Patents

Literature

41results about How to "Meet location requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

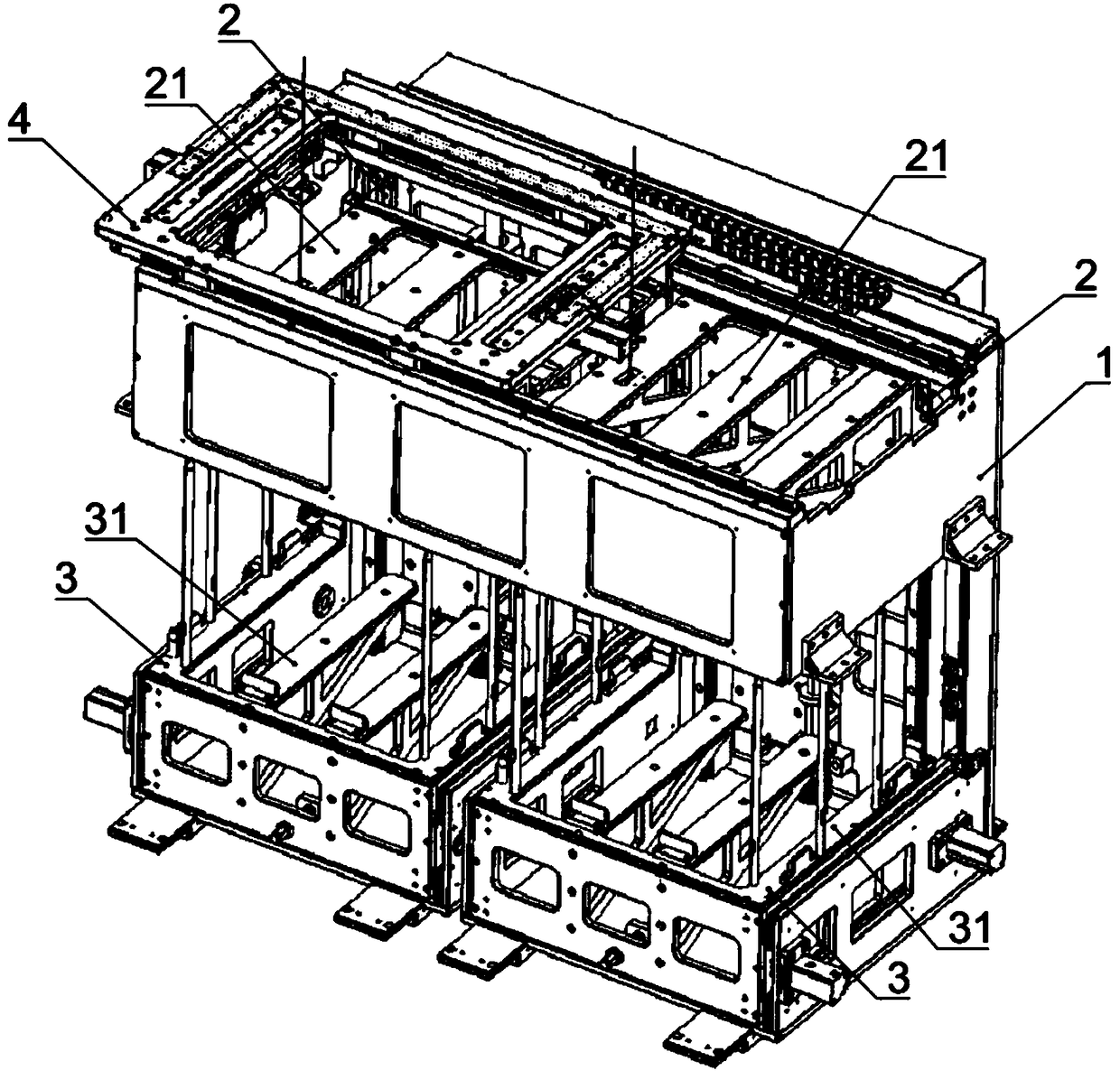

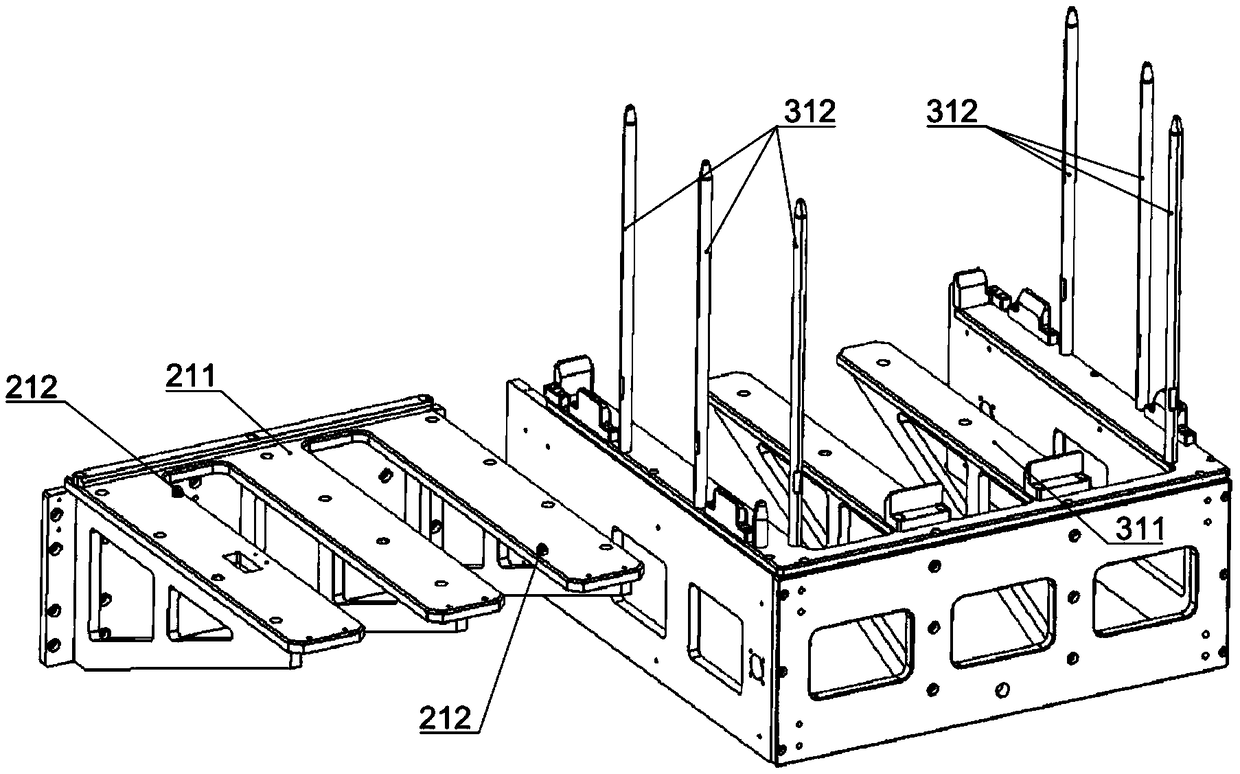

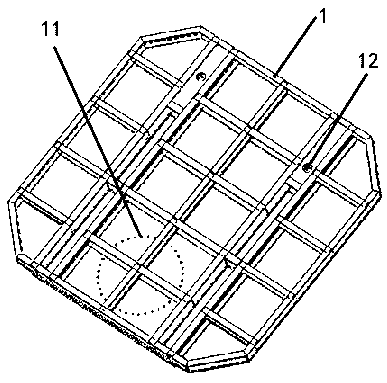

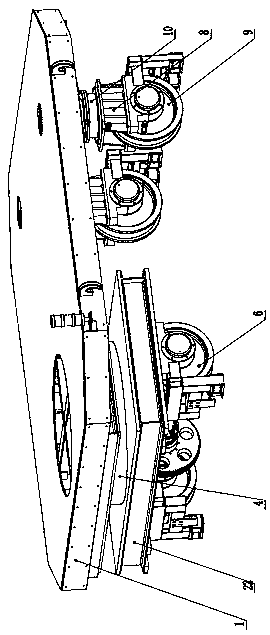

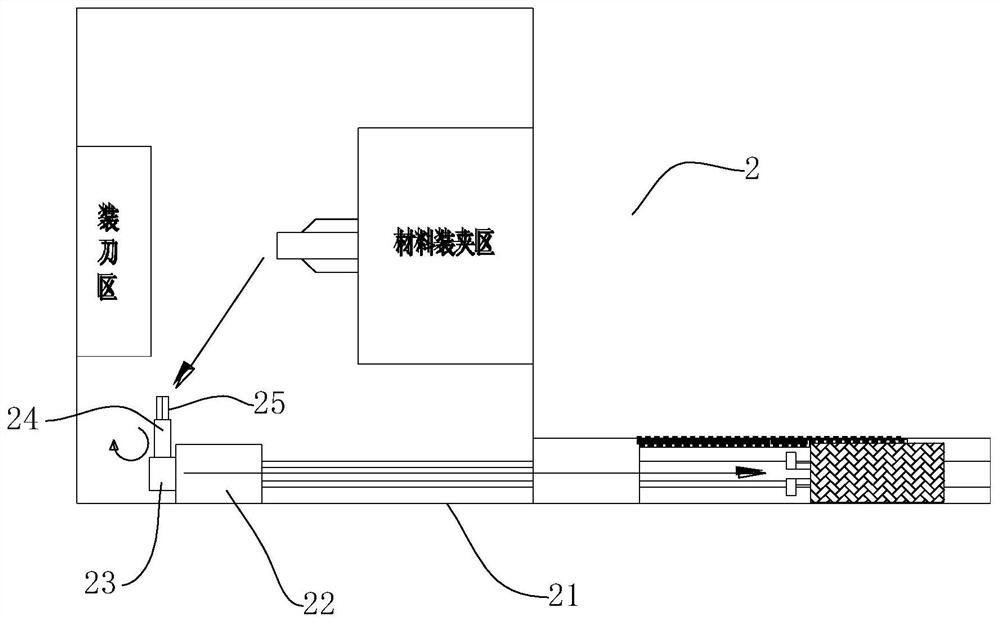

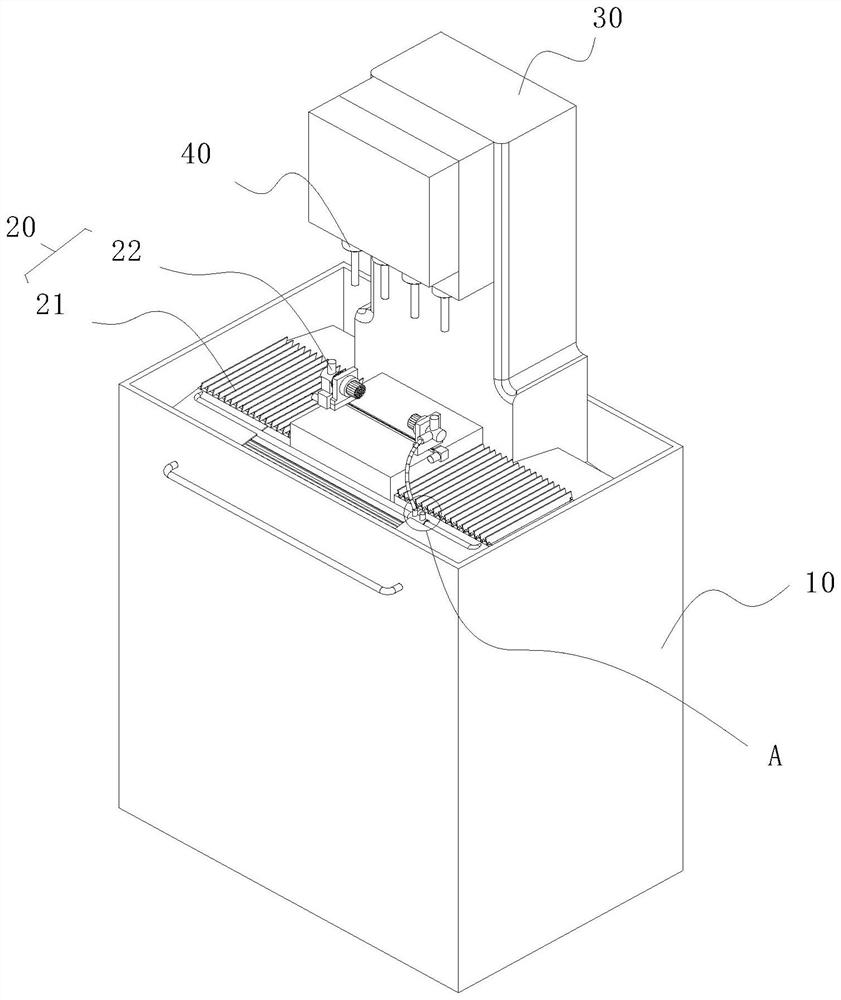

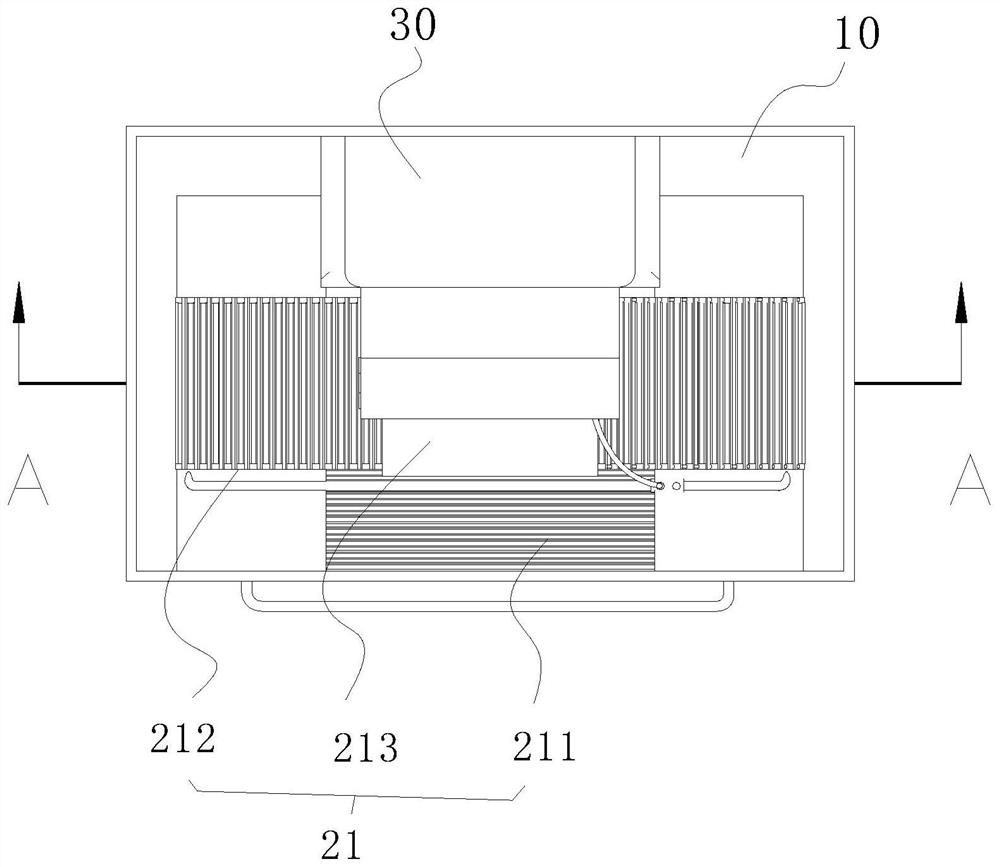

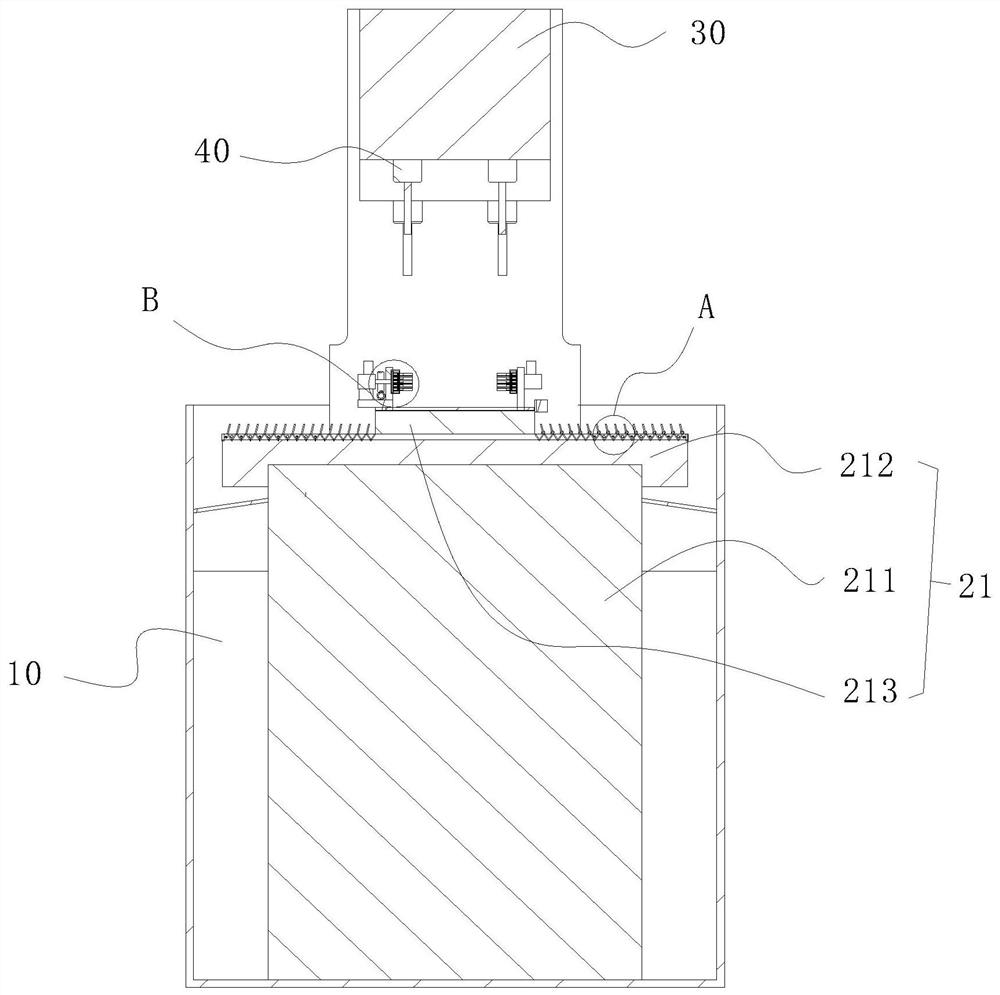

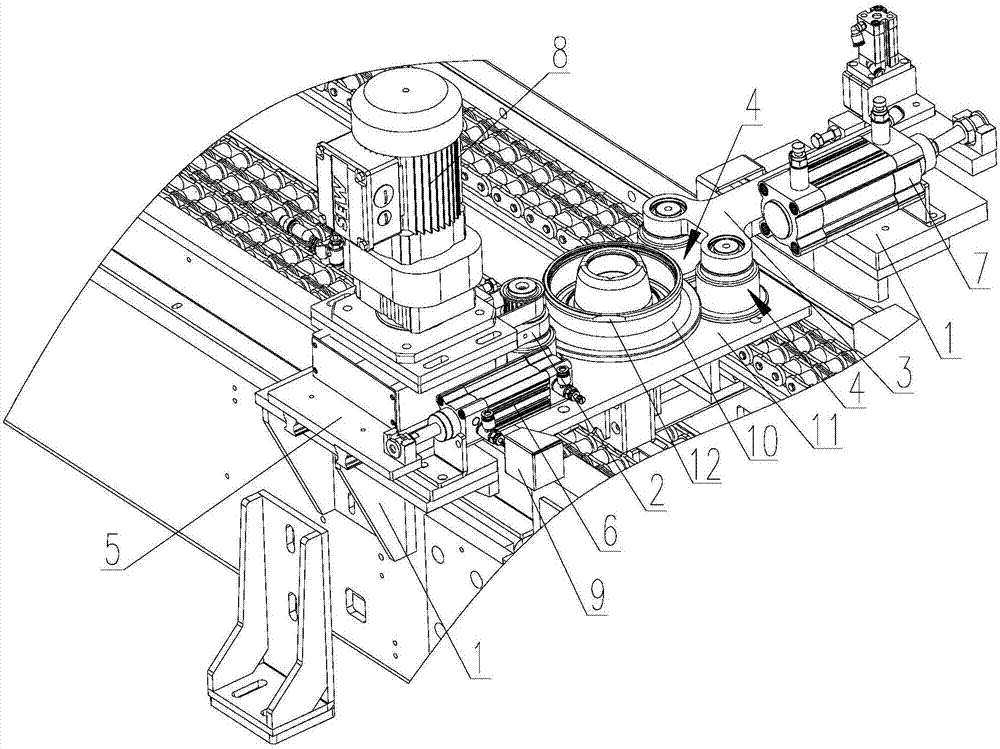

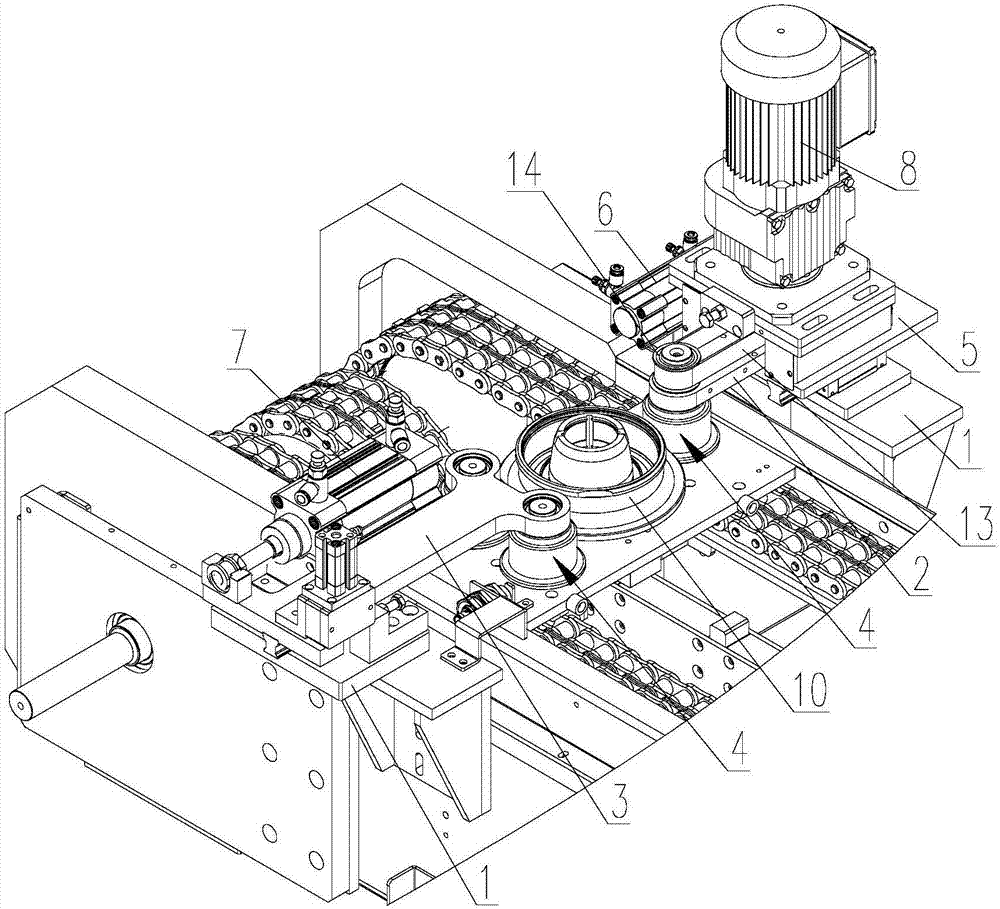

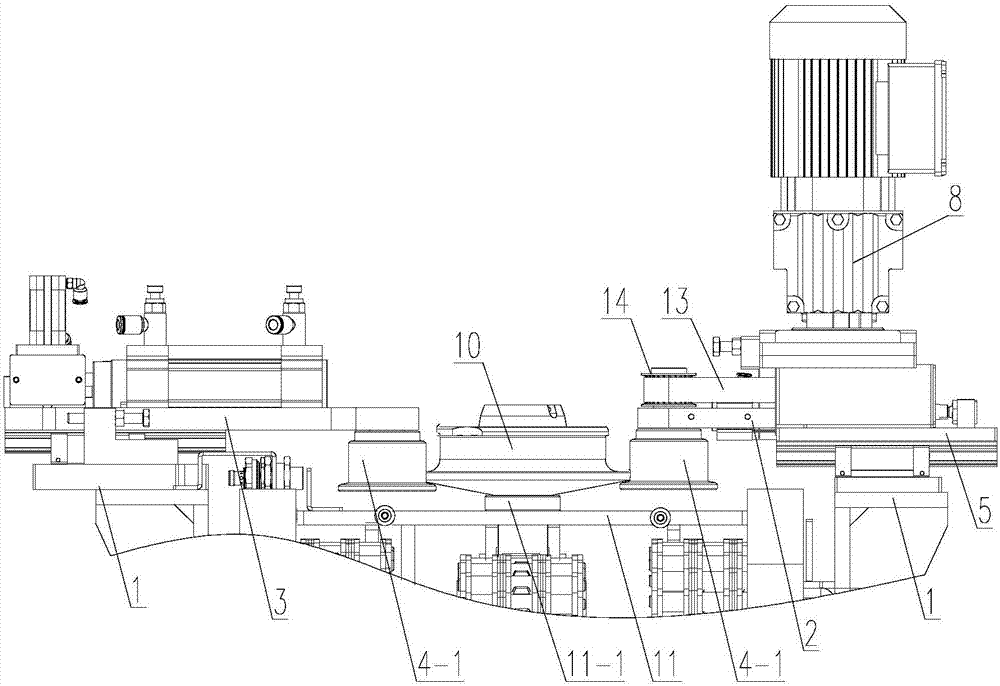

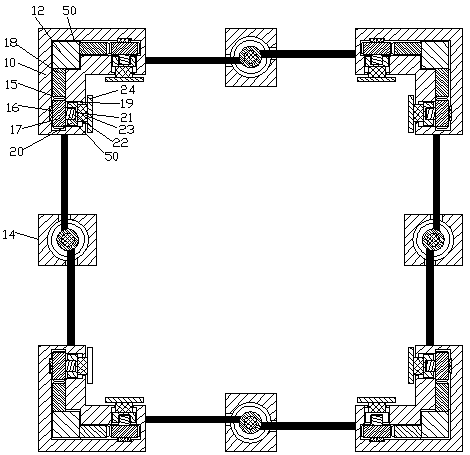

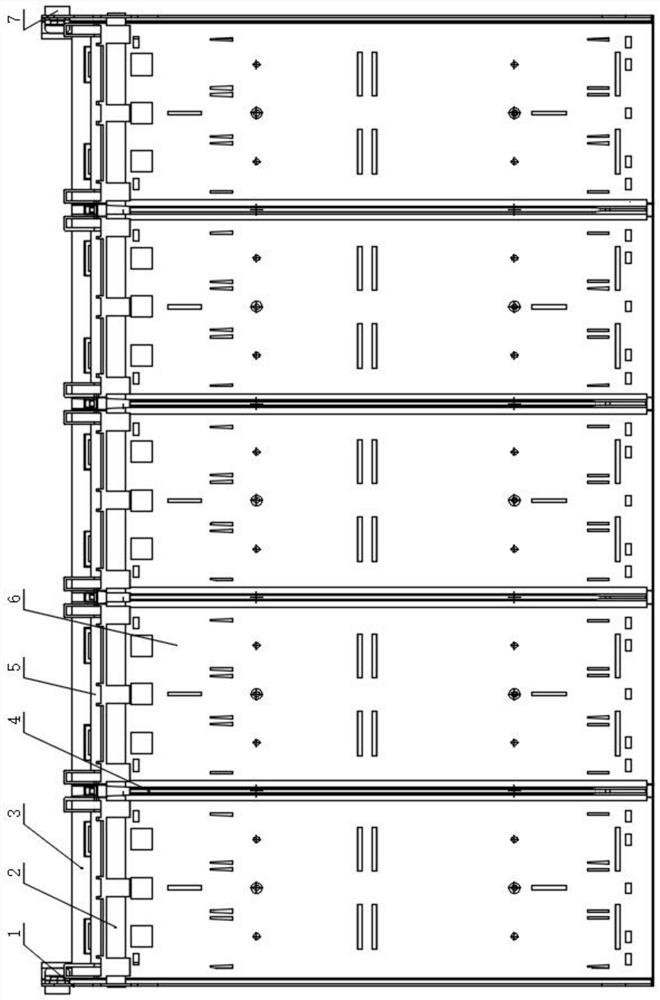

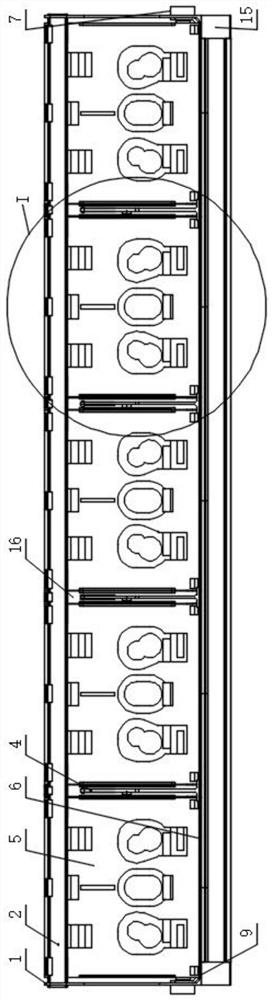

Clip type feeding mechanism

PendingCN109051647AReduce waiting timeImprove work efficiencyConveyor partsMechanical conveyorsEngineeringTransfer mechanism

The invention provides a clip type feeding mechanism which comprises a rack and a transfer mechanism. The rack is provided with a feeding area and a material returning area which are used for carryingmaterial plates and arranged in parallel. The ends of the feeding area and the material returning area are provided with transferring areas which communicate with each other. The other end portions of the feeding area and the material returning area are provided with a feeding area used for material feeding and a discharging area used for material discharging. The transfer mechanism moves in thetransferring area and carries the material plates to the material returning area. The feeding area and / or the material returning area are / is provided with a lifting device and a horizontal moving device which are independent from each other. The lifting device is used for conveying the material plates among the transferring area, the feeding area and the discharging area through lifting motion; the horizontal moving device is used for inputting the material plates to or outputting the material plates from the feeding area and the discharging area through horizontal motion; and the lifting device penetrates the horizontal moving device in a lifting manner and transfers the material plates to the horizontal moving device. By means of the clip type feeding mechanism, material plate lifting, feeding and carrying work can be conducted while the material plates are loaded and unloaded.

Owner:SUZHOU RS TECH

Rail electric flat carriage

PendingCN110589393AReduce risk of capsizingSmooth turningMechanical conveyorsRailway transportEngineeringDrive motor

The invention relates to a rail electric flat carriage. The carriage comprises a carriage body frame and a front drive axle, wherein the front drive axle comprises a differential mechanism and a halfaxle connected with the differential mechanism to drive front wheels of the rail electric flat carriage to move, the differential mechanism is connected with a driving motor, a rotary supporting seatused for bearing the middle part of the front end of the carriage body frame is arranged on the front drive axle, a front rotary support is arranged between the rotary supporting seat and the carriagebody frame, two rear wheel seats are arranged on the carriage body frame, two rear wheels of the rail electric flat carriage are rotatably assembled on the rear wheel seats, rear rotary supports withrotating axes in the vertical direction are arranged between the two rear wheel seats and the carriage body frame, and the carriage body frame is supported by three supporting points of the front rotary support and the two rear rotary supports. When a trolley makes a turn on the track, a triangular support formed by the three supporting points is relatively stable when the carriage body frame deviates relative to the wheels and the track, so that the risk of the overturning of the carriage body frame is greatly reduced, and the trolley can make a turn more stably.

