An ejector head adjustment press-fit detection device in a vacuum booster assembly line

A vacuum booster and detection device technology, which is applied in the field of automobile parts manufacturing, can solve the problems of low automation, difficulty in ensuring the accuracy of ejector head inspection, accuracy of press-fit monitoring data, etc., and achieve stable and reliable equipment operation, photoelectric Reliable isolation function and good electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment and accompanying drawing, the present invention is described in further detail:

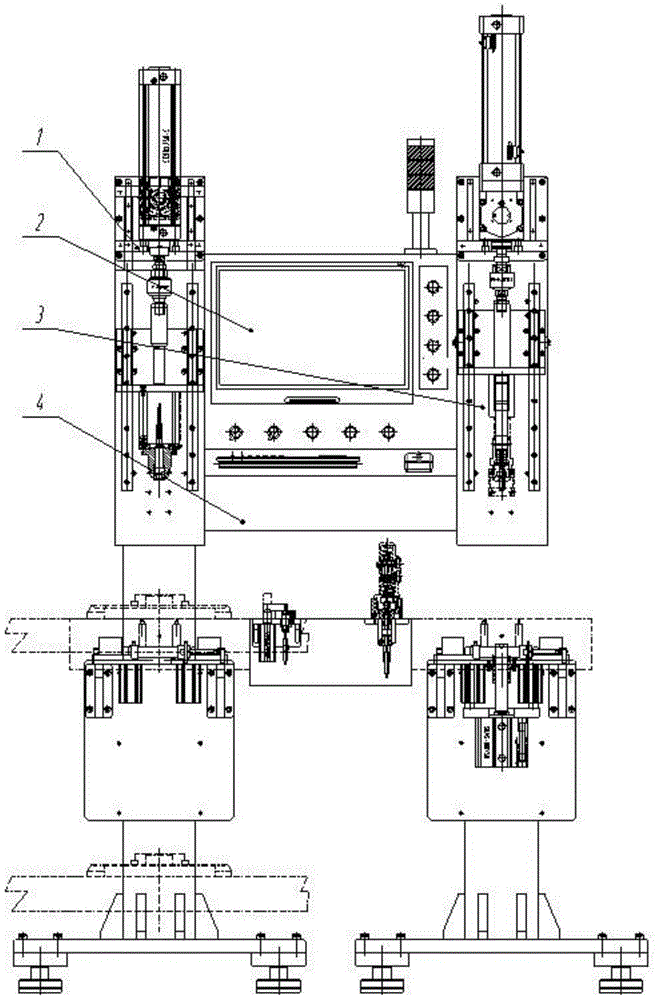

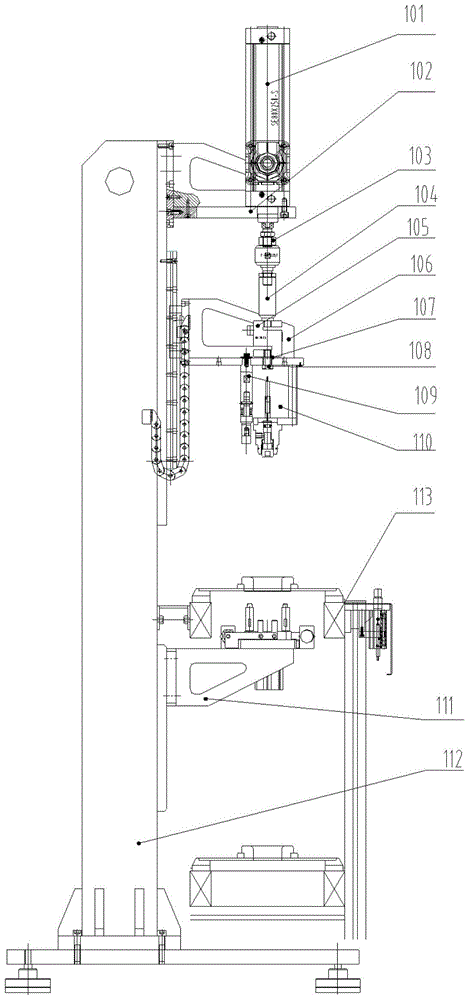

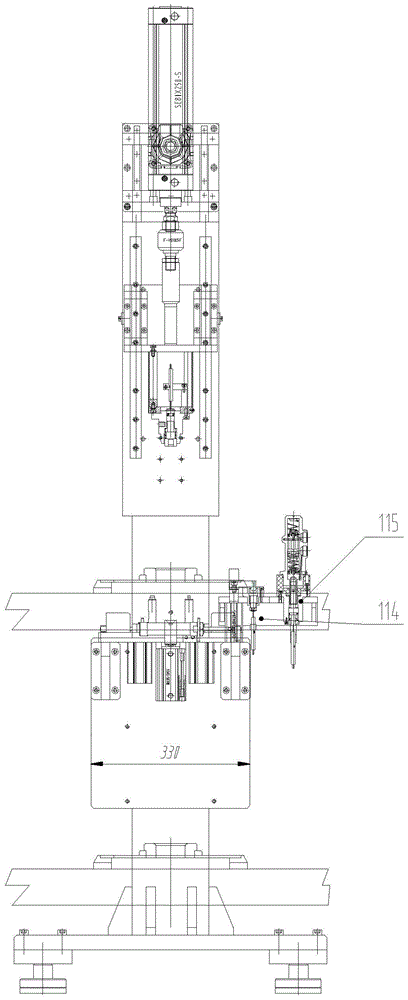

[0018] like figure 1 As shown, the ejector head adjustment and press-fit detection device in the vacuum booster assembly line of the embodiment includes the ejector head adjustment device 1, the automatic control device 2, the push rod head press-fit detection device 3, the material box 4 and the air circuit control device ; The automatic control device 2 is set between the ejector head adjustment device 1 and the push rod head press-fit detection device 3 , and the material box 4 is set under the automatic control device 2 .

[0019] The automatic control device 2 includes a data acquisition and control unit, a PC, and a PCI bus. The PC and the data acquisition and control unit are connected through the PCI bus. The data acquisition and control unit controls the gas circuit control device according to the instructions of the PC, and then controls the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com