Tube-type slab lattice paste extrusion production line

A production line and grid technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems that lead powder is easy to fly everywhere, affect battery performance, pollute the environment, etc., and achieve the effect of avoiding flying everywhere and ensuring performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

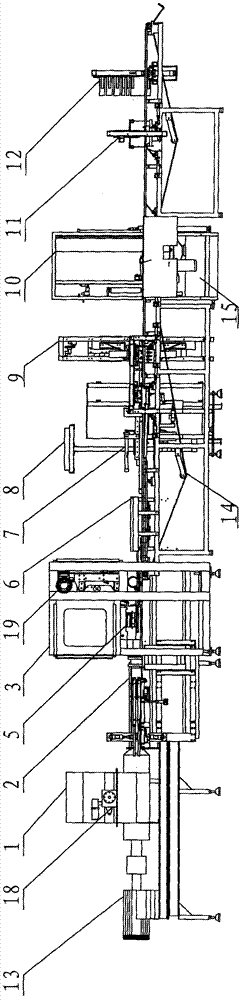

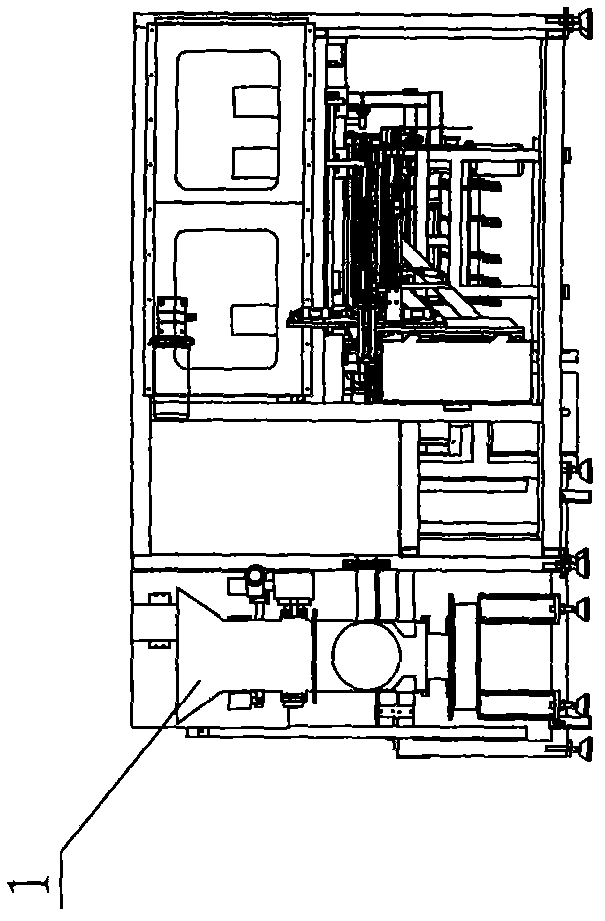

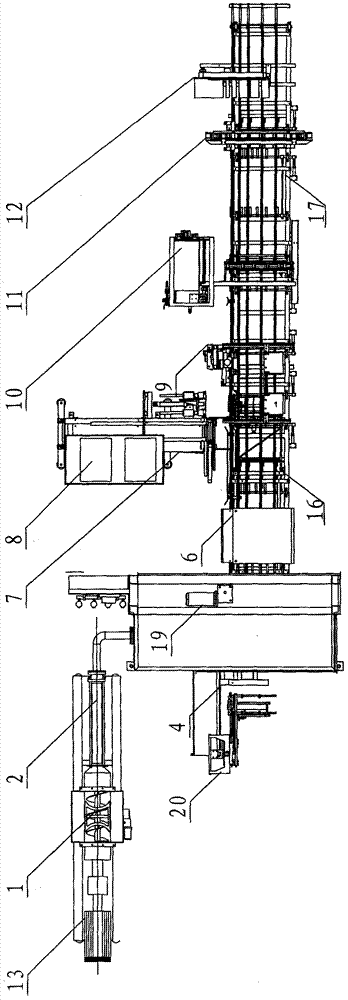

[0015] Such as figure 1 , 2 As shown in , 3, a tubular grid paste extrusion production line includes paste extrusion hopper 1, paste delivery pipe 2, paste extrusion frame 3, grid conveying device 4, paste extrusion head 5, paste extrusion one-time flushing 6, Back cover conveying device 7, welding control system 8, ultrasonic welding device 9, paste extruding secondary flushing 10, paste extruding weighing device 11, waste plate rejecting device 12, paste extruding motor 13, conveying tensioning device 14, waste water recycler 15 , 1# pole plate conveying device 16, 2# pole plate conveying device 17, lead paste stirring motor 18, slide table moving device 19, grid clamping device 20; The plaster hopper 1 is installed on the plaster extruding frame 3, the lead plaster conveying pipe 2 is installed at the lower part of the plaster extruding hopper 1, and is connected with the plaster extruding head 5, behind which are the grid clamping device 20 and the sliding table moving de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com