Owner:HENAN UNIV OF SCI & TECH

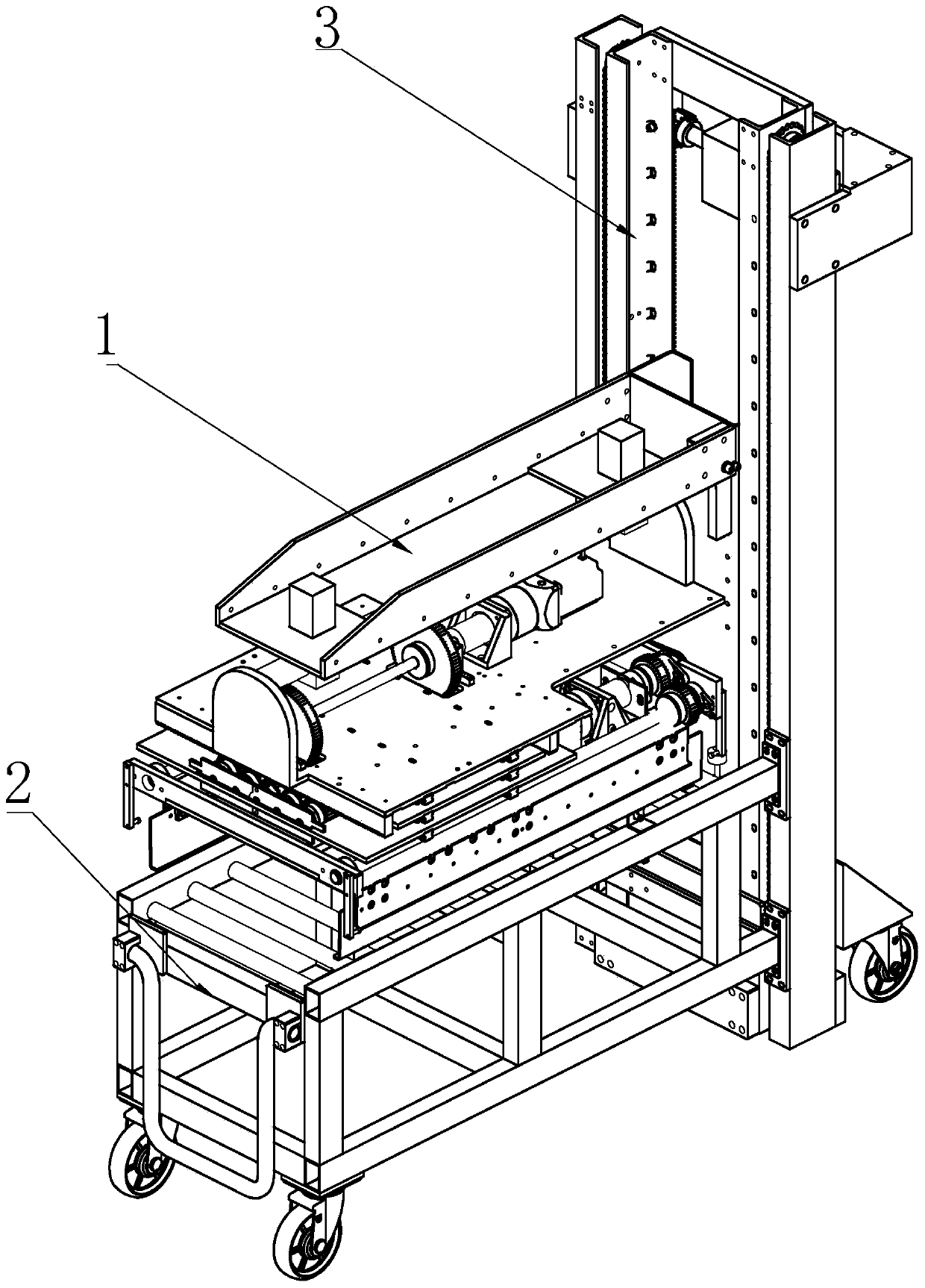

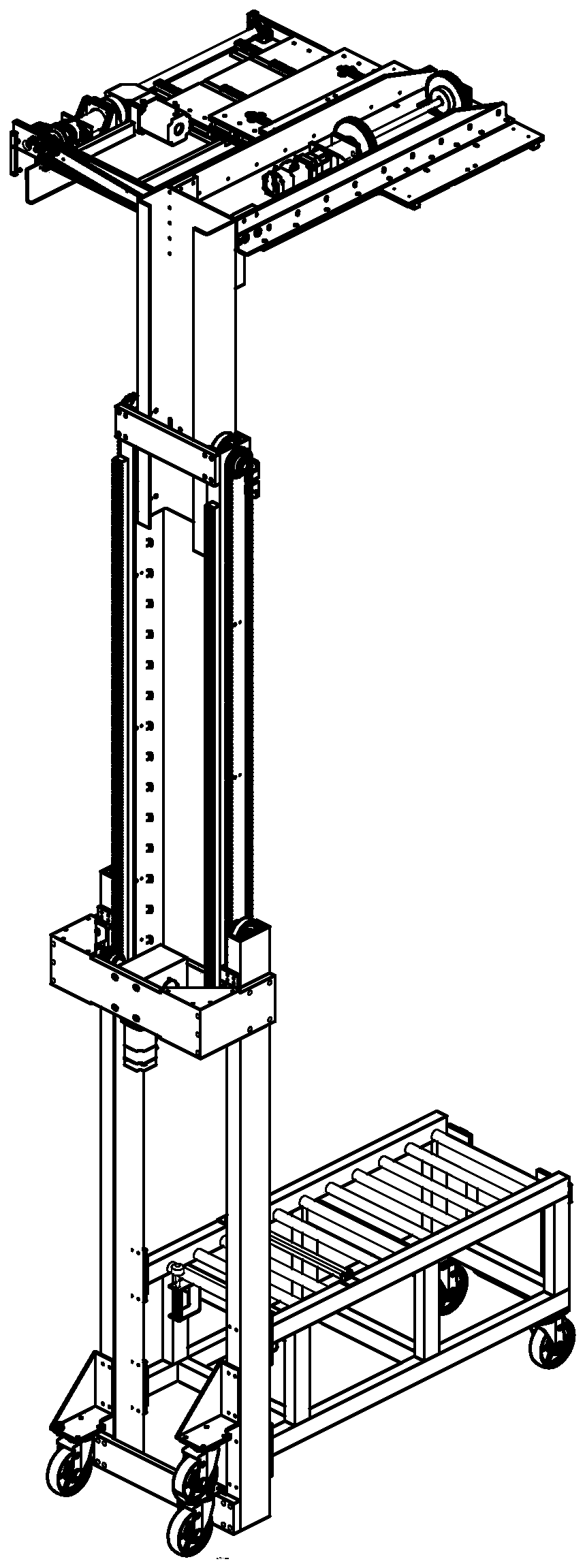

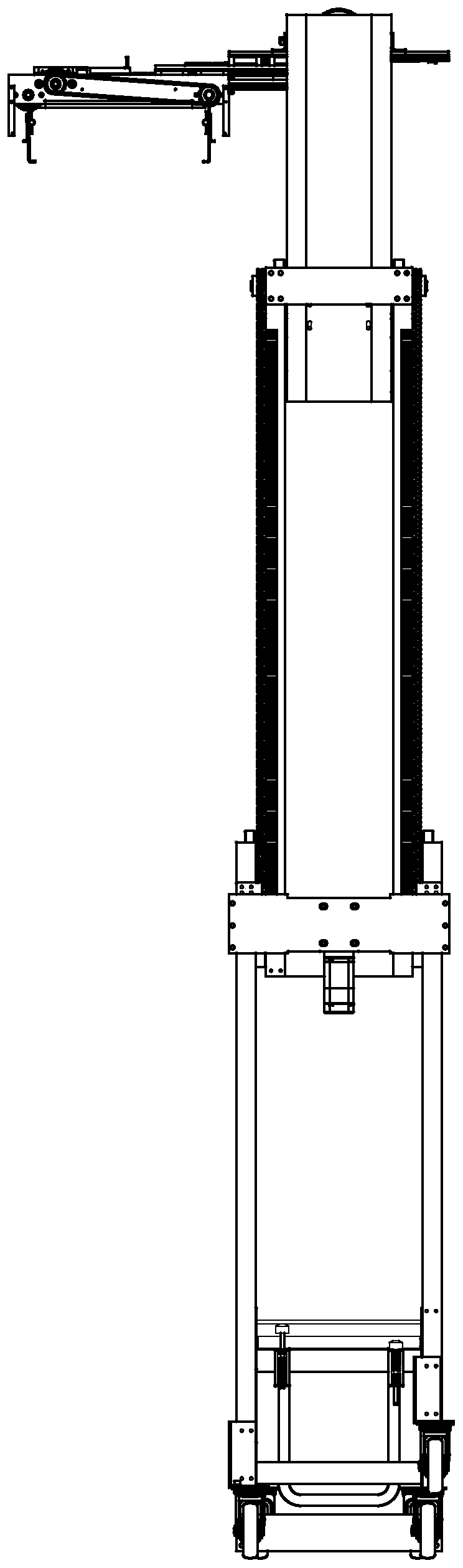

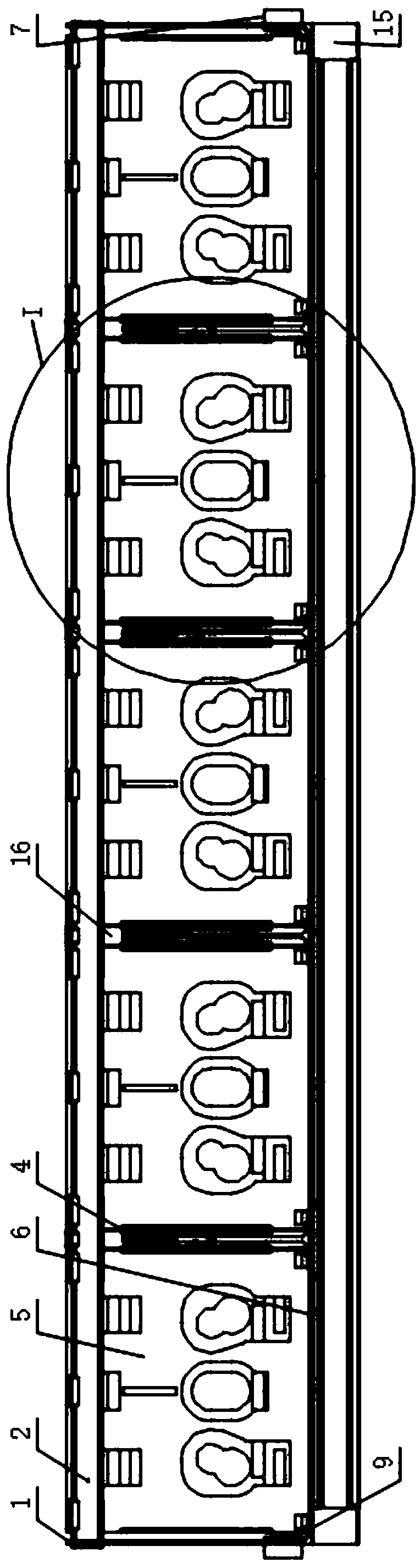

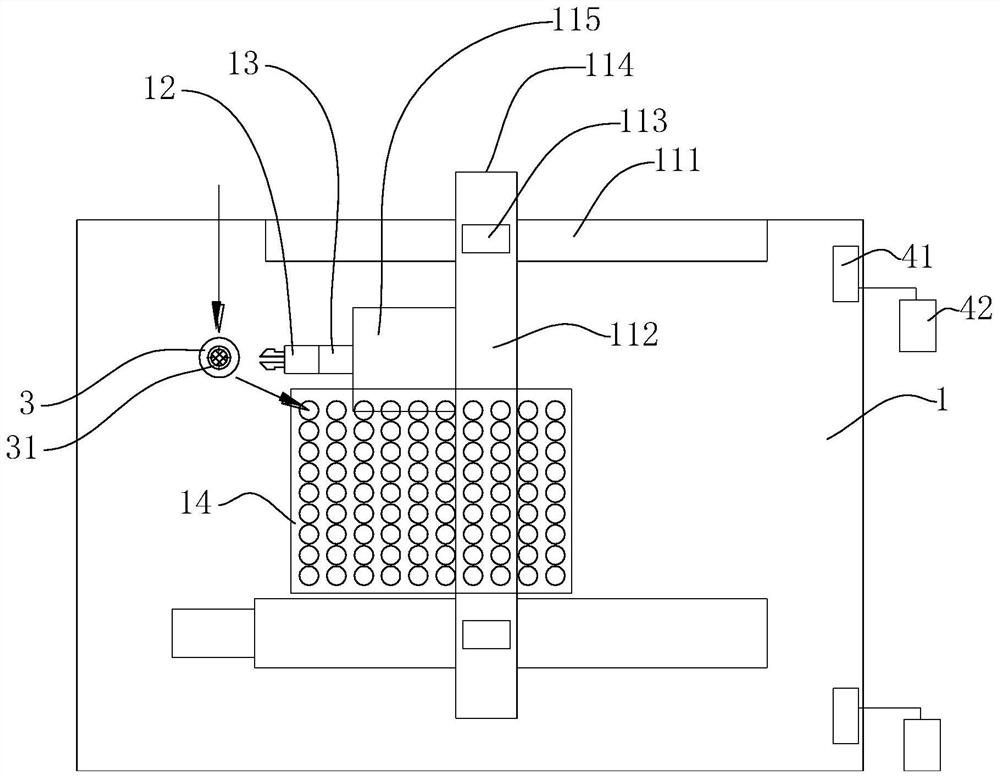

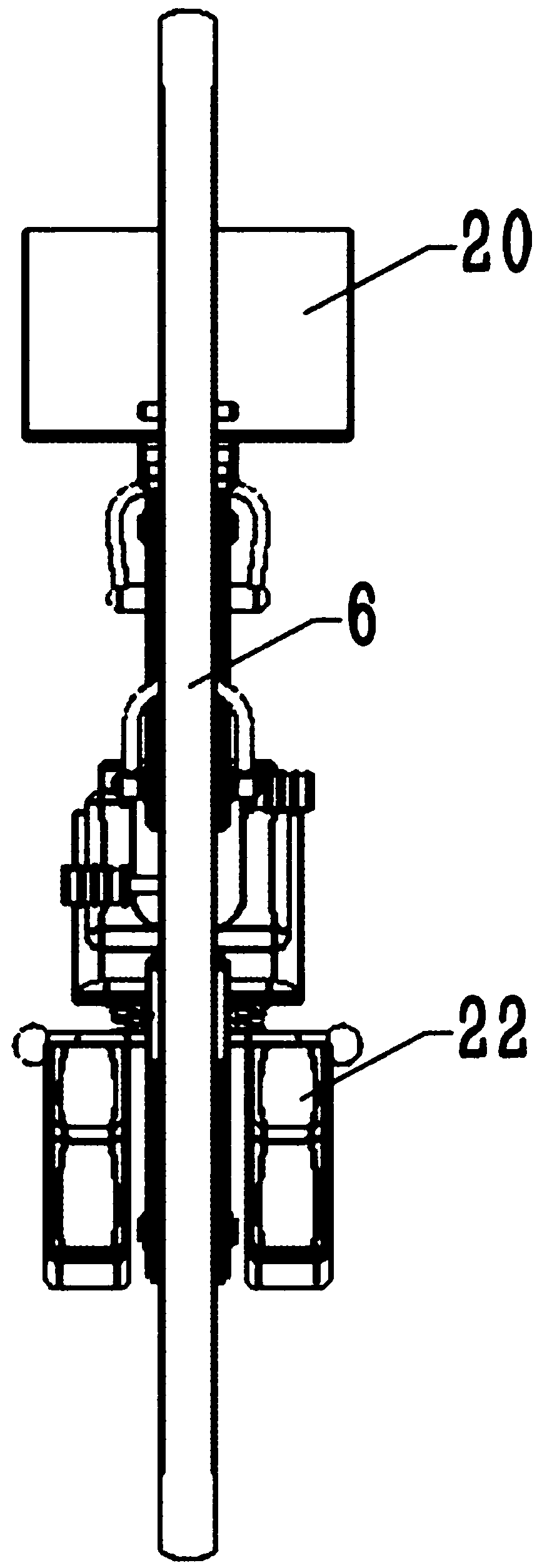

Grabbing type racking and unracking machine

PendingCN110775510AAchieve positioningPrevent slidingConveyorsCultivating equipmentsStructural engineeringMachine

The invention discloses a grabbing type racking and unracking machine. The machine comprises a vertical support, an objective table, a transverse motion mechanism performing transverse motion relativeto the objective table, and a lifting device driving the transverse motion mechanism to move up and down. One end of the objective table is connected to the vertical support, the lifting device ascends and descends on the vertical support, the transverse motion mechanism and the lifting device are connected to move up and down along with the lifting device, truckles facilitating walking are arranged on the vertical support and the objective table, and metamorphic grabbing mechanisms performing synchronous reverse rotation are arranged on the transverse motion mechanism in pairs towards the objective table. The grabbing type racking and unracking machine has the advantages that the machine can walk conveniently inside a channel, cargo racking and unracking can be achieved, and meanwhile other objects are not affected.

Owner:FUJIAN PROV AGRI MACHANIZATION INST

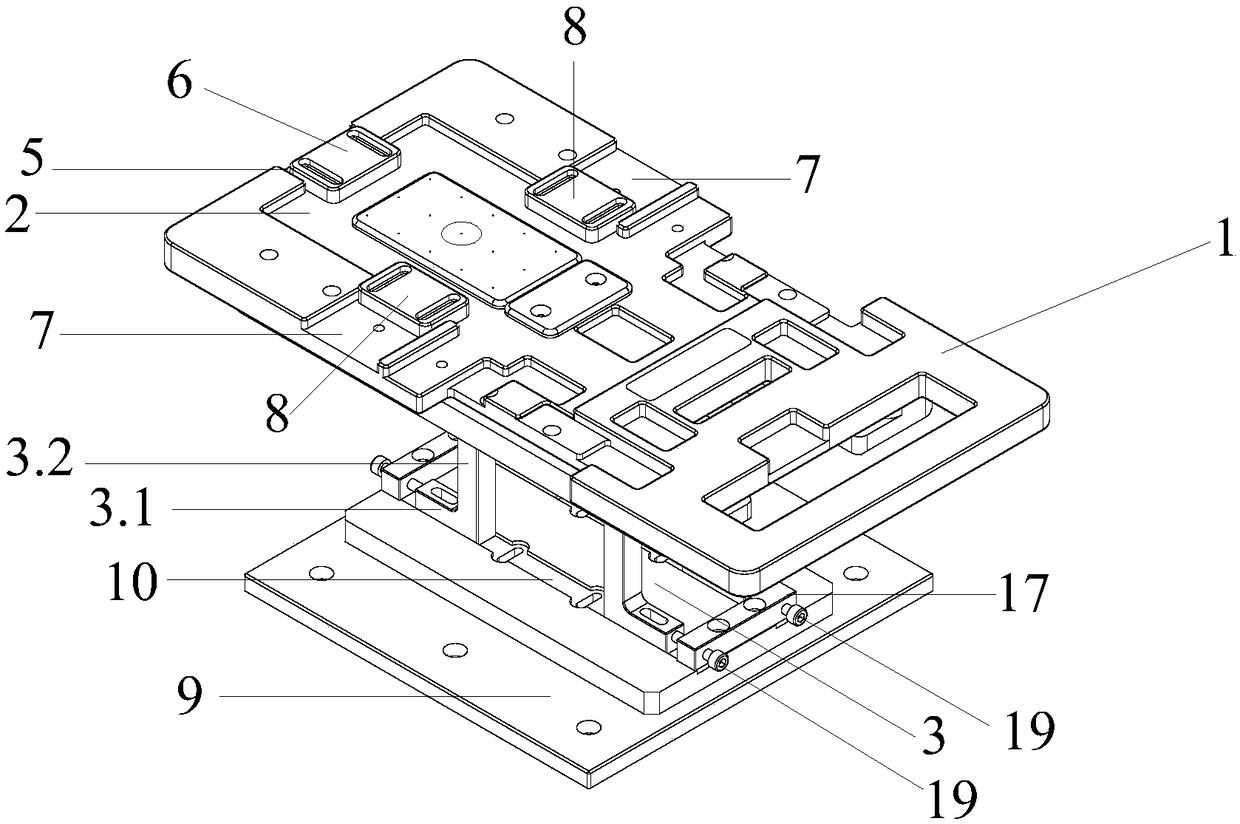

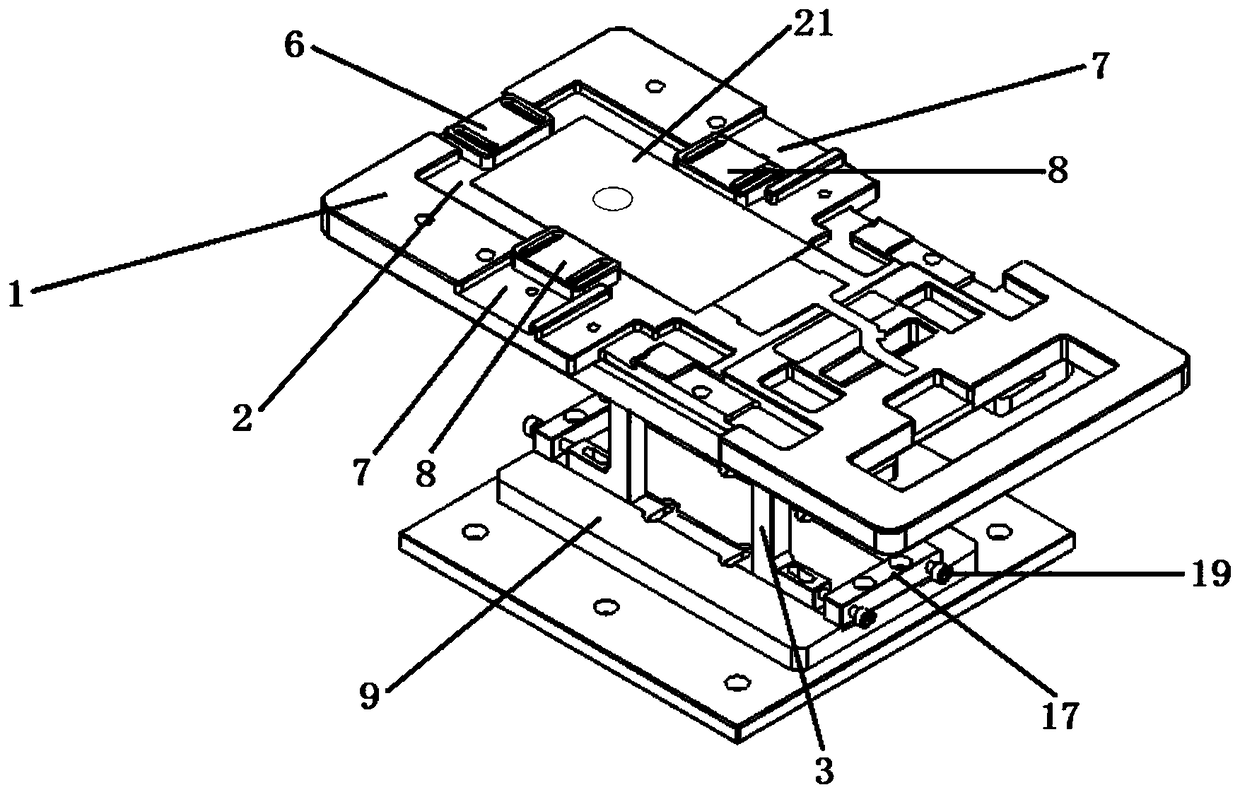

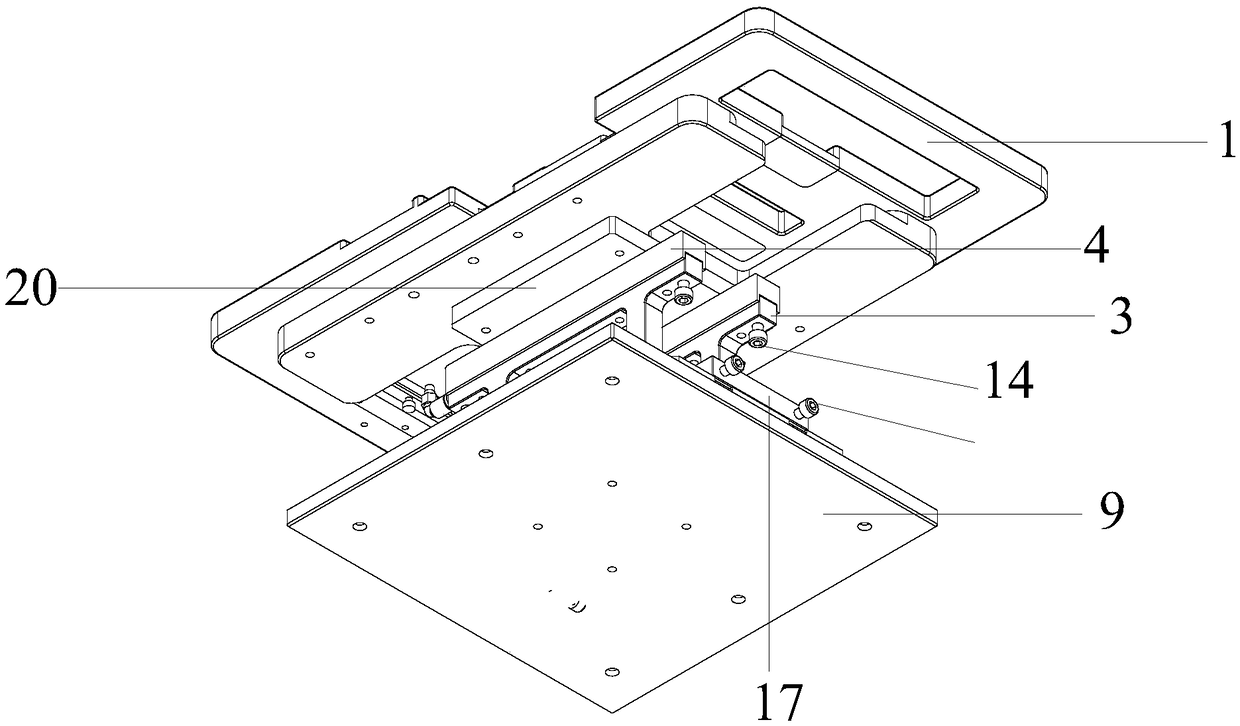

Multi-degree-of-freedom manual positioning device for liquid crystal panel

PendingCN109129244AAdjustable detection positionMeet location requirementsWork holdersWork benchesLiquid-crystal displayMulti degree of freedom

The invention discloses a multi-degree-of-freedom manual positioning device for a liquid crystal panel. An X-axis adjusting structure capable of driving the liquid crystal panel located in a panel installing groove to move in the length direction of a panel installing bracket and a Y-axis adjusting structure capable of driving the liquid crystal panel located in the panel installing groove to movein the width direction of the panel installing bracket are arranged at the positions, corresponding to the panel installing groove, of the panel installing bracket; and the panel installing bracket is arranged on a bracket rotating adjusting mechanism capable of enabling the panel installing bracket to turn over front and back or turn over left and right. The position of the to-be-detected liquidcrystal panel in the length direction of the panel installing bracket and the position of the to-be-detected liquid crystal panel in the width direction are adjusted through the X-axis adjusting structure and the Y-axis adjusting structure, the bracket rotating adjusting mechanism drives the panel installing bracket to turn over front and back or left and right, the to-be-detected liquid crystalpanel has the degree of freedom in four directions, adjusting is convenient, the structure is stable, and adjustability of the detection position of the to-be-detected liquid crystal panel in multipledirections is achieved.

Owner:WUHAN JINGLI ELECTRONICS TECH

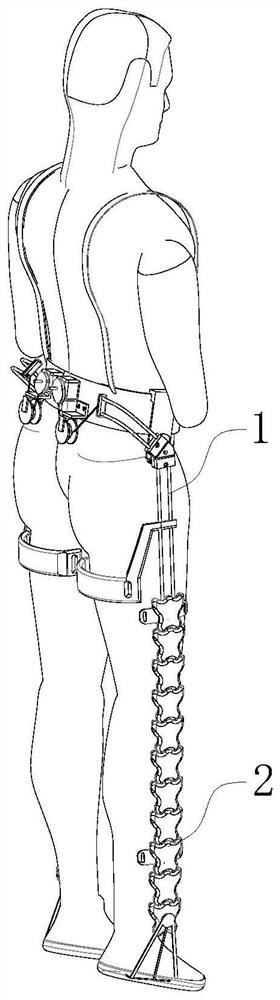

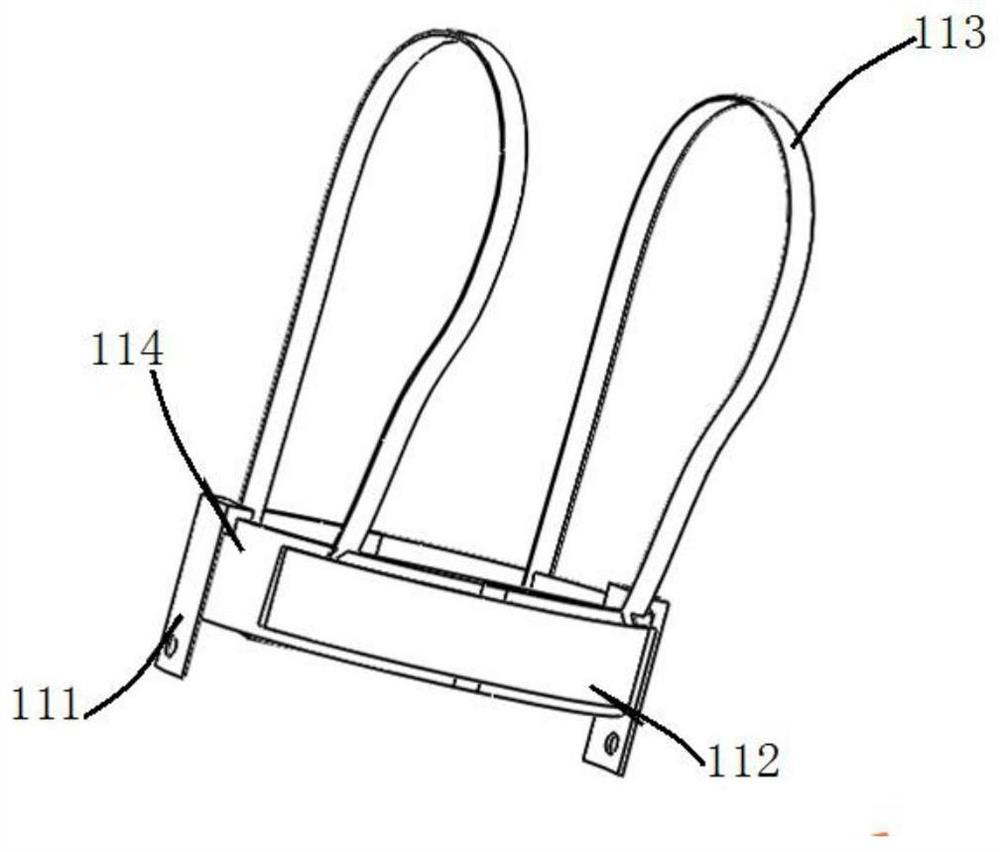

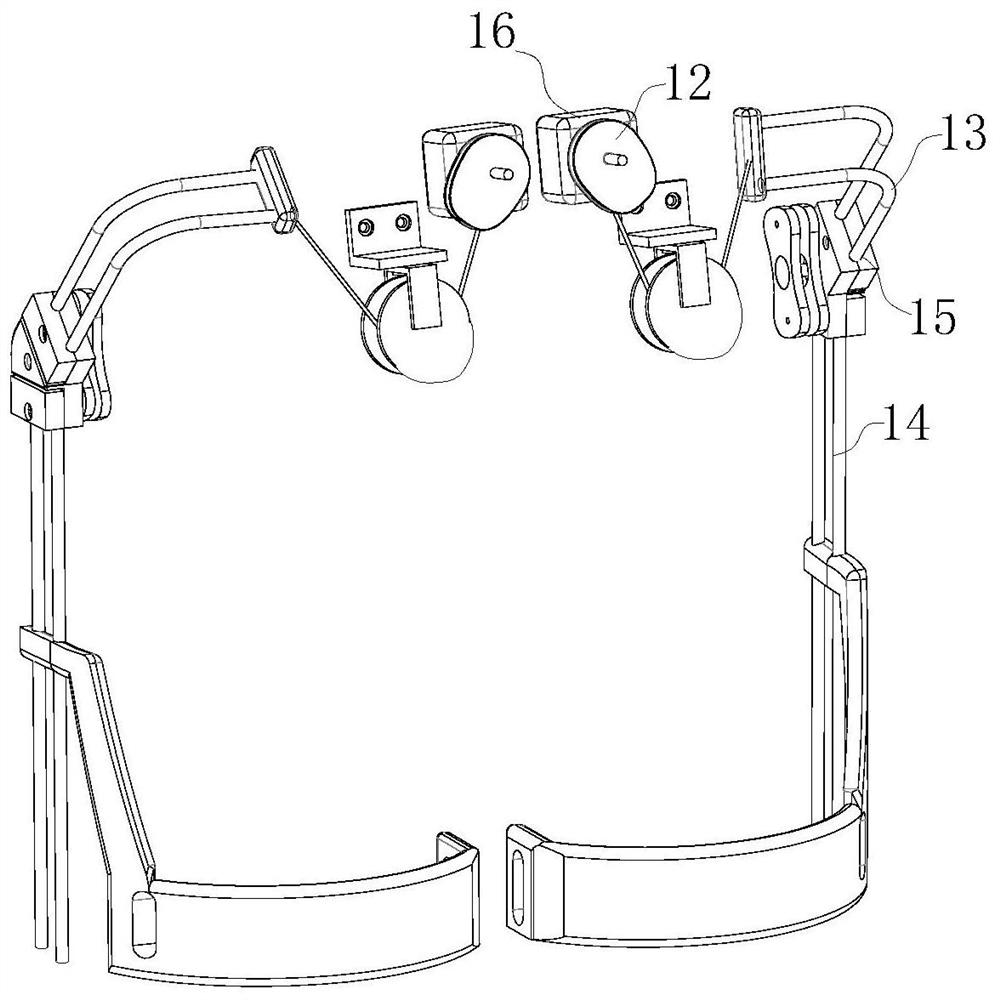

Rigid-flexible coupling wearable walking aid exoskeleton system

PendingCN112022618AMeet location requirementsImprove coordinationProgramme-controlled manipulatorChiropractic devicesHuman bodySpinal column

The invention relates to a rigid-flexible coupling wearable walking aid exoskeleton system. The exoskeleton system comprises a power assisting system and a supporting system; the power assisting system comprises a waist wearing mechanism used for wearing the exoskeleton system on the body of a user and a power mechanism used for driving the thighs of the user to be lifted up or put down; the supporting system comprises a supporting chain formed by connecting a plurality of supporting joints; the supporting chain is of a spine-like bionic structure; all the supporting joints can rotate by a large angle in a sagittal plane and slightly rotate in a coronal plane and a horizontal plane, so that the knee joints and the ankle joints cannot be interfered in a human lower limb movement process; and the supporting system is in driving transmission connection with the power mechanism, so that in the human lower limb movement process, assistance can be provided in a supporting phase and the supporting system moves along with the lower limbs of the human body in a swing phase. The exoskeleton system is simple in structure, light in weight, comfortable to wear, convenient to put on and take off, high in coordination with human lower limb movement and capable of helping walking and providing supporting assistance.

