Recyclable steel crown beam

A steel crown beam two and crown beam technology, applied in the field of recyclable steel crown beams, can solve the problems of waste of resources, inability to reuse, inconvenient assembly of crown beam structures, etc., and achieve the effect of solving straightness deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

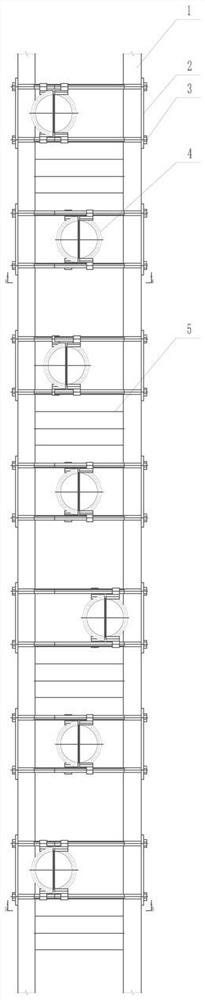

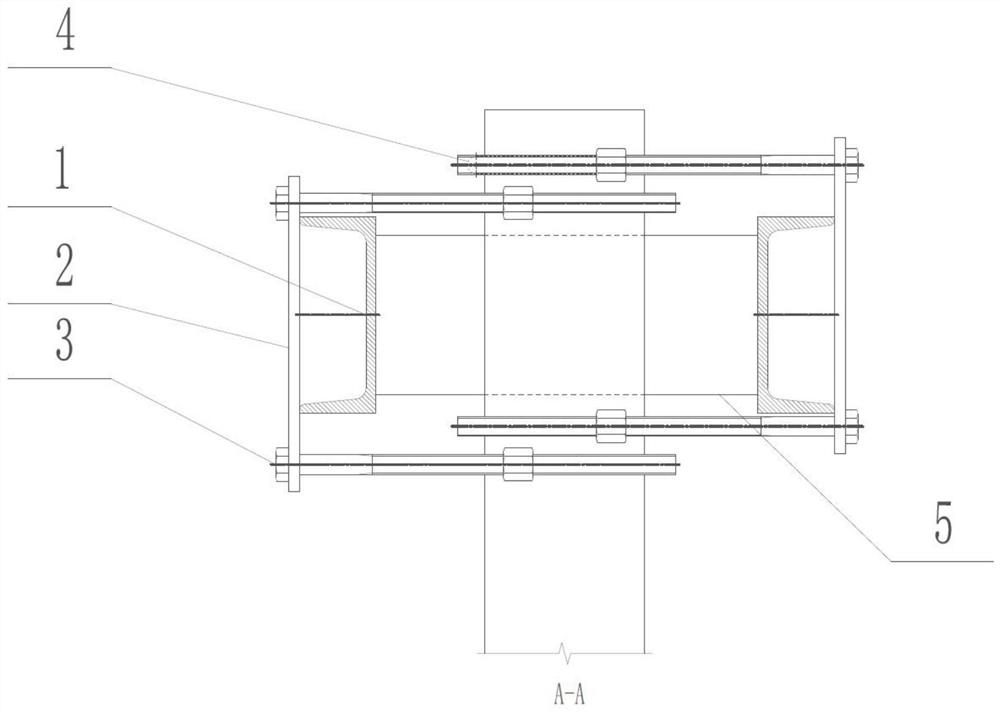

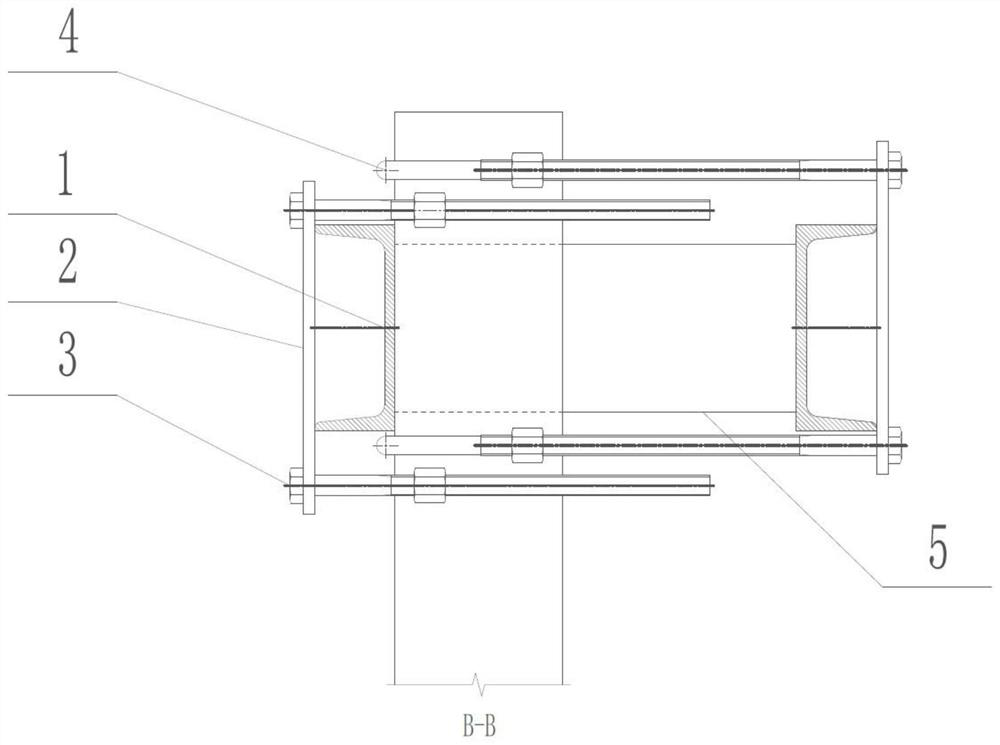

[0034] Please refer to the attached Figure 1-3 , 7-10, the purpose of this embodiment is to provide a recyclable steel crown beam, including: a double crown beam structure, a plurality of steel pipe piles; wherein, a plurality of steel pipe piles are detachably installed in the double crown beam structure Above; multiple supports 5 are provided on the double crown beam structure, and multiple steel pipe piles can be adjusted along the single crown beam structure or the double crown beam structure in the horizontal, vertical and piling depth directions.

[0035] Specifically, the double crown beam structure includes a steel crown beam one and a steel crown beam two, and the steel crown beam one and the steel crown beam two are section steel 1, and the section steel 1 can be a channel steel, an I-beam or a rectangular steel pipe, etc.; the section steel crown beam one A plurality of support pieces 5 are fixedly installed between the steel crown beam two and the steel crown beam...

Embodiment 2

[0039] Please refer to the attached Figure 4-10 , the purpose of this embodiment is to provide a recyclable steel crown beam, including: a single crown beam structure, a plurality of steel pipe piles; wherein, a plurality of steel pipe piles are detachably installed on the single crown beam structure; The beam structure is provided with multiple supports 5, and the multiple steel pipe piles can be adjusted along the single-crown beam structure in the horizontal direction, the vertical direction and the depth direction of piling.

[0040] Among them, the single crown beam structure is preferably shaped steel 1, and the shaped steel 1 can be channel steel, I-beam or rectangular steel pipe, etc.; the single crown beam structure is provided with multiple height-adjustable supports 5, and multiple height-adjustable supports A plurality of steel pipe piles with the same or different diameters are detachably installed on the piece 5. It should be pointed out that those skilled in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com