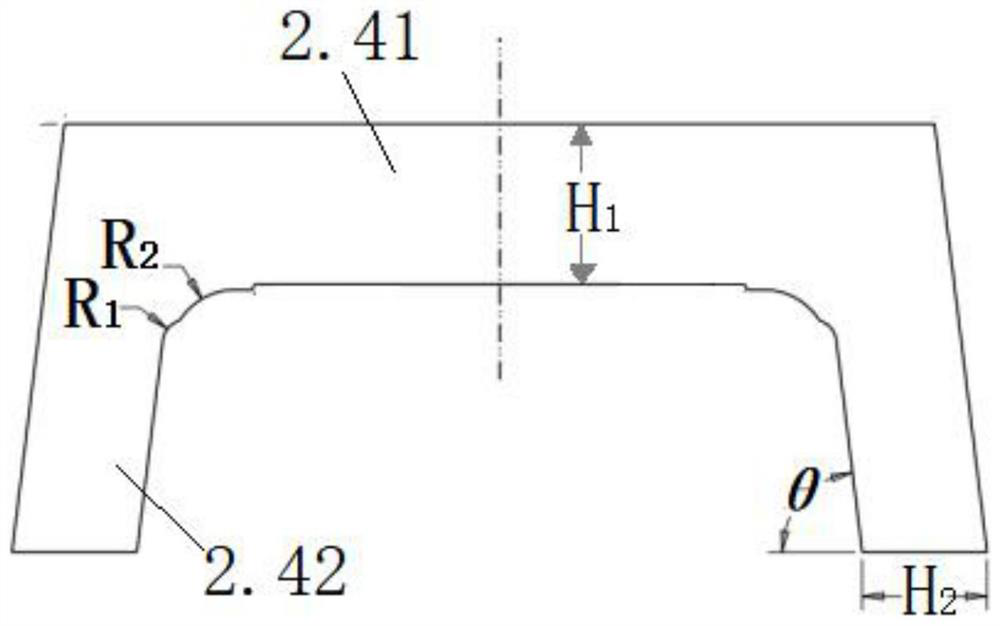

[0039] like figure 1 As shown, the steel structure assembly 2 includes an upp...

Embodiment 2

[0050] The difference between embodiment 2 and embodiment 1 is: the thickness H of the web 1 is 40mm.

Embodiment 3

[0052] The difference between embodiment 3 and embodiment 1 is: the thickness H of the web 1 is 44mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com