Uplift cast-in-place pile for reinforcing seabed and construction method thereof

A construction method and technology of cast-in-place piles, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as increasing the cost of cast-in-place piles, easy erosion of the soil around piles, and threats to the stability of piles, etc., to achieve increased The effects of penetration and diffusion distance, improvement of anti-scouring ability, and simple and easy-to-operate construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

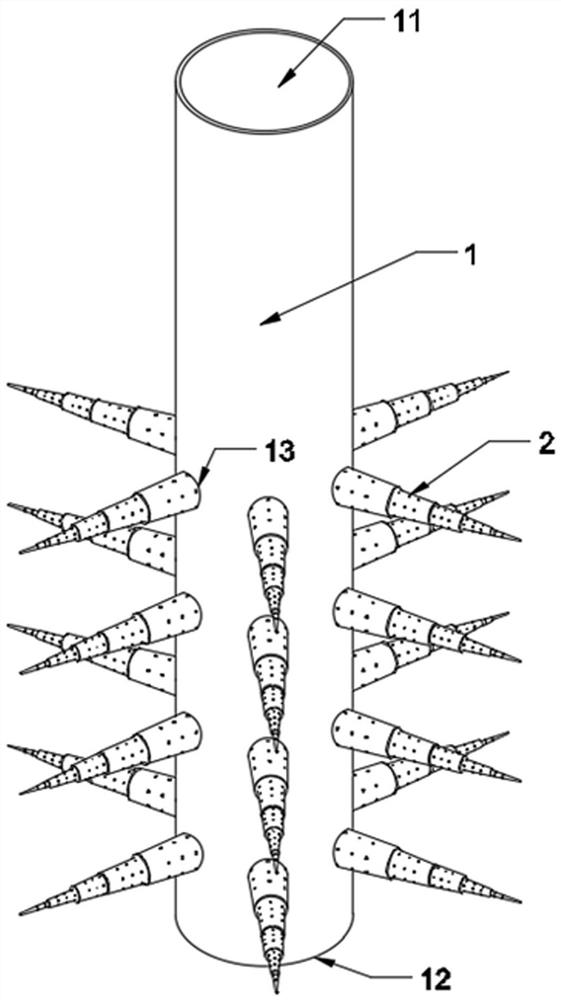

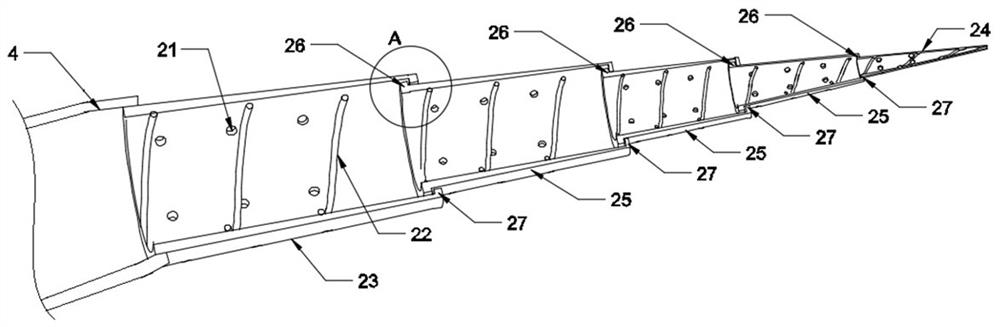

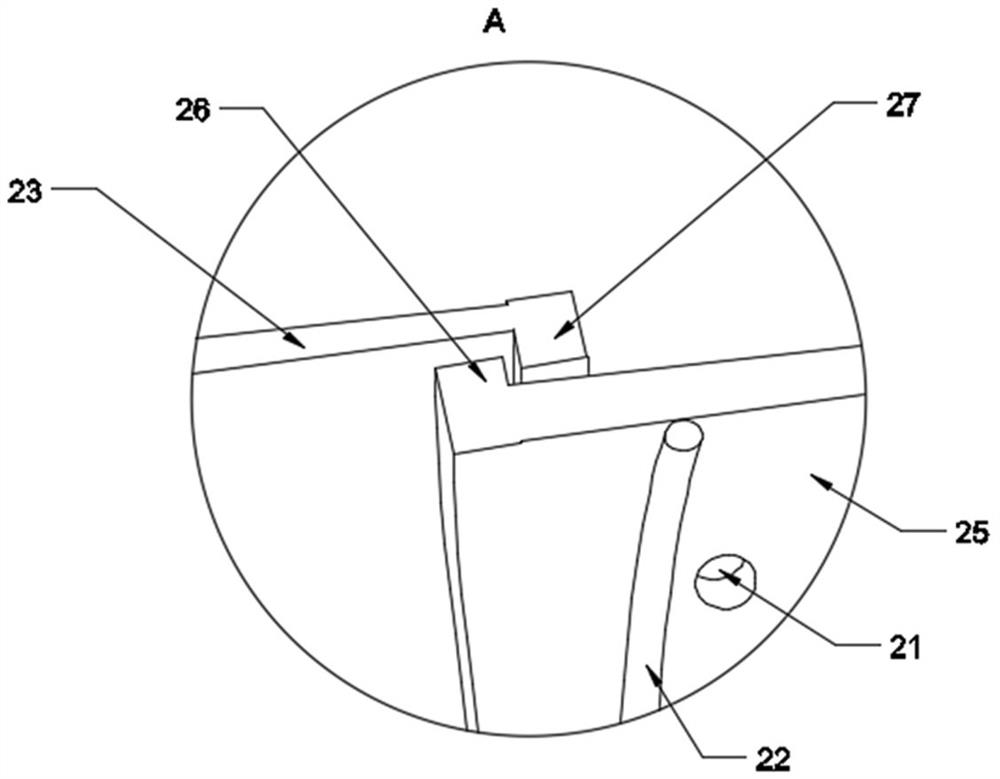

[0060] The construction process of the general seabed soil mass is as follows: Figure 7 As shown, the cast-in-place pile of this embodiment is provided with 7 thorn groups, which are respectively named as the first thorn group to the seventh thorn group from top to bottom. The construction method includes the following steps:

[0061] S1. Use the construction ship 3 to transport the cast-in-situ piles to the construction location, keep all the thorns 2 in the contracted state in the pile body 1, so as to avoid the thorns 2 from affecting the penetration of the pile body 1 into the seabed soil, and the first pipeline 4 is connected After the largest diameter end of the protruding thorn 2 and the pump, the pile body 1 is penetrated into the seabed to a predetermined depth until it is stable (the state is as follows: Figure 7 (a));

[0062] S2. Use a pump to inject high-pressure water flow into the protrusion 2 from the largest diameter end of the protrusion 2 through the first ...

Embodiment 2

[0066] The construction process of using the uplift cast-in-place piles for strengthening the seabed of this embodiment for the weaker and poorer seabed soil is as follows: Figure 8 As shown, the cast-in-place pile of this embodiment is provided with 7 thorn groups, which are respectively named as the first thorn group to the seventh thorn group from top to bottom. The construction method includes the following steps:

[0067] S1. Use the construction ship 3 to transport the cast-in-situ piles to the construction location, keep all the thorns 2 in the contracted state in the pile body 1, so as to avoid the thorns 2 from affecting the penetration of the pile body 1 into the seabed soil, and the first pipeline 4 is connected After the largest diameter end of the protruding thorn 2 and the pump, the pile body 1 is penetrated into the seabed to a predetermined depth until it is stable (the state is as follows: Figure 8 (a));

[0068] S2. Use a pump to inject high-pressure water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com