Patents

Literature

85results about How to "With overload protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

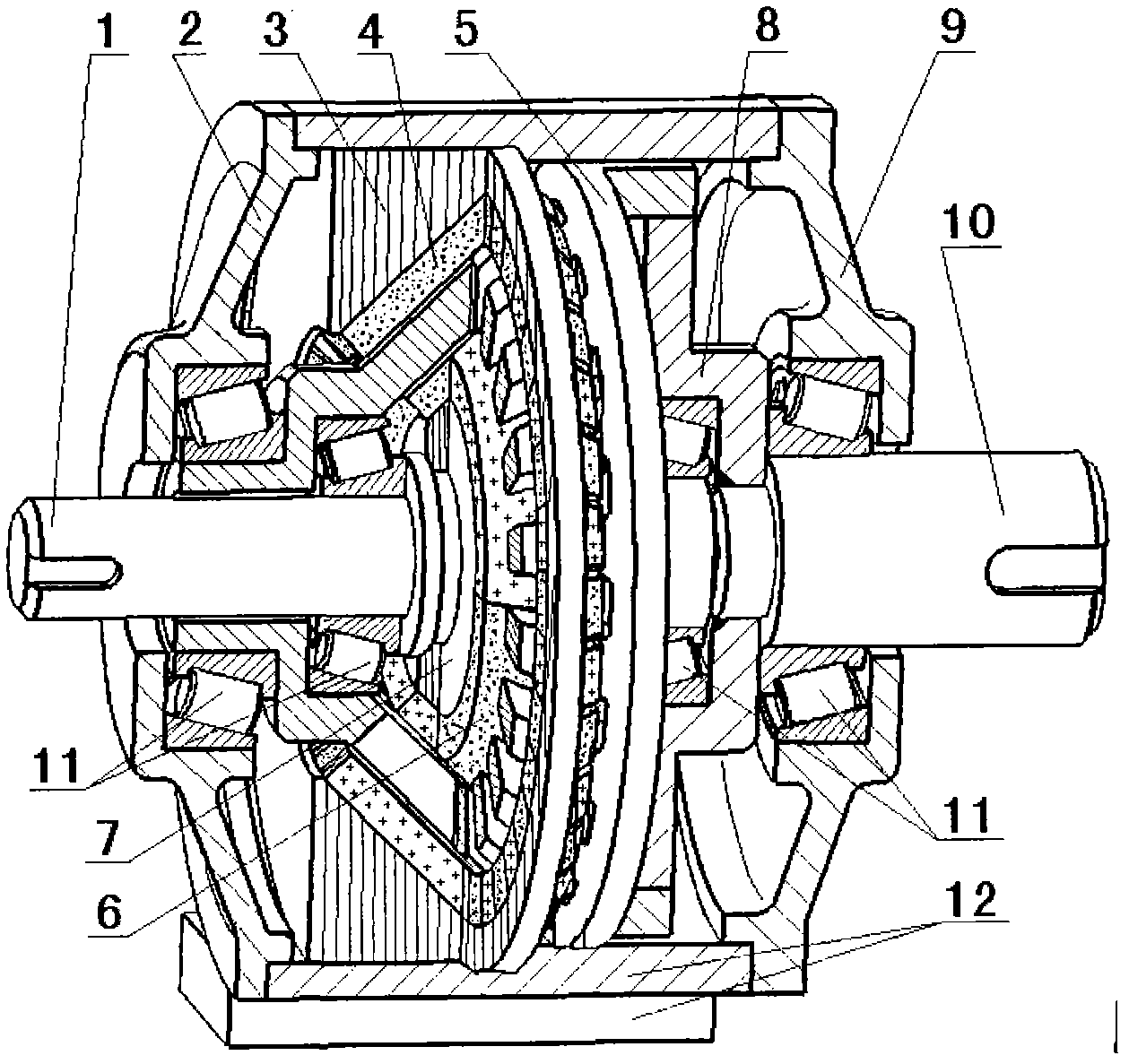

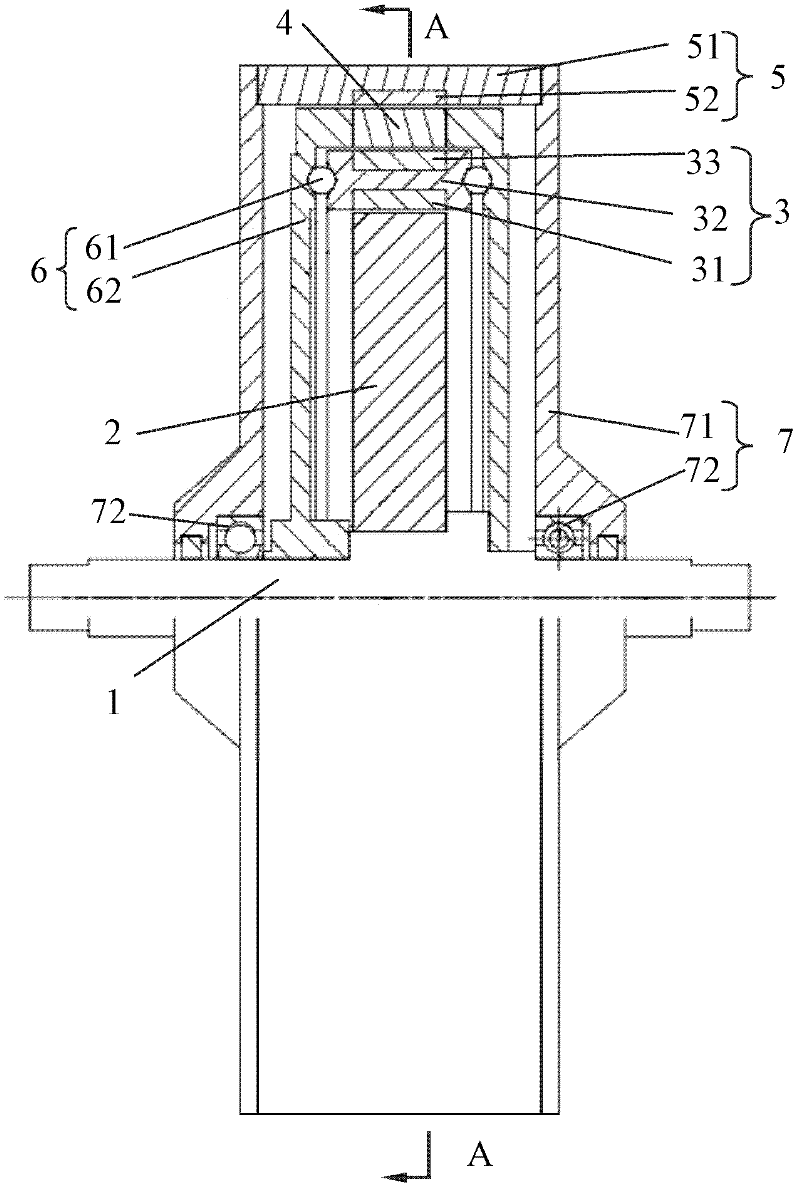

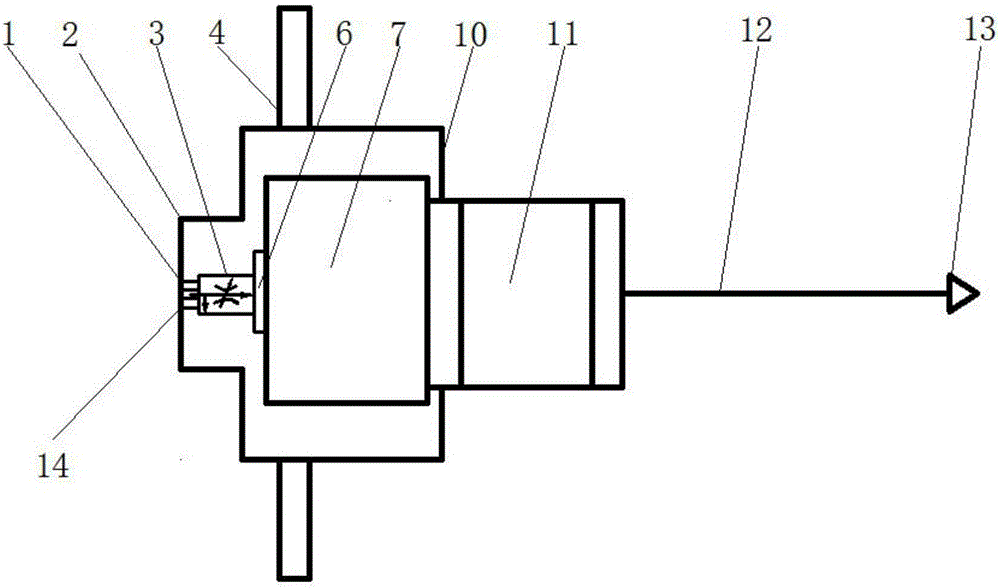

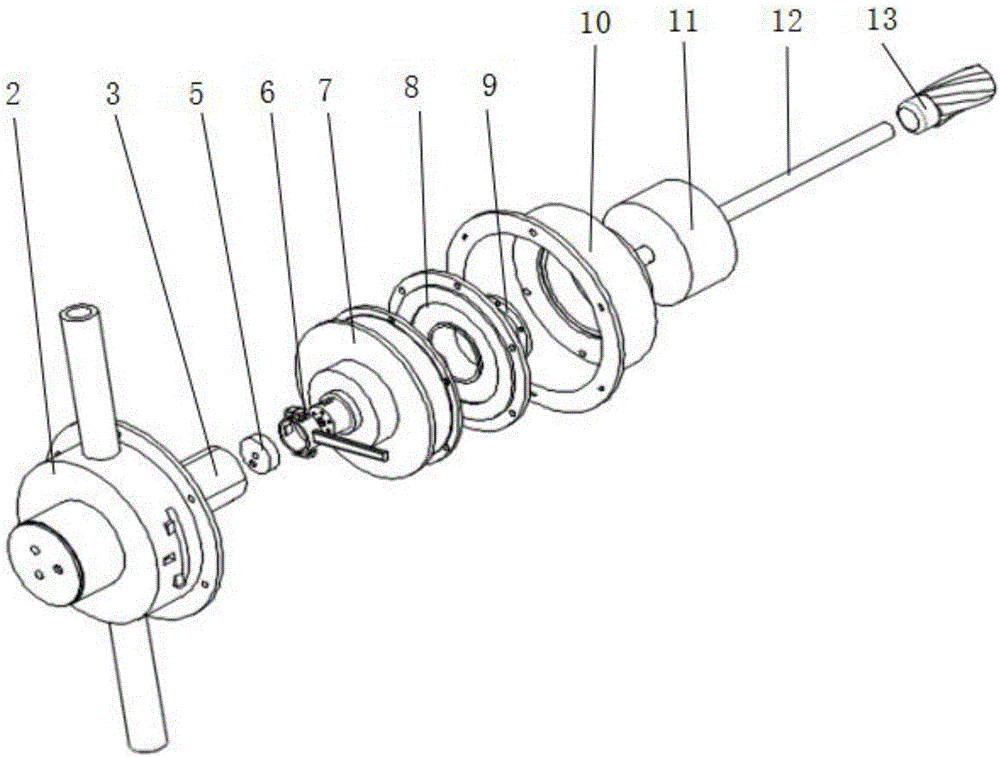

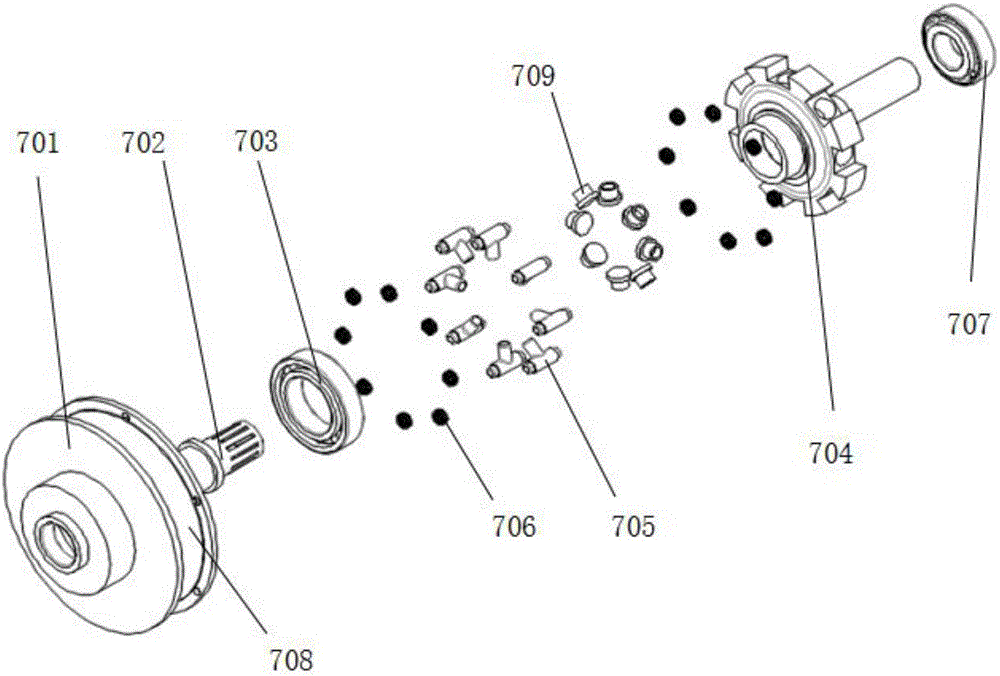

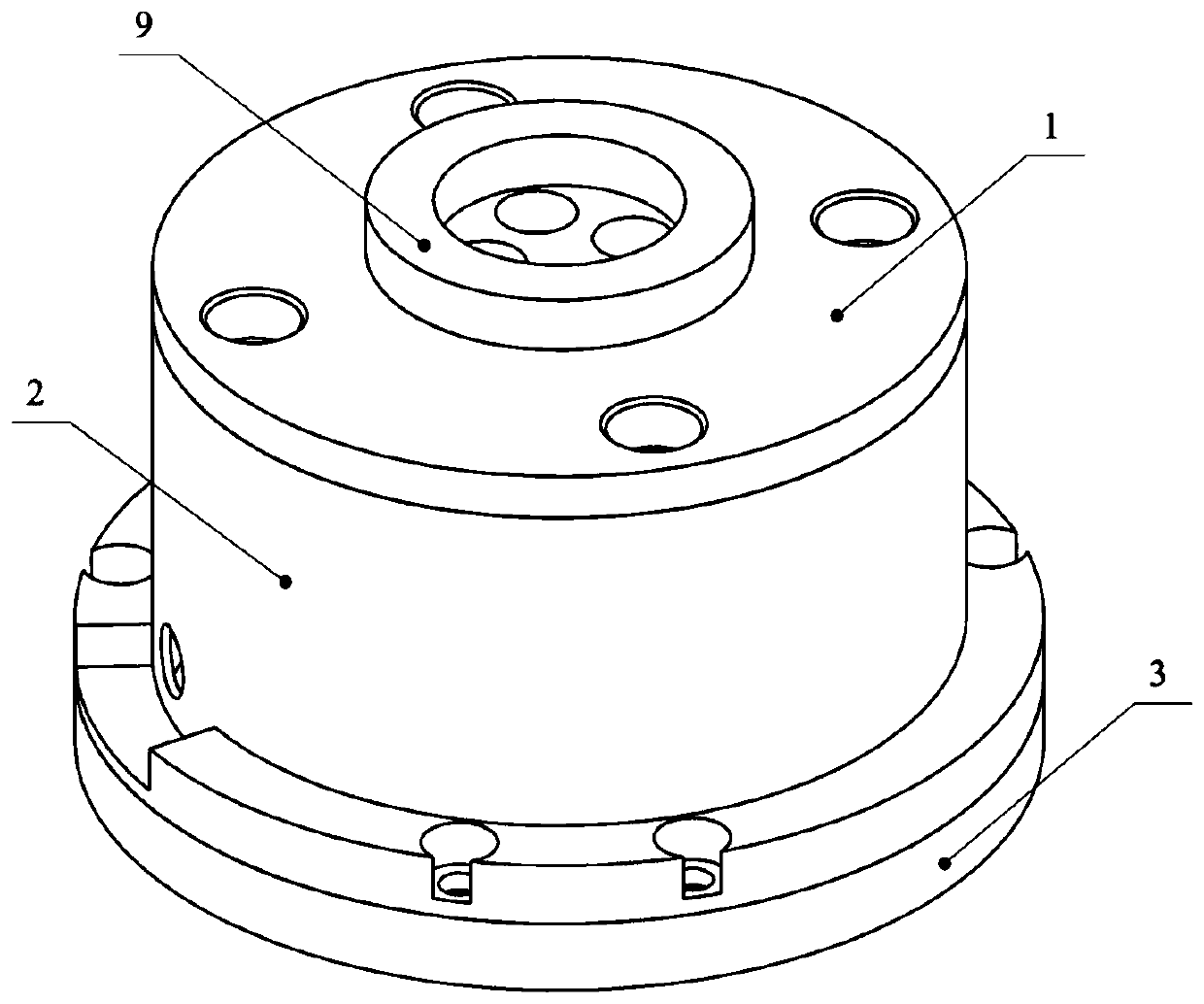

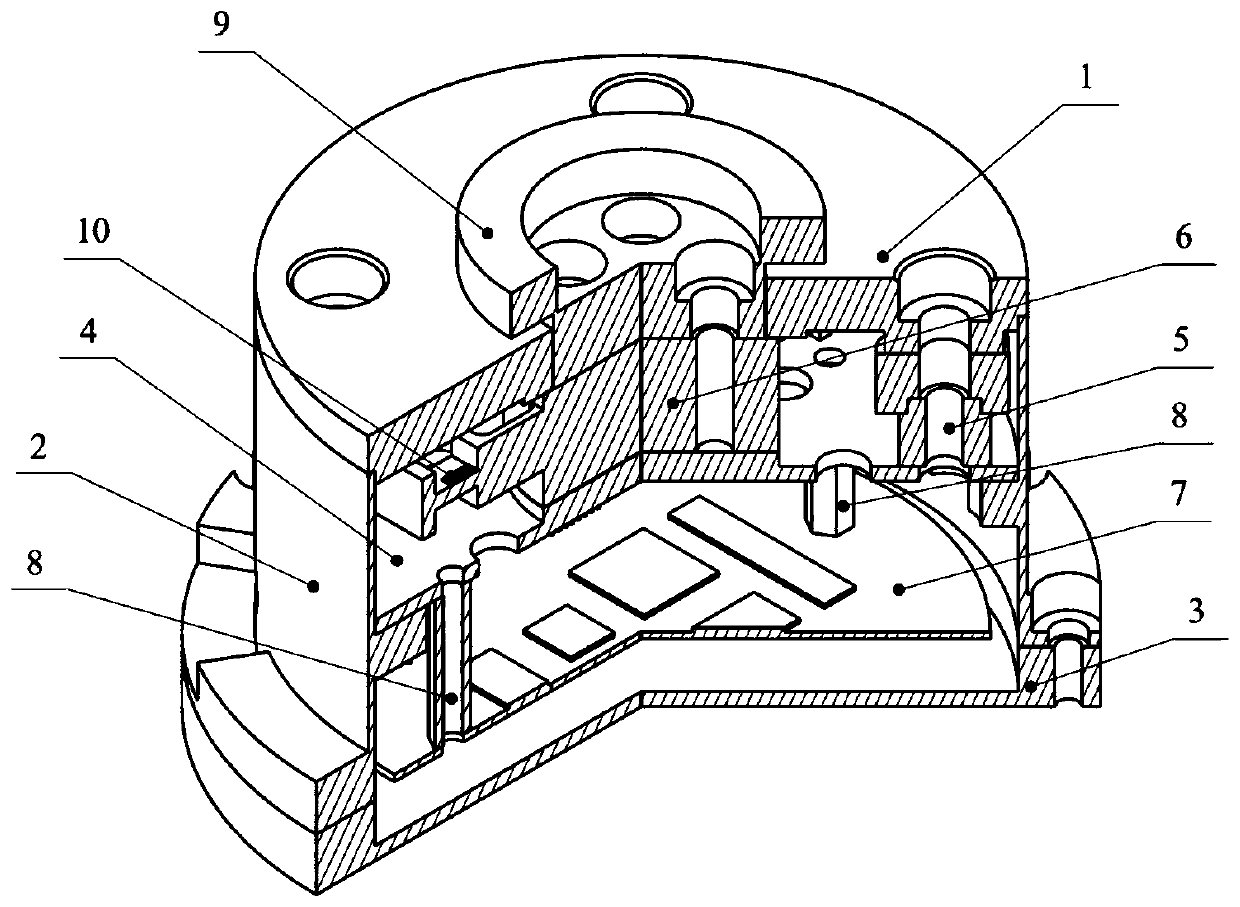

