Clip type feeding mechanism

A clip-type, tray technology, applied in conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of discontinuous feeding and low efficiency, and achieve the effect of reducing waiting time and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

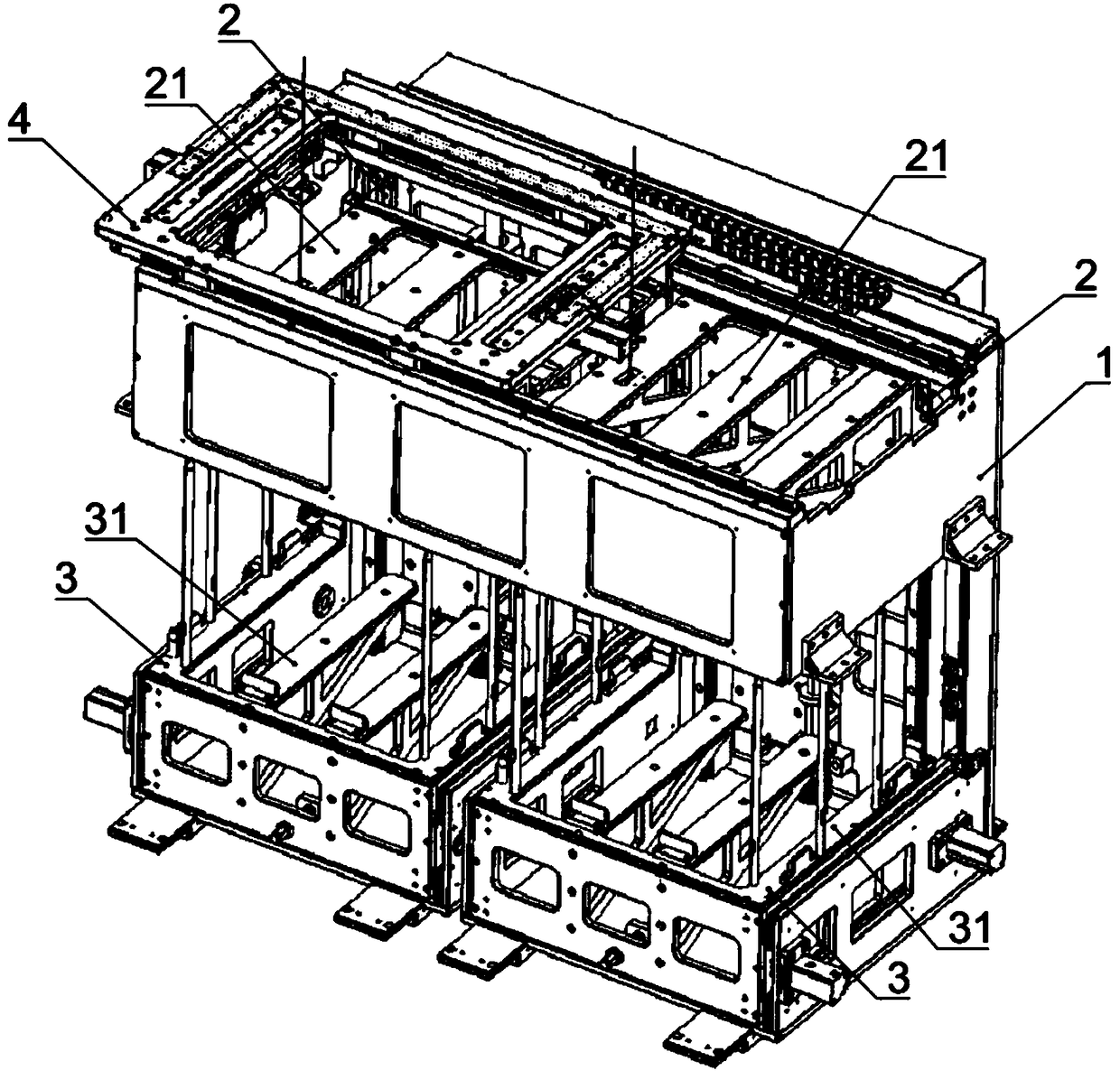

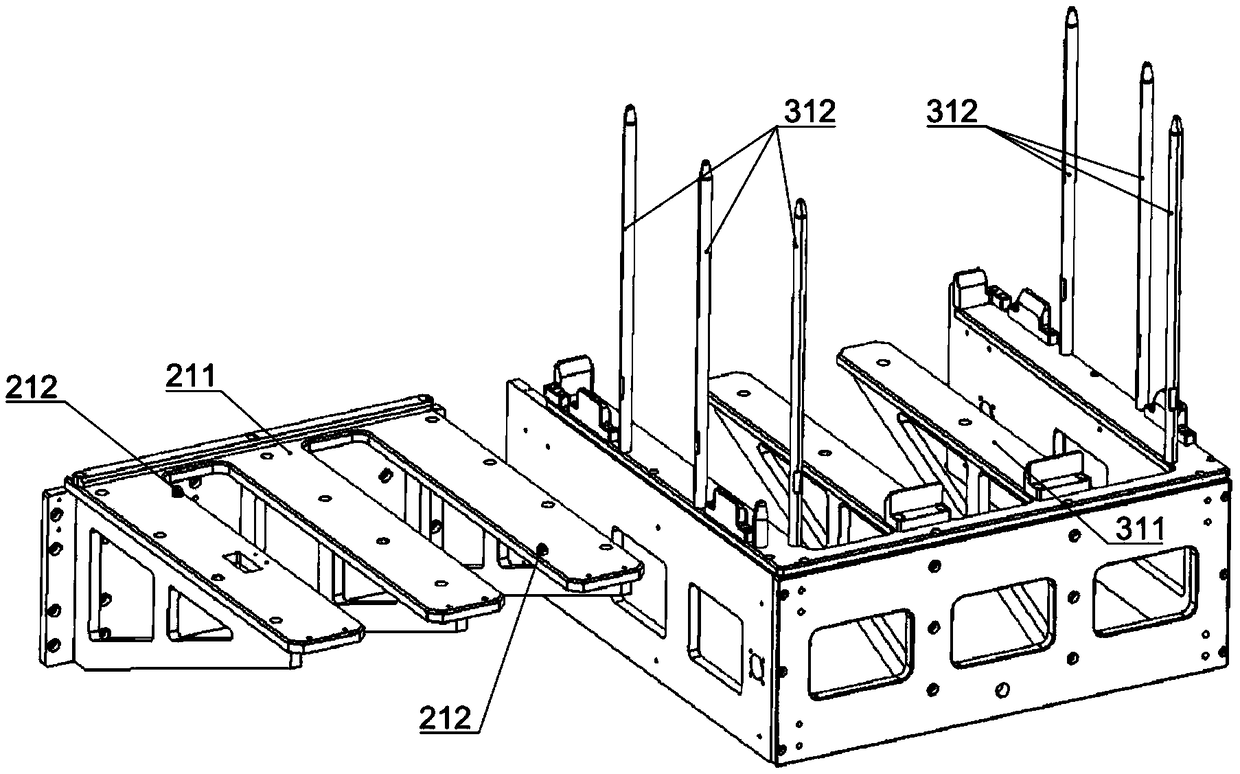

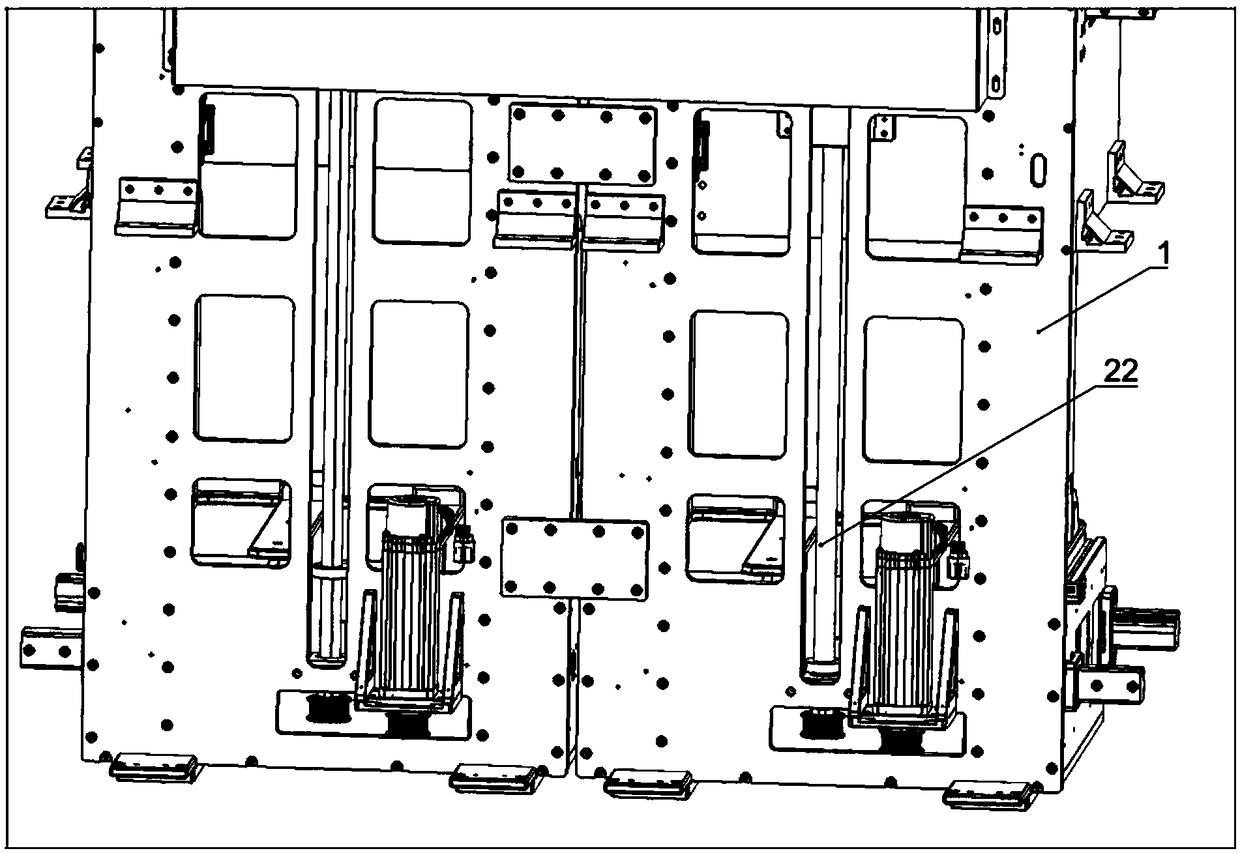

[0046] This embodiment provides a clip-type feeding mechanism, the structure of which is as follows: figure 1 Shown, comprise frame 1, have on the frame 1 the feeding area ( figure 1 middle left) and return area ( figure 1 Middle right side), the ends of the feeding area and the returning area have a transfer area connected to each other, and the other ends of the feeding area and the returning area respectively have a material transfer area for loading and unloading materials, wherein the transfer area includes the upper feeding area and unloading area. The feeding area on the left is the transfer area when the material tray with the workpiece is transported from the loading area, and the clamping device located on the upper part of the transfer area takes the workpiece away. A transfer mechanism 4 is provided in the transfer area, and the transfer mechanism 4 reciprocates on the transfer area for transferring the tray between the feeding area and the returning area. . A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com