Fully automatic rapid powder filling system

A fully automatic, powder filling technology, applied in the direction of electrode carrier/current collector, can solve the problems of low production efficiency, easy flying of lead powder, environmental pollution, etc., to improve labor productivity and avoid flying everywhere.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

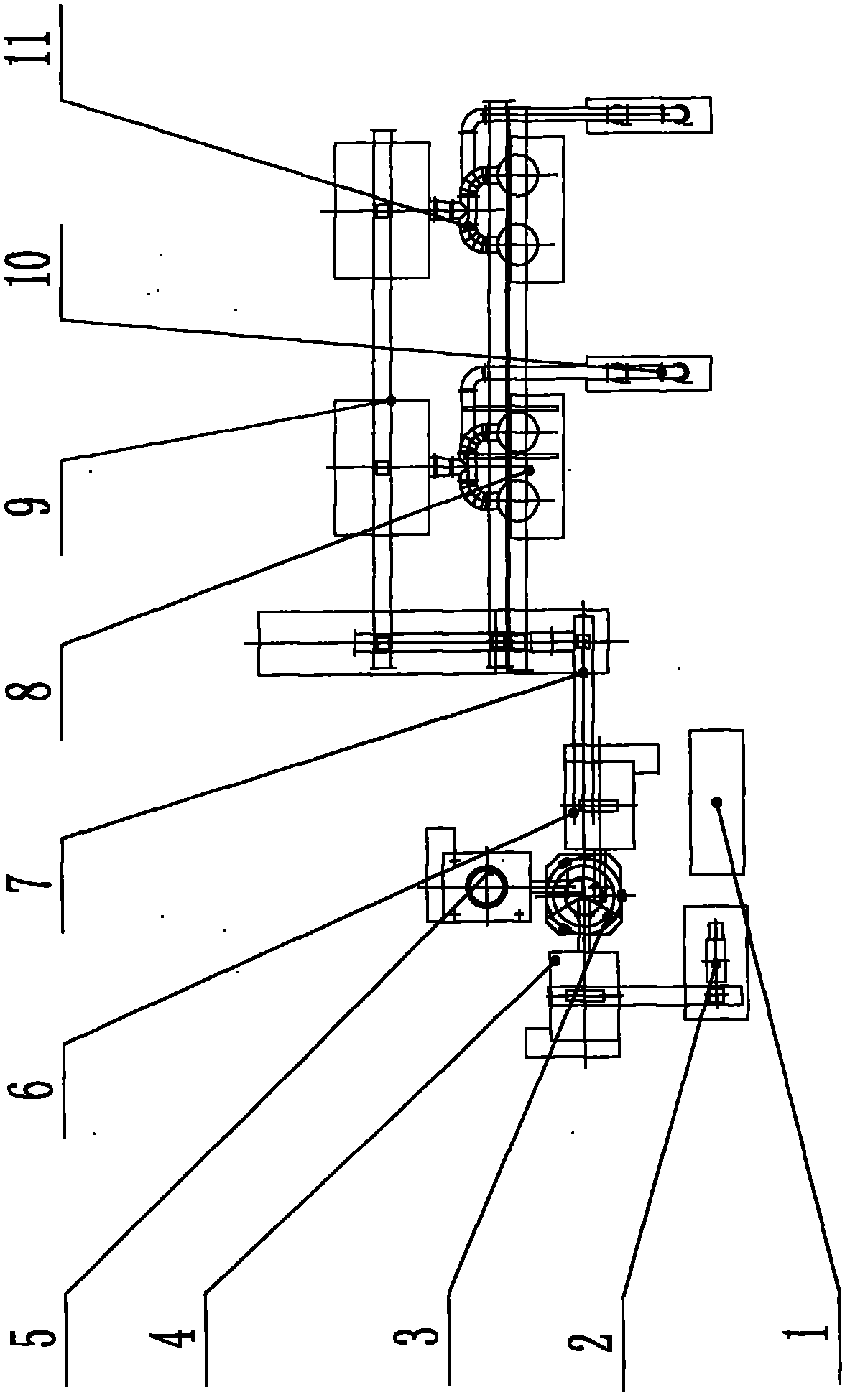

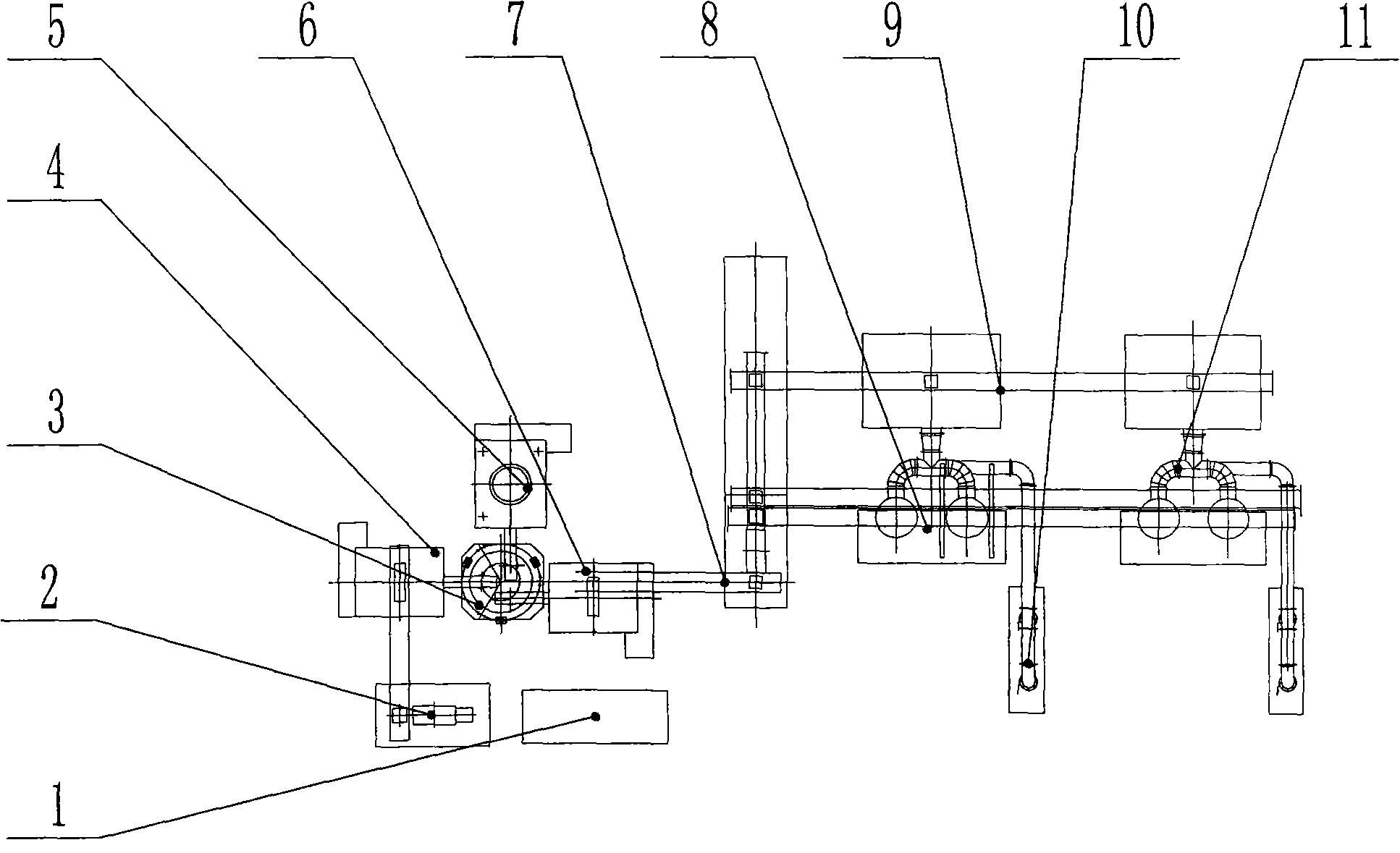

[0011] Such as figure 1 As shown, a fully automatic fast powder filling system, including PLC control cabinet 1, lead powder lifting device 2, lead powder weighing and mixing system 3, conveying screw 7, powder filling host 8, net electrostatic precipitator 9, bottom smashing Tooling 10, blower 11, lead powder lifting device 2, lead powder weighing and mixing system 3, conveying screw 7, and powder filling host 8 are connected in sequence. An electrostatic precipitator 9 is installed above, an air cylinder 11 is installed on the powder filling host 8, and the lead powder weighing and mixing system 3 is connected to the storage hopper a4, the storage hopper b5, and the storage hopper c6 respectively.

[0012] The powder (active substance) is transported by the conveying system to the storage hopper a4, storage hopper b5, and storage hopper c6 for storage. The signal device can detect the amount of powder in the storage hopper, and the powder can be weighed, mixed and transporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com