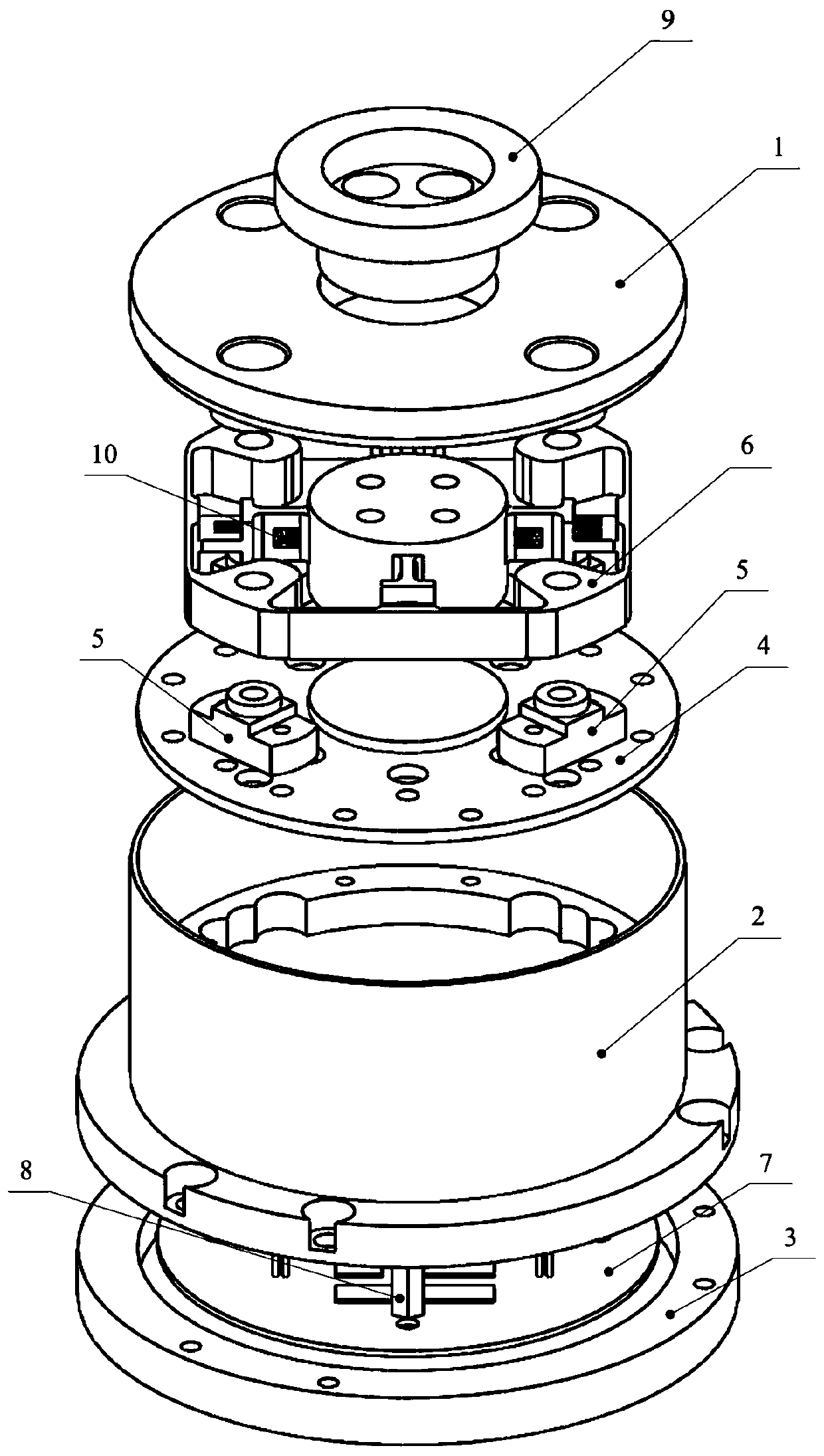

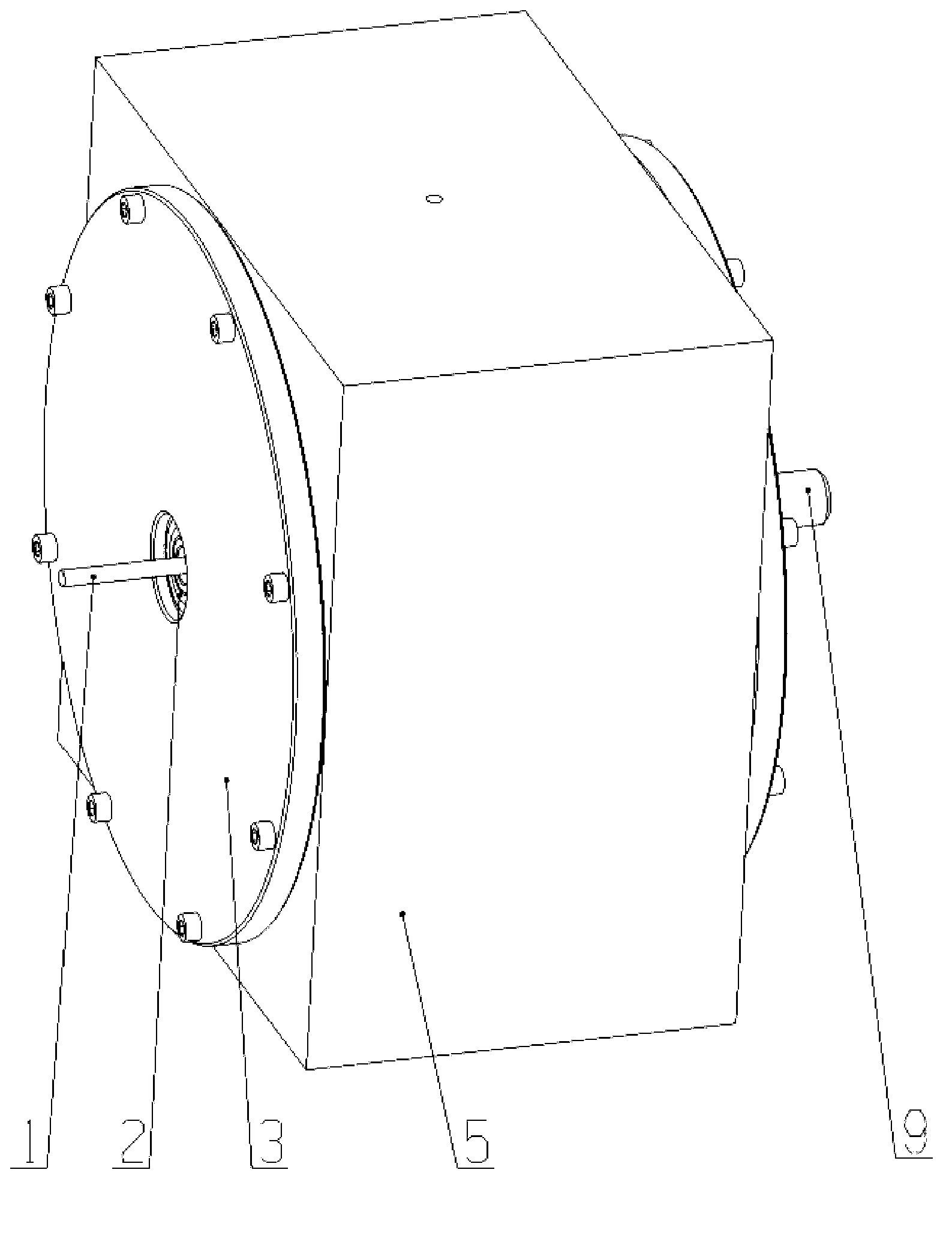

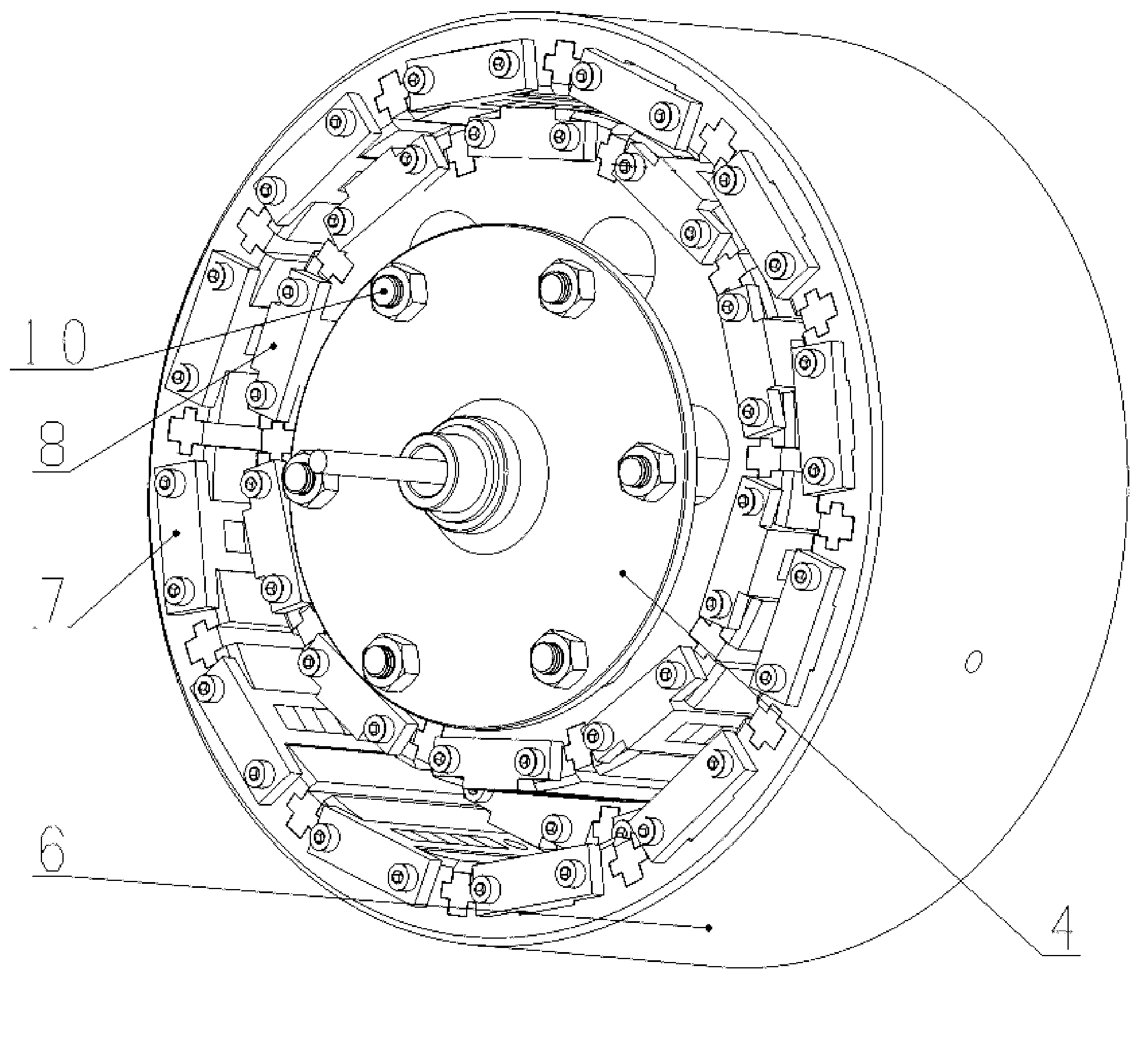

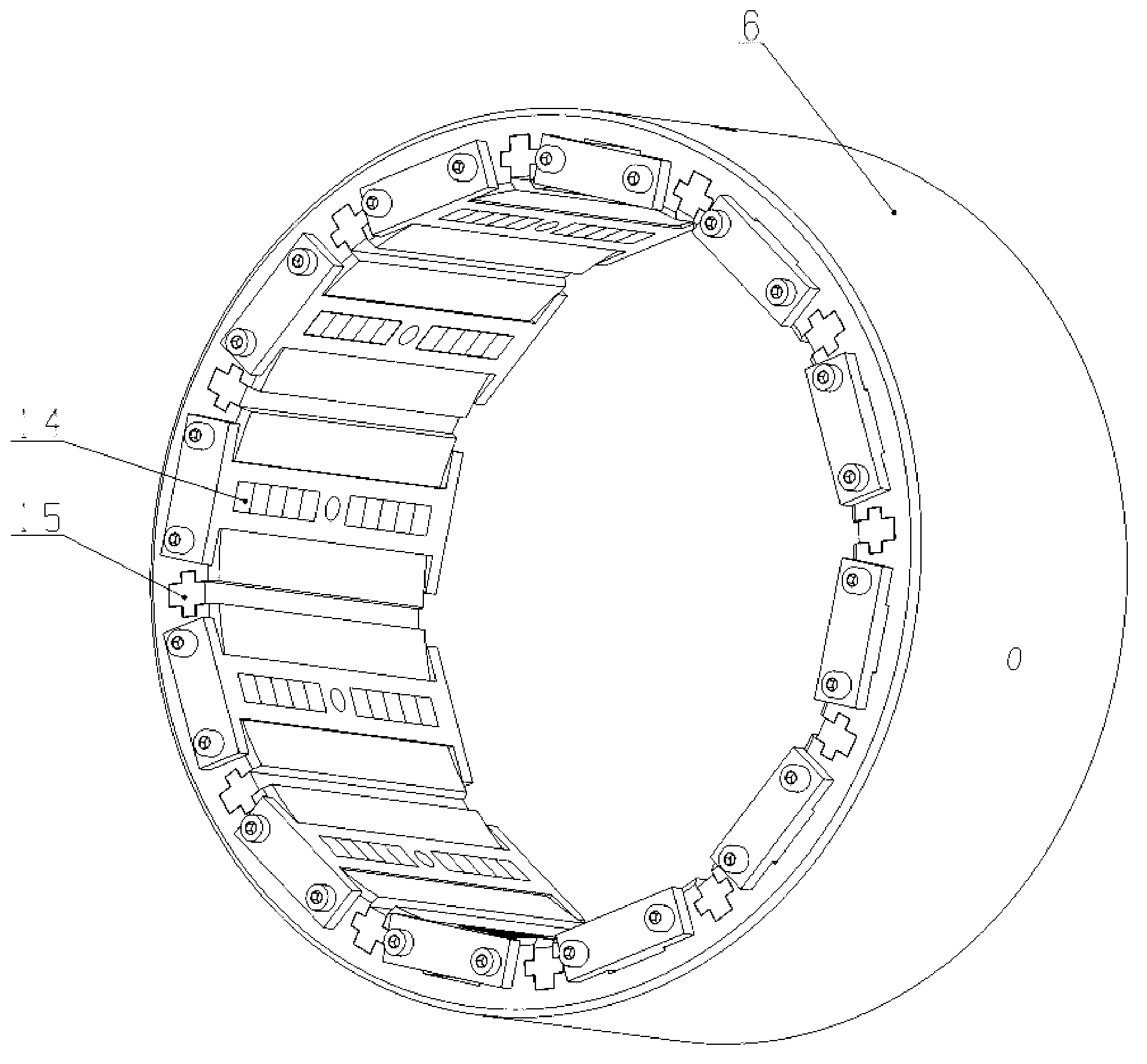

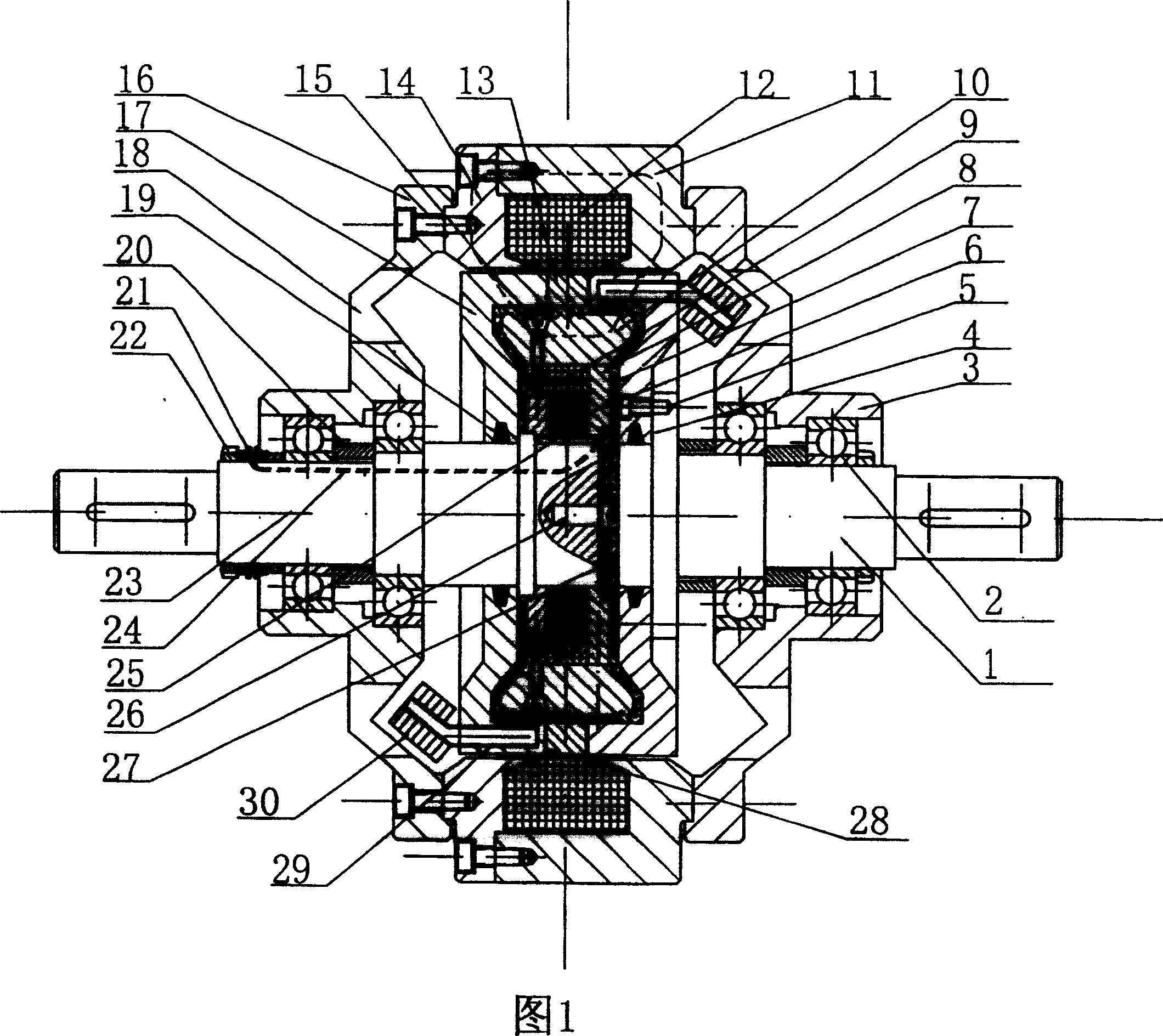

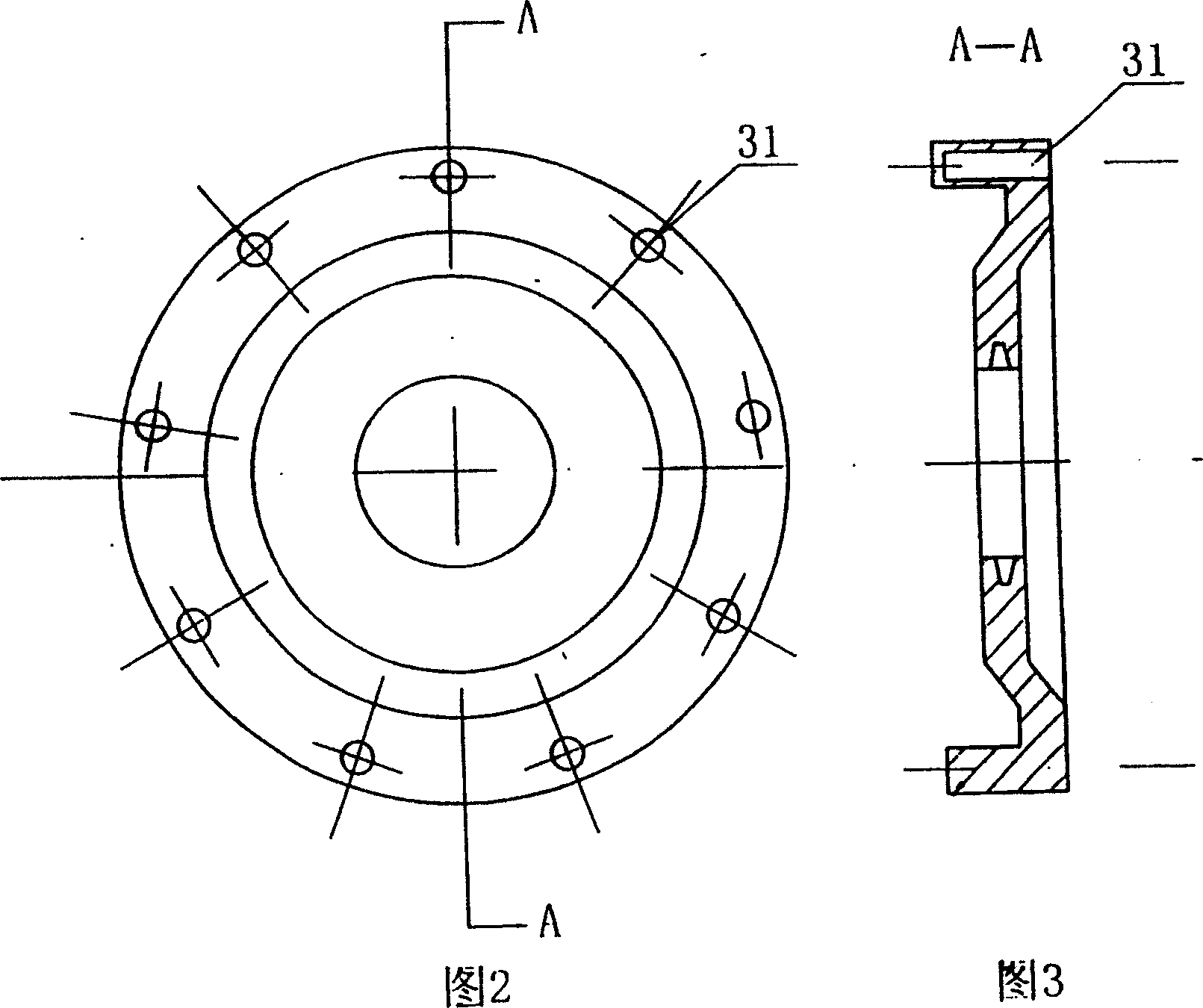

Magnetic rheological soft startor

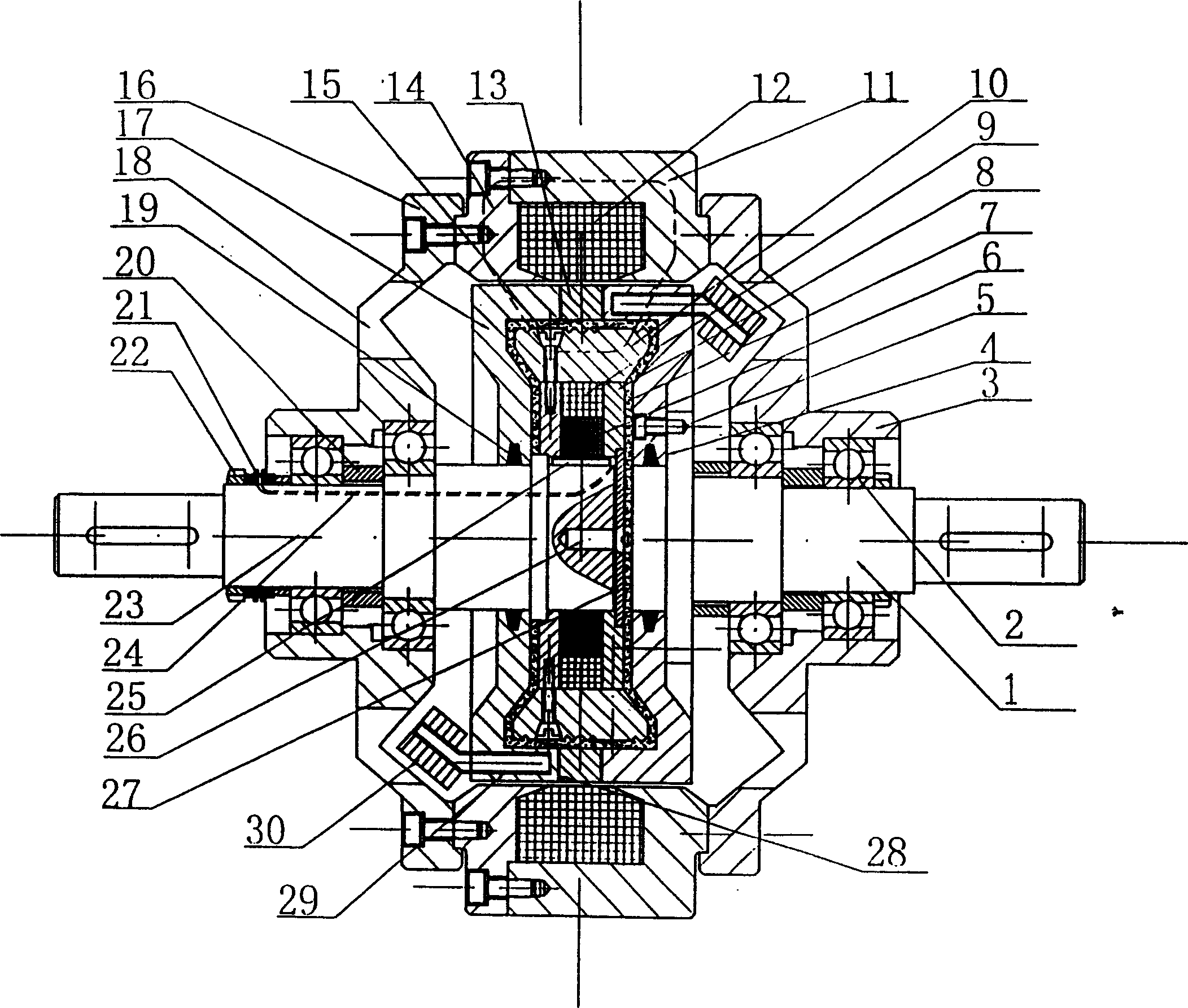

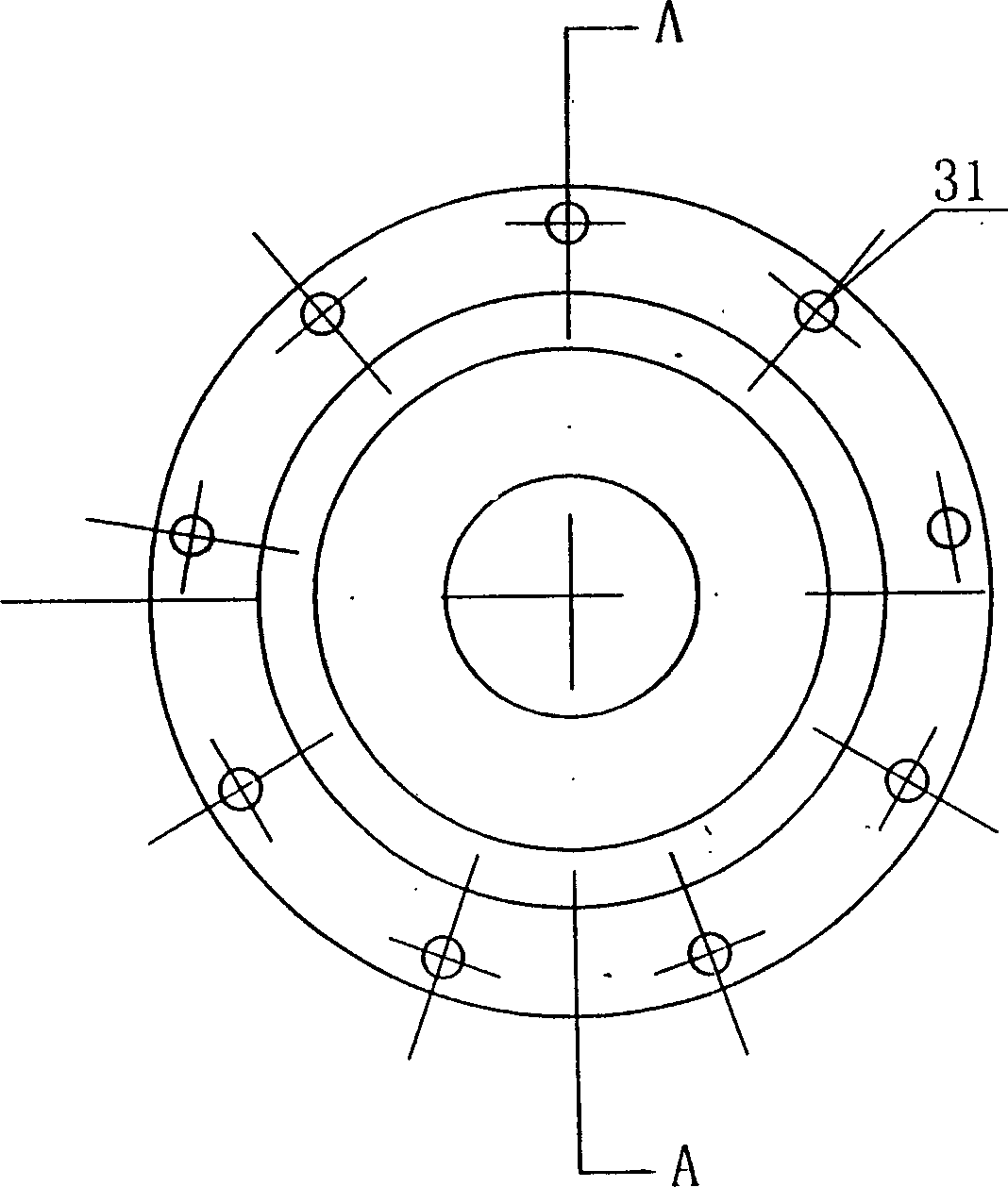

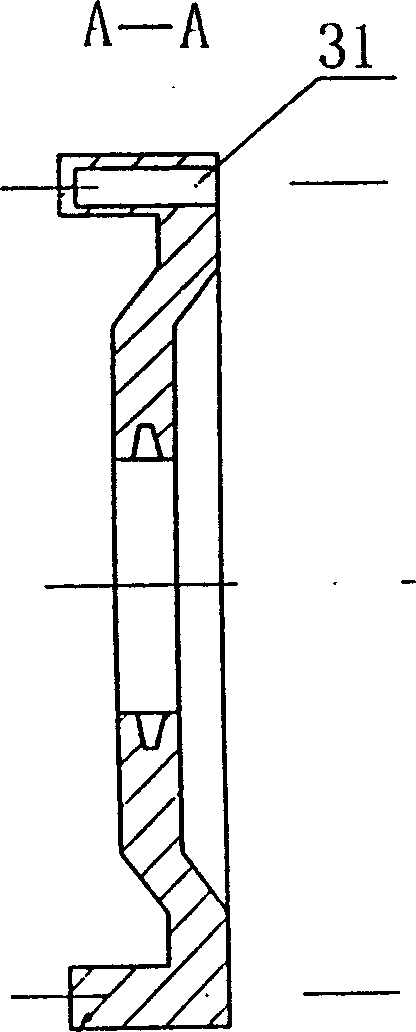

A magnetic rheological soft starter is used in mechanical transmission. In order to eliminate impact of clutch during starting, new material magnetic rheological fluid (MRF) is introduced as the power transmission medium, and magnetic field electromagnetic winding produces is used in altering the rheological characteristic and controlling transmitted torque to reach the aim of smooth starting. For small structure, great torque and reduced heat produced during operation, the present invention makes driving part in cavity holding driven part, adopts two electromagnetic windings to control the rheological characteristic of MRF in radial and axial work gap, and mounts heat pipe to the end cap of the driving part to lower its temperature. The present invention is used mainly in soft starting of mechanical unit, power transmission, speed regulation and overload protection.