Owner:HEBEI UNIV OF TECH

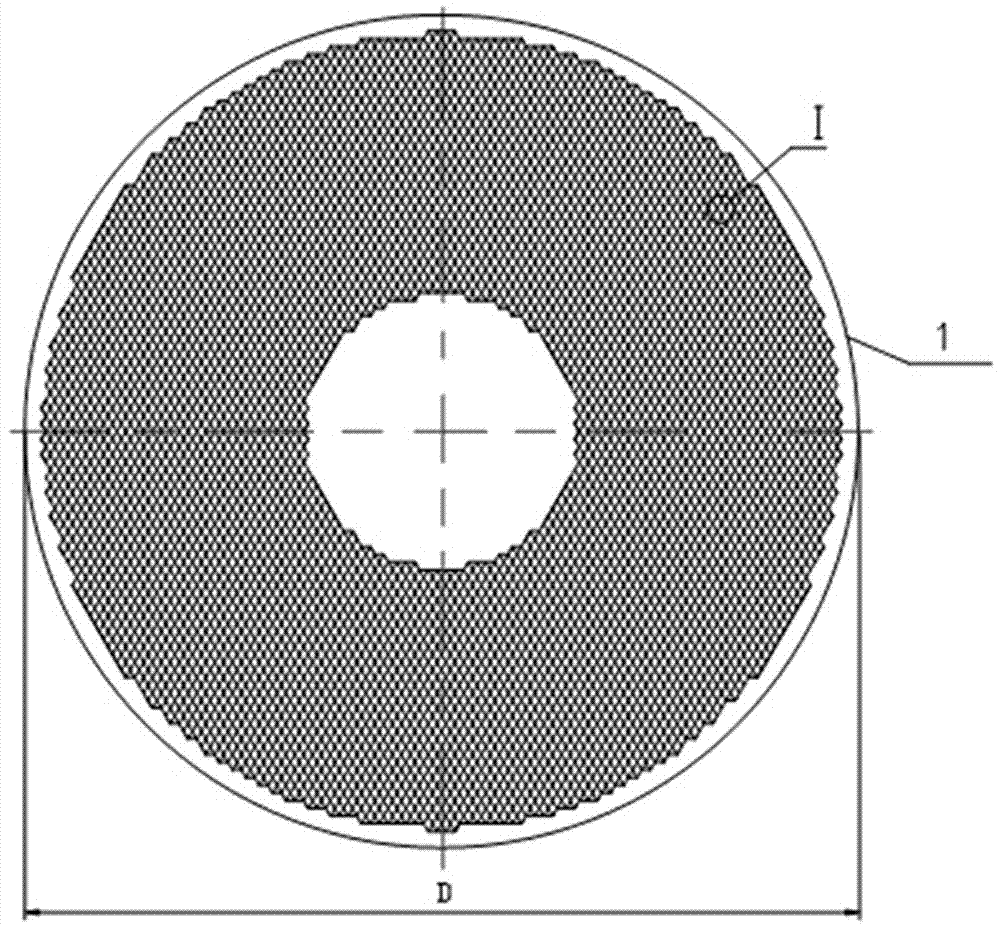

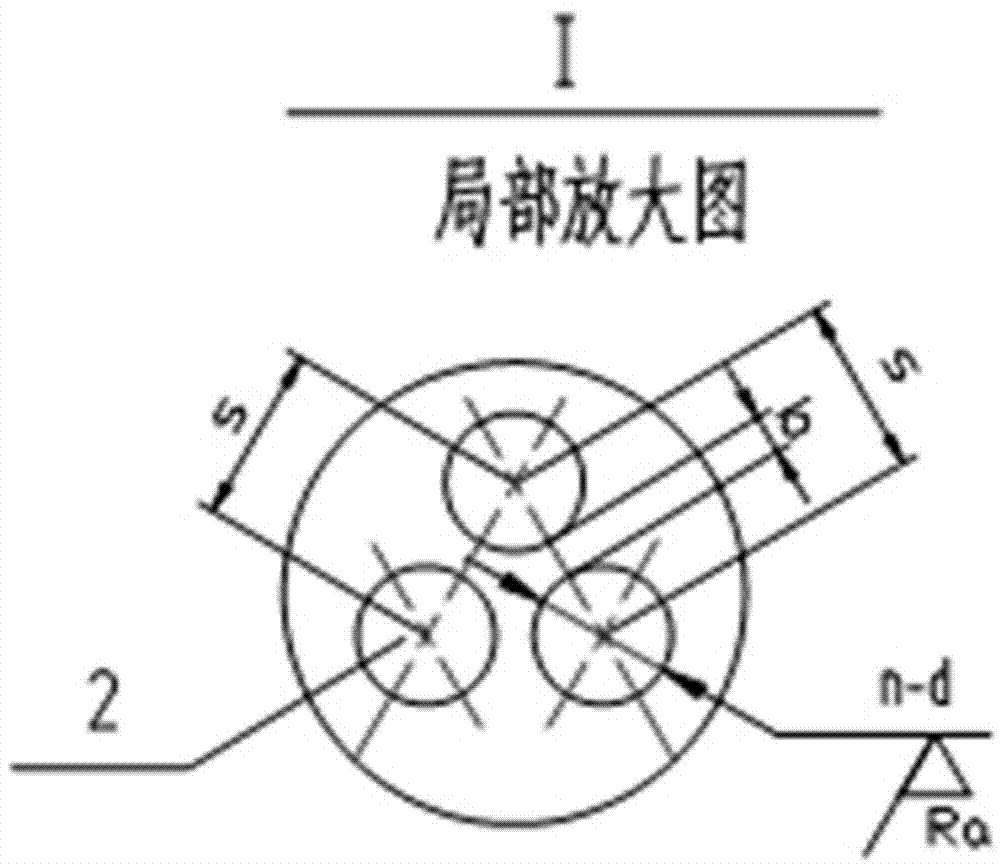

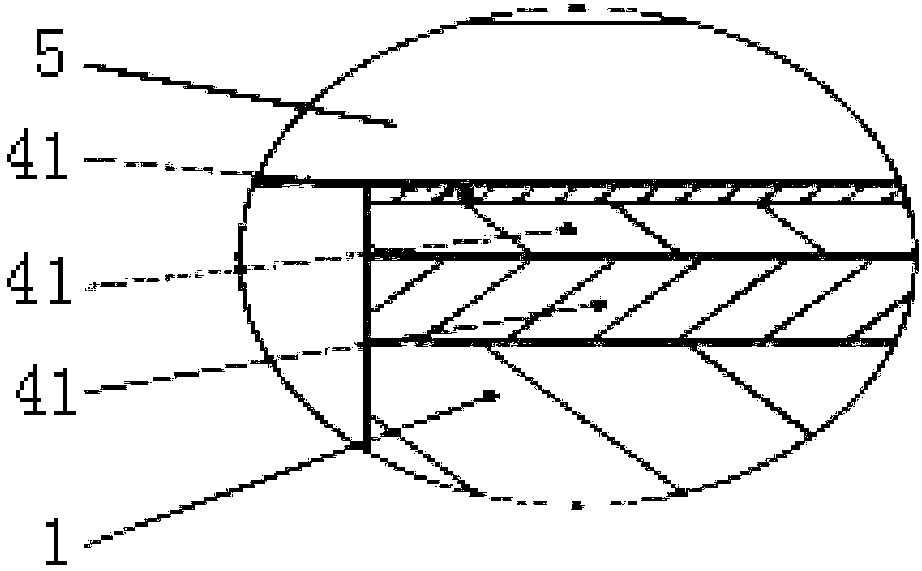

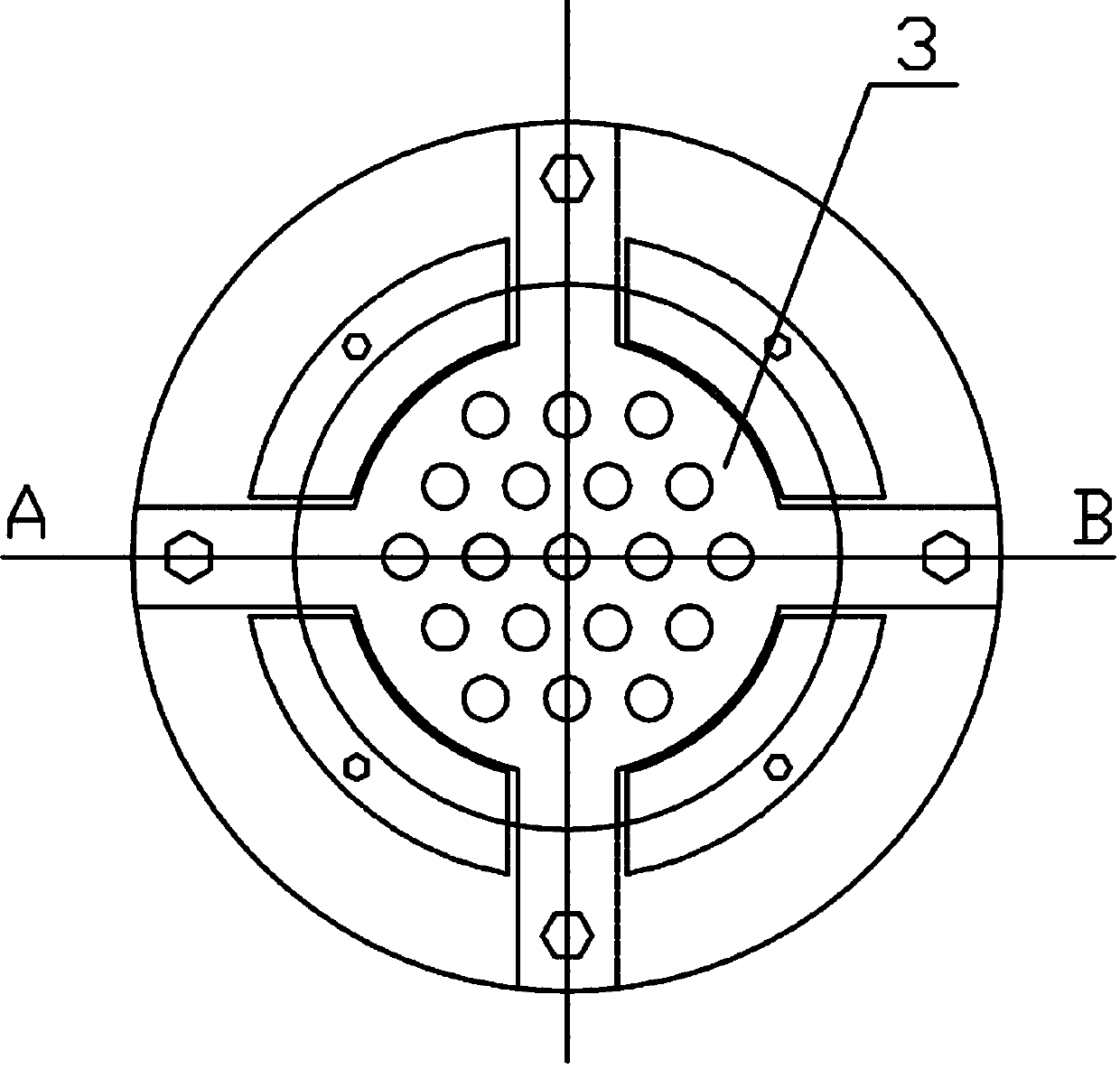

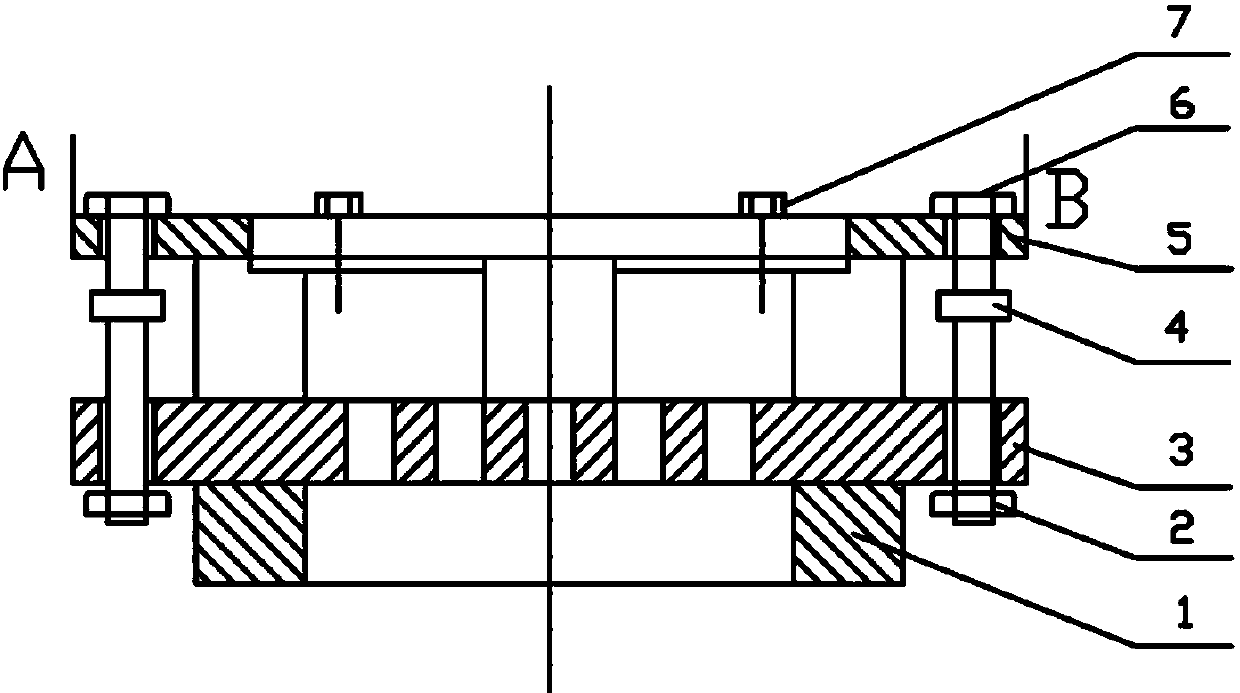

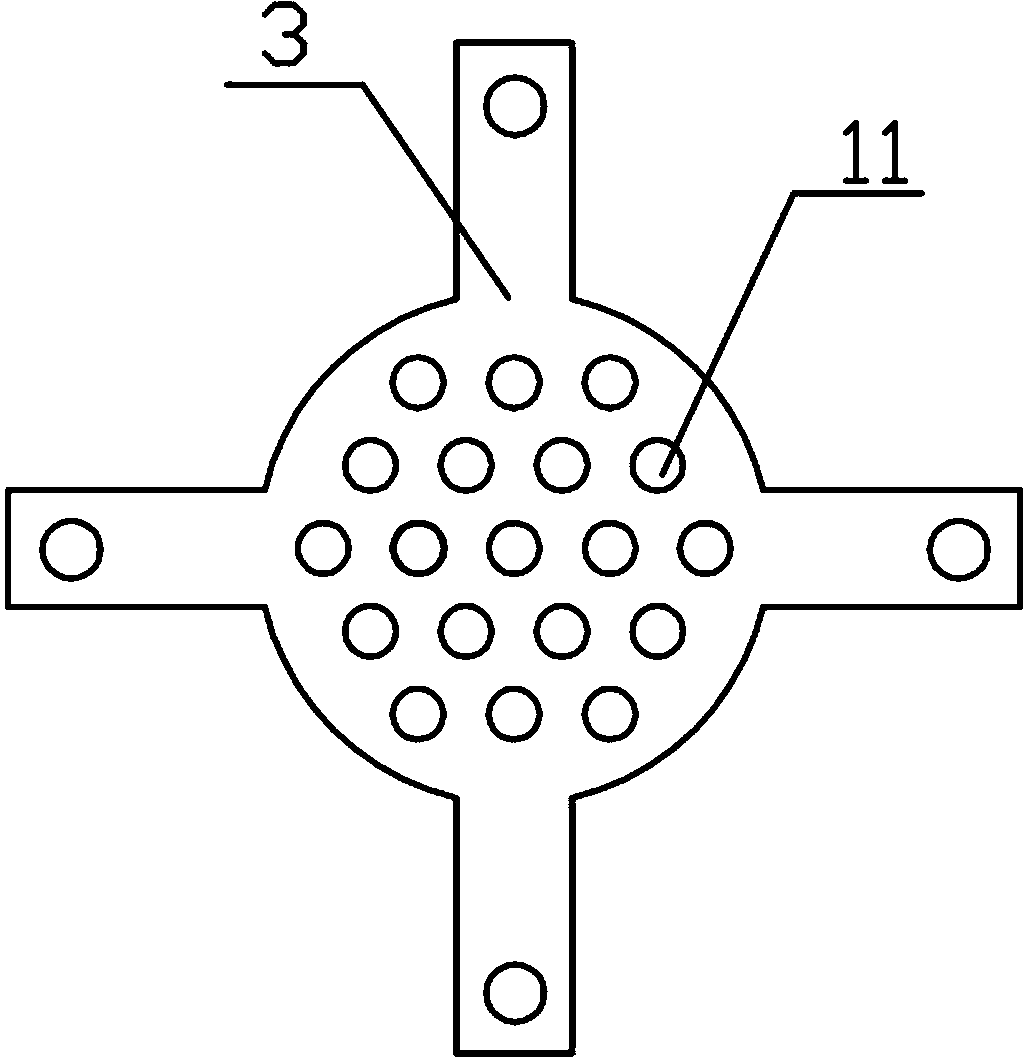

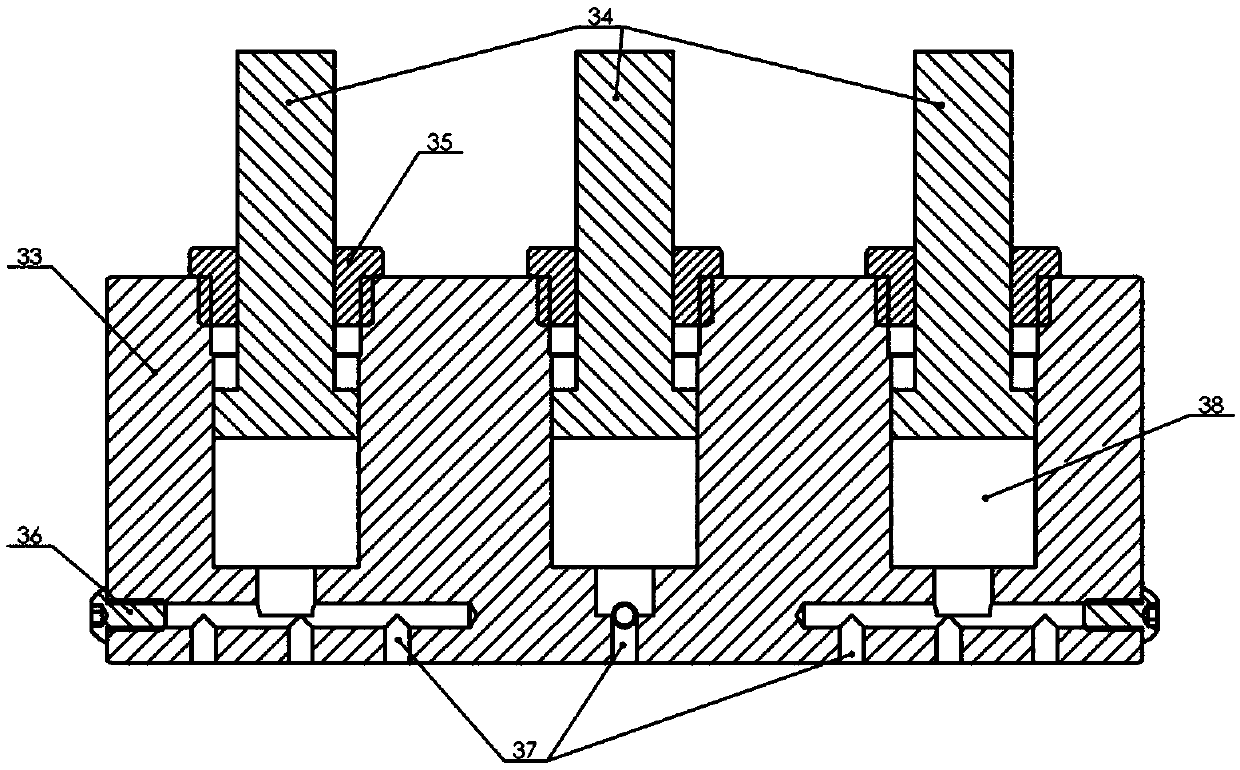

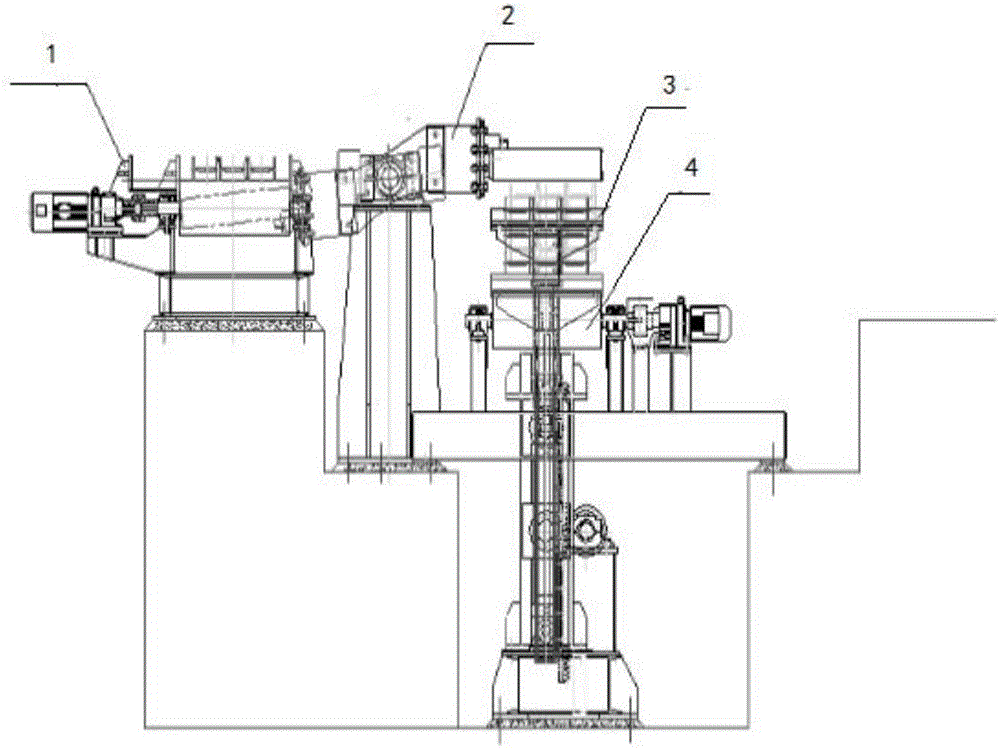

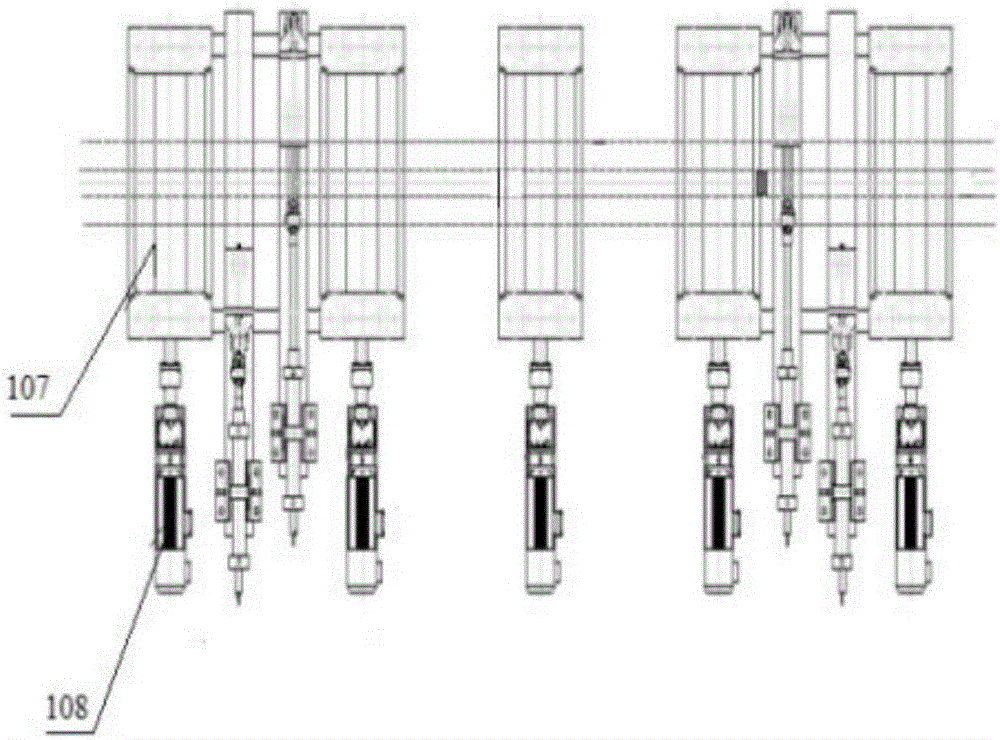

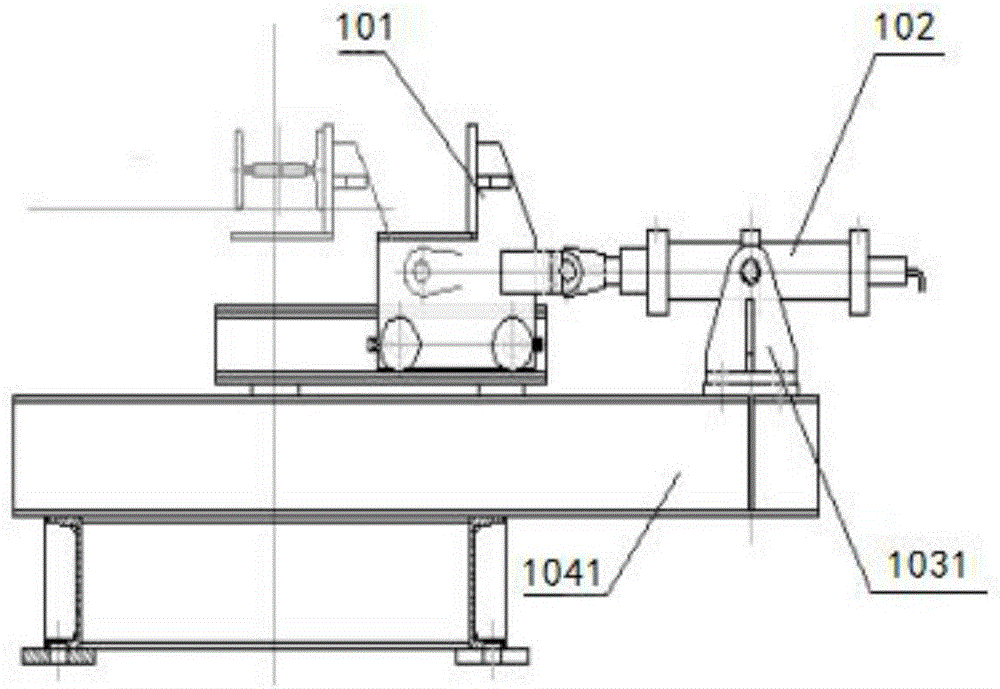

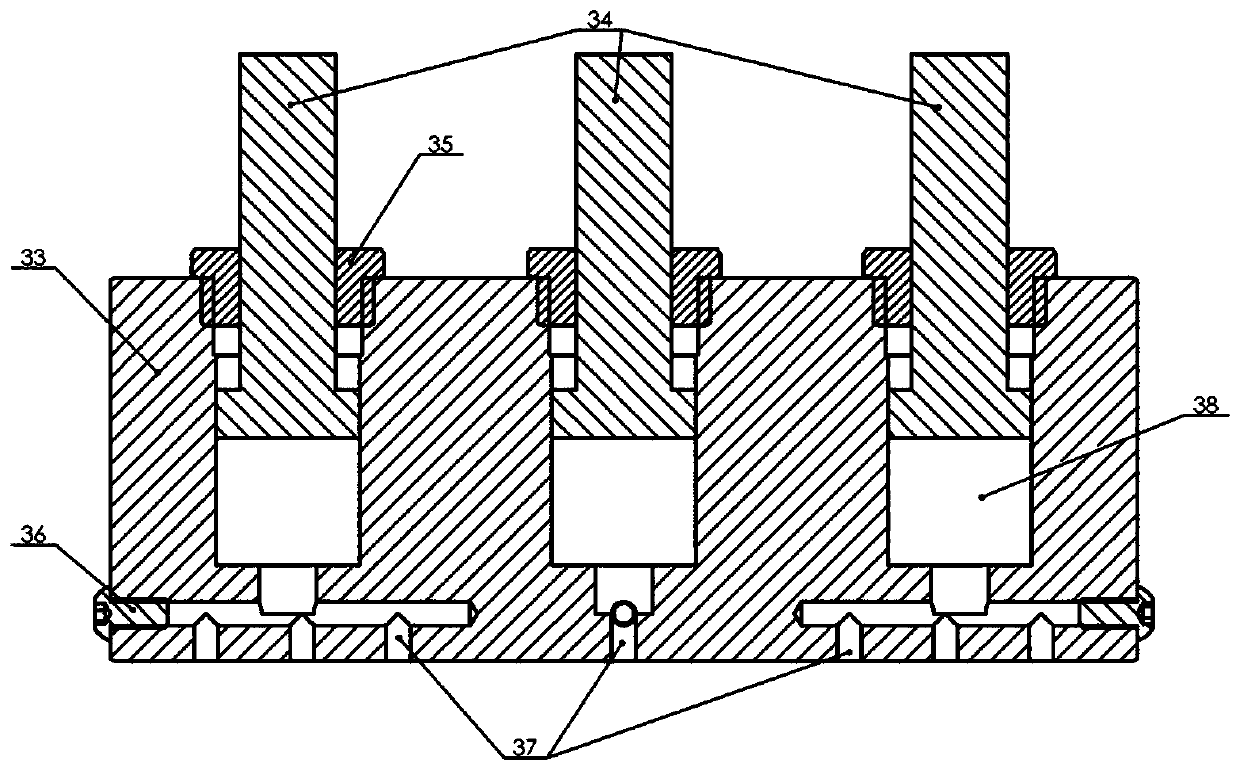

Machining method of group of holes in large-sized metal tube plate

ActiveCN104259767ASatisfy position accuracyMeet location requirementsChemical industryNumerical control

The invention relates to a machining method of a group of holes in a large-sized metal tube plate. The machining method is used to manufacture metal tube plates for large-sized reaction vessels and heat exchangers in the petroleum and chemical industries. The machining method includes: 1, making a drilling procedure according to a design drawing, clamping the tube plate on a CNC (computer numerical control) boring and milling machine (or a CNC drilling machine, similarly hereafter), starting the CNC boring and milling machine, entering the drilling procedure, machining guide holes for all tube holes in the tube plate; 2, placing the tube plate flat on a support, with the guide holes facing up, adjusting the support to keep the surface of the tube plate horizontal, and firmly clamping the tube plate; placing three radial drilling machines outside the periphery of the tube plate, using each radial drilling machine to machine each 120-degree range of the tube holes in the tube plate, and using the three radial drilling machines to drill and ream the tube holes in the tube plate until a group of holes is obtained. The machining method has the advantages that machining of the group of holes in the large-sized metal tube plate is achieved with the CNC boring and milling machine (or the CNC drilling machine) and the radial drilling machines, equipment cost is low, work efficiency is high, and machining cost is low.

