Bridge support

A technology for bridge bearings and bridges, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as inability to meet the design elevation and position requirements of track girders, inability to eliminate girder pier installation errors, and different installation misalignment error values, etc. Achieve the effect of meeting the design elevation and position requirements, occupying a small space, and eliminating vertical installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

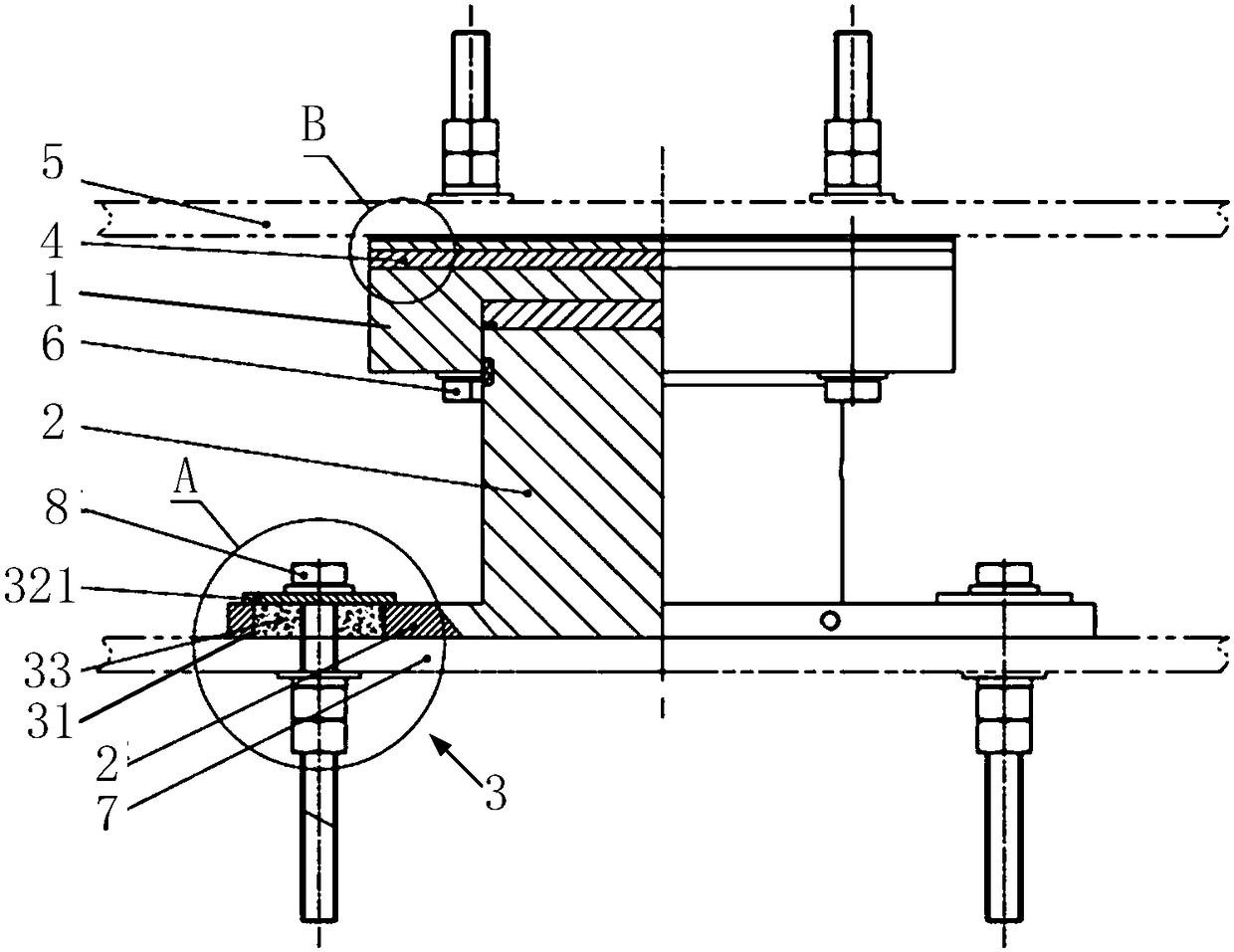

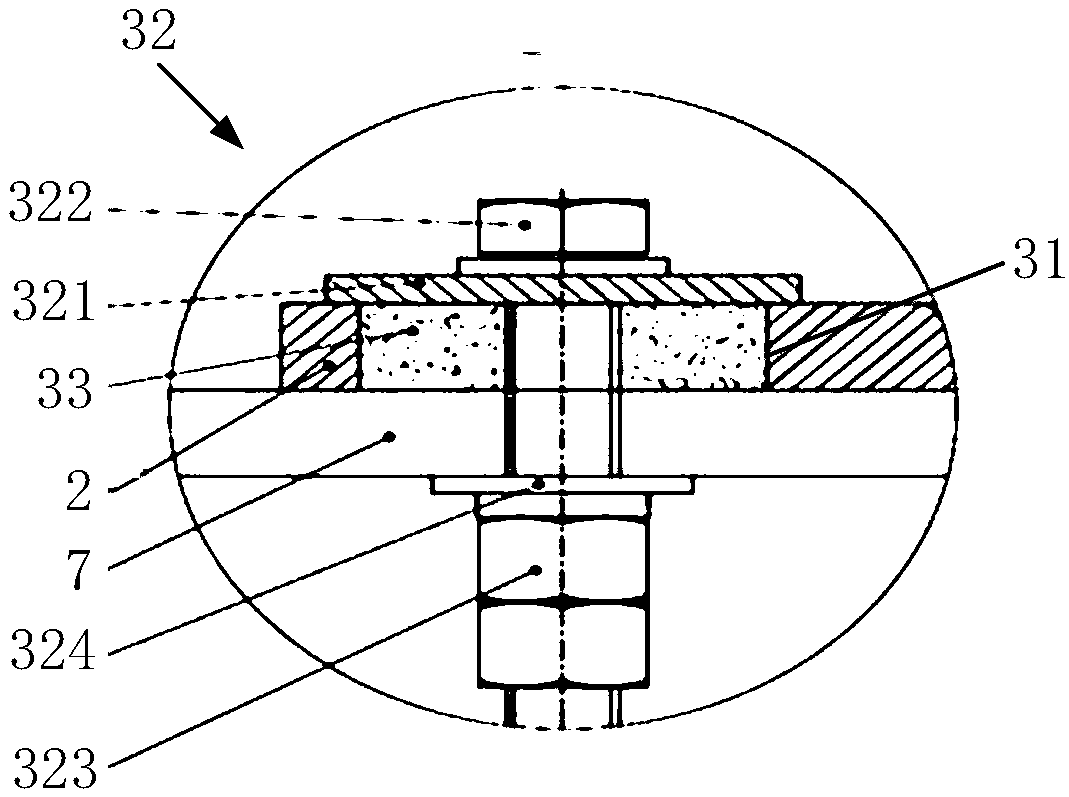

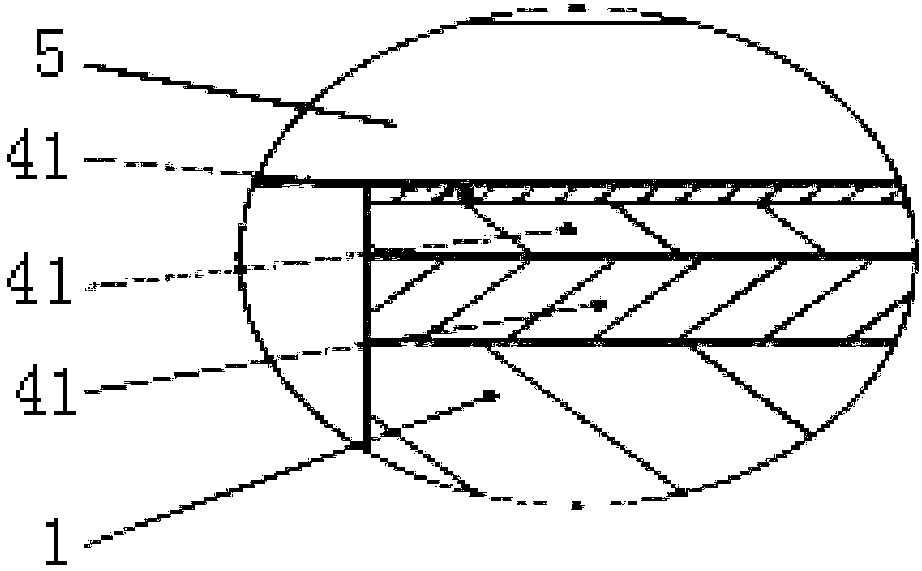

[0027] like figure 1 An embodiment of the bridge bearing of the present invention is shown, which can be applied to bridge bearings such as a basin bearing, a spherical bearing, and a plate rubber bearing. This embodiment is described by taking the basin bearing as an example. In this embodiment, the bridge support includes an upper seat plate 1 , a lower seat plate 2 , a horizontal adjustment component 3 and a height adjustment component 4 . Wherein, the upper seat plate 1 is connected with the bottom of the bridge girder; the lower seat plate 2 is connected with the bridge pier; In this embodiment, the adjustment hole 31 is provided on the lower seat plate 2, and the adjustment hole 31 provides a moving space for the lower seat plate 2 to adjust the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com