Simple profile steel stacking device

A palletizing device and section steel technology, which is applied in the field of simple section steel palletizing devices, can solve the problems that the working efficiency of section steel palletizing devices is difficult to meet its needs, the transportation path of profiles is long, and the space occupied is large, so as to save investment costs, Reduced working time and compact space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

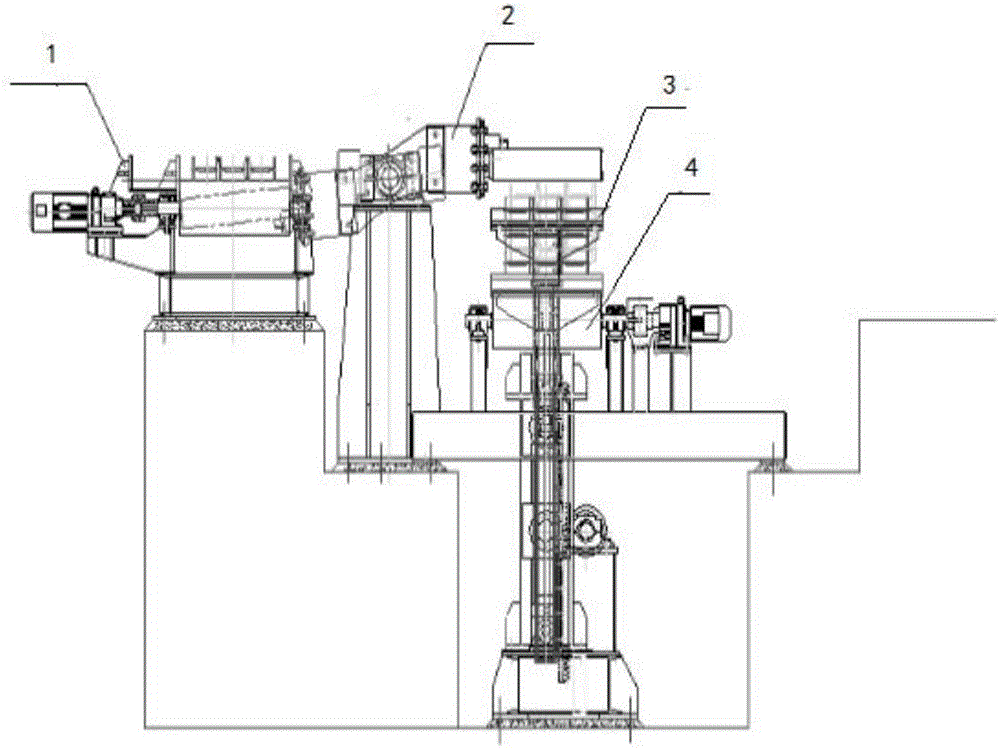

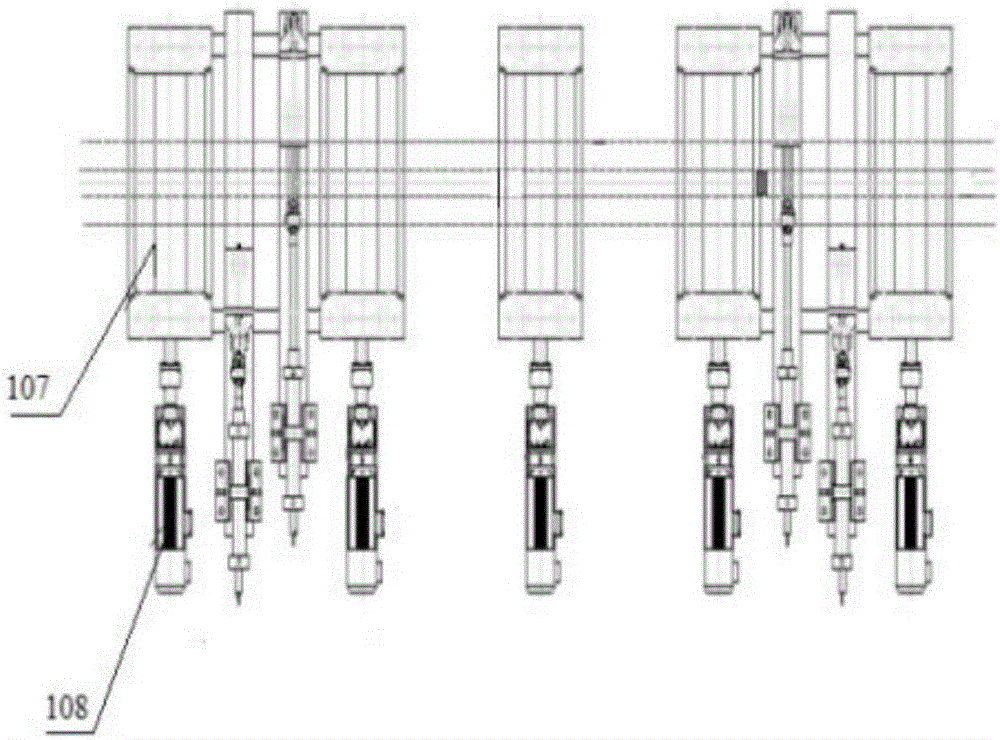

[0040] Such as Figure 1-8 As shown, a simple section steel palletizing device in this embodiment includes a steel pushing device 1, a turning manipulator 2, a lifting manipulator 3 and a collection roller table 4, wherein:

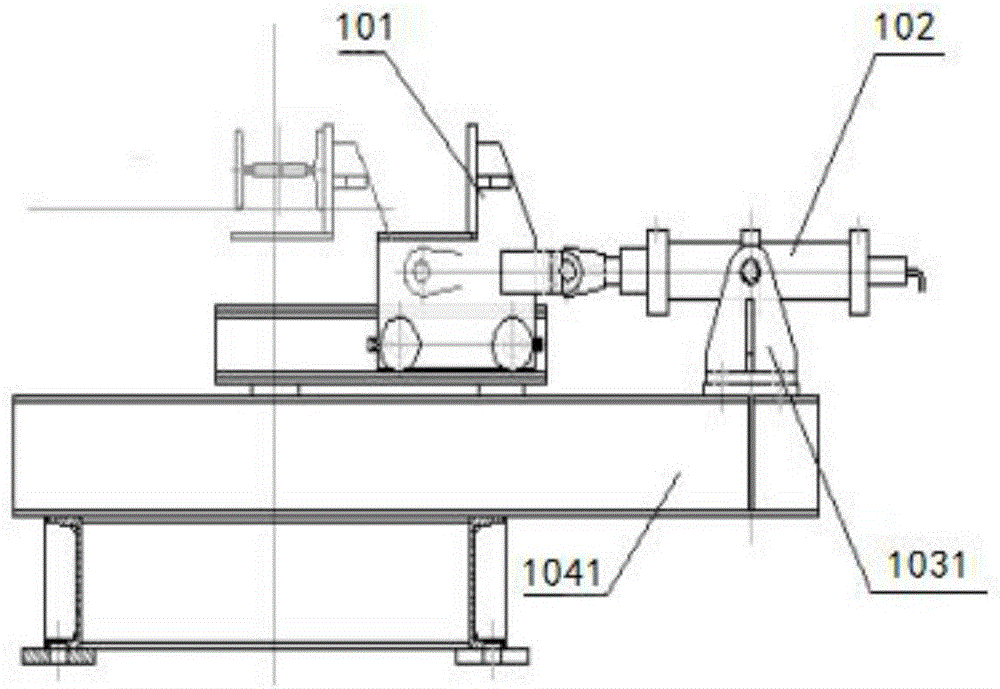

[0041] Pushing steel device 1 comprises the first pushing steel device and the second pushing steel device, and the first pushing steel device comprises the first hydraulic cylinder support 1031, and the first hydraulic cylinder 102 is installed on the first hydraulic cylinder support 1031, and the first hydraulic pressure The cylinder 102 is connected to the first push head 101 through a cross bar, and the lower part of the first hydraulic cylinder support 1031 is installed on the front base 1041; the second pushing device includes a second hydraulic cylinder support 1032, which is installed on the second hydraulic cylinder support There is a second hydraulic cylinder 106, the second hydraulic cylinder 106 is connected with the second push head 105 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com