Owner:云南大为化工装备制造有限公司

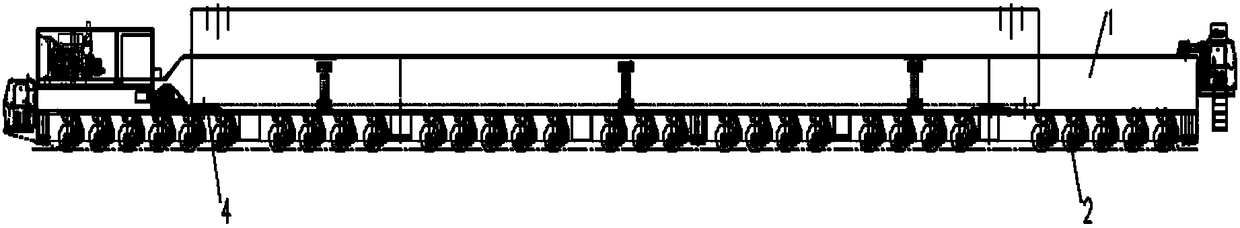

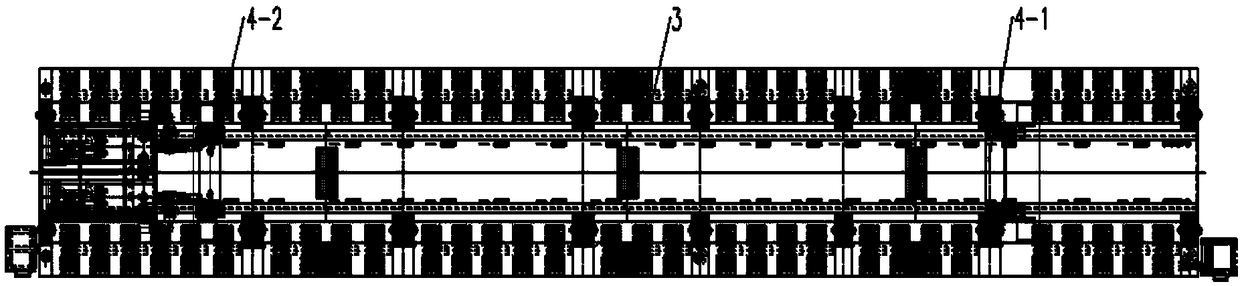

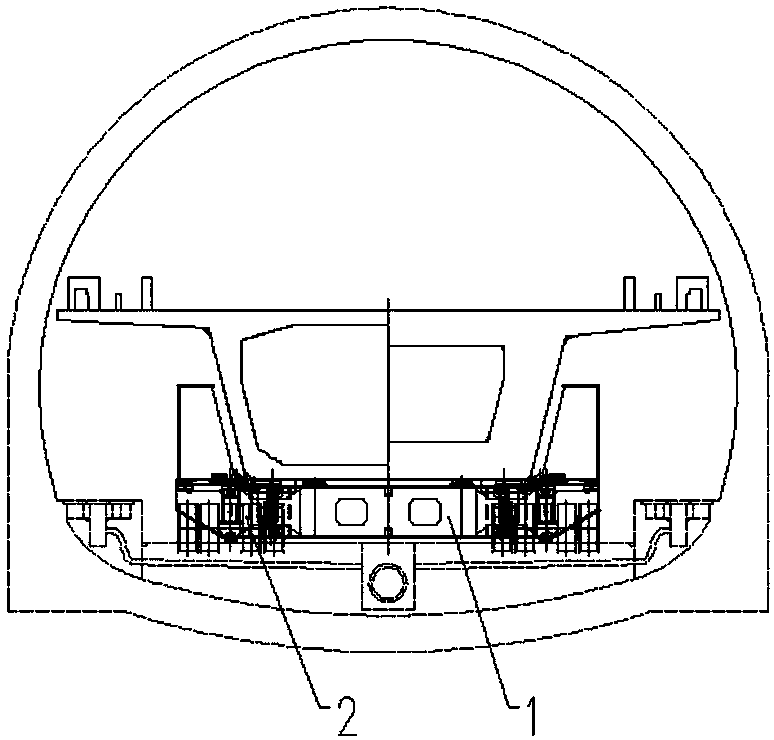

U-shaped tunnel-crossing beam transporting vehicle with adjustable wheel track and beam-feeding method of U-shaped tunnel-crossing beam transporting vehicle

The invention provides a U-shaped tunnel-crossing beam transporting vehicle with an adjustable wheel track and a beam-feeding method of the U-shaped tunnel-crossing beam transporting vehicle. The beamtransporting vehicle at least comprises a vehicle body, traveling wheel sets and a beam carrying trolley; the vehicle body comprises a middle beam located in the middle and two side beams located onthe two sides; a plurality of cross beams are arranged in the longitudinal direction of the middle beam in a penetrating mode at intervals; the two ends of the outer sides of the multiple cross beamsare connected to the lower ends of the side beams correspondingly, so that the U-shaped structure of the vehicle body is formed; the traveling wheel sets are located at the lower ends of the side beams of the vehicle body and detachably connected with the side beams of the vehicle body, and the lower ends of the side beams are provided with two supporting positions of the traveling wheel sets; andthe beam carrying trolley comprises a front beam carrying trolley body and a rear beam carrying trolley body which are detachably connected. Therefore, according to the U-shaped tunnel-crossing beamtransporting vehicle with the adjustable wheel track and the beam-feeding method of the U-shaped tunnel-crossing beam transporting vehicle, the space below the flanges of box girders is utilized to the greatest extent, the transporting height is decreased, the transporting requirement of the large-span large-tonnage box girders can be met, especially the requirements for tunnel-crossing transporting of the box girders can be achieved, the forward travelling range of the front trolley body is further expanded, and longitudinal stability when a front cart of a bridge erecting machine takes the girders is improved.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

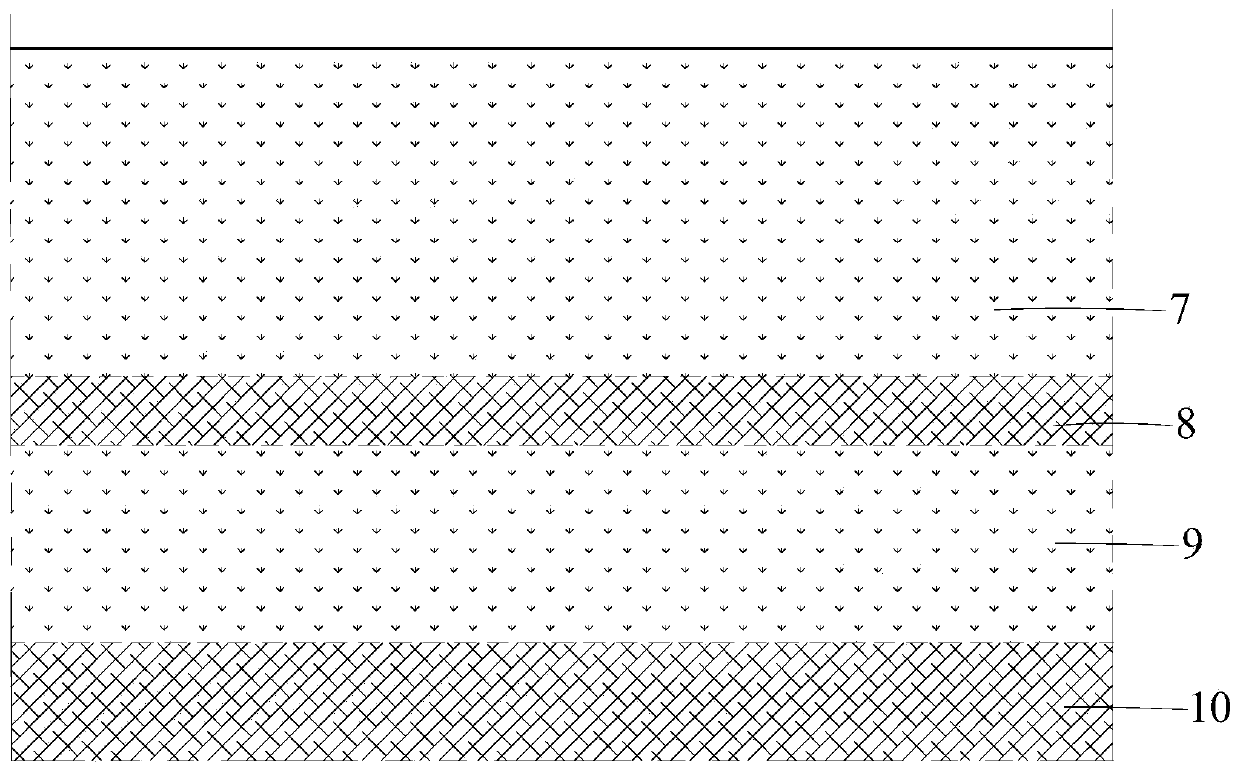

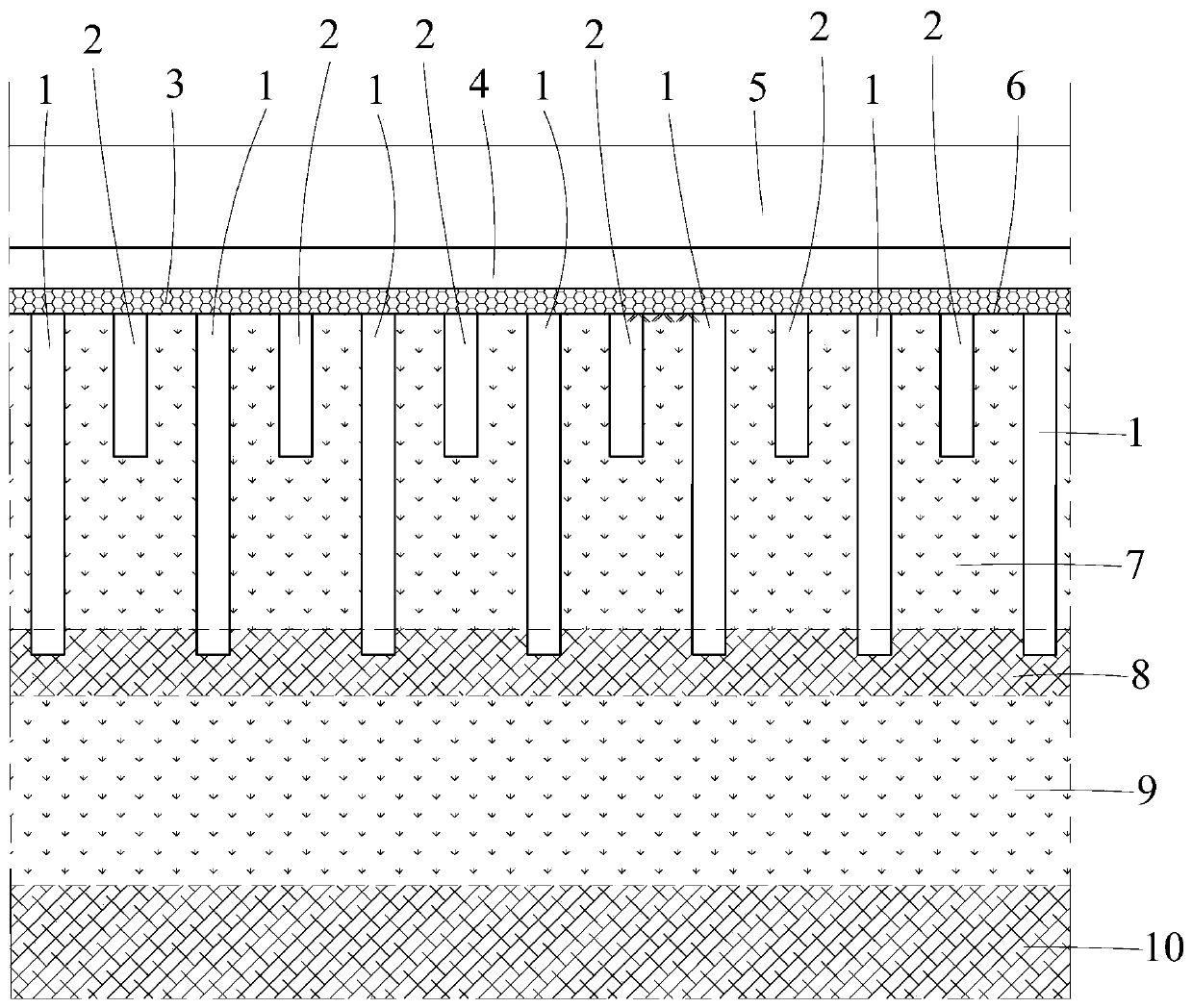

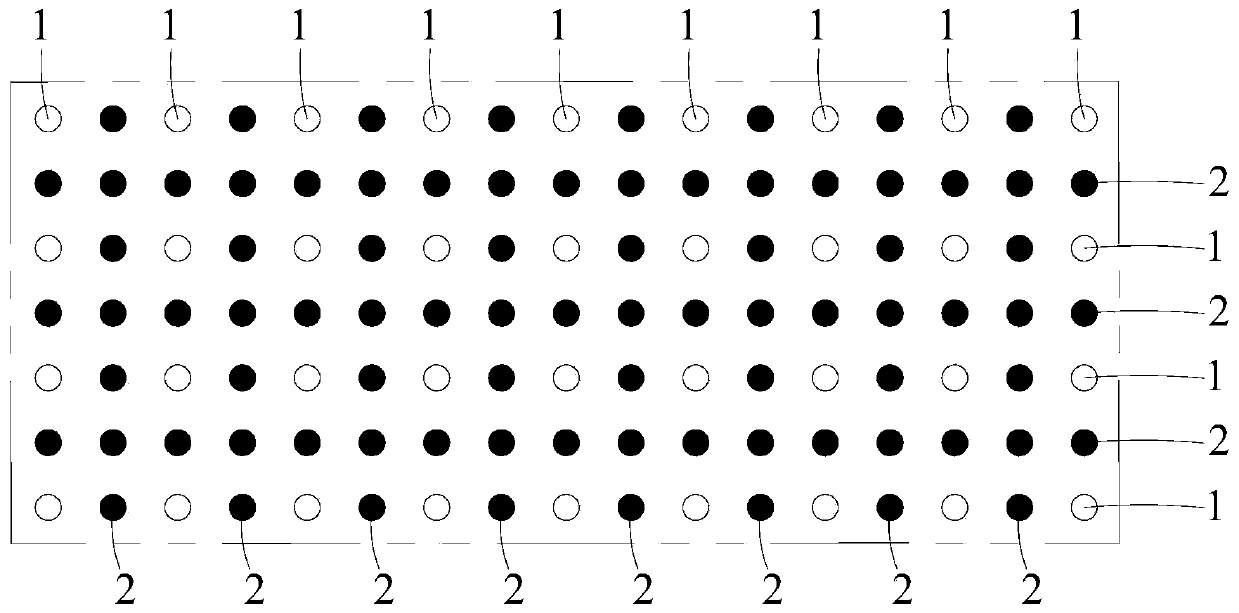

Foundation treatment structure suitable for deep soft foundation with sandwiched thin bearing stratum and construction method

PendingCN111321751ASave engineering investmentSolve the large settlementBulkheads/pilesPipeBearing capacity

The invention belongs to the field of geotechnical engineering, and particularly relates to a foundation treatment structure suitable for a deep soft foundation with a sandwiched thin bearing stratumand a construction method. The foundation treatment structure comprises a raft, a mattress layer, pipe piles and stirring piles, wherein the mattress layer is arranged at the bottom of the raft and located at the top of an upper soft soil foundation layer; the pipe piles are arranged at intervals and arranged at the bottom of the mattress layer, and the lower ends of the pipe piles are located ina middle bearing stratum; and the stirring piles are arranged at intervals and arranged at the bottom of the mattress layer and located in the upper soft soil foundation layer. According to the foundation treatment structure suitable for the deep soft foundation with the sandwiched thin bearing stratum, the engineering investment is saved; and settlement of a composite foundation is reduced, the bearing capacity of the composite foundation is improved, and the problems that the foundation settlement is large, the foundation bearing capacity is low and the pipe piles are prone to piercing the middle bearing stratum when the pipe piles are located in the middle bearing stratum are solved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

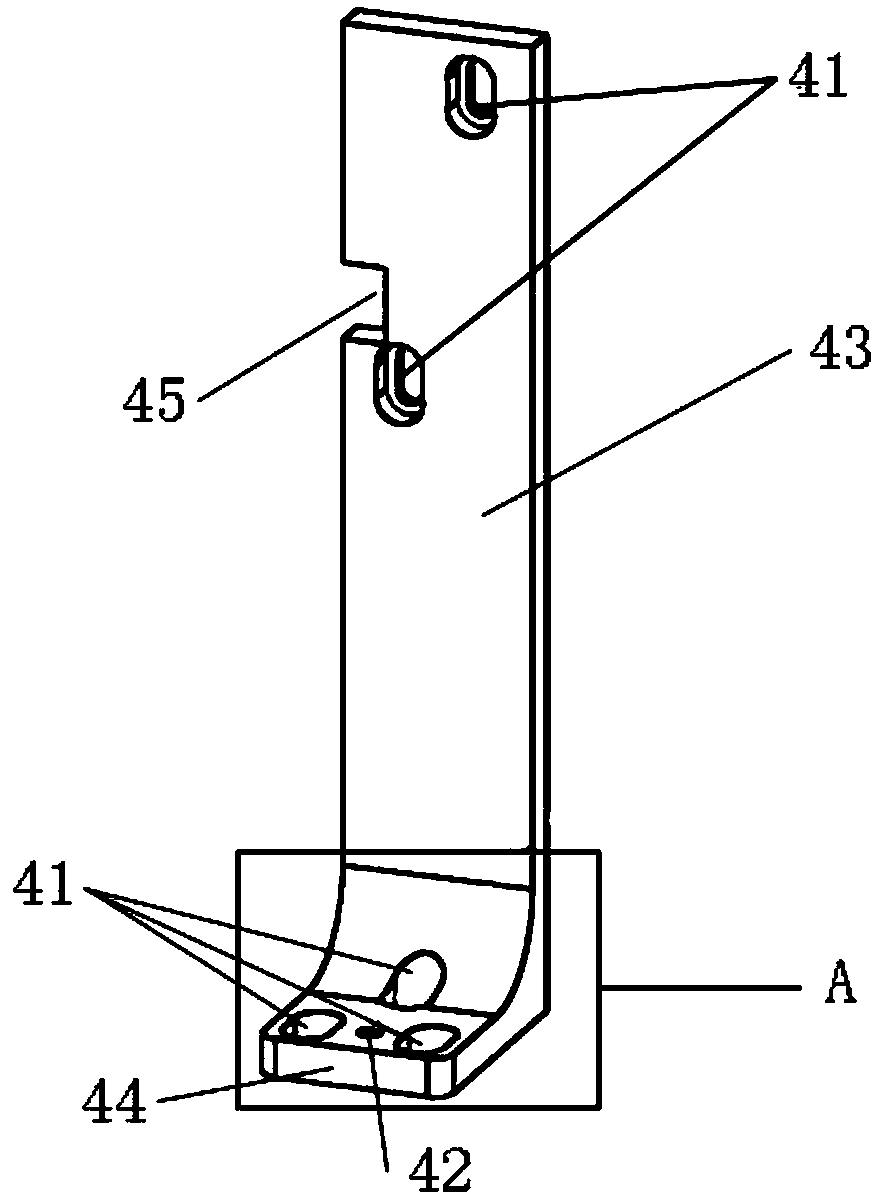

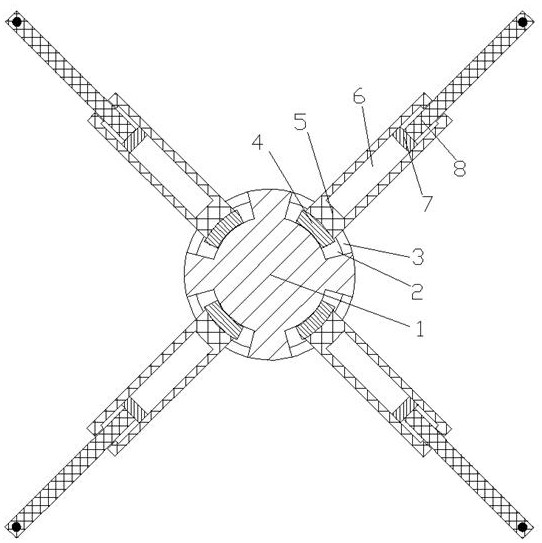

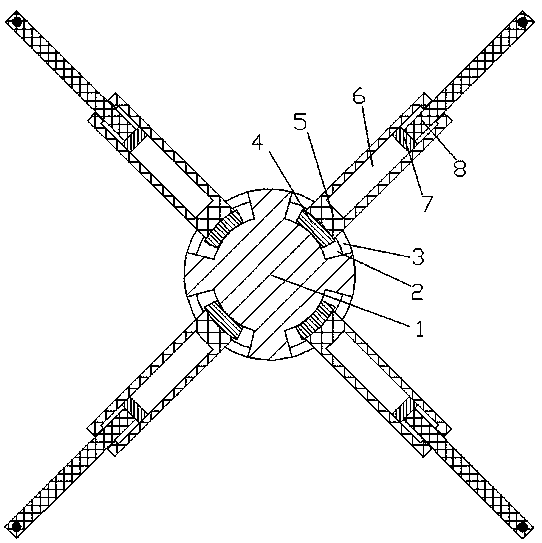

A special fixture and method for machining the tenon end face of aero-engine blade

ActiveCN112247618BRapid positioningQuick clampingChucksPositioning apparatusAxial displacementAviation

The invention discloses a special fixture and method for processing the tenon root end face of an aero-engine blade, belonging to the technical field of numerical control machining of aero-engine blades; comprising a base, a blade tip clamping assembly, a blade tenon root wedge-shaped surface clamping assembly, and a blade tenon root side clamp Clamping assembly; the blade tenon root wedge surface clamping assembly clamps the blade tenon root wedge surface through the first cylindrical positioning shaft and the second cylindrical positioning shaft; the blade tenon root side clamping assembly includes a ball head positioning pin and a ball head thread clamping and positioning The pin is clamped and positioned from the side of the tenon root of the blade; the blade tip clamping assembly includes the front plate of the base, the three-jaw chuck and the chuck base; the three-jaw chuck is installed on the side wall of the front plate of the base through the chuck base Above: The pulling force of the blade tip is positioned by the three-jaw chuck, and the axial displacement of the blade along its process cylinder axis is limited. The invention realizes the positioning and clamping of the entire engine blade under the condition of ensuring that the engine blade is not damaged during the blade clamping process.

Owner:西安三航动力科技有限公司

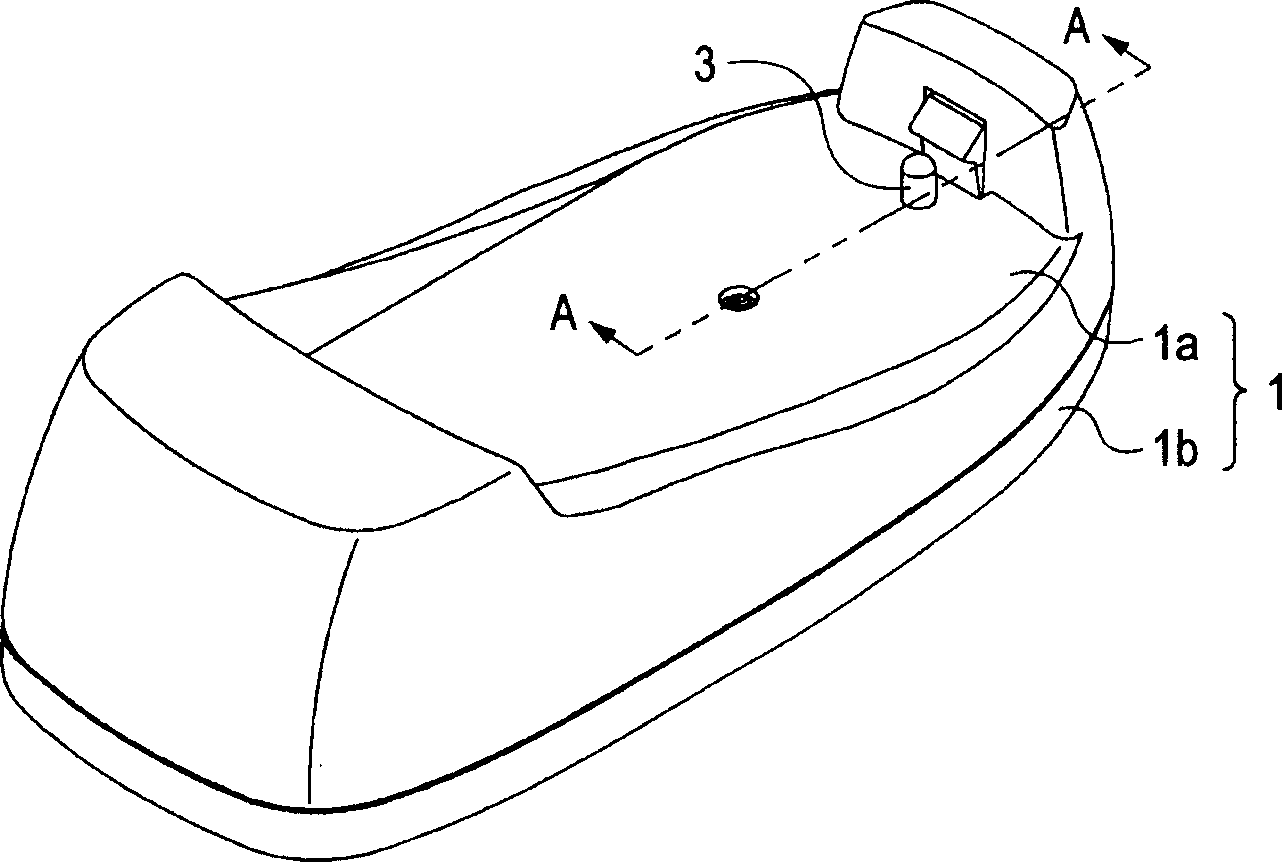

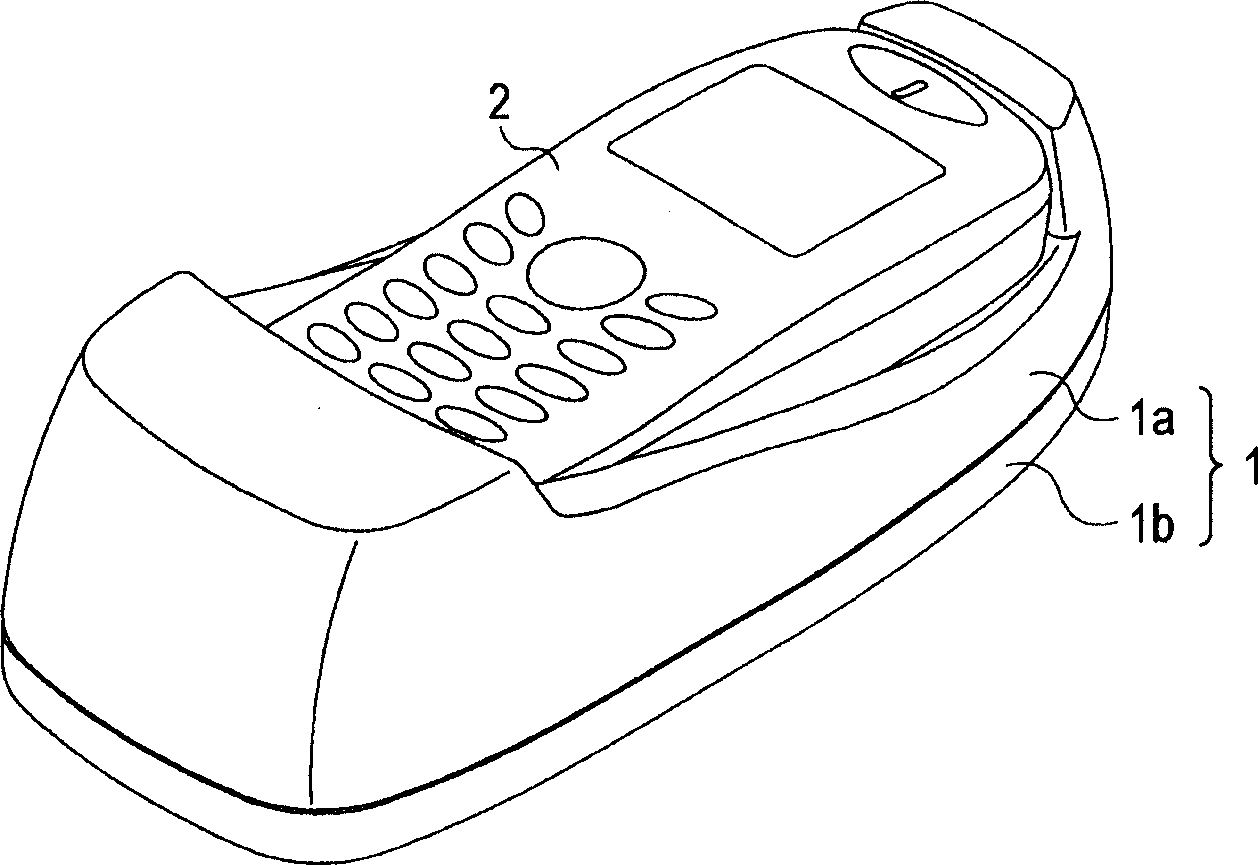

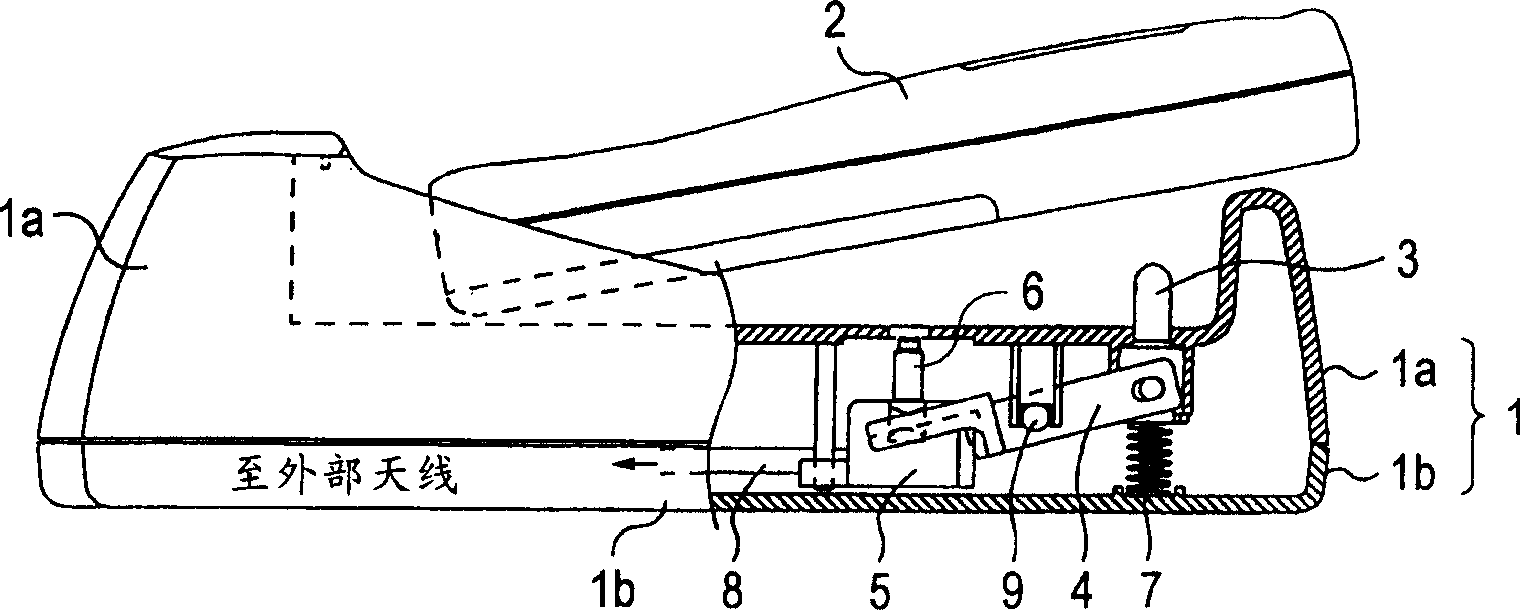

On-Board holder

InactiveCN1509562ADoes not result in contactMeet location requirementsVehicle componentsTelephone set constructionsOn boardClockwise

A holder arranged such that the position of a connection plug is not limited and the connection plug does not touch an electronic apparatus a portable telephone; when the electronic apparatus is set. U nder a state where the portable telephone is not set in the one board holder, a pin projects from the setting face of an upper case. The pin is pushed down into a case, when the portable telephone is set. A guide can turn about a post and oscillates clockwise when the pin is pushed dwn to push up a plug holder fixed to the other end of the guide. A connection plug is fixed to the plug holder. When the pin is pushed down by setting the portable telephone and the plug holder is pushed up by the guide the connection plug projects from an upper case. When the connection plug projects to enter a hole made in the back face of the portable telephone forward end of the connection plug touches a connector provided at the end of the hole.