Owner:CHONGQING UNIV

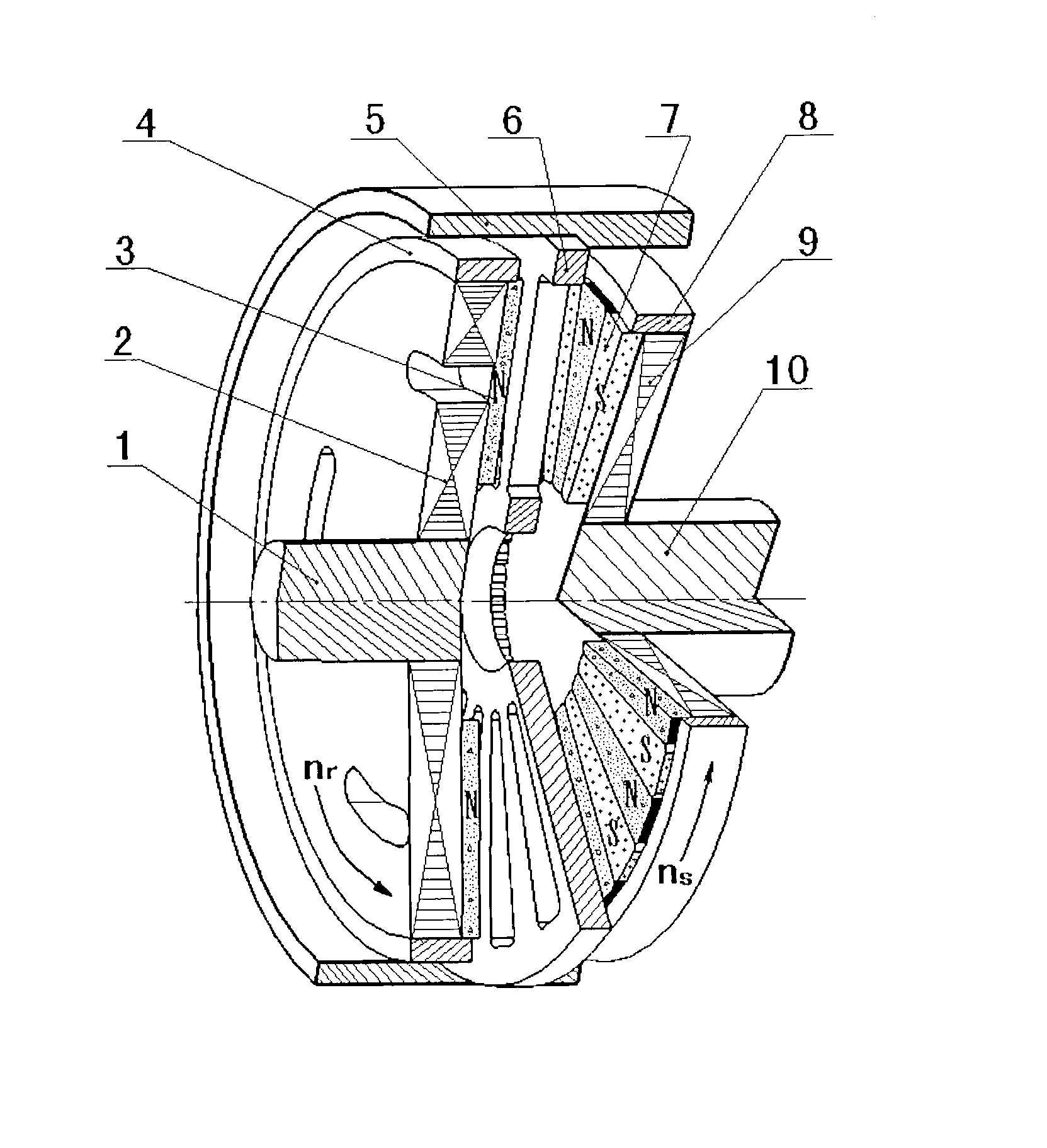

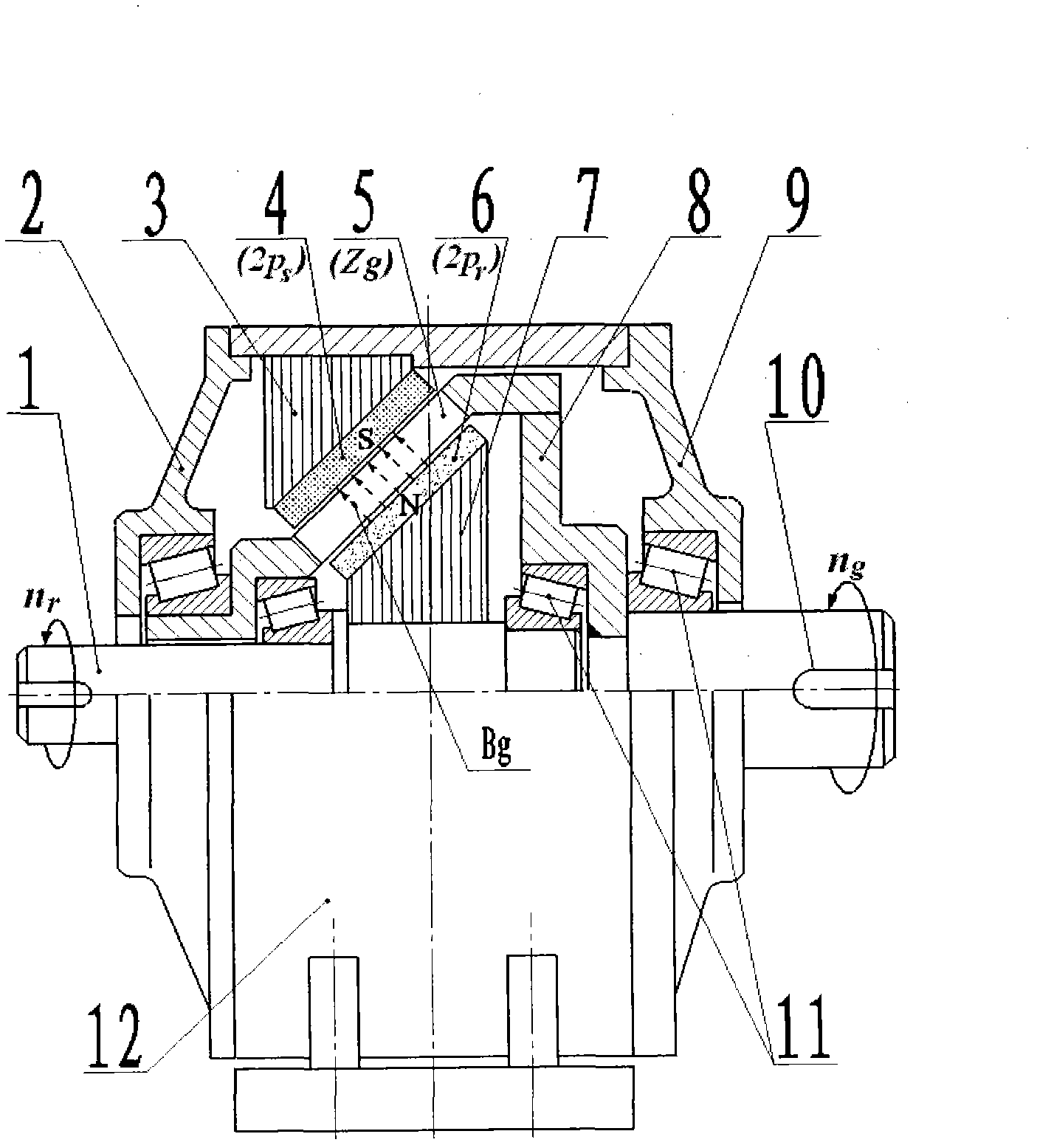

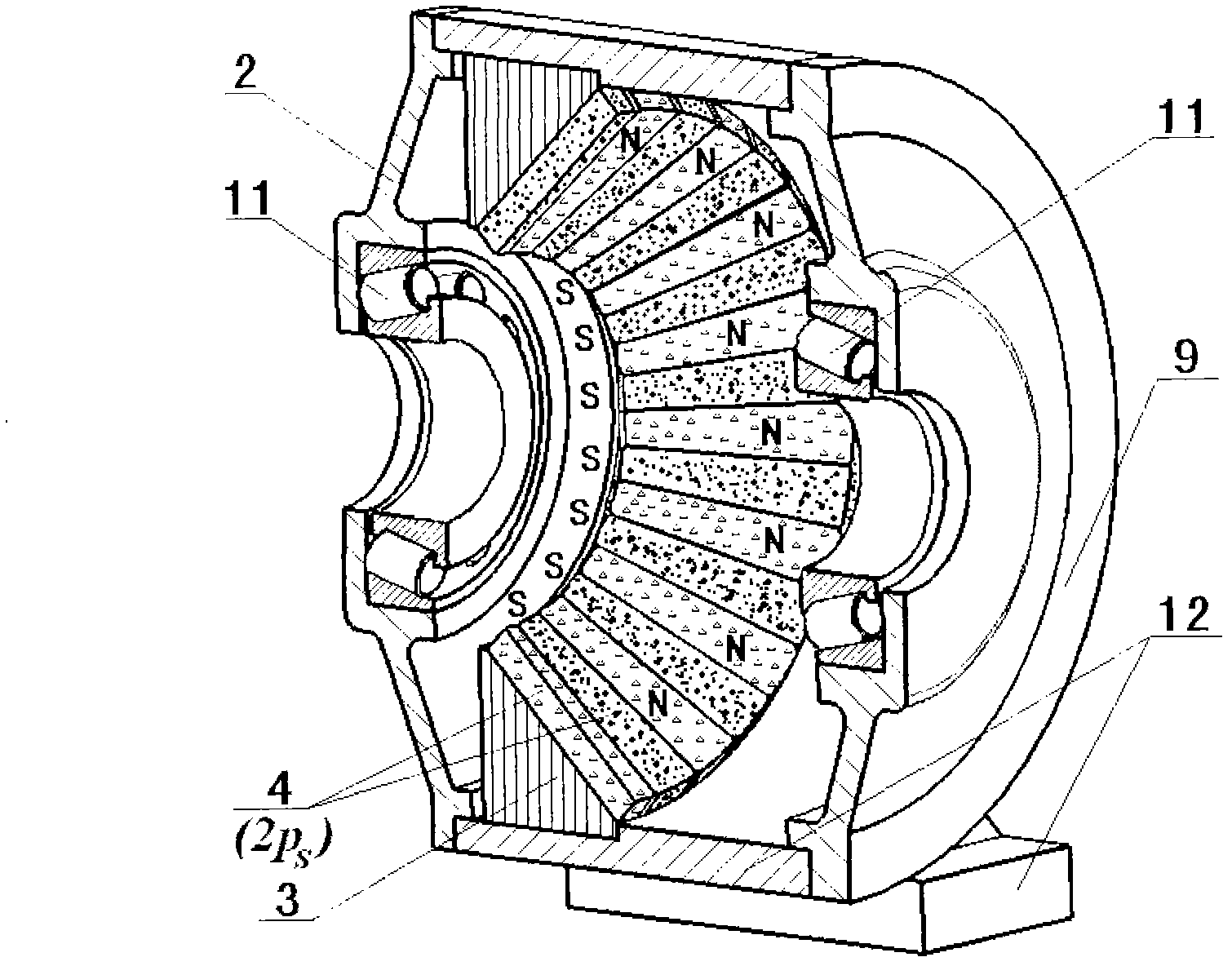

Magnetism transmission gear pair of novel transverse magnetic field

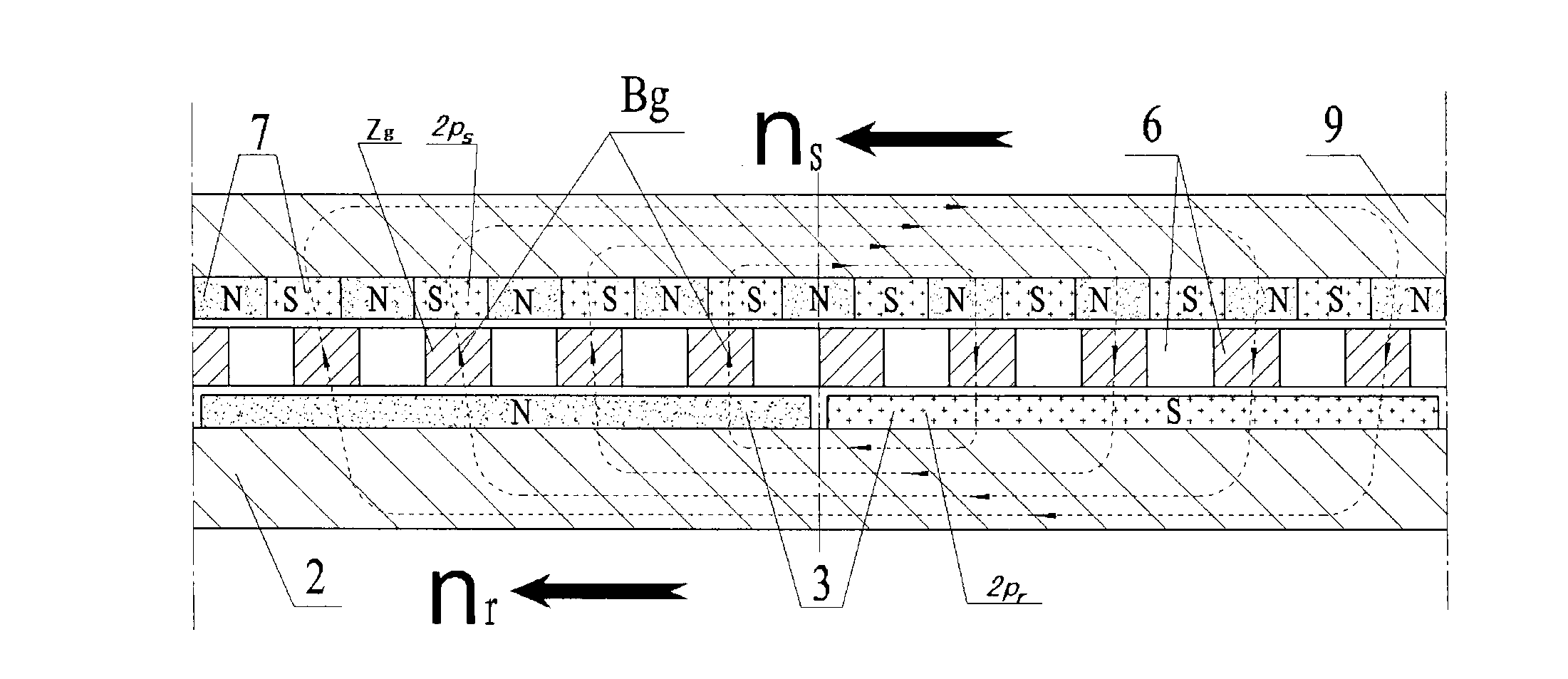

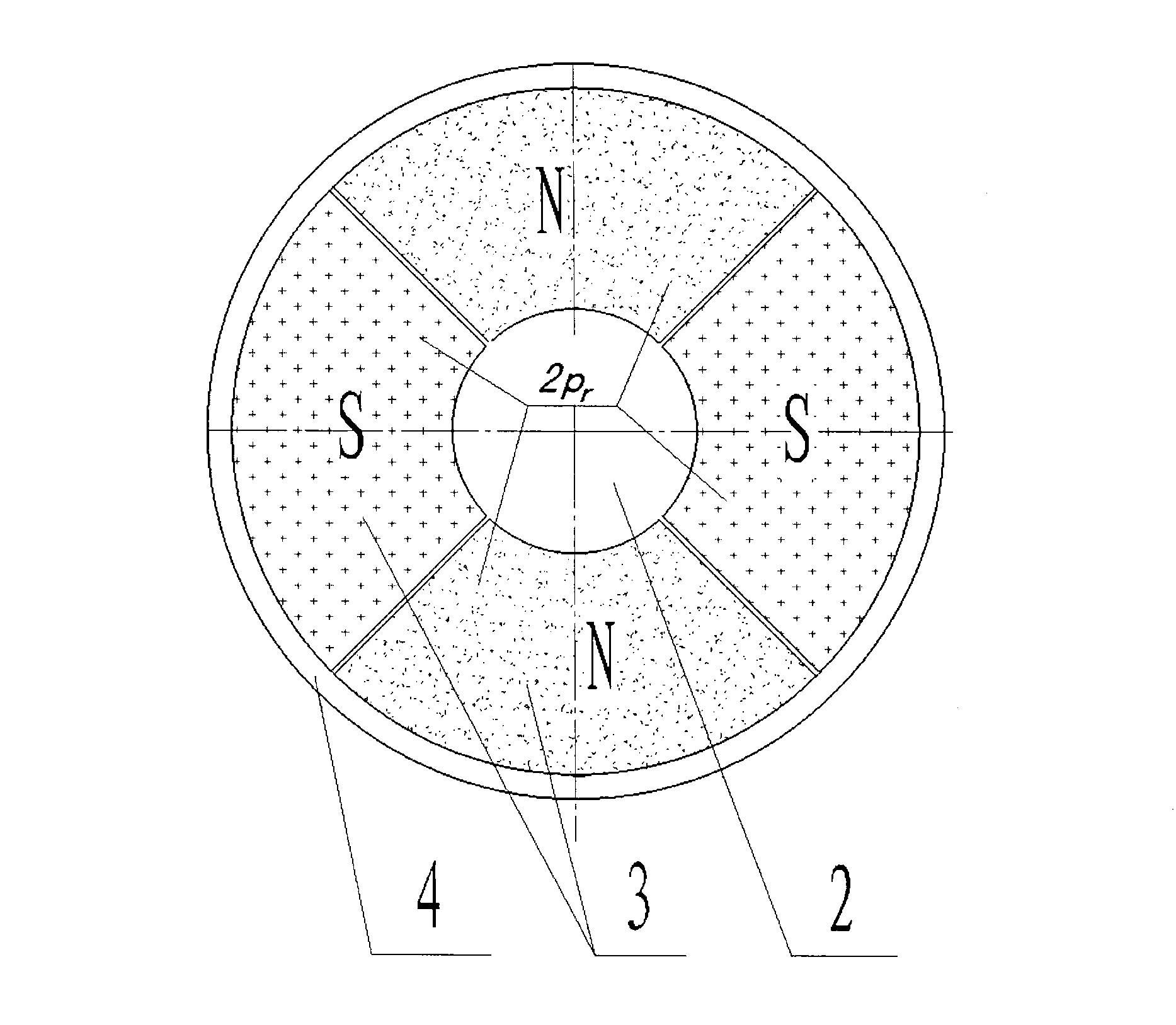

The invention relates to a magnetism transmission gear pair of a novel transverse magnetic field, which can be widely applied to wind power generation, electric cars, ship drive and other industrial transmission fields requiring direct drive. The magnetism transmission gear pair is characterized in that a driving wheel and a driven wheel of the magnetism transmission gear pair are of a flat disk shape, 2pr driving wheel permanent magnets 3 are distributed on the driving wheel, and 2ps driven wheel permanent magnets 7 are distributed on the driven wheel; a ferromagnetic magnetic modulation grid 6 playing a role of modulating an air-gap magnetic field is arranged between the driving wheel and the driven wheel, air gaps are reserved between the ferromagnetic magnetic modulation grid 6 and the end surfaces of the driving wheel and the driven wheel, and the ferromagnetic magnetic modulation grid 6, the driving wheel and the driven wheel have no mechanical contact and are distributed along the same axis; the air-gap magnetic field Bg passes through an air-gap plane along a route parallel to a rotation axis to form a transverse magnetic field of the magnetism transmission gear pair; and during working, power speed change transmission without mechanical contact and friction is realized by utilizing a principle of heteropolarity attraction of an N pole and an S pole of a permanent magnet material.

