Drilling auxiliary device for wooden furniture machining

An auxiliary device and wooden furniture technology, which is applied in the direction of wood processing equipment, manufacturing tools, fixed drilling machines, etc., can solve the problems of scattered sawdust, inconvenient cleaning, and low efficiency, so as to protect ears, facilitate centralized processing, and reduce noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

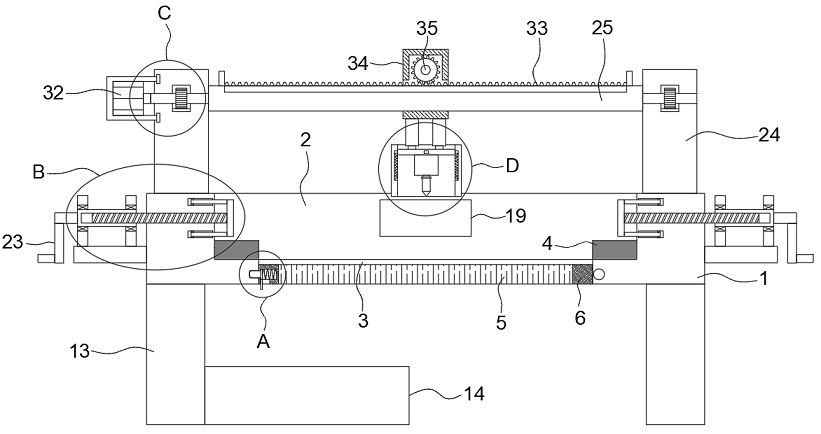

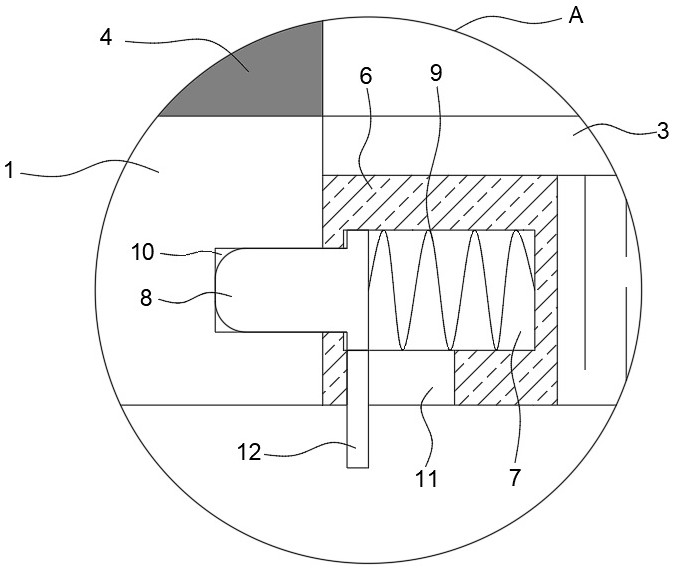

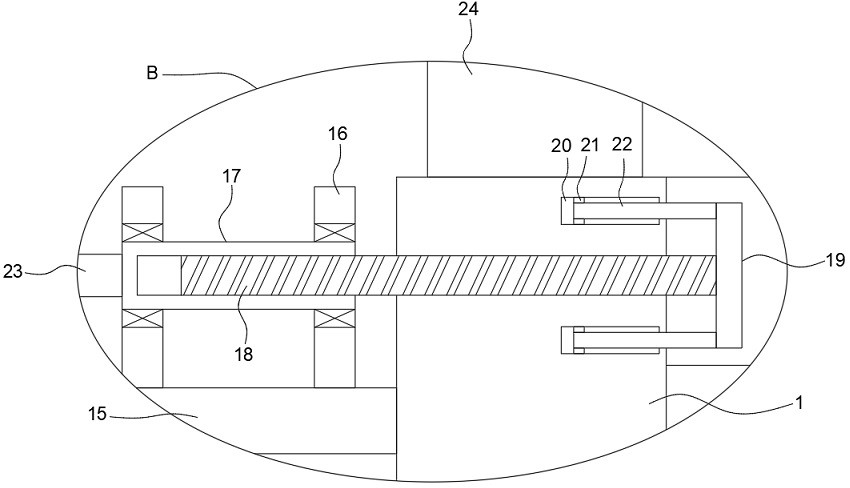

[0027] refer to Figure 1-5 , a drilling auxiliary device for processing wooden furniture, comprising a square processing table 1, the upper end of the processing table 1 is provided with a square processing groove 2, the inner bottom wall of the processing groove 2 is provided with a square chip opening 3, the processing groove 2. On the inner bottom wall and on the outside of the chip opening 3, a square buffer washer 4 is fixedly connected. Put the wooden plate that needs to be drilled into the buffer washer 4 in the processing tank 2, so that the wooden plate can be slowed down when drilling. The vibration that takes place then plays the role of protecting the drill bit 39, and the chip opening 3 is provided with a sound insulation board 5, which has the effect of reducing noise. The right inner wall of the port 3 is rotationally connected, and the left end of the installation frame 6 is provided with a movable groove 7, and the movable groove 7 is slidingly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com