Owner:PANASONIC CORP

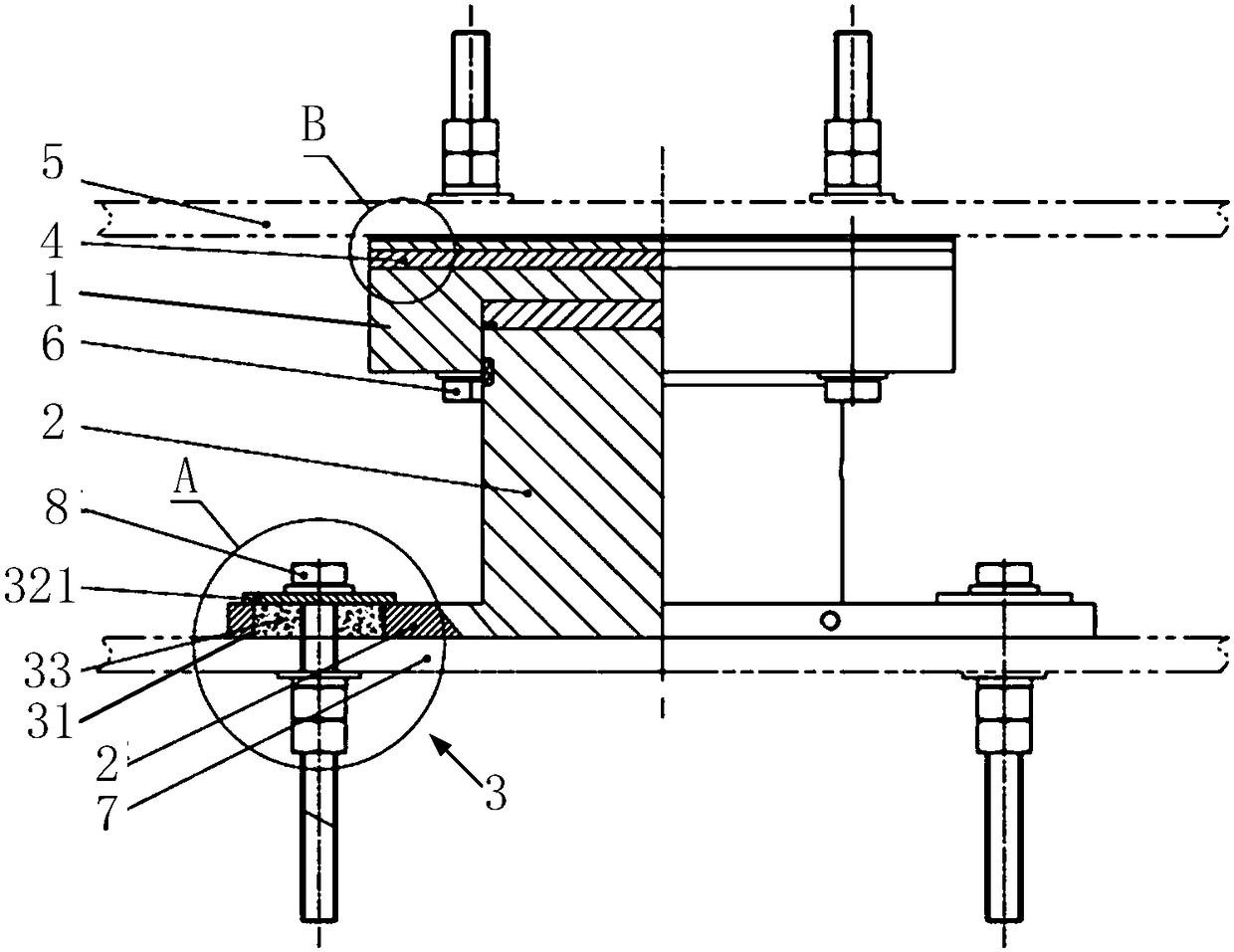

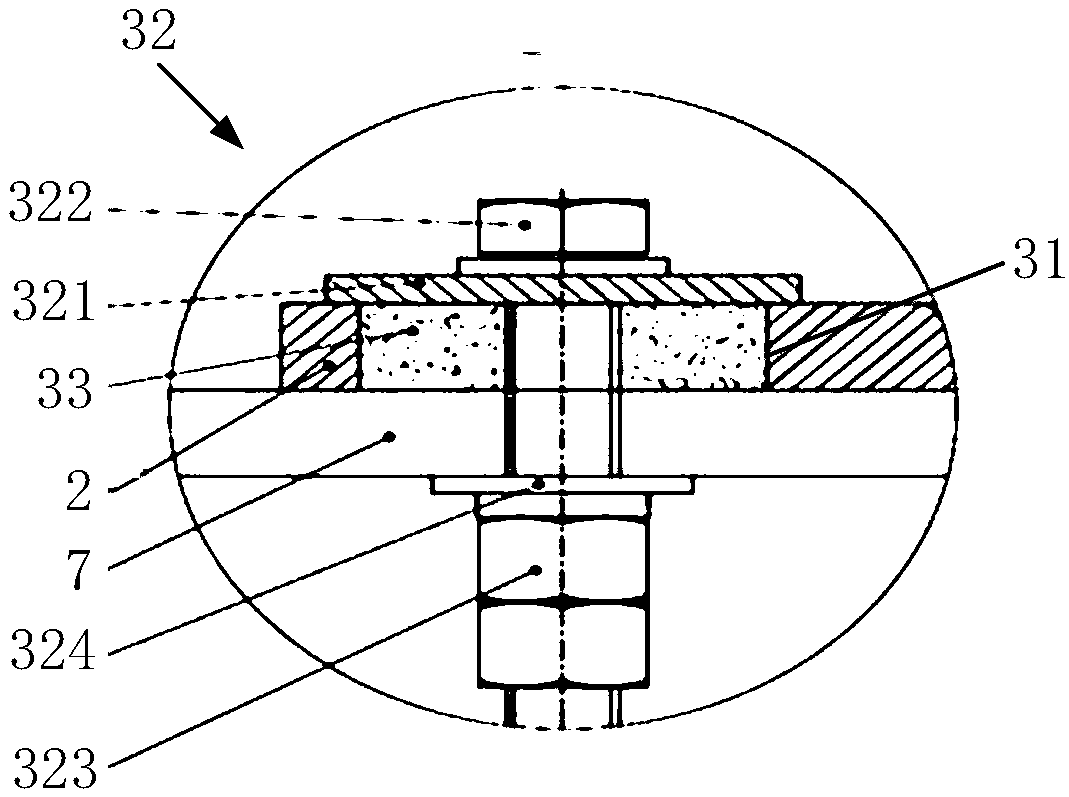

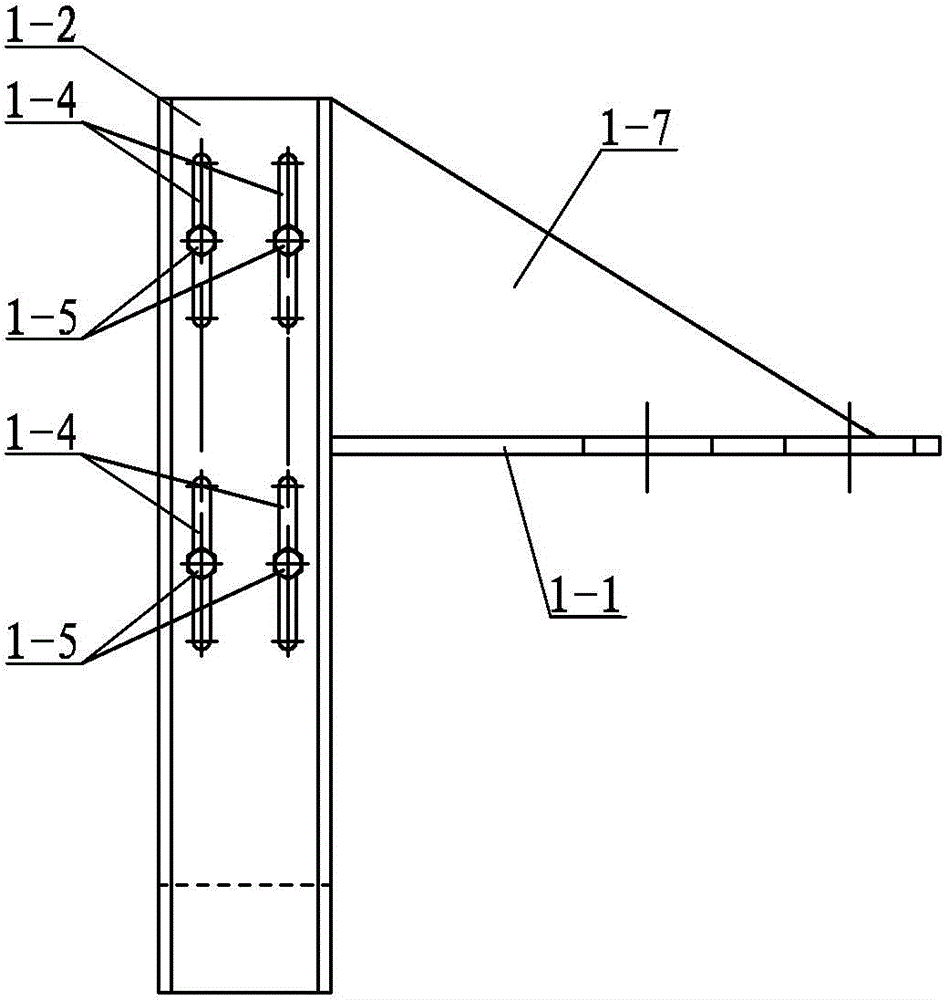

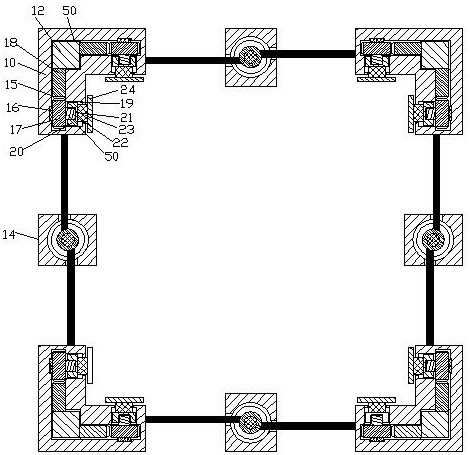

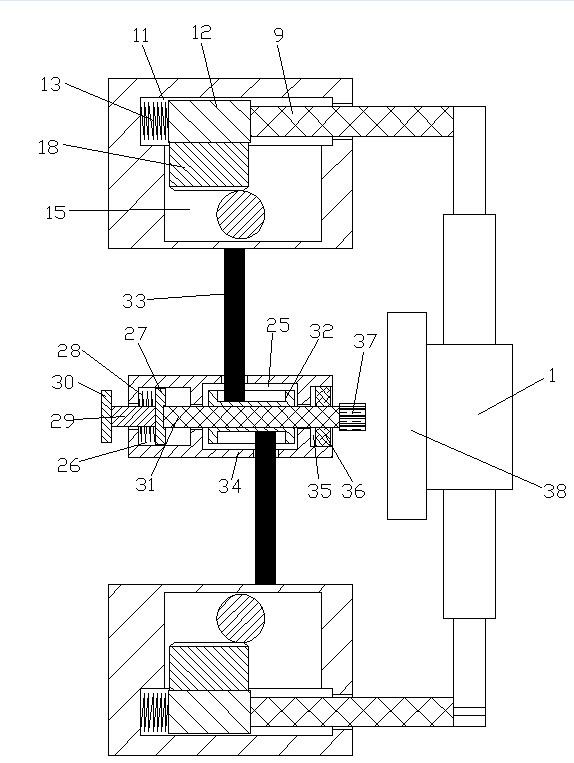

Bridge support

ActiveCN108221651AEasy to useEliminate horizontal installation errorsBridge structural detailsStructural engineering

The invention provides a bridge support. The bridge support comprises an upper support plate, a lower support plate, a horizontal regulating component and a height regulating component and is characterized in that the upper support plate is used for being connected with the bottom of a bridge beam, the lower support plate is used for being connected with a pier, the horizontal regulating componentis used for eliminating the horizontal mounting errors of the bridge beam and the pier, the height regulating component is used for eliminating the vertical mounting errors of the bridge beam and thepier, the horizontal regulating component comprises regulating holes for regulating the horizontal position of the support and positioning parts used for fixing the horizontal position of the support, the regulating holes are arranged in the upper support plate and / or the lower support plate, and the positioning parts are arranged at the regulating holes; the height regulating component is arranged between the upper support plate and the bottom of the bridge beam or between the lower support plate and the pier. The bridge support has the advantages that bridge design elevation and position requirements are satisfied, and the bridge support is high in regulation precision, simple in structure and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

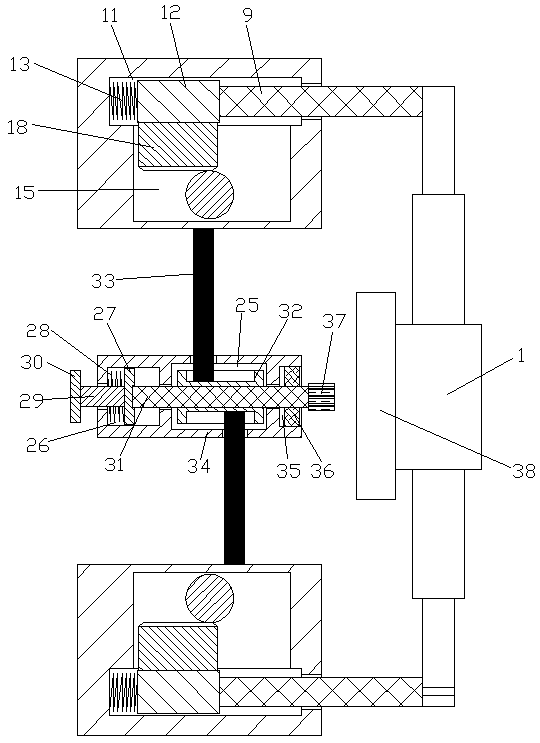

Friction test adjustable limiting device

InactiveCN103376231ARealize removableMeet location requirementsUsing mechanical meansMaterial analysisMechanical engineeringFriction test

The invention discloses a friction test adjustable limiting device which comprises a bearing sleeve, wherein a pressure adjustment plate is arranged in the bearing sleeve; a plurality of through holes are formed in the pressure adjustment plate; the pressure adjustment plate is connected with a lug plate through screws; positioning nuts and limiting nuts are arranged on the screws; guide screws are arranged on the lug plate; fixing bolts are arranged on the guide screws. According to the friction test adjustable limiting device, due to adoption of a structure that the pressure adjustment plate is connected with the lug plate through the screws, the pressure adjustment plate is movable; in the friction test, a position requirement for an anchoring fixed sheet during passive end oil pressure measurement and steel bundle anchoring can be met; the problem of inaccurate friction test data or fracture and slippage of a steel stranded wire during the steel bundle anchoring is solved; tension of a test steel bundle can be normally transmitted to a measured part; after the test is finished, the steel bundle can be reliably anchored.

Owner:CHINA NUCLEAR IND 22ND CONSTR

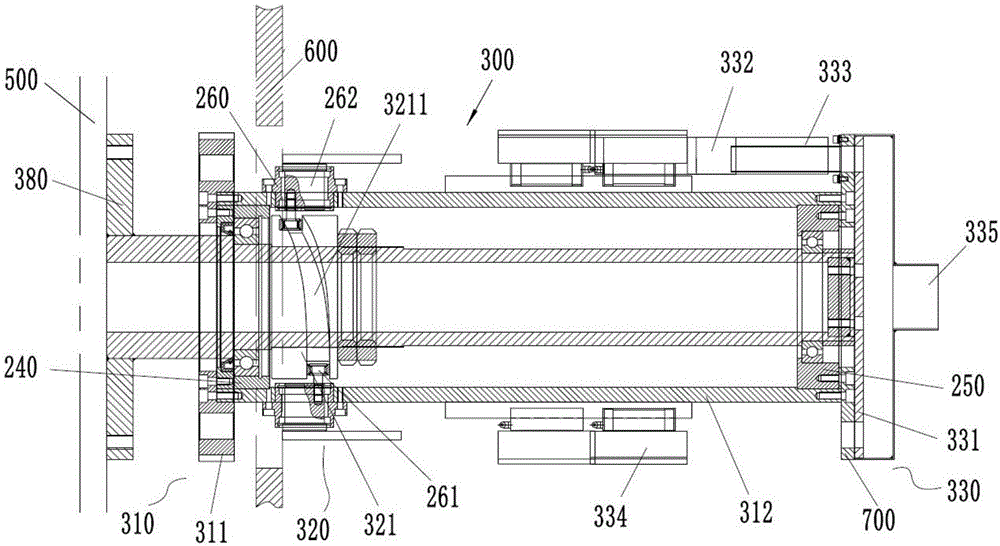

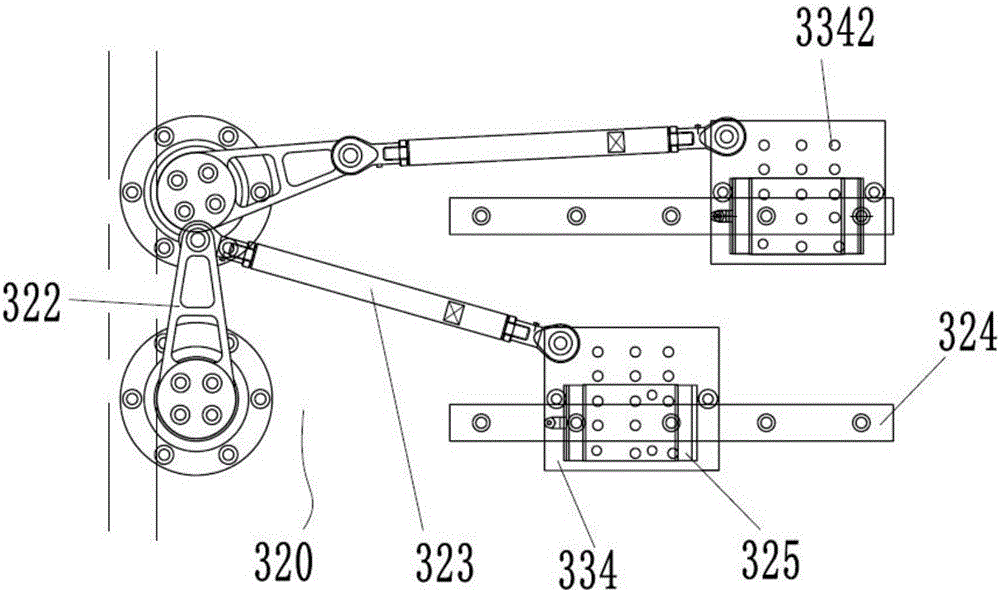

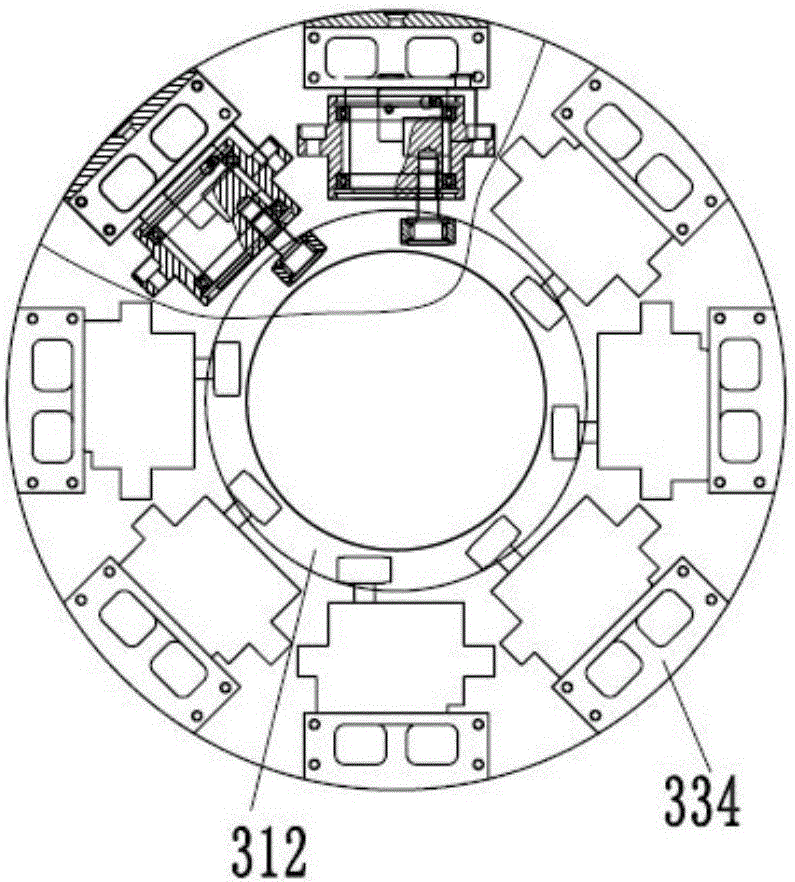

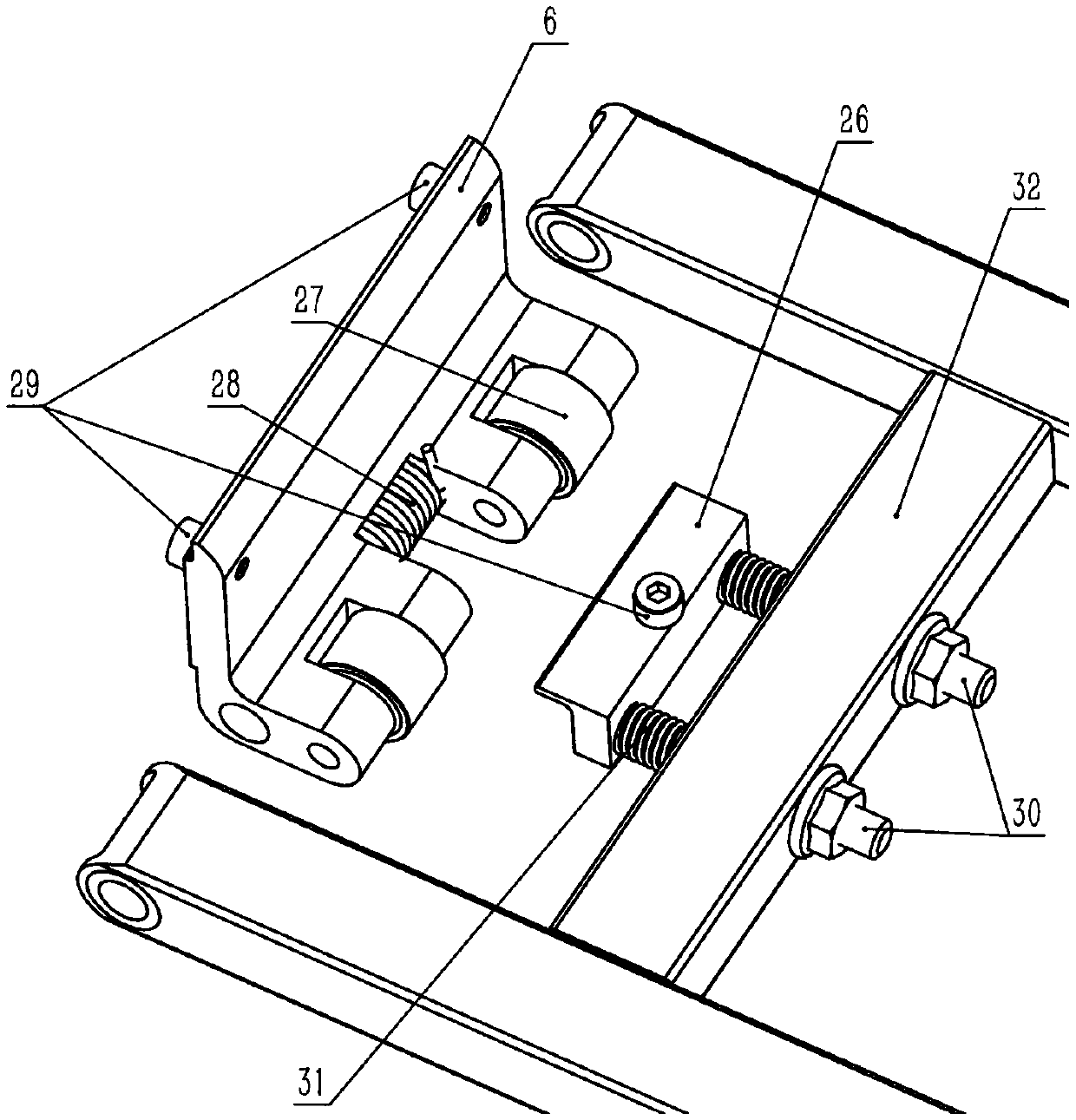

Longitudinal distance varying device on operation side

ActiveCN106236384AReasonable structural designCompact layoutAbsorbent padsBaby linensEngineeringPulley

The invention discloses a longitudinal distance varying device on operation side. The longitudinal distance varying device comprises a hollow operation-side distance varying support seat, an operation-side rotating unit, a plurality of operation-side distance adjusting units, an operation-side adsorbing unit, a swinging mechanism and a flow limiting mechanism, wherein the operation-side distance varying support seat is mounted on a main support board of diaper production equipment; the operation-side rotating unit comprises an operation-side distance varying rotating disc and an operation-side distance varying synchronous pulley connected to one end of the operation-side distance varying rotating disc; the flow limiting mechanism is detachably arranged in an adsorbing hole of an operation-side adsorbing disc and used for balancing pressure between an upper cavity of the adsorbing hole and an air inlet channel of the adsorbing hole, so that vibration produced when a lug is separated from the operation-side adsorbing disc is reduced. The longitudinal distance varying device is simple in structure and convenient to use, can effectively solve the problem of wrinkles and deformation caused by vibration in a diaper transfer process, guarantees dimensions of diaper lug products and guarantees product quality.