Owner:余虹锦

Cylinder type speed-changing linear permanent magnet generator used for wave power generation

InactiveCN104578672ANon-contactWith overload protectionMachines/enginesEngine componentsPhysicsLow speed

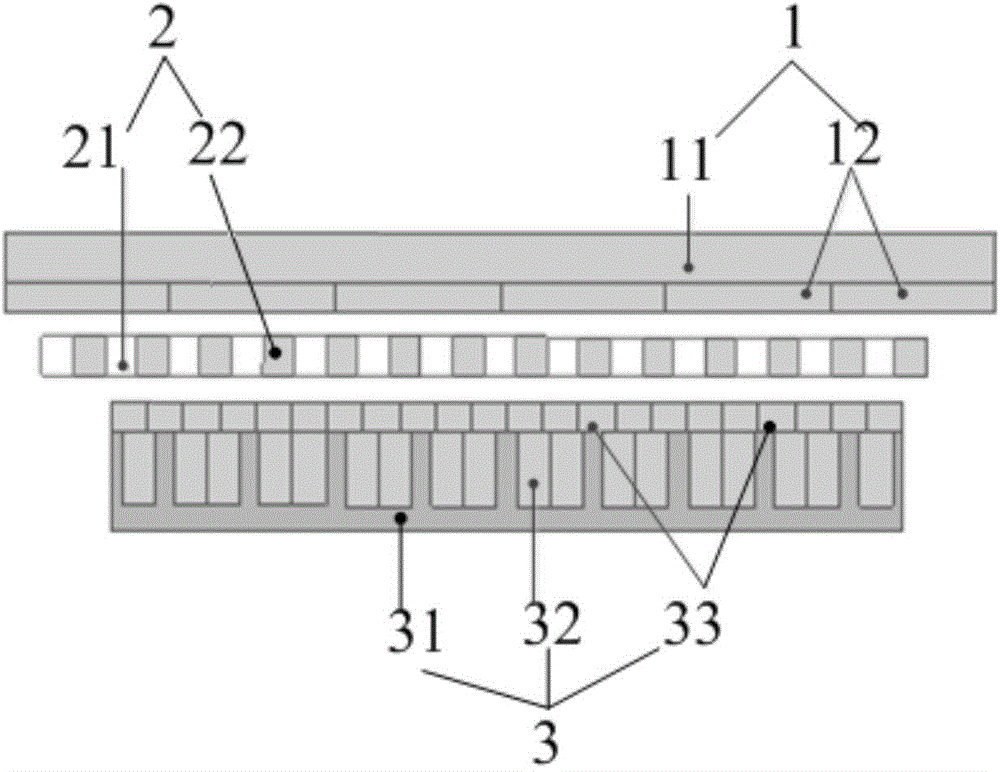

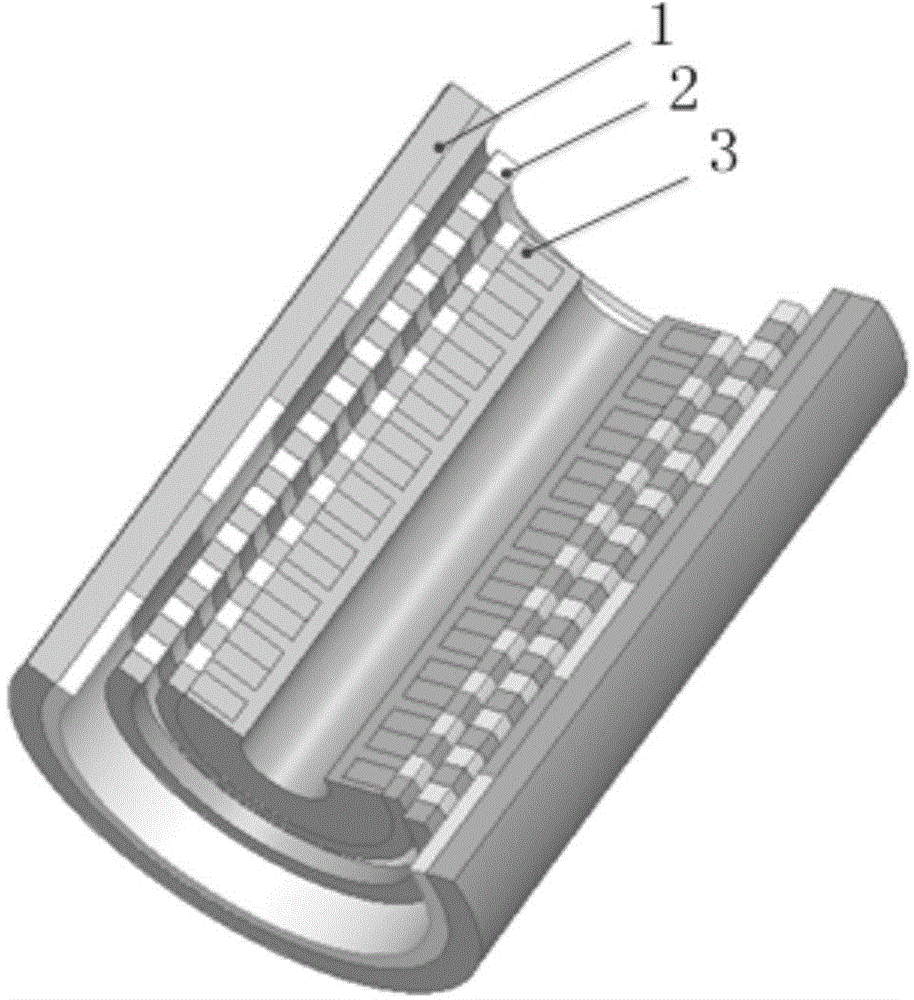

The invention discloses a cylinder type speed-changing linear permanent magnet generator used for wave power generation. The cylinder type speed-changing linear permanent magnet generator comprises a high speed rotor, a low speed rotor and a motor stator, wherein the high speed rotor, the low speed rotor and the motor stator are of a cylinder structure and arranged from outside to inside in a sleeving mode. A first air gap is formed between the high speed rotor and the low speed rotor. A second air gap is formed between the low speed rotor and the motor stator. The high speed rotor comprises a high speed rotor iron core. The inner surface of the high speed rotor iron core is provided with high speed permanent magnet pole pieces in a surface-adhering or embedding mode. The low speed rotor comprises magnetizers and non-magnetizers, wherein the magnetizers and the non-magnetizers are arranged at intervals in the axial direction in a staggered mode. The motor stator comprises a stator iron core. A stator iron core gear groove of the outer surface of the stator iron core is provided with stator coils in an embedded mode. The outer surfaces of the stator coils are provided with stator permanent magnet pole pieces in a surface-adhering mode. By means of cylinder type speed-changing linear permanent magnet generator, additional large-sized speeders are not needed to arrange in a whole wave power generation system, the volume is small, and the power capturing and power generating efficiency is high.