Owner:昆山市联园大数据科技有限公司

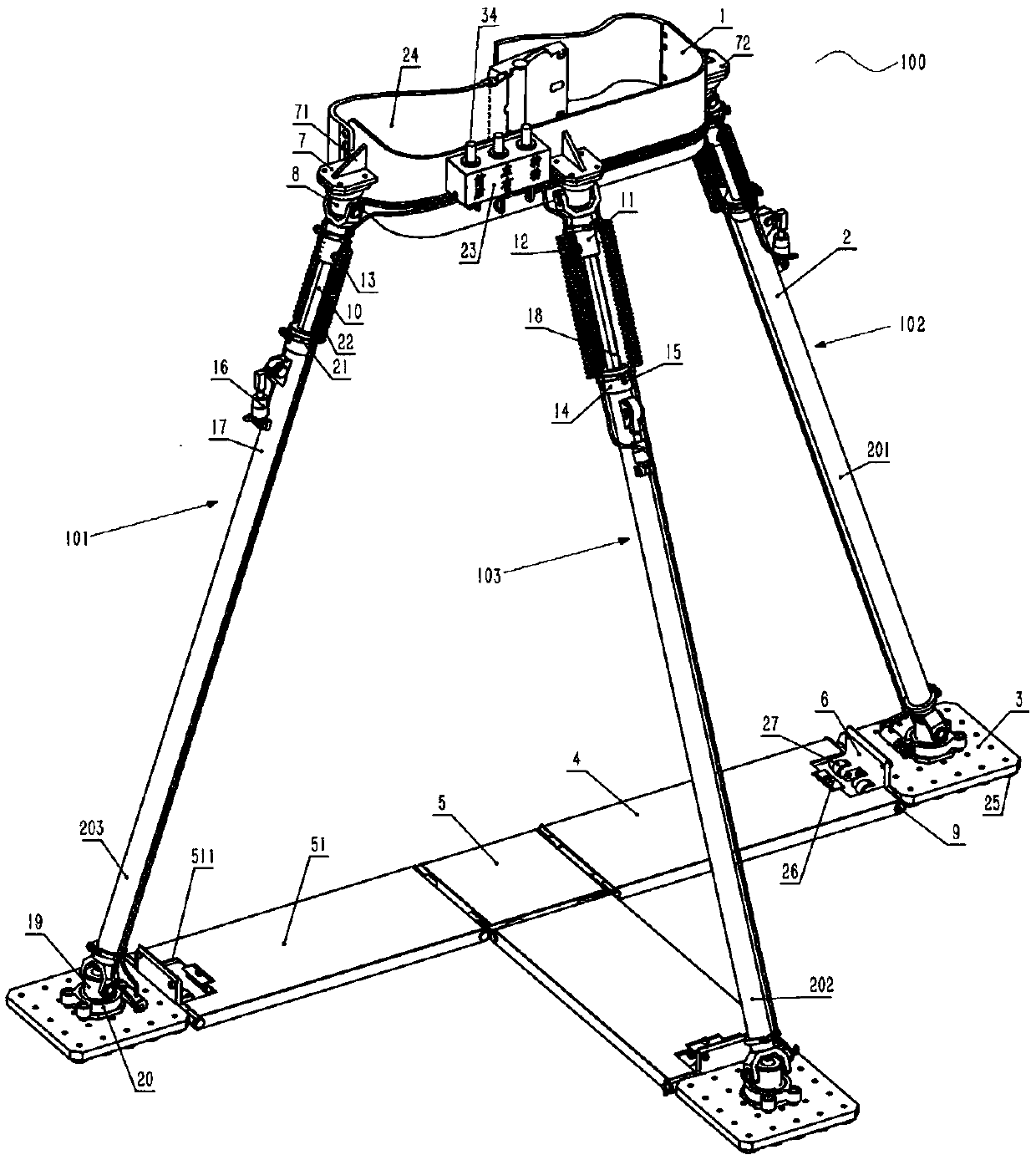

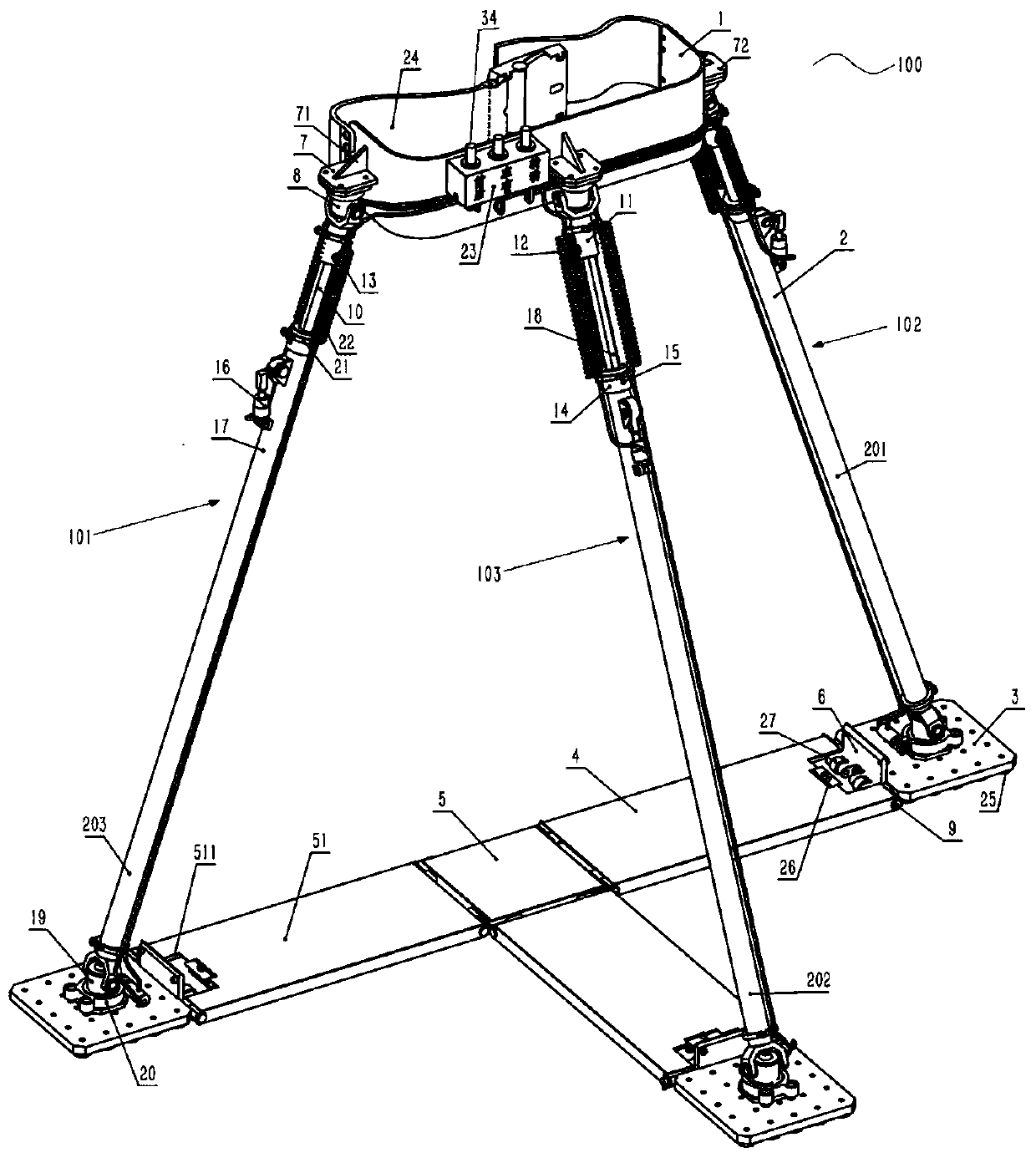

Stabilizing device

ActiveCN109606559AAvoid unstable situationsMake the most of structural spaceVessel partsSelf lockingEngineering

The invention discloses a stabilizing device, and the stabilizing device comprises a waist fixing frame, support legs and a bottom plate component. Connecting flanges are respectively arranged on theleft side, the right side and the rear side of the waist fixing frame, hooke hinges are arranged at the two ends of the support leg, the connecting flange is fixedly connected with the upper hooke hinge, an unlocking device is fixed at the middle part of a bottom plate supporting connecting frame, an anchor plate, the bottom plate supporting connecting frame and the unlocking device are connectedthrough a rotating pair, a center connecting block is connected with the bottom plate supporting connecting frame through the rotating pair, the bottom plate supporting connecting frame is distributedon the left side, the right side and the rear side of the center connecting block in a T-shape, a telescopic sleeve and a telescopic rod are coaxially arranged, and can move but cannot rotate, and amoving brake limits the moving of the telescopic sleeve and the telescopic rod. The stabilizing device can be folded, has the function of going forwards and backwards, left and right and up and down and rotating, the multi-position and multi-angle change is realized to meet various position requirements, the stabilizing device has a self-locking function on each position, and a user can maintain the stable posture at the state on any position.

Owner:YANSHAN UNIV

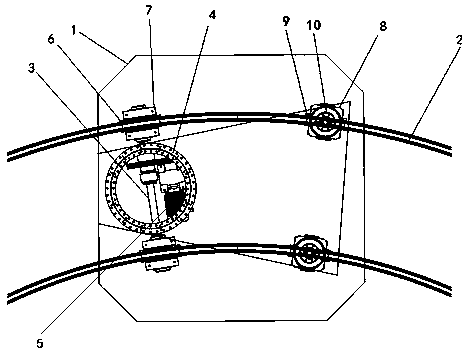

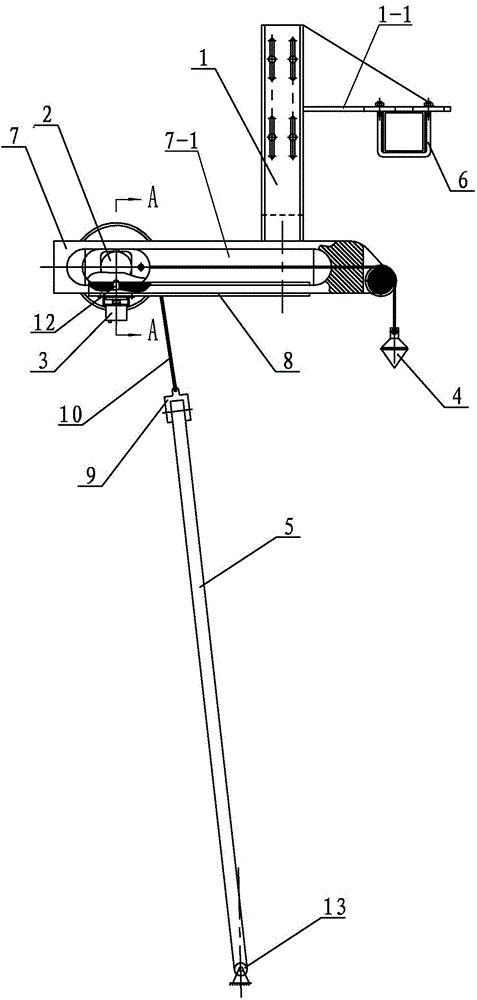

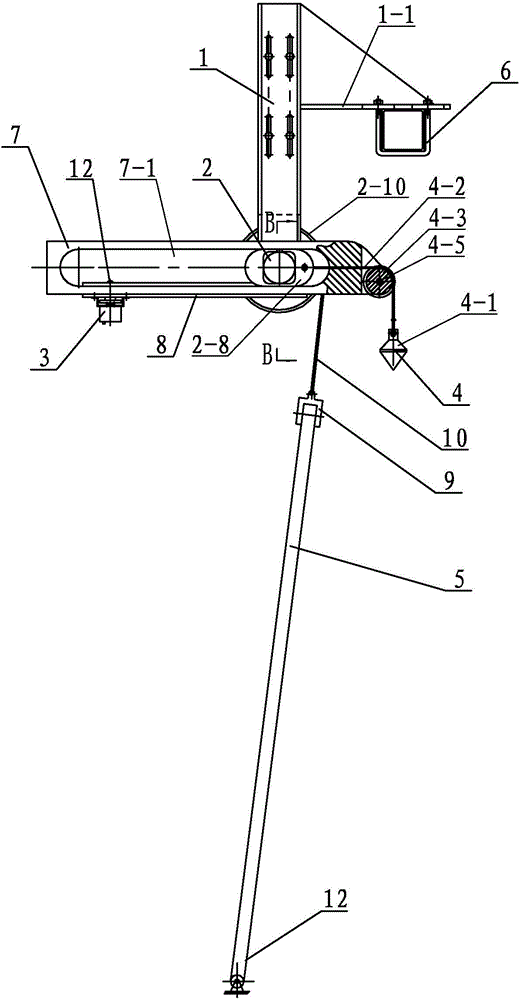

Rope counterweight sun wing auxiliary turning mechanism

ActiveCN103935534BAdjustable rotation speedMeet location requirementsCosmonautic condition simulationsPulleyMagnet

The invention provides a rope balance weight type solar wing auxiliary turning mechanism, and relates to a solar wing auxiliary turning mechanism. The problem that due to the fact that an existing solar wing driving mechanism can not be unfolded and folded on the ground, a solar wing unfolding mechanism used for ground tests is needed is solved. A horizontal sliding frame is arranged below a front channel plate on a vertical sliding frame. Slide ways are arranged on the front end face and the rear end face of the horizontal sliding frame. Driving mechanisms are arranged in the slide ways and slide along a guide rail leftward and rightward. The guide rail is fixedly connected with the horizontal sliding frame. A lock pin through hole is formed in the left side of the guide rail, and a lock pin is arranged in the lock pin through hole. A magnet is arranged below the lock pin. A solar wing steel wire rope is wound on a rope wheel of the driving mechanism, wherein one end of the solar wing steel wire rope is fixed to the rope wheel through a lock catch, the other end of the solar wing steel wire rope is connected with a solar wing through a connecting piece, the other end of the solar wing is fixed to a support, a balance weight mechanism is connected with a sliding block, and a pulley installation frame is arranged on the right side of the horizontal sliding frame. The rope balance weight type solar wing auxiliary turning mechanism is used for solar wing ground unfolding tests.

Owner:HARBIN INST OF TECH

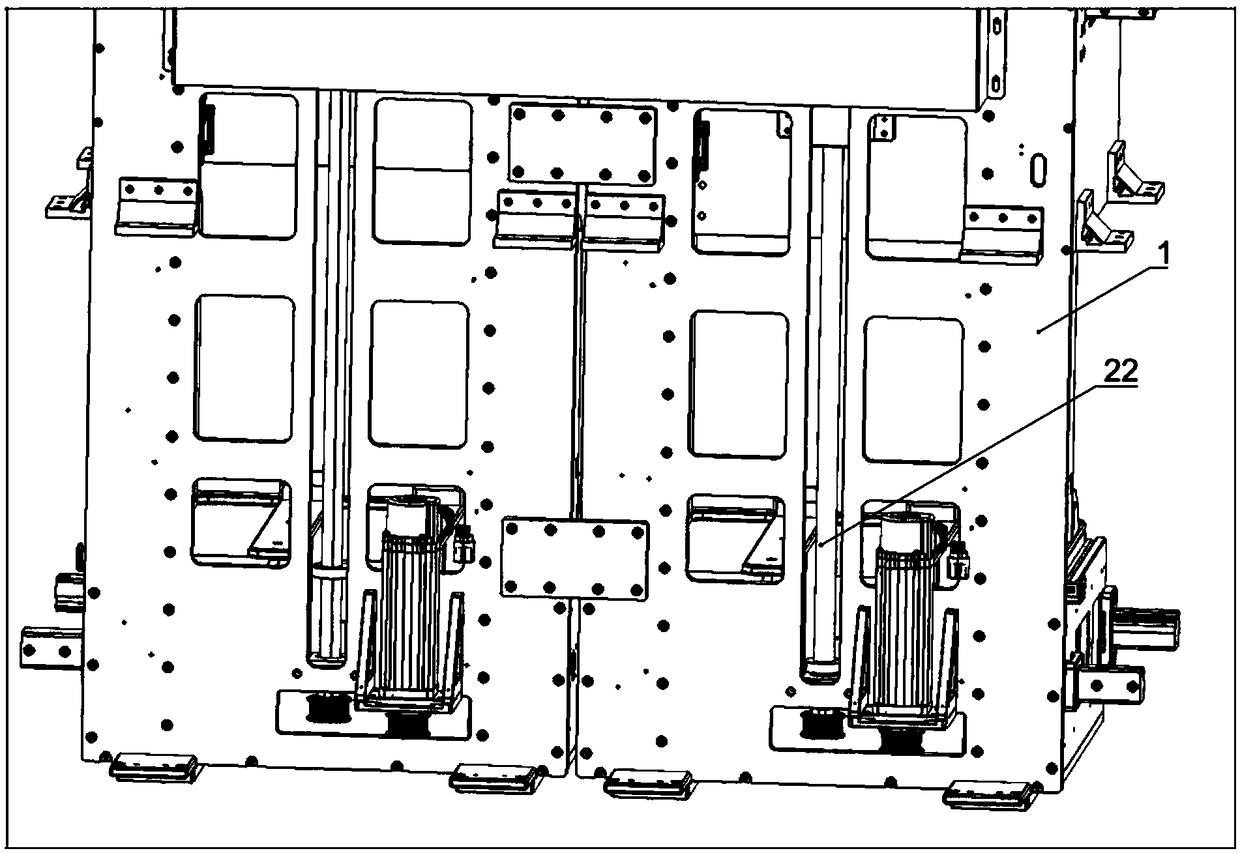

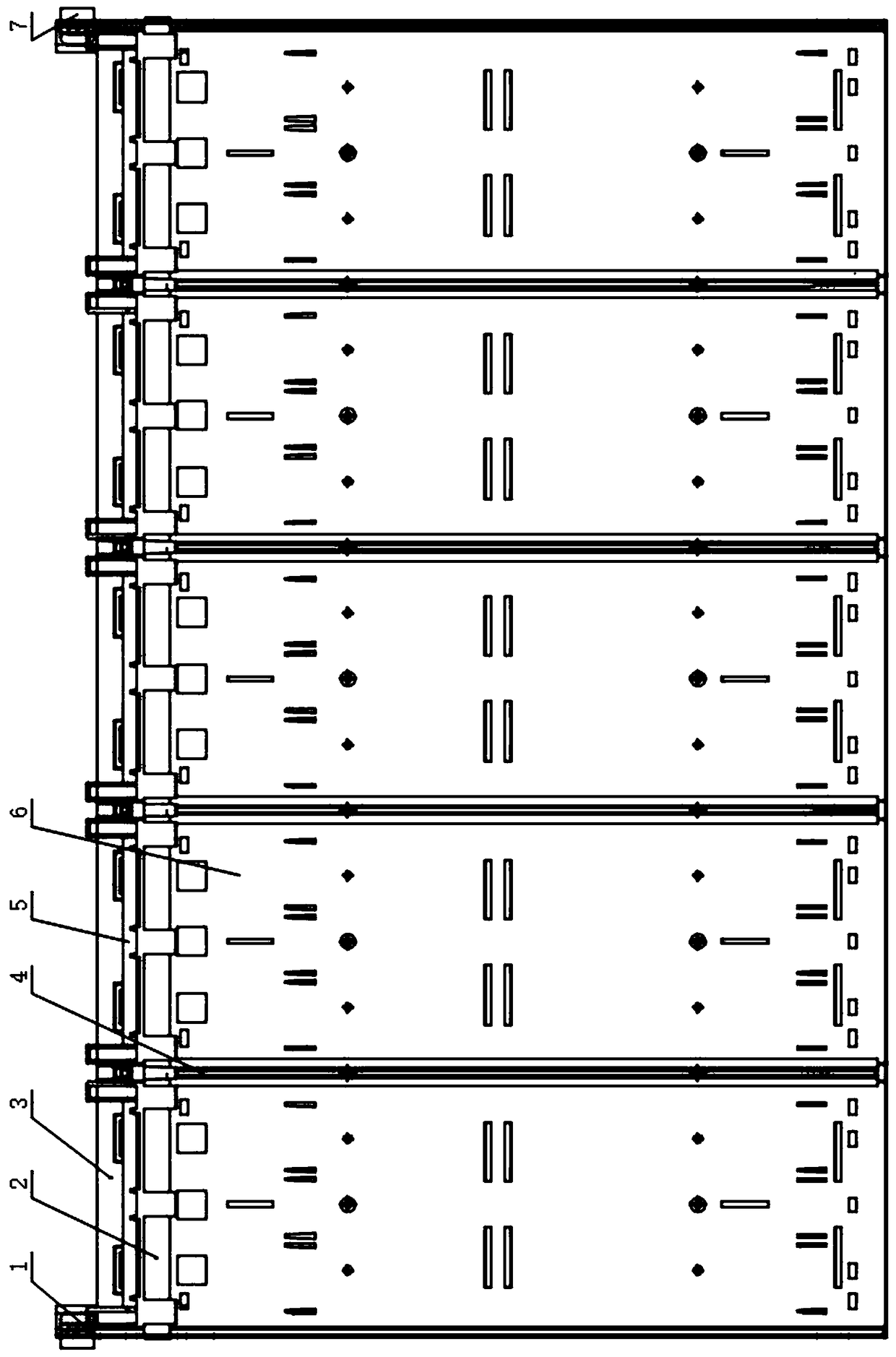

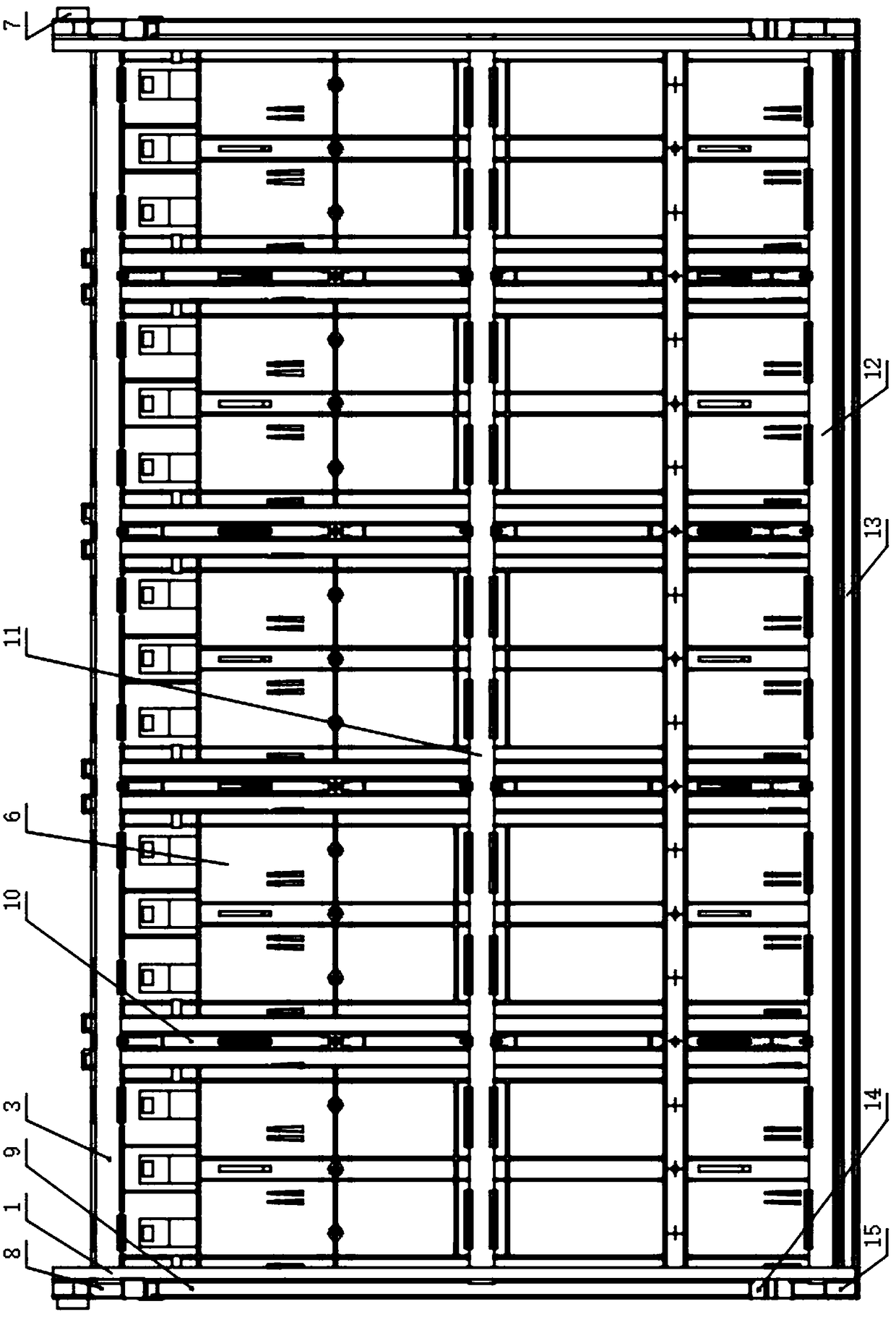

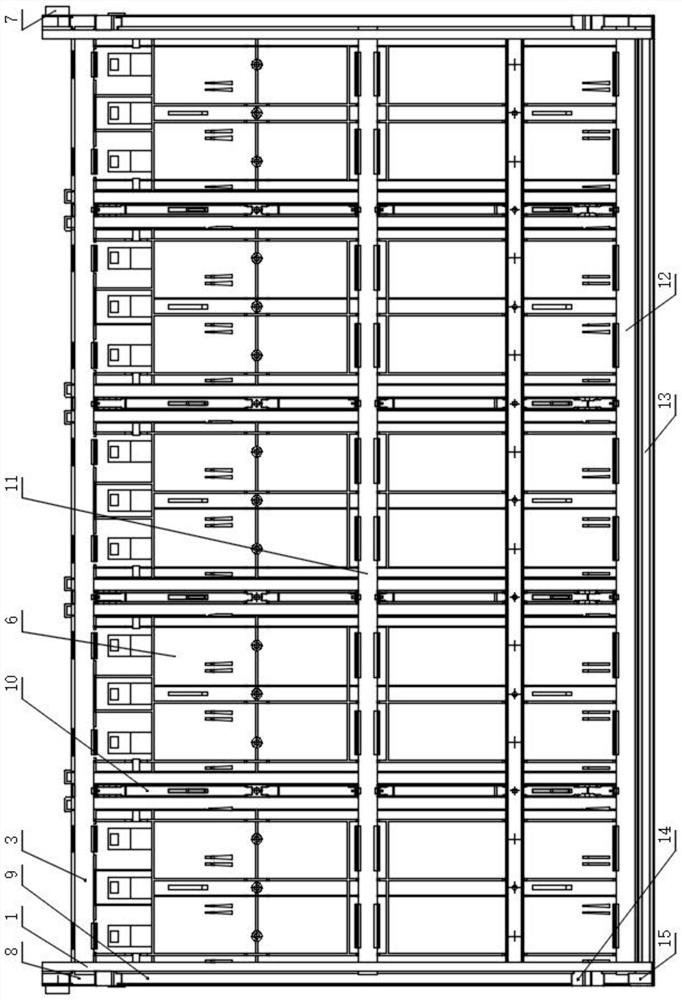

Goods chamber structure of vending machine

ActiveCN109448239ASave installation timeSave disassembly timeCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringAlloy

The invention relates to a goods chamber structure of a vending machine. Two side plates are arranged at an interval, an upper beam is arranged at upper ends of the two side plates, a gear beam is arranged at the rear end of the two side plates, and a front beam is arranged at front ends of the two side plates. A plurality of detachable base plates are arranged on the front beam and the rear beam,and a plurality of detachable motor plates are arranged on the upper beam and the rear beam. Detachable partition plates are arranged on the front beam and the rear beam among adjacent base plates orarranged at upper end faces of the base plates. Appropriate widths and mounting positions of the base plates and the motor plates can be selected, the partition plates can be mounted and demounted conveniently, the base plates, the motor plates, the partition plates, tracks and springs can be freely combined according to goods sold on site, and high flexibility is realized. The beams, the side plates and the like are made from aluminum alloy, the base plates, the motor plates and the like are made from plastic, and the integral weight is sharply reduced while mechanical strength is greatly improved. Due to convenient mounting modes of a center plate, the spring, the tracks and the like, efficiency in mounting and demounting is further improved.

Owner:天津雷云智能科技有限公司

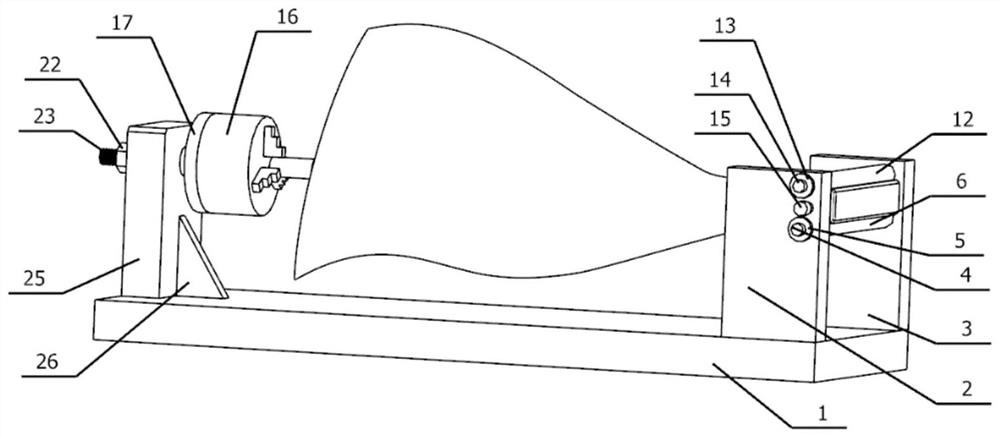

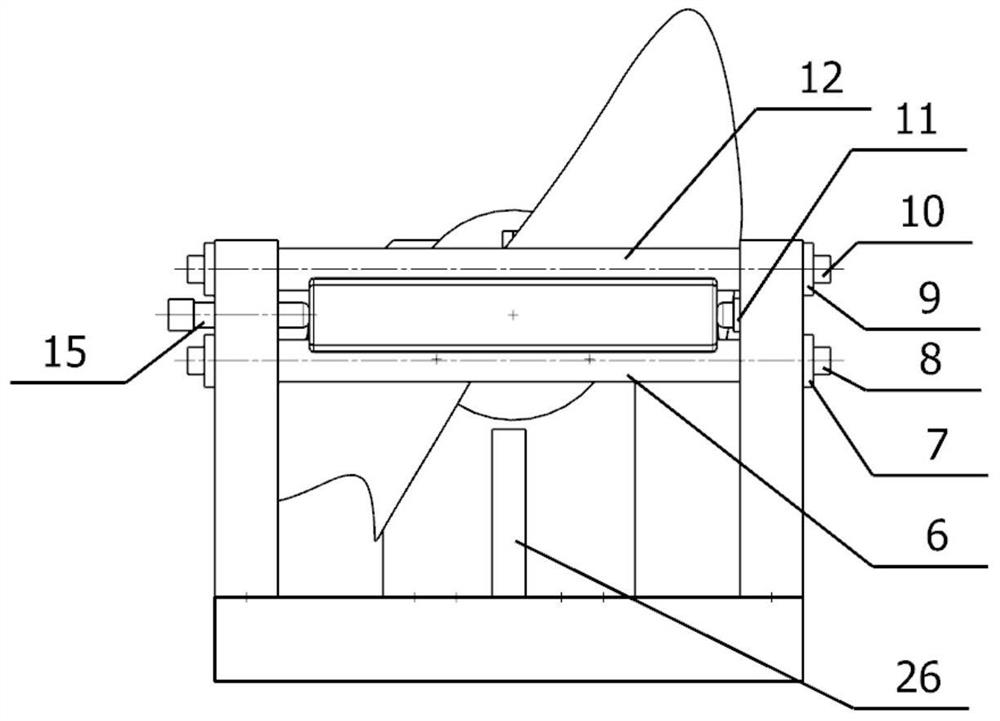

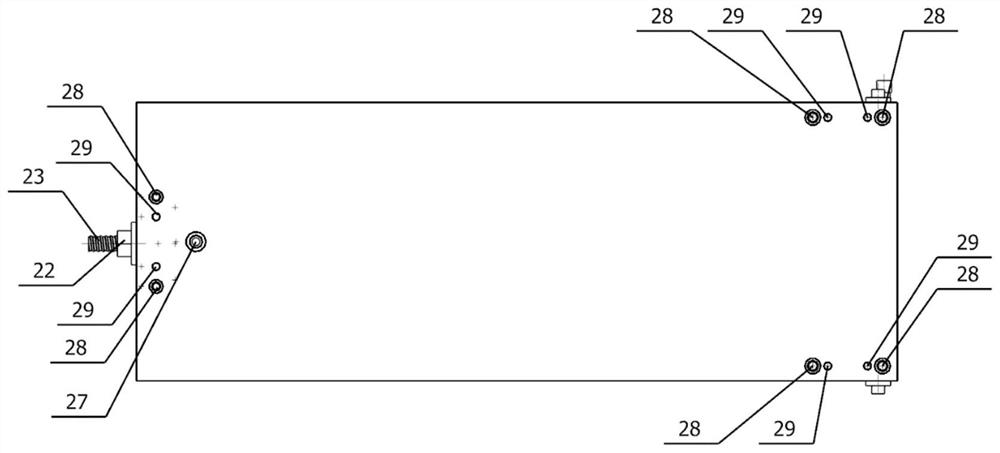

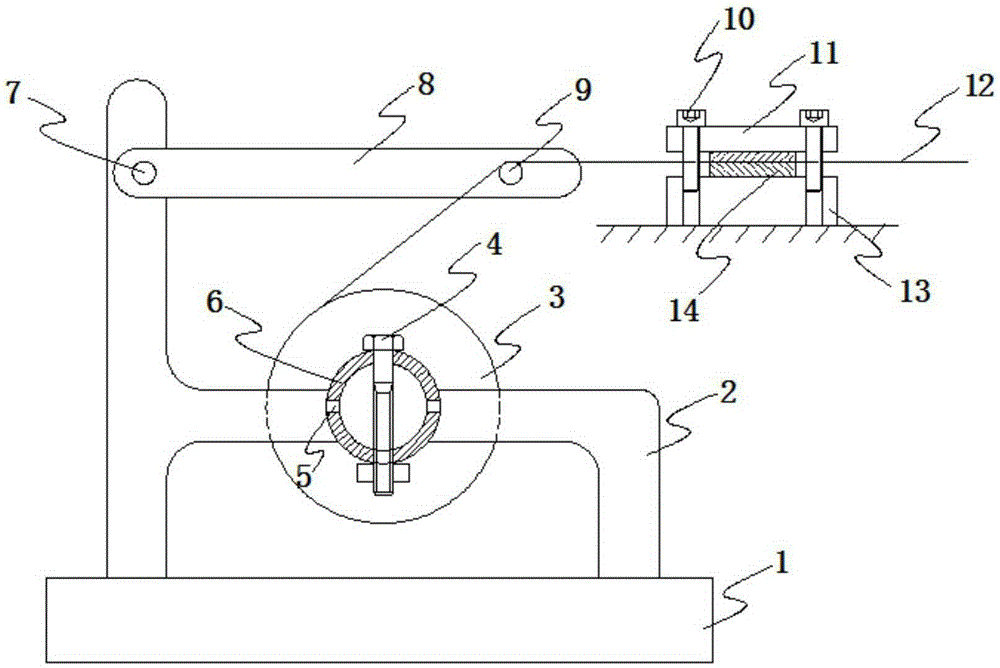

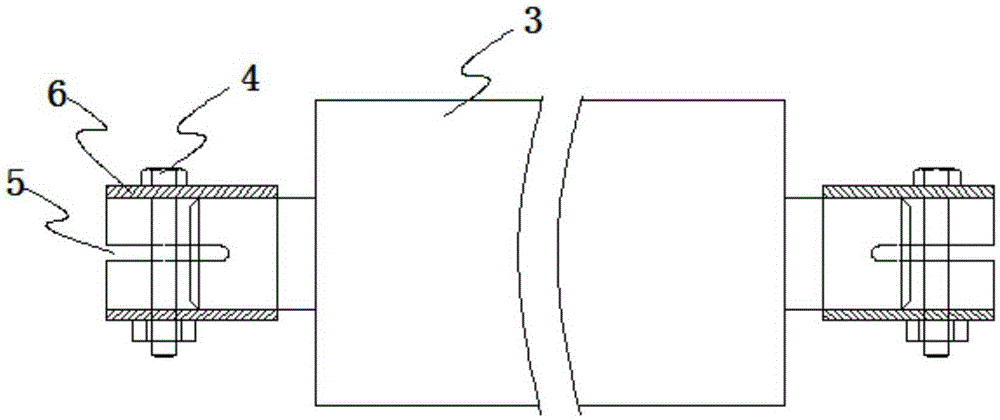

Spinning tension adjusting device

The invention relates to the field of spinning machines, in particular to a spinning tension adjusting device. According to the device, the function of the adjustable spinning yarn tension is achieved. The spinning tension adjusting device structurally comprises a base, a supporting frame, bearing bushes, a rotating shaft, a supporting rod, a yarn guiding rod, an upper pressing plate, yarn, a lower pressing plate and a yarn pressing block. The supporting frame is welded to the base. The bearing bushes are arranged at the two ends of the supporting frame respectively and provided with rectangular grooves. A first fastening bolt is arranged on one sides of the rectangular grooves. The supporting rod is arranged at the top end of the supporting frame and connected with the supporting frame through the rotating shaft. The yarn guiding rod is arranged at the right end of the supporting rod. A yarn pressing mechanism is arranged on the right side of the supporting rod and comprises the upper pressing plate, the lower pressing plate, the yarn pressing block and second fastening bolts. The spinning tension adjusting device is easy to operate and convenient to use, and the spinning production efficiency is improved.

Owner:SUZHOU BUWU JIAXIANG TEXTILE TECH CO LTD

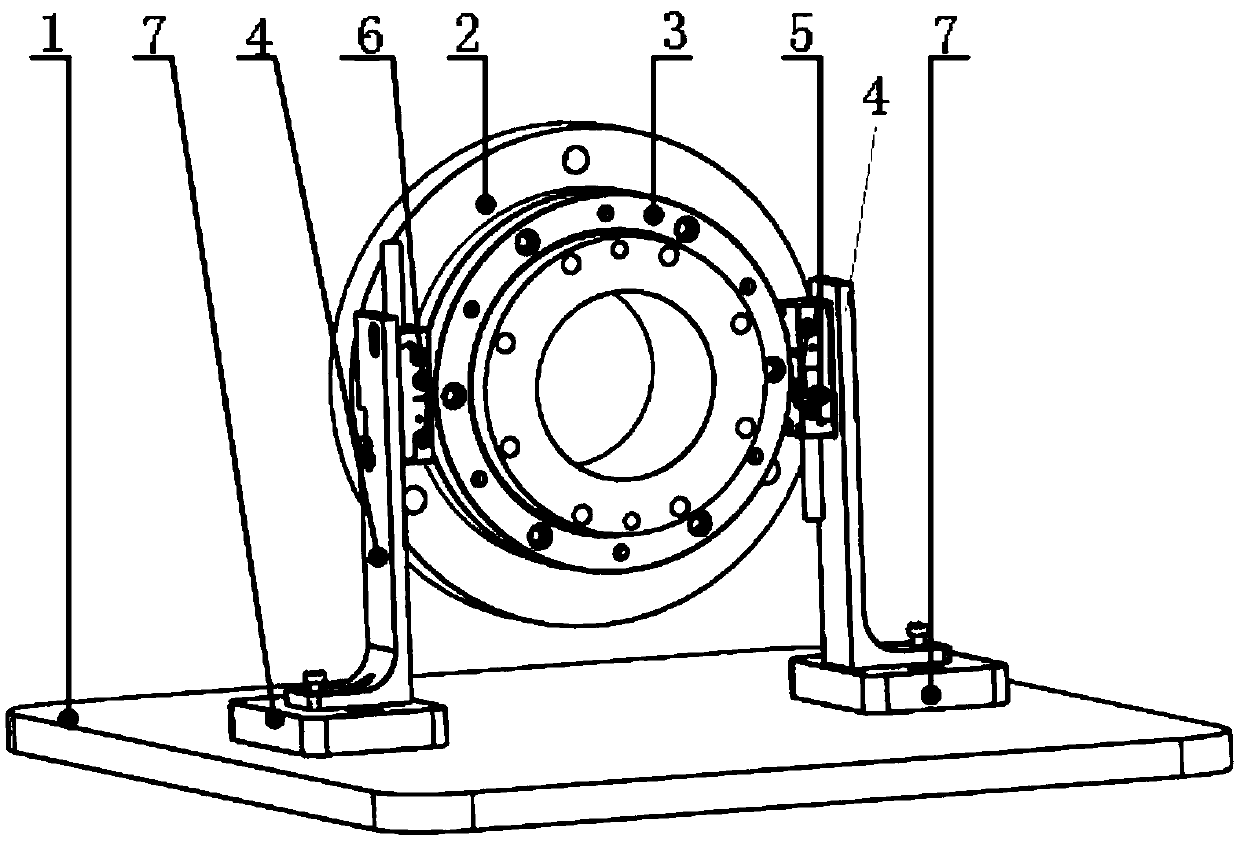

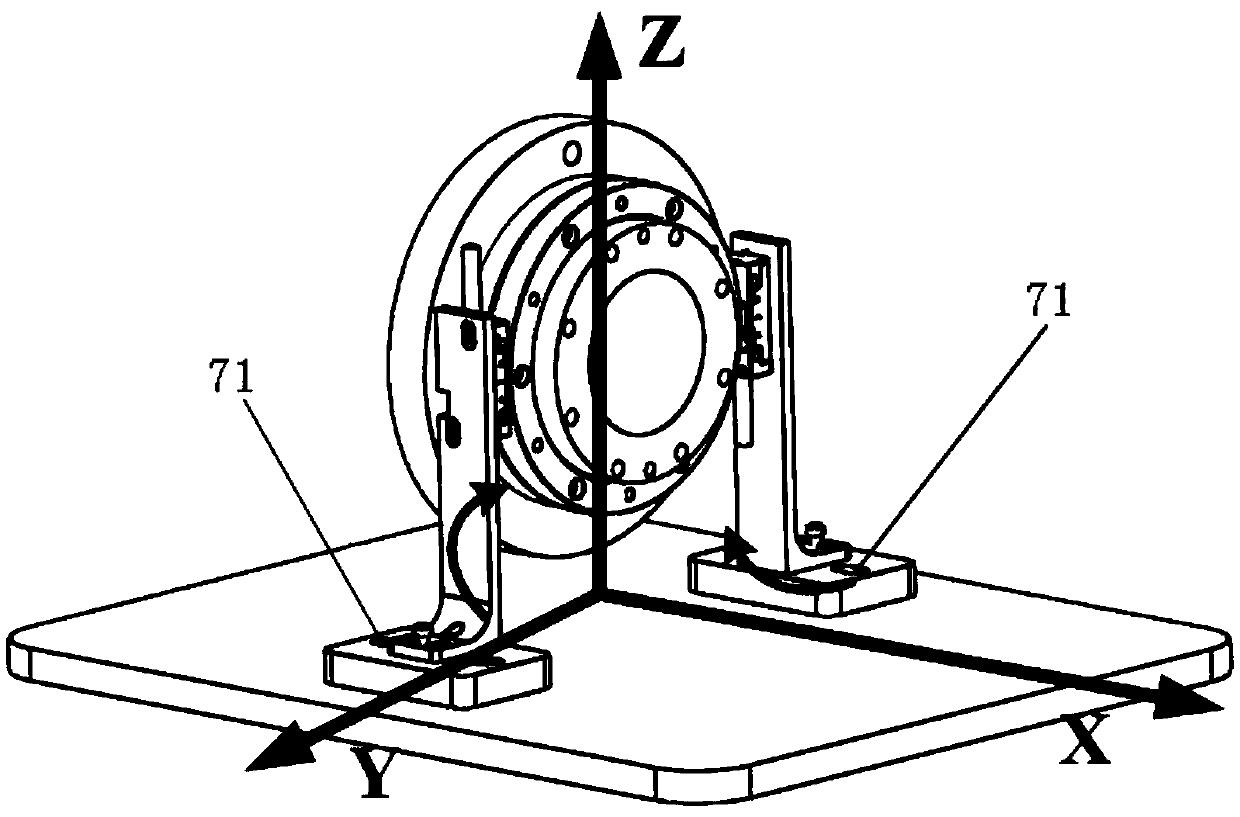

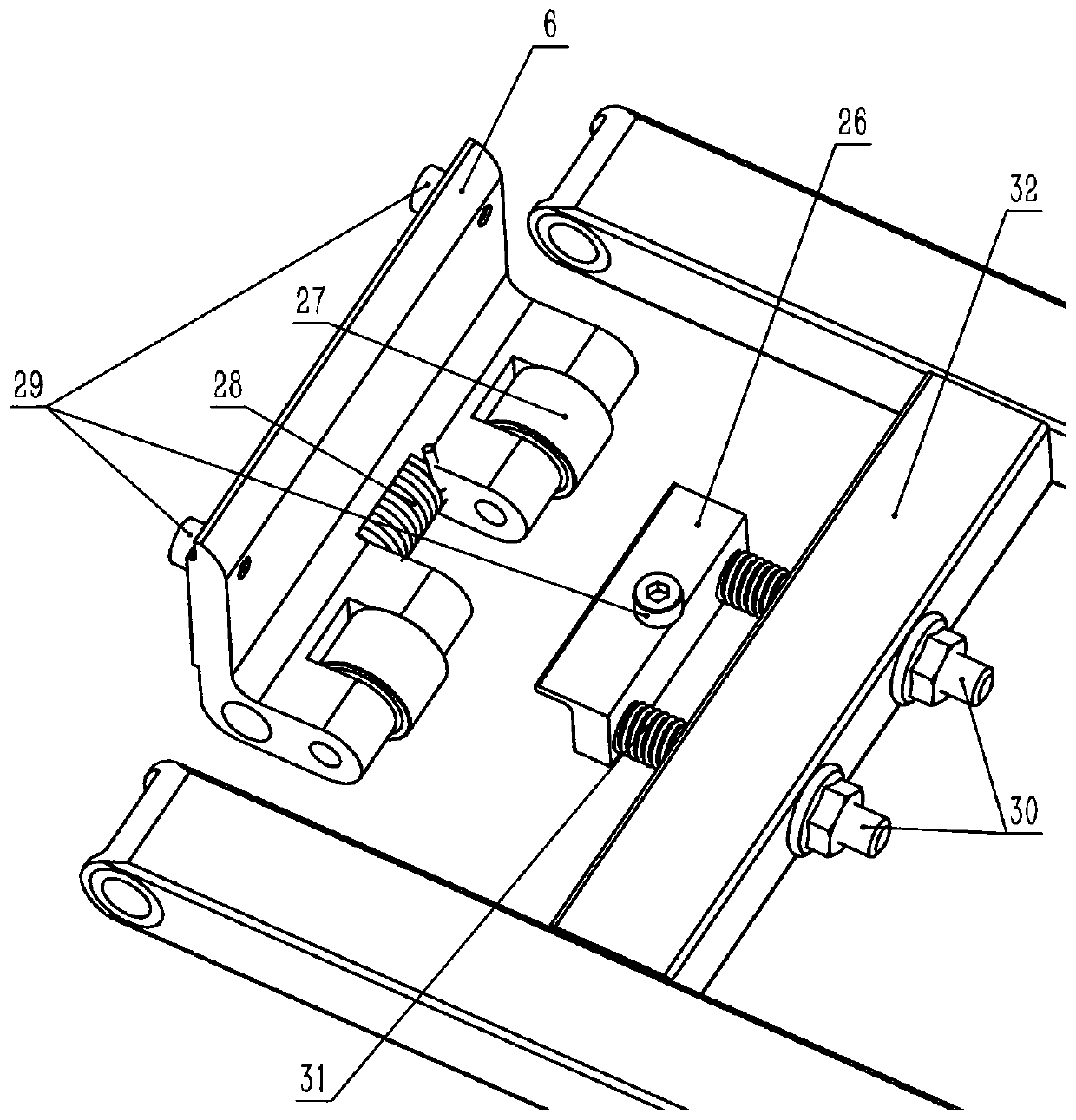

Open double-reading head circular grating system quick installation and adjustment mechanism

PendingCN109612411AMeet location requirementsAchieve regulationUsing optical meansGratingMulti degree of freedom

The invention discloses an open double-reading head circular grating system quick installation and adjustment mechanism. The open double-reading head circular grating system quick installation and adjustment mechanism comprises a base plate, a ring flange and a circular grating, reading head installation seats are diametrically arranged on the two sides of the circular grating, the reading head installation seats are fixedly connected with a positive reading head and a reverse reading head correspondingly, cushion blocks are arranged at the bottoms of the reading head installation seats, and fixedly connected with the base plate; the reading head installation seats are provided with a plurality of first step groove holes in the Z direction and the Y direction, the first step groove holes are used for adjusting the distance of the reading heads relative to the circular grating in the Z direction and the Y direction, threaded holes are further formed in the reading head installation seats, and the pitching angle of the reading head mounting seats to the X direction is adjusted through fastening bolts; and the cushion blocks are provided with second step groove holes in the X direction, and the second step groove holes are used for adjusting the distance of the reading heads relative to the circular grating in the X direction and the torsional swinging angle of the reading head installation seats relative to the Z direction. According to the open double-reading head circular grating system quick installation and adjustment mechanism, through the quick installation and adjustment mechanism, the multi-degree of freedom adjustment of the reading heads is realized, the volume is small, the structure is simple, installation and adjustment are convenient, and the circular grating and the diametrical double-reading head can be rapidly installed and adjusted.

Owner:CHONGQING JIANSHE IND GRP

Simple profile steel stacking device

PendingCN106829513AUnique structureInnovative designStacking articlesDe-stacking articlesHydraulic cylinderDrive shaft

The invention discloses a simple profile steel stacking device, and belongs to the technical field of profile steel stacking. The simple profile steel stacking device comprises a steel pushing device, an overturning manipulator, a lifting manipulator and a collecting roller way, the steel pushing device includes a first steel pushing device and a second steel pushing device, the overturning manipulator comprises an overturning electromagnet, a swing arm is connected on the left side of the overturning electromagnet, a bearing block is connected on the left side of the swing arm, a drive shaft is mounted on the bearing block, a first support is mounted below the drive shaft, the drive shaft is connected with a swing cylinder supporting seat through a bearing, a gear rack swing cylinder is mounted on the swing cylinder supporting seat, a second support is mounted below the swing cylinder supporting seat, the lifting manipulator is arranged below the overturning electromagnet and comprises a base, and a drive shaft and a third hydraulic cylinder are arranged above the base. The simple profile steel stacking device is simple in structure, easy to operate and maintain and high in automation degree, safety can be remarkably improved, driving time is shortened, and production efficiency is improved.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

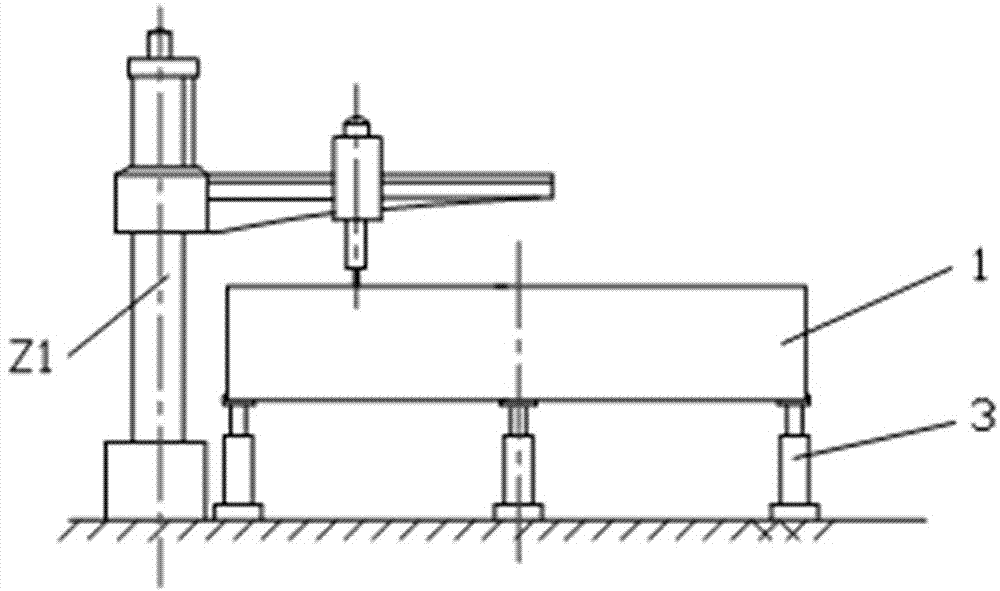

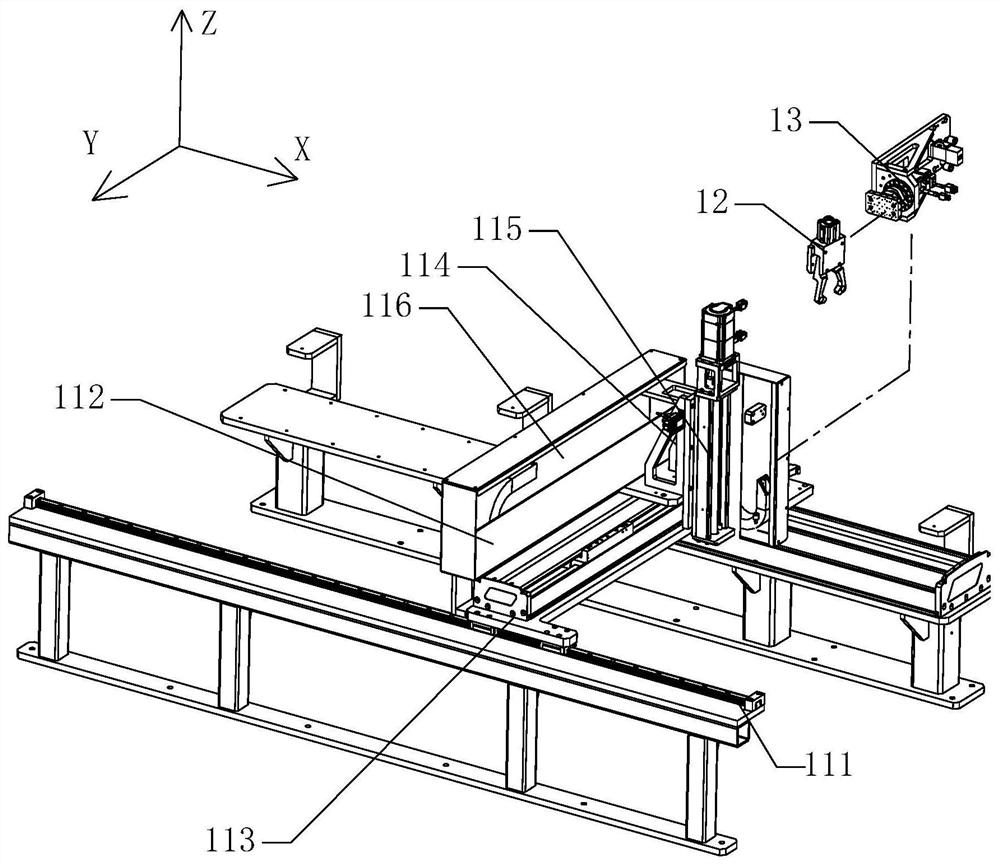

Automatic part taking equipment for high-speed machining of valve body part

PendingCN114684598AMeets placement requirements for placement on palletsMeet location requirementsConveyorsLoading/unloadingEngineeringMachining process

The invention discloses automatic part taking equipment for high-speed machining of valve body parts, belongs to the technical field of valve body machining and conveying, and aims to solve the problems that a company develops a high-speed and high-precision machining process of valve bodies, and an existing part taking device in the valve body machining process cannot meet the high-speed machining requirement, so that the automatic part taking equipment for high-speed machining of the valve body parts is researched and developed. According to the technical scheme, a piece taking and placing mechanism comprises a three-axis moving mechanism of a portal frame structure, a thumb air cylinder, a right-angle rotating mechanism and a tray supporting table; the three-axis moving mechanism comprises two parallel moving rails, an X-direction moving table, a Y-direction moving table and a Z-direction moving table, wherein the X-direction moving table is assembled on the moving rails through the two ends of a portal frame, the Y-direction moving table horizontally moves at the position of a cross beam of the portal frame, the Z-direction moving table vertically moves on the cross beam of the portal frame, and a thumb air cylinder is installed on the Z-direction moving table through a right-angle rotating mechanism. And the effects that the valve body is efficiently clamped, and the position of the valve body can be adjusted and placed are achieved.

Owner:苏州飞航防务装备有限公司

stabilization device

ActiveCN109606559BAvoid unstable situationsMake the most of structural spaceVessel partsSelf lockingEngineering

The invention discloses a stabilizing device, and the stabilizing device comprises a waist fixing frame, support legs and a bottom plate component. Connecting flanges are respectively arranged on theleft side, the right side and the rear side of the waist fixing frame, hooke hinges are arranged at the two ends of the support leg, the connecting flange is fixedly connected with the upper hooke hinge, an unlocking device is fixed at the middle part of a bottom plate supporting connecting frame, an anchor plate, the bottom plate supporting connecting frame and the unlocking device are connectedthrough a rotating pair, a center connecting block is connected with the bottom plate supporting connecting frame through the rotating pair, the bottom plate supporting connecting frame is distributedon the left side, the right side and the rear side of the center connecting block in a T-shape, a telescopic sleeve and a telescopic rod are coaxially arranged, and can move but cannot rotate, and amoving brake limits the moving of the telescopic sleeve and the telescopic rod. The stabilizing device can be folded, has the function of going forwards and backwards, left and right and up and down and rotating, the multi-position and multi-angle change is realized to meet various position requirements, the stabilizing device has a self-locking function on each position, and a user can maintain the stable posture at the state on any position.

Owner:YANSHAN UNIV

Four-shaft and four-head linkage engraving and milling machine

PendingCN114102264AMeet location requirementsImprove work efficiencyPositioning apparatusMetal working apparatusEngravingEngineering

The invention provides a four-shaft and four-head linkage engraving and milling machine which comprises a rack, one end of the interior of the rack is provided with a clamping moving device, the other end of the interior of the rack is provided with a machine head, and the execution end of the machine head is connected with a plurality of cutters; the clamping and moving device comprises a translation assembly installed in the rack and a tool clamp connected with the execution end of the translation assembly. The multi-angle displacement device can drive a workpiece to perform multi-angle displacement so as to meet the position requirements of a plurality of cutters during machining, so that the working efficiency is improved.

Owner:漳州市方凯塑胶制品有限公司

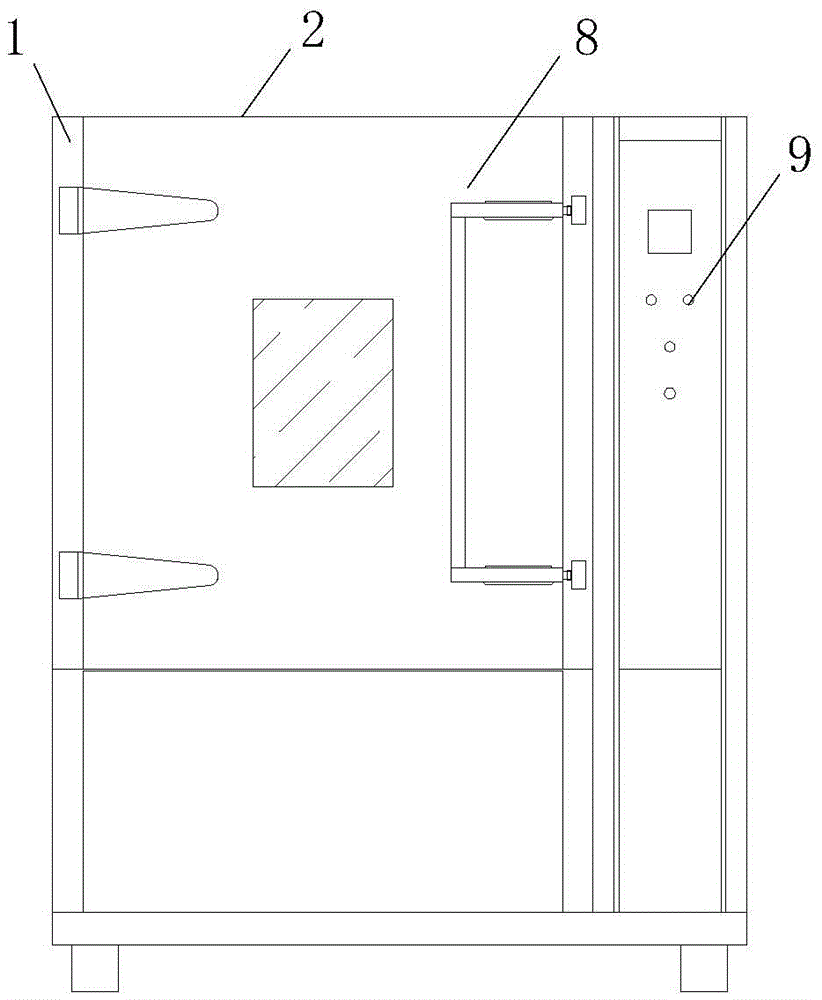

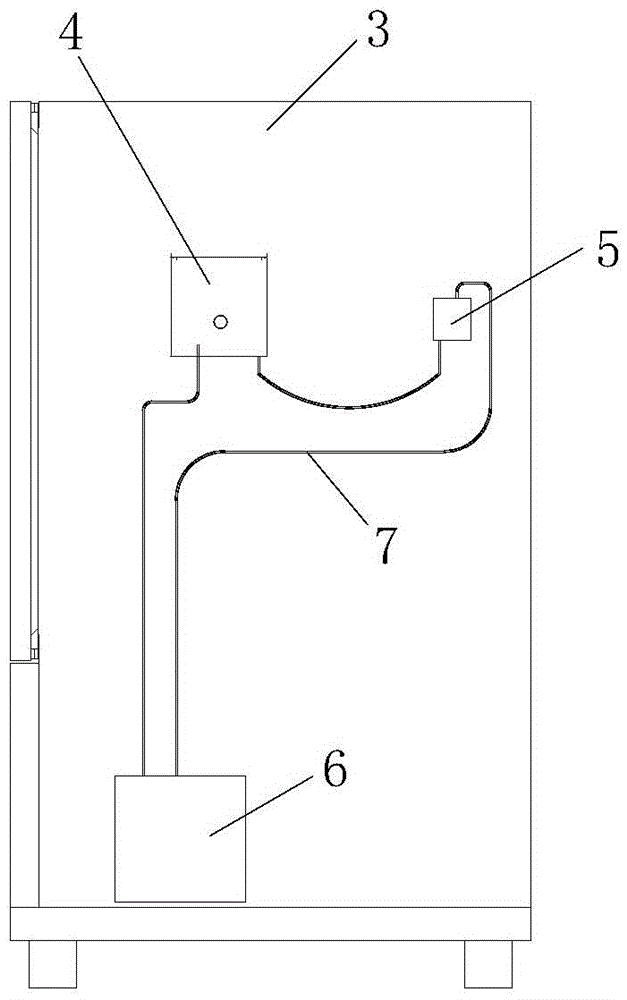

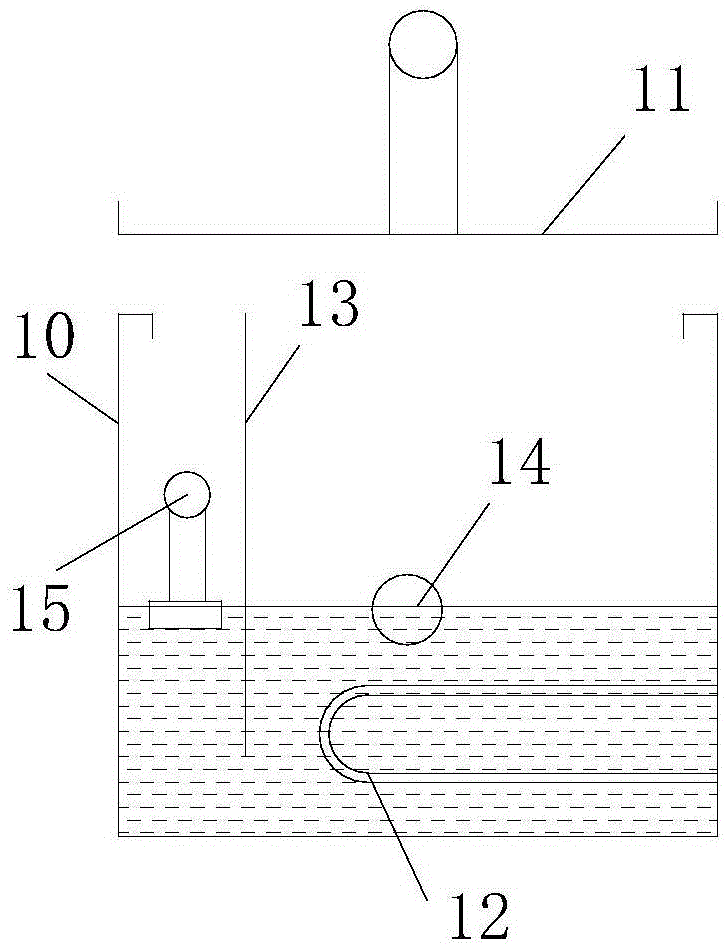

Constant temperature constant humidity box with removable humidifier

InactiveCN105547976AIncrease flexibilityEasy to disassembleWeather/light/corrosion resistanceThermal insulationControl room

The invention provides a constant temperature constant humidity box with a removable humidifier, the constant temperature constant humidity box includes a machine box, a work room, a control room and an air circulation device; a thermal insulation layer is arranged between the work room and the control room; the work room is internally provided with an article placement rack; the air circulation device is arranged on the work room, the control room is internally provided with the removable humidifier, a controller, a water tank and a water drain pipeline, the removable humidifier, the controller and the water tank are arranged on a path of the water drain pipeline, the controller conveys water in the water tank to the removable humidifier by the water drain pipeline, and the removable humidifier and the water tank are connected by the by the water drain pipeline.