Owner:SOUTHEAST UNIV

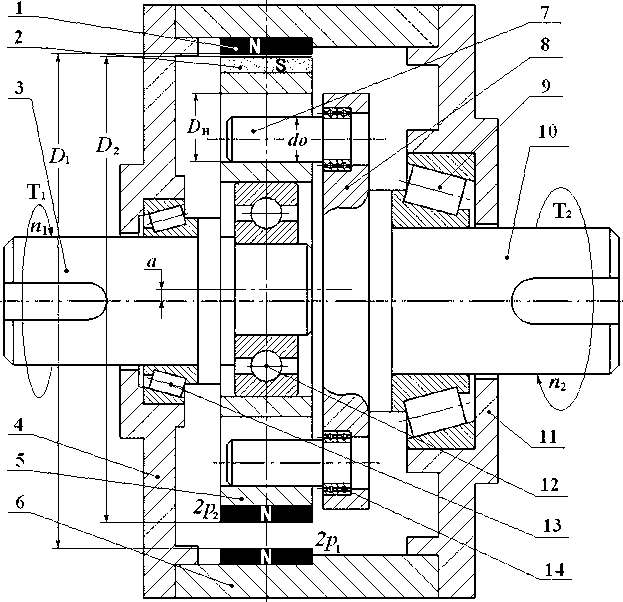

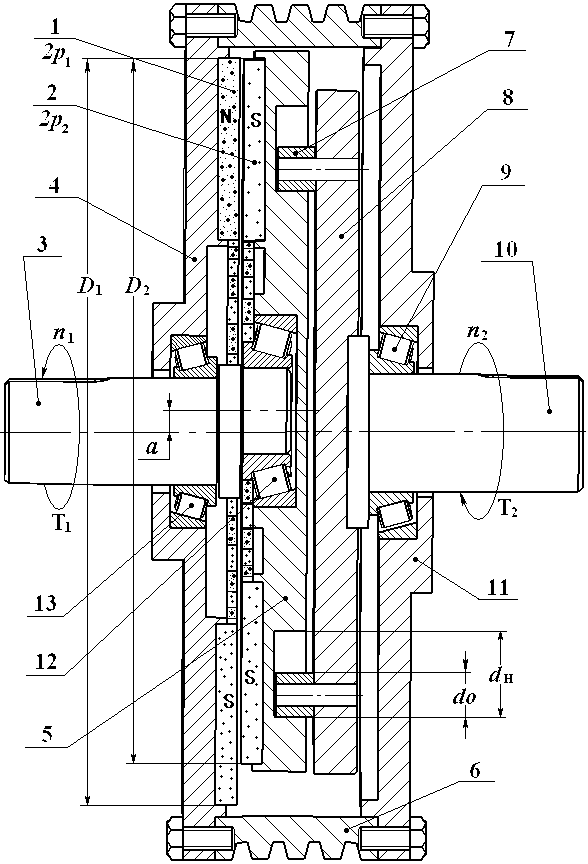

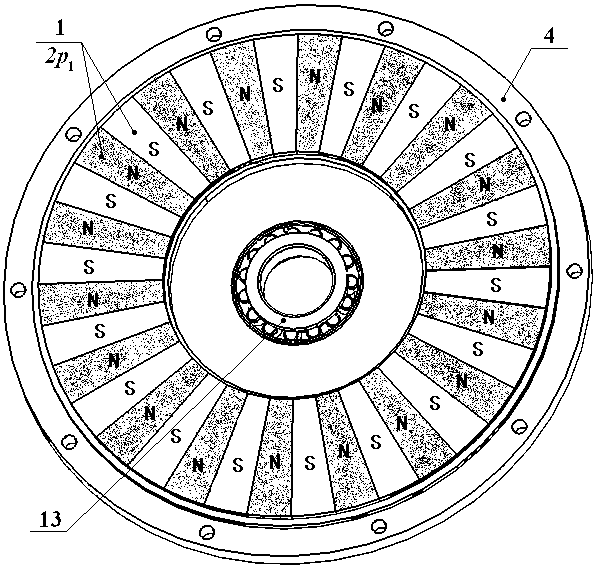

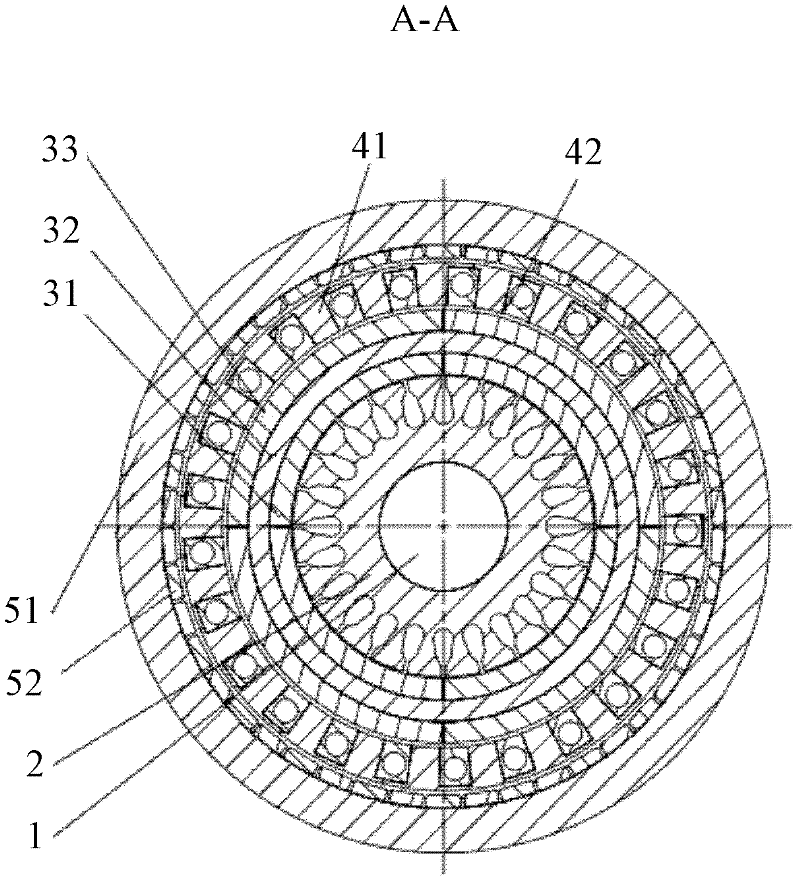

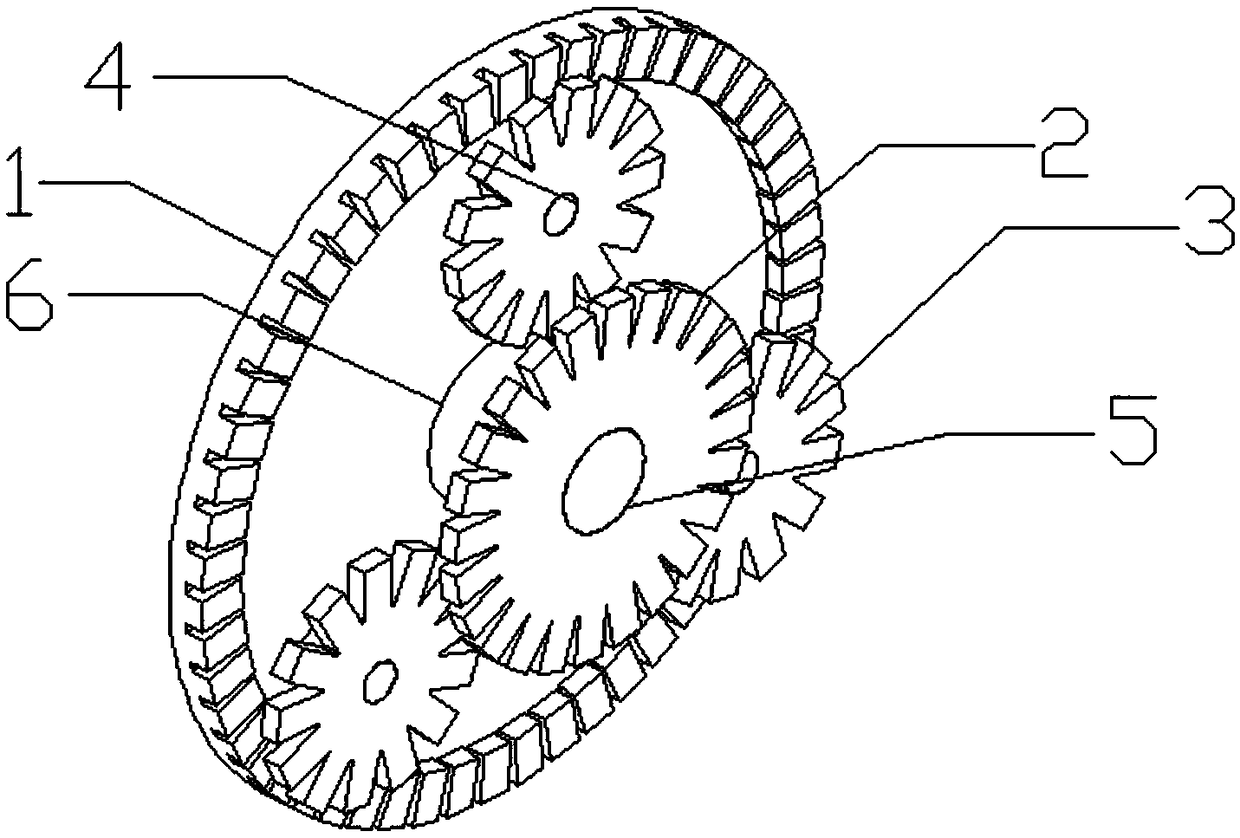

Little pole difference magnetic field coupling type magnetism transmission eccentricity gear pair of novel radial direction magnetic field

InactiveCN103107676ATo achieve technical and economic effectReduce lossDynamo-electric brakes/clutchesElectric machinesLow speedMagnetic field coupling

Disclosed is a little pole difference magnetic field coupling type magnetism transmission eccentricity gear pair of a novel radial direction magnetic field. The little pole difference magnetic field coupling type magnetism transmission eccentricity gear pair of the novel radial direction magnetic field can be applied widely in the field of industry transmissions of wind power generation, electric automobile, vessel driving and the like. The little pole difference magnetic field coupling type magnetism transmission eccentricity gear pair of the novel radial direction magnetic field is characterized in that a stator with a 2p1 stator permanent magnet 1 are distributed in the inner hole of a machine shell 6. A magnetism transmission gear pairs are formed by planet rotors of 2p2 planet rotor permanent magnet 2 are distributed on the excircle of a planet rotor iron core5. A number difference between the pole number 2p1 and 1p2 is small. The permanent magnets on the two magnetic gear pairs penetrate through an air gap magnetic field coupling of the radial direction eccentricity, and are connected to an eccentricity structure by the little pole difference two magnetic gear pairs. A second bearing 12 and a third bearing 13 are installed on an eccentricity input shaft 3. The planet rotor iron core 5 is driven by the eccentricity input shaft 3 to revolve in autogiration around the axis. A low speed autogiration of the planet rotor is output through a pin hole type output structure.

Owner:余虹锦

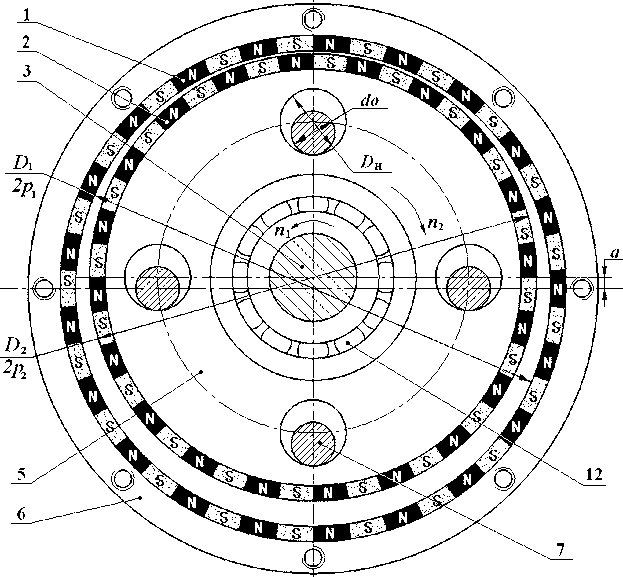

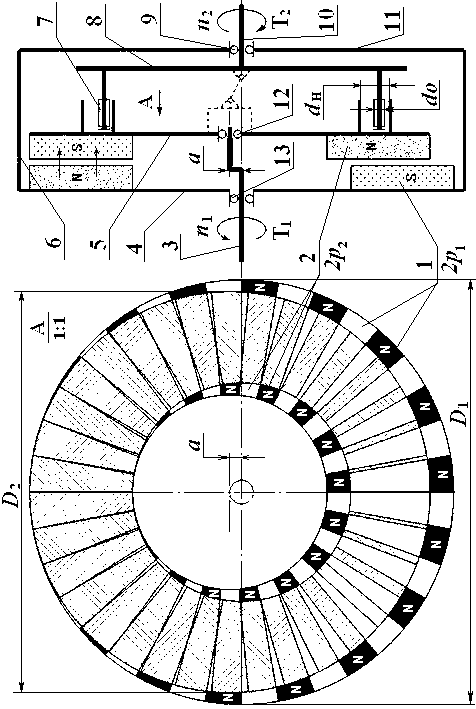

Small range magnetic transmission eccentric disc-shaped gear pair of novel horizontal magnetic field

InactiveCN102996752ATo achieve technical and economic effectReduce lossGearingMagnetic disksMagnetic field coupling

The invention discloses a small range magnetic transmission eccentric disc-shaped gear pair of a novel horizontal magnetic field, and the gear pair can be widely applied to wind power generation, electric vehicles, ship driving and other industrial transmission fields which need direct driving. The small range magnetic transmission eccentric disc-shaped gear pair of the novel horizontal magnetic field is characterized in that a magnetic transmission gear pair comprises a disc-shaped large disk on which 2p1 large disk permanent magnet bodies 1 are distributed and a disc-shaped planetary disk on which 2p2 planetary disk permanent magnetic bodies 2 are distributed; the range between the numbers of poles 2p1 and 2p2 is smaller; permanent magnet bodies on the two disks are coupled through an air gap horizontal magnetic filed between the two disks; an eccentric input shaft 3 which is sleeved with a bearing II 12 and a bearing III 13 connects the two disks with small range into an eccentric structure; the eccentric input shaft 3 drives a planetary turntable 5 to revolve around a rotary shaft; the planetary disk permanent magnetic bodies 2 which revolve eccentrically and the large disk permanent magnet bodies 1 are coupled through the magnetic field so as to drive the planetary turntable to reversely revolve around the axes of the planetary turntable, and the low-speed revolution of the planetary turntable is output through a hole-pin output structure.

Owner:余虹锦

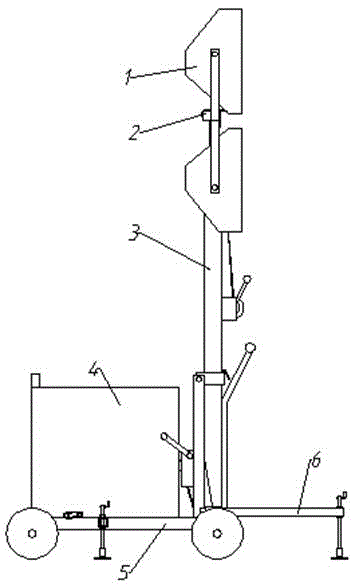

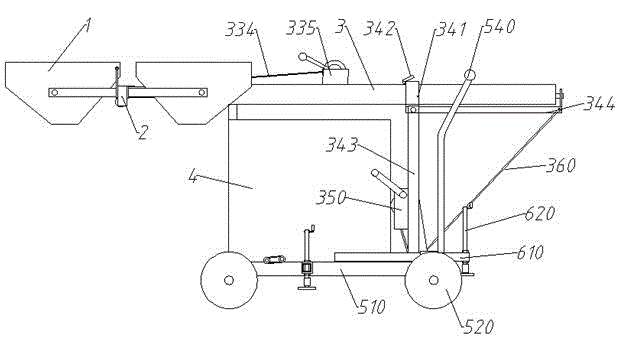

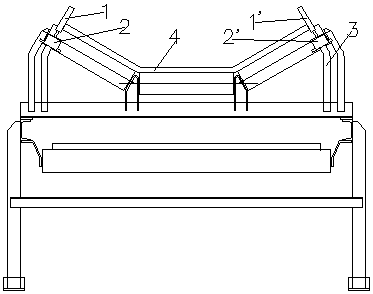

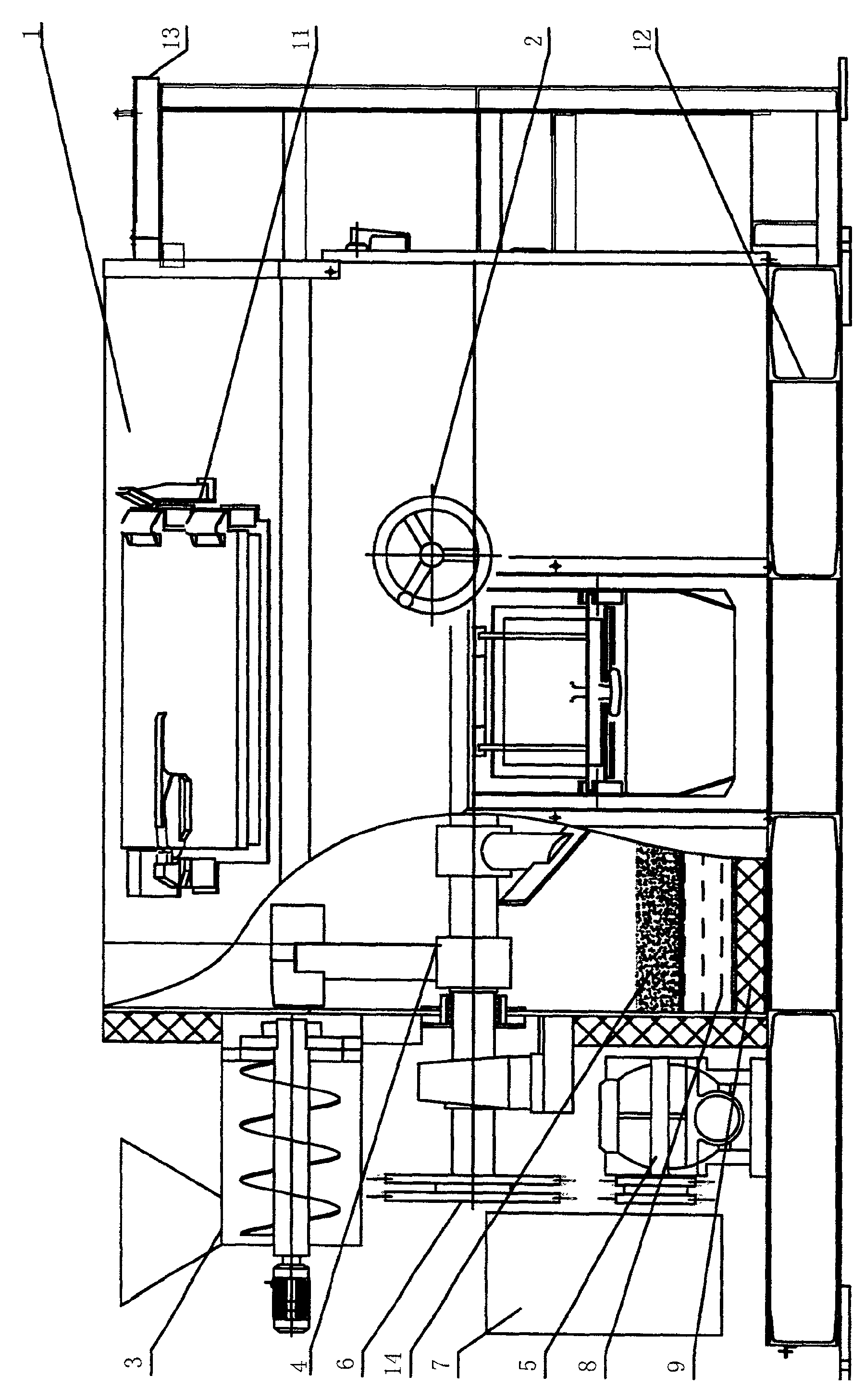

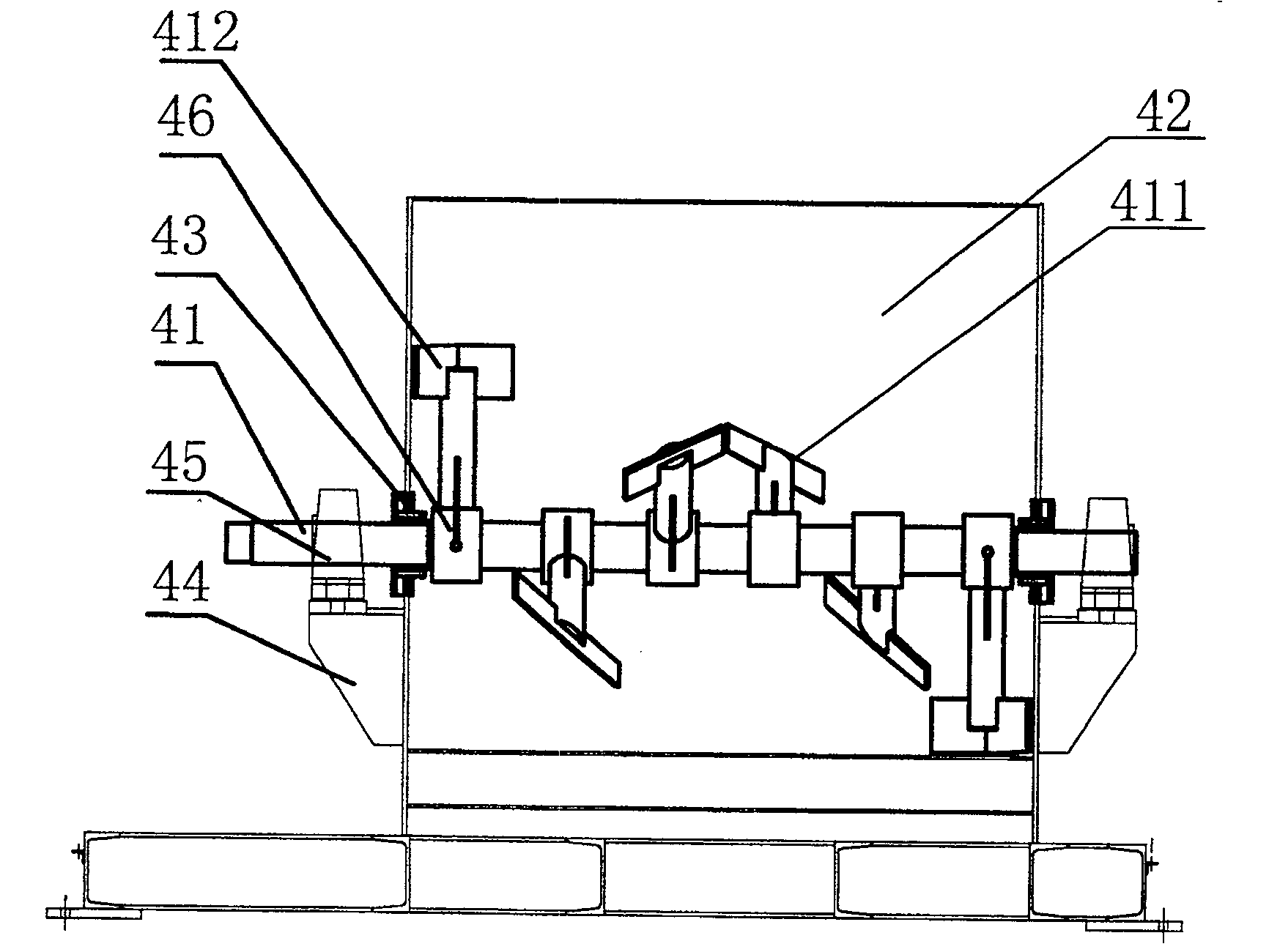

Medium-sized mobile lamp vehicle

InactiveCN102865463AReasonable matchCompact designLighting support devicesElectric lighting with built-in generatorsEngineeringLight source

The invention provides a medium-sized mobile lamp vehicle, which comprises an illuminating light source (1), a lamp projection angle adjusting mechanism (2), a lamp tower (3), a generator set (4), a chassis (5) and supporting legs (6), wherein the illuminating light source (1) and the lamp projection angle adjusting mechanism (2) are arranged on the lamp tower (3); the lamp tower (3) is fixed on the chassis (5) through a fixing seat; the generator set (4) is carried on the chassis (5); and the supporting legs (6) are arranged at the rear end, the left side end and the right side end of the chassis (5). The medium-sized mobile lamp vehicle is compact in structure, low in cost and multifunctional, has reliable windproof and anti-tilting parking stability and a good mobile passing ability, and meets requirements on outdoor emergency or temporary illumination.

Owner:GUANGDONG UNIV OF TECH

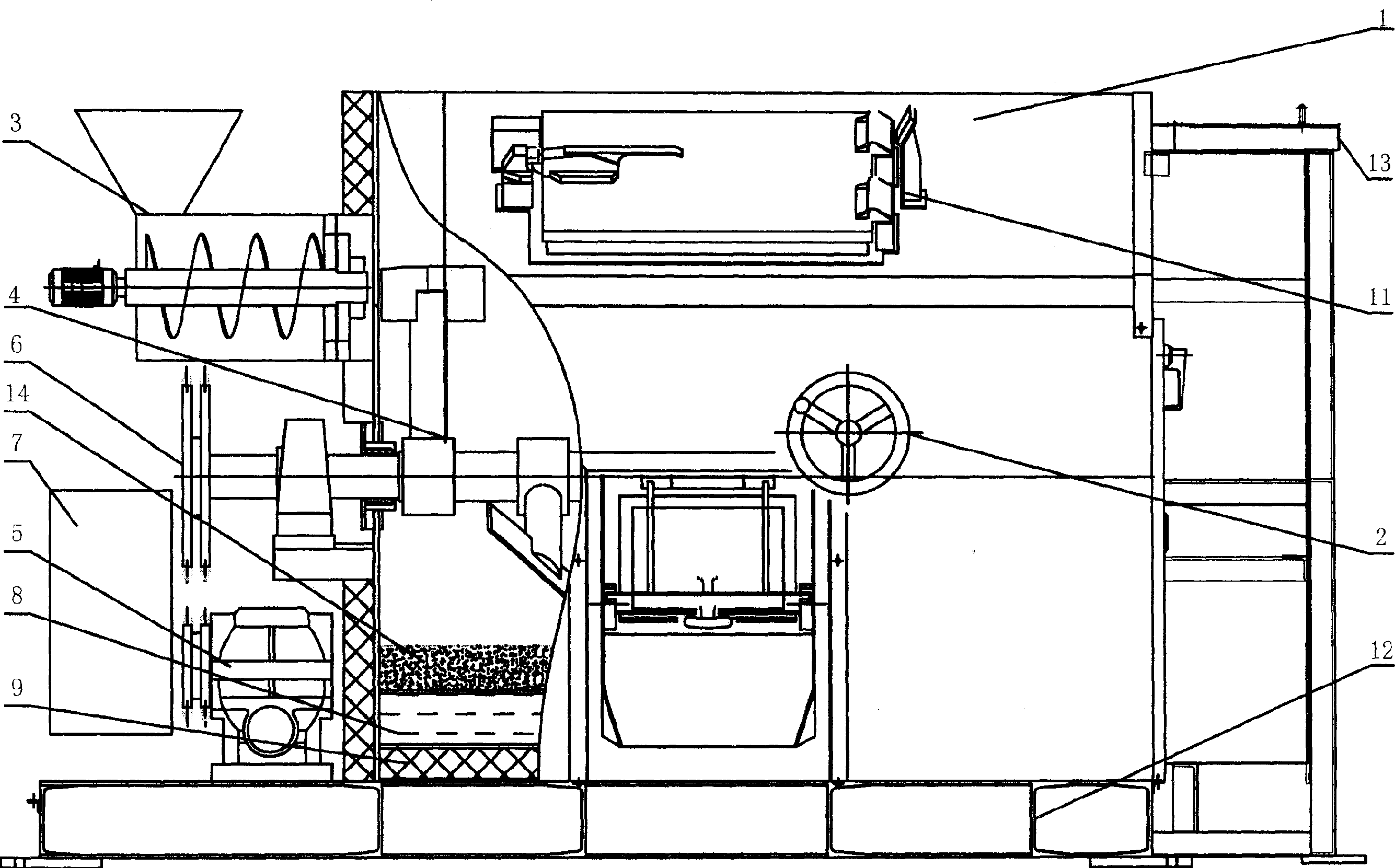

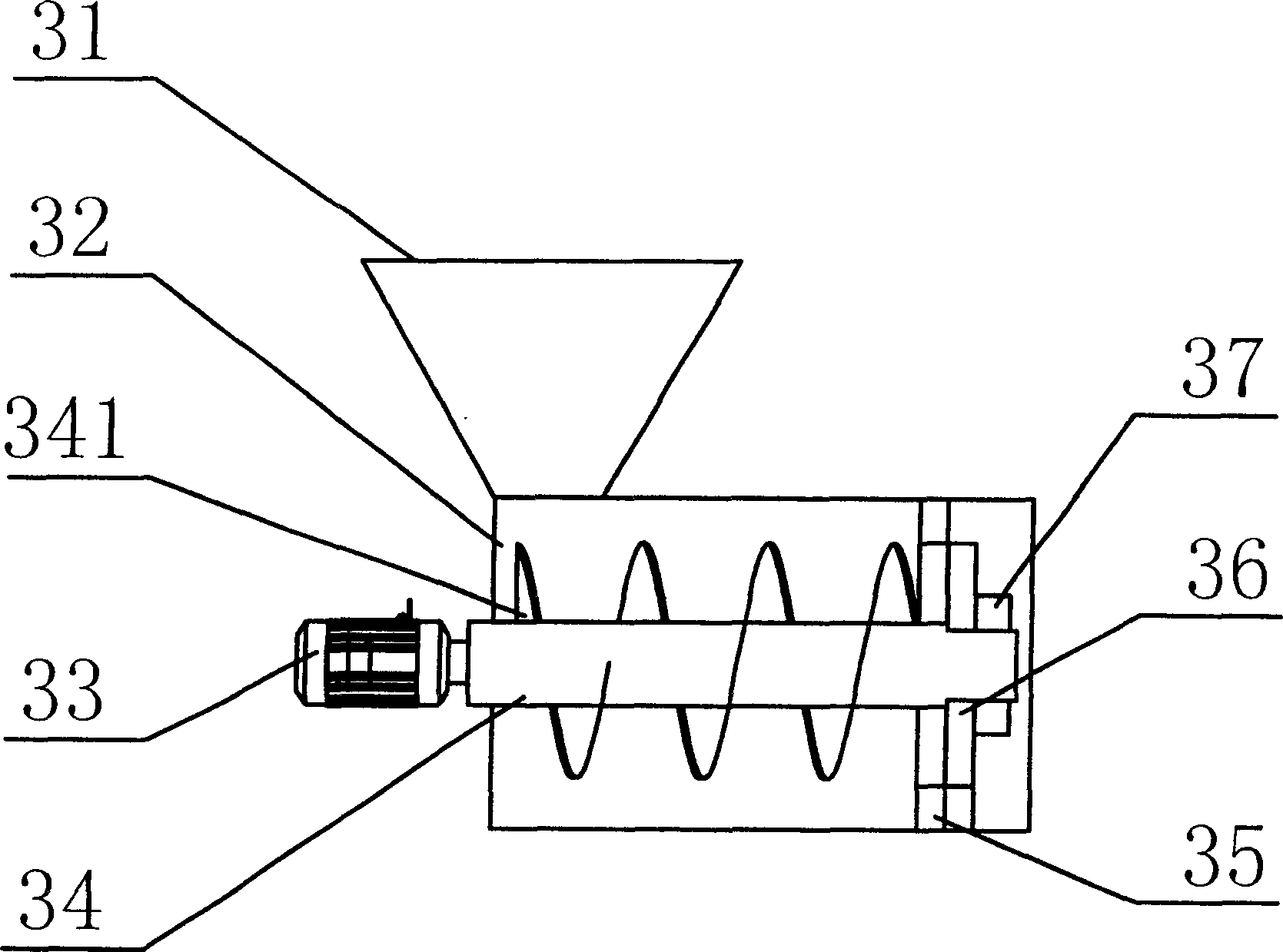

Multifunctional kitchen refuse treatment machine

InactiveCN1799715AWith overload protectionGuaranteed service lifeSolid waste disposalEngineeringElectric control

The invention relates to a multi-functional kitchen-remains treatment device, which can realize the whole automatic process of breaking, filtering, mixing, heating, keeping warm, processing ferment and the deodorization of kitchen-remains. Said multi-functional kitchen-remains treatment device comprises: a frame for containing each devices while its top has a detection door and the upper end of one side of said frame has a breaking device connected with said frame; a mixing device is arranged between the detection door and the discharging device, while the bottom of said mixing device has a zymocyte storage pot; a power device is arranged at the lower end on one side of frame; a transmission device is arranged at the middle of one side of frame and between said mixing device and power device; a electrical controller is arranged outside the power device and transmission device; a discharging device is arranged at the lower part of front end of frame which is relative to the detection door; a heat preservation device is mounted between the discharging device and the power device and the chassis; a heating device is above said heat preservation device; and a deodorization device connecting with upper part of frame is arranged outside the frame.

Owner:SHENZHEN SHENGDEYI HI TECH

Novel magnetic drive oblique gear pair with oblique air-gap magnetic field

A novel magnetic drive oblique gear pair with an oblique air-gap magnetic field can be widely applied to the industrial drive field of wind power generation, electric cars, ship drive and the like with the requirement of direct driving. The novel magnetic drive oblique gear pair is characterized in that the inner hole of a stator of the magnetic drive oblique gear pair is conical internally; 2ps of stator permanent magnets 4 are distributed on an internally-conical stator iron core 3; a driving gear is conical externally; 2pr of driving gear permanent magnets 6 are distributed on an conical driving gear iron core 7; conical hollow driven gear ferromagnetic grids 5 for modulating the action of a space oblique air-gap magnetic field are mounted between the driving gear permanent magnets 6 and the stator permanent magnets 4; conical space oblique air gaps in coaxial distribution exist among the conical hollow driven gear ferromagnetic grids 5, the driving gear permanent magnets 6 and the stator permanent magnets 4 so as to form an air-gap magnetic field Bg of the magnetic drive oblique gear pair to pass along the conical space air gaps, thereby forming an oblique magnetic field of the magnetic drive oblique gear pair. During work, the power variable speed drive of the magnetic drive oblique gear pair is realized without mechanical contact and friction by utilizing the principle that N pole and S pole of a permanent magnetic material are attracted to each other based on different polarity.

Owner:余虹锦