Owner:SUZHOU DONGHUA TESTING INSTR

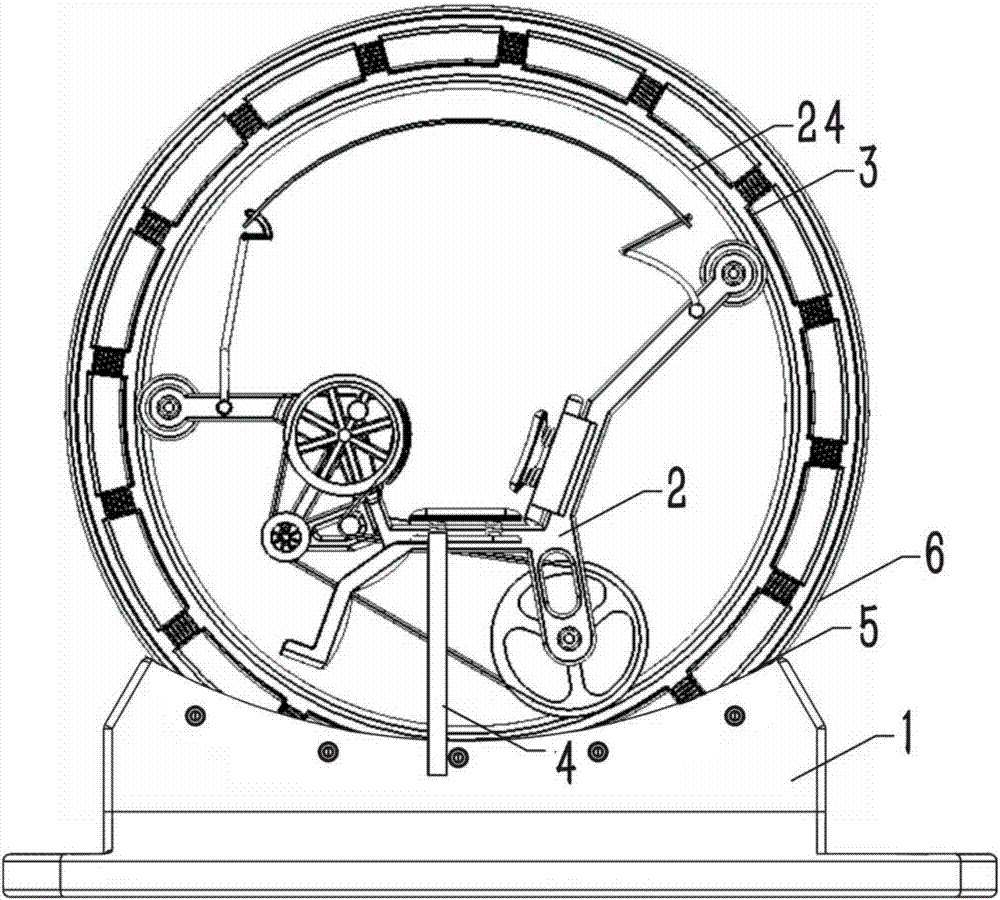

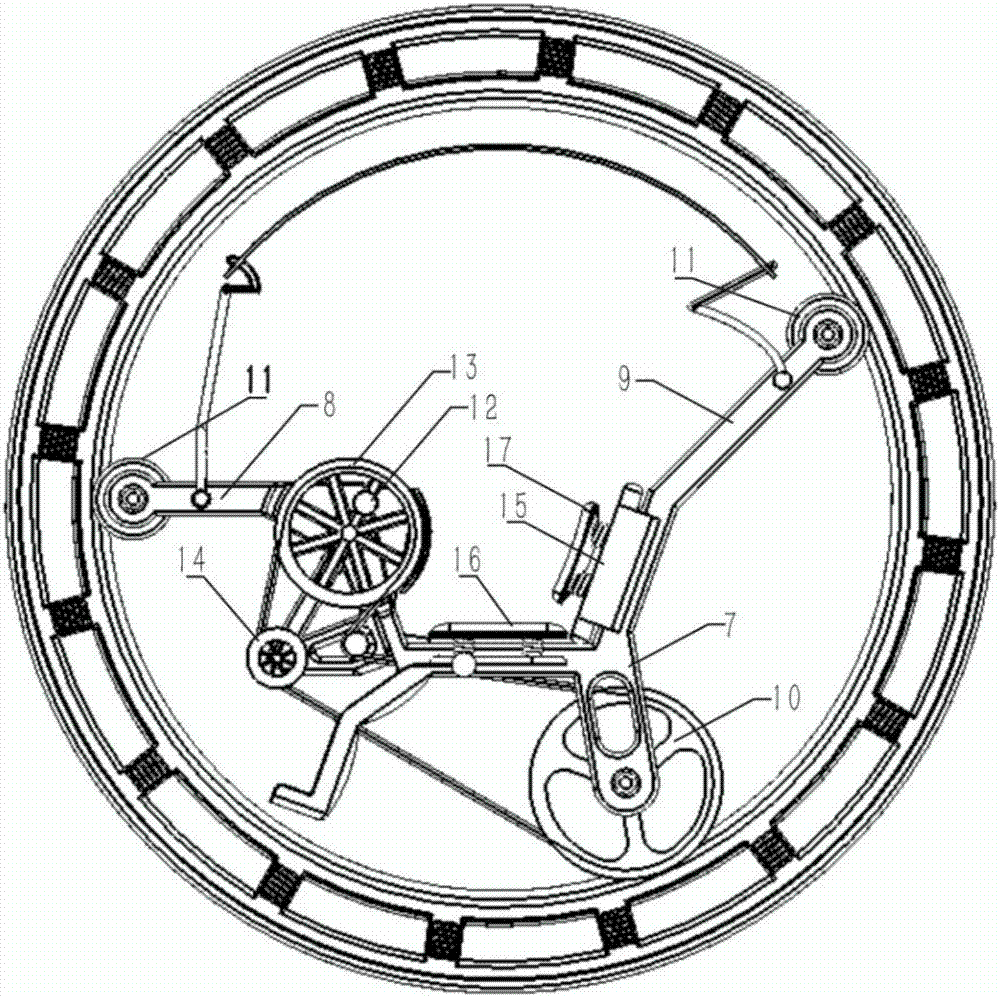

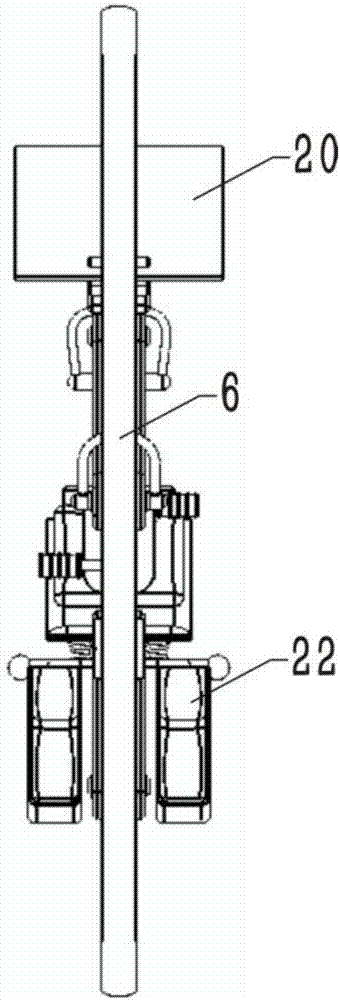

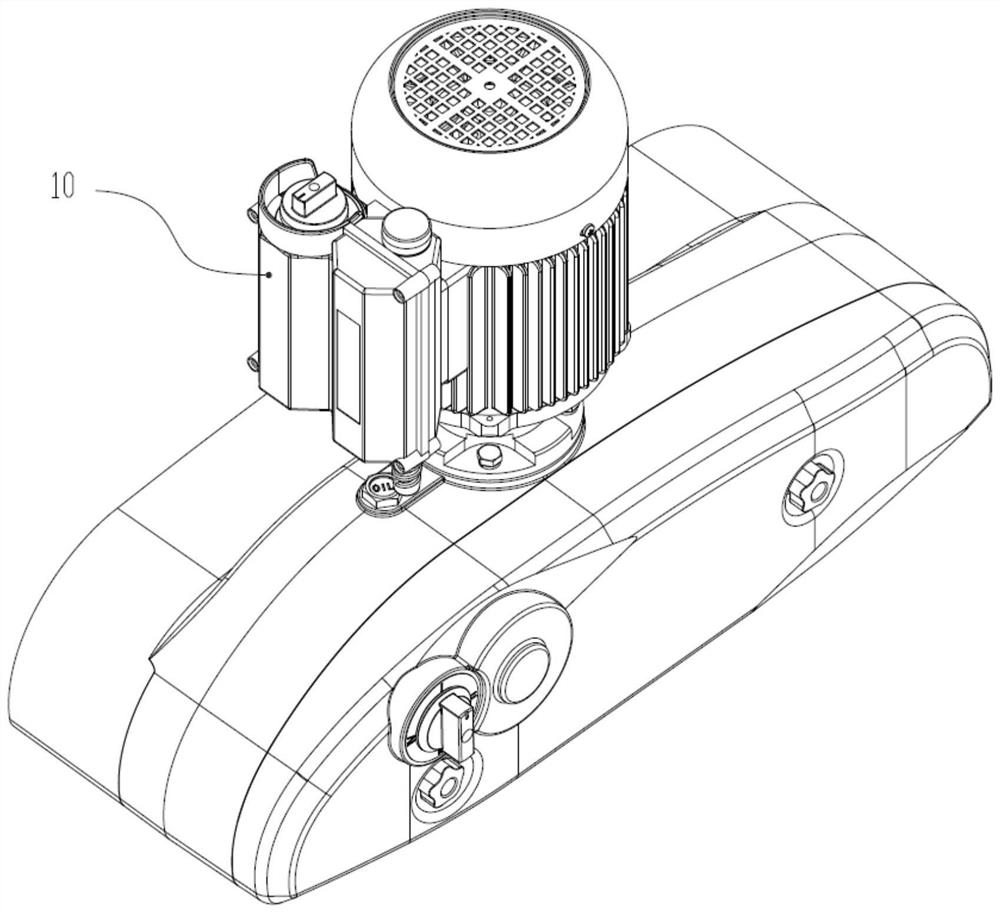

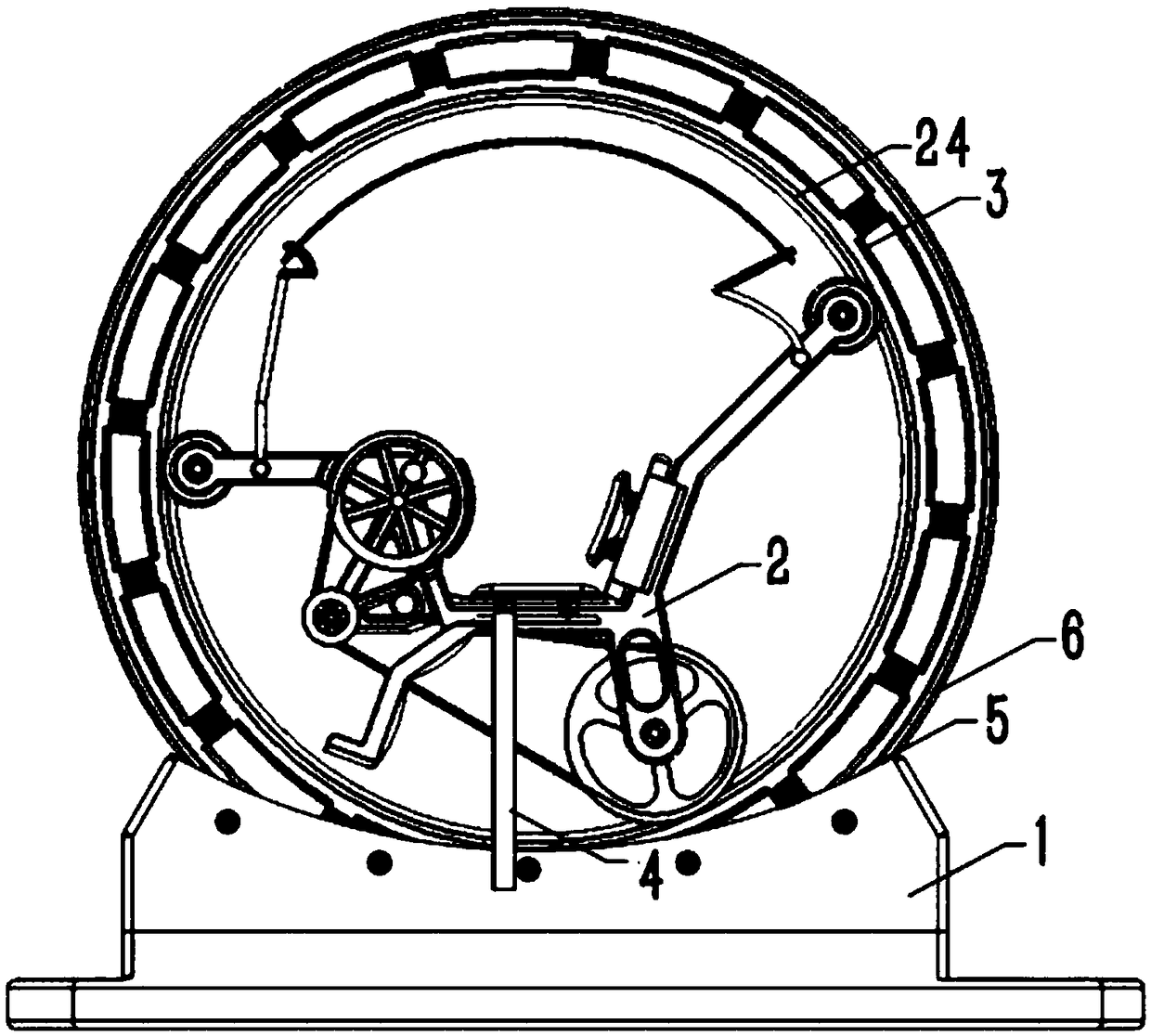

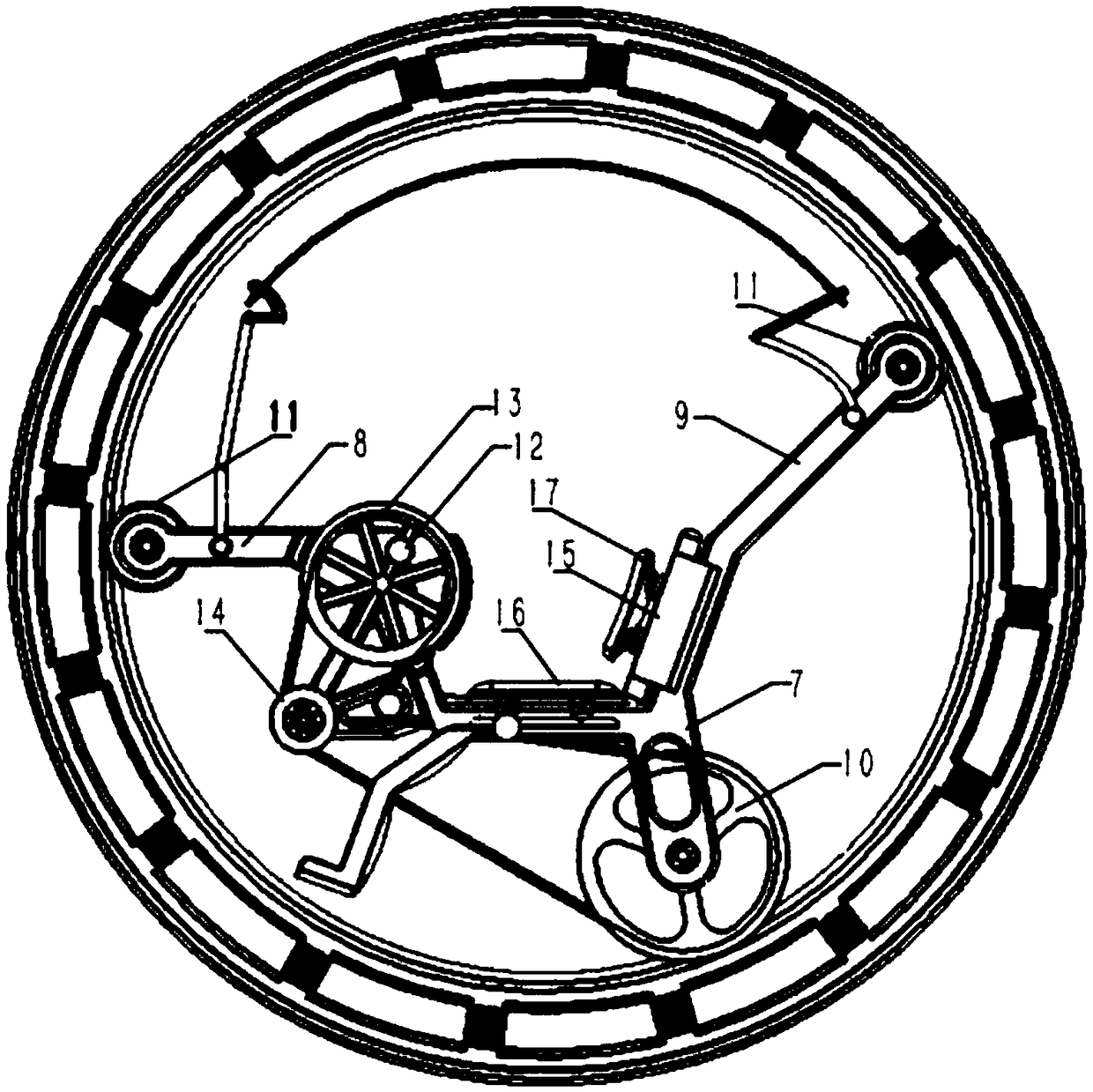

Medical base-fixed wheel-type sitting fitness equipment

ActiveCN107456718AReasonable designEasy to useMovement coordination devicesCardiovascular exercising devicesEdge surfaceBody contact

The invention discloses medical base-fixed wheel-type sitting fitness equipment. A sitting fitness support is integrally located within the internal scope of a ring-shaped rotary supporting body and is connected with a fitness base under the ring-shaped rotary supporting body through a support fastener; the upper end of the fitness base is provided with an arc clamp port, the lower end of the ring-shaped rotary supporting body is located in the arc clamp port, the outer edge surface of the ring-shaped rotary supporting body contacts with the arc clamp port, and the ring-shaped rotary supporting body is clamped and supported through the arc clamp port. The sitting fitness support is fixed through the fitness base, the ring-shaped rotary supporting body is positioned and supported, and the equipment is reasonable in integral design and convenient in use; a base-fixed wheel-type fitness type is adopted, training is performed mainly through sitting postures, the situation that traditional fitness equipment for arm training can only adopt standing training is changed, operation form is simplified, use efficiency is improved, and the base-fixed wheel-type sitting fitness equipment is more responsive to the needs of young people.

Owner:山东中大智慧健康科技服务管理有限公司

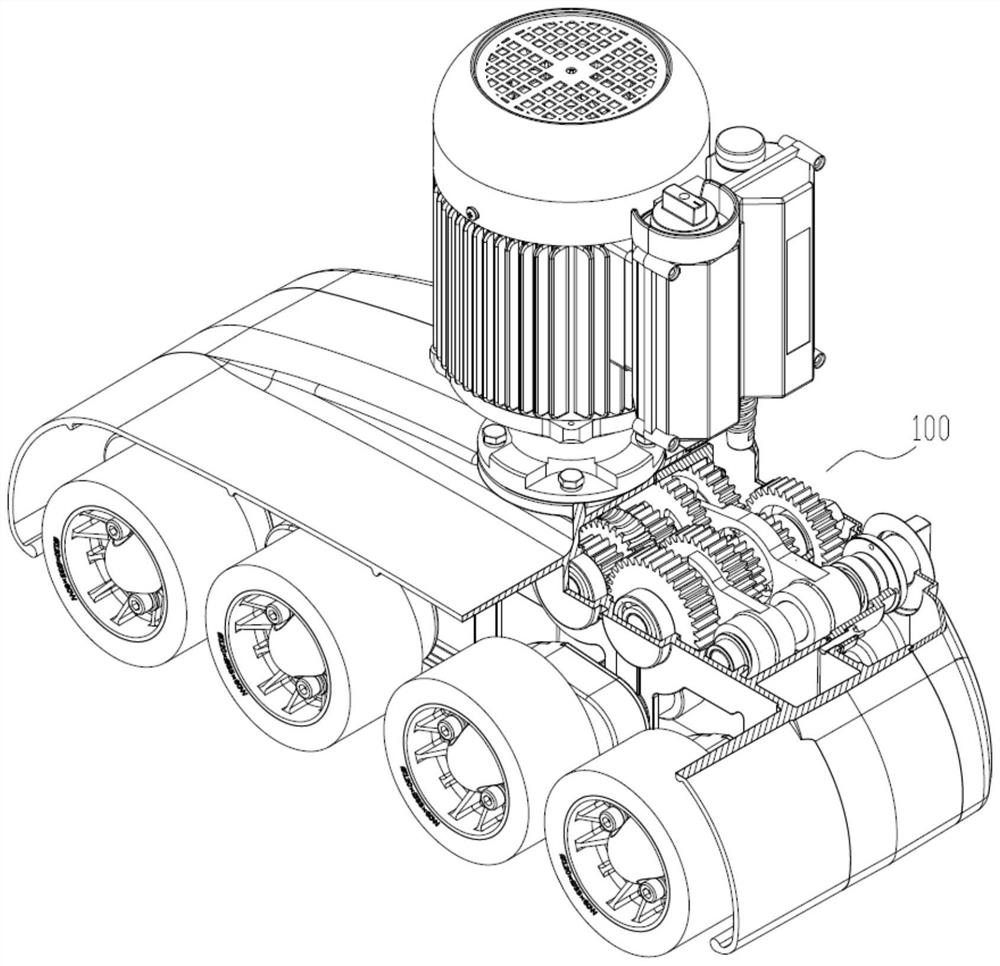

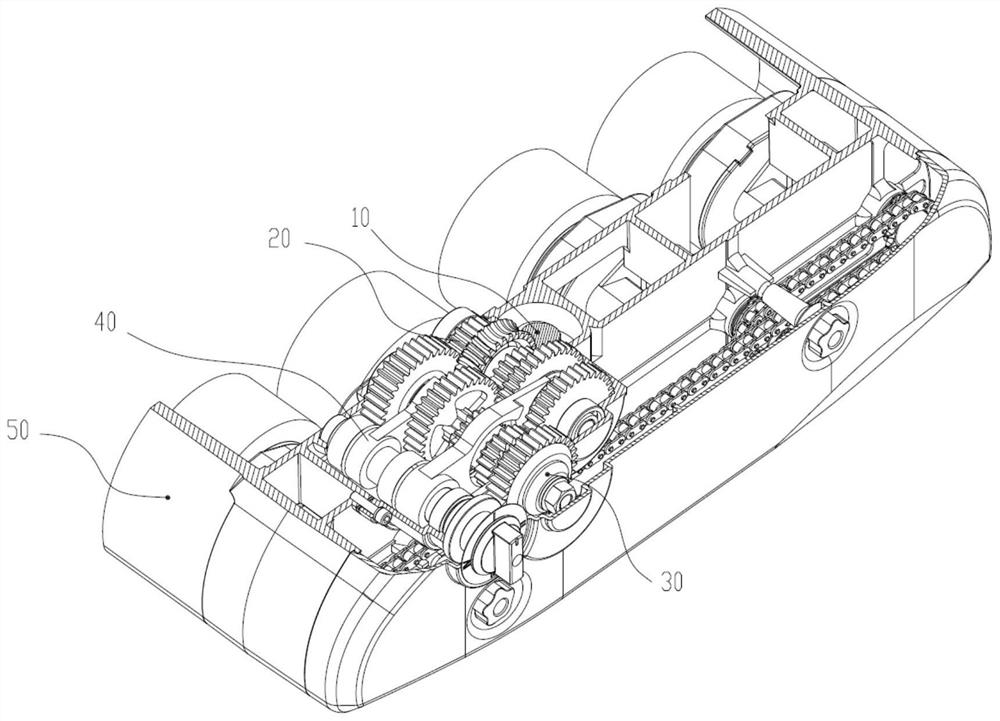

Combined gearbox

PendingCN112096806AConvenient nestingMeet location requirementsControlled membersGearboxesDrive shaftGear wheel

The invention discloses a combined gearbox. The combined gearbox comprises an input module, a speed change module, an output module and a box body, wherein the speed change module comprises a drivingshaft, a driven shaft and a gear shifting mechanism; the driving shaft is sequentially sleeved with a first gear, a second gear, a third gear and a fourth gear in the axial direction; the driven shaftis sequentially sleeved with a fifth gear, a sixth gear, a seventh gear and an eighth gear which are engaged with the corresponding gears on the driving shaft in the axial direction; the gear shifting mechanism is clamped to a first annular groove in the third gear and a second annular groove in the sixth gear; a first transmission part is arranged between the third gear and the second gear, anda second transmission part is arranged between the third gear and the fourth gear; and a sixth transmission part is arranged between the sixth gear and the fifth gear, and a fifth transmission part isarranged between the sixth gear and the seventh gear. The combined gearbox provides more speed choices, is compact and simple in structure, can shift gears as needed without disassembly and assembly,and is convenient and reliable in speed change.

Owner:FOSHAN V PLUS MACHINERY CO LTD

Use method of medical fixed base type wheel type sitting type fitness equipment

InactiveCN109157797AConvenient adsorption and cleaningMeet location requirementsMovement coordination devicesCardiovascular exercising devicesEngineeringYounger people

The invention discloses a use method of medical fixed base type wheel type sitting type fitness equipment, wherein, the seated fitness support frame is integrally located in the inner range of the circular rotating support body and is connected with the lower fitness base through a support fixture. The upper end of the fitness base is an arc-shaped bayonet, so that the lower end of the circular rotary support body is located in the arc-shaped bayonet, the outer surface of the circular rotary support body is brought into contact with the arc-shaped bayonet, and the circular rotary support bodyis clamped and supported through the arc-shaped bayonet. A seat-type fitness support frame is fixed by a fitness base, and a circular rotating support body is positioned and supported, so that the whole design is reasonable and convenient to use; Adopting fixed base type wheel type fitness mode, mainly through sitting exercise, changes the status quo that the traditional upper limb exercise fitness equipment can only use standing exercise, simplifies the operation form, improves the use efficiency, and makes it more in line with the needs of young people.

Owner:杨国兰

Auxiliary shock-absorbing device for cargo box

ActiveCN110254982BEasy to adjustMeet location requirementsLarge containersGear wheelClassical mechanics

The invention discloses an auxiliary shock-absorbing device for a container, which comprises a circular connecting block, an anti-extrusion plate is fixedly connected to the rear end surface of the circular connecting block, and the ends of the telescopic rods away from the center of the circle pass through the telescopic space. The inner wall extends outwards and is hinged with a connecting rod extending backward. A block is provided at a position corresponding to the rear side of the connecting rod, and adjacent blocks are connected by a tightening device. The fixed One end of the connecting shaft away from the transmission gear passes through the inner wall of the spline groove and is fixedly connected with a friction plate. In the work of the present invention, the telescopic sleeve rod can adjust the angle according to the change of the position of the block at the four corners, and at the same time, can adjust the distance to meet the position requirements of the block when using different cargo boxes, improve the scope of application of the device, and resist extrusion. The greater the extrusion force on the pressing plate, the greater the frictional force, which prevents the device from falling off when the cargo box door is subjected to a relatively large extrusion force, and ensures the safe use of the device.

Owner:蒙阴县鹏程万里车辆有限公司

Disc part code scanning and alignment mechanism

ActiveCN107416479ARealize alignmentMeet location requirementsConveyor partsManufacturing computing systemsScannerElectric machinery

The invention relates to the technical field of disc part alignment, in particular to a disc part code scanning and alignment mechanism. The alignment mechanism comprises an installing frame and a controller and further comprises a driving fork arm and a driven fork arm which are oppositely arranged. Friction wheels are rotationally arranged at the inner end of the driving fork arm and the inner end of the driven fork arm. The installing frame is provided with a sliding plate in a sliding manner. The driving fork arm is fixed to the sliding plate. The sliding plate and the driven fork arm are arranged on the installing frame in a sliding manner. The installing frame is provided with a first power device and a second power device. Disc parts are clamped through the friction wheels on the driving fork arm and the driven fork arm, and the friction wheels are used for driving the disc parts to rotate. When a code scanner scans identification codes on the peripheral faces of the disc parts, the code scanner can feed back signals to the controller, the controller is used for controlling a motor to continuously rotate for a certain time, the disc parts are rotated to the preset position, disc part alignment is achieved, and the position requirement for the disc parts in the automatic production process is met.

Owner:STON ROBOT CHANGZHOU

Magnetic suspension type shock absorber for new-energy automobile

The invention discloses a magnetic suspension type shock absorber for a new-energy automobile. The magnetic suspension type shock absorber for the new-energy automobile comprises circular connecting blocks, wherein anti-extrusion plates are fixedly connected to the back end surfaces of the circular connecting blocks; one ends, far away from circle centers, of telescopic rods penetrate through the inner walls of telescopic spaces so as to outwards extend and are hinged with connecting rods extending backwards; clamping blocks are arranged at the positions corresponding to the back sides of the connecting rods; each two adjacent clamping blocks are connected through contraction device; and one ends, far away from transmission gears, of fixed connecting shafts penetrate through the inner walls of spline grooves and are fixedly connected with friction plates. During the work of the magnetic suspension type shock absorber for the new-energy automobile provided by the invention, the angles of telescopic sleeve rods can be adjusted along with the position changes of the clamping blocks at four corner parts, and meanwhile, the distance adjustment can be carried out, so that the requirements on the positions of the clamping blocks during the use of different containers are met, and the application range of the device is improved; and the larger the extrusion forces stressed on the anti-extrusion plates, the larger the friction forces are, so that the occurrence of the phenomenon that the device falls off when container doors are stressed by the larger extrusion forces is prevented, and the safety use of the device is ensured.

Owner:蒙阴县鹏程万里车辆有限公司

A vending machine warehouse structure

ActiveCN109448239BReduce weightHigh strengthCoin-freed apparatus detailsApparatus for dispensing discrete articlesElectric machineryEngineering

The invention relates to a warehouse structure for a vending machine. Two side plates are arranged at intervals, an upper beam is arranged at the upper end of the two, a rear beam is arranged at the rear end of the two, and a front beam is arranged at the front end of the two. For the disassembled substrate, a plurality of detachable motor plates are arranged on the upper beam and the rear beam; a detachable partition is provided on the front beam and the rear beam between adjacent substrates or a detachable partition is provided on the upper end of the substrate. plate. In the present invention, the base plate and the motor plate can be selected with appropriate width and installation position. With the separators that are easy to install and disassemble, the base plates, motor plates, separators, crawlers and springs can be freely combined according to the commodities sold on site, which is very convenient. Flexible; the beams and side plates are made of aluminum alloy, the base plate, motor plate, etc. are made of plastic, the overall weight is greatly reduced, but the mechanical strength is increased a lot; the convenient installation method of the center plate, spring, track, etc., The efficiency of installation and disassembly is further improved.

Owner:天津雷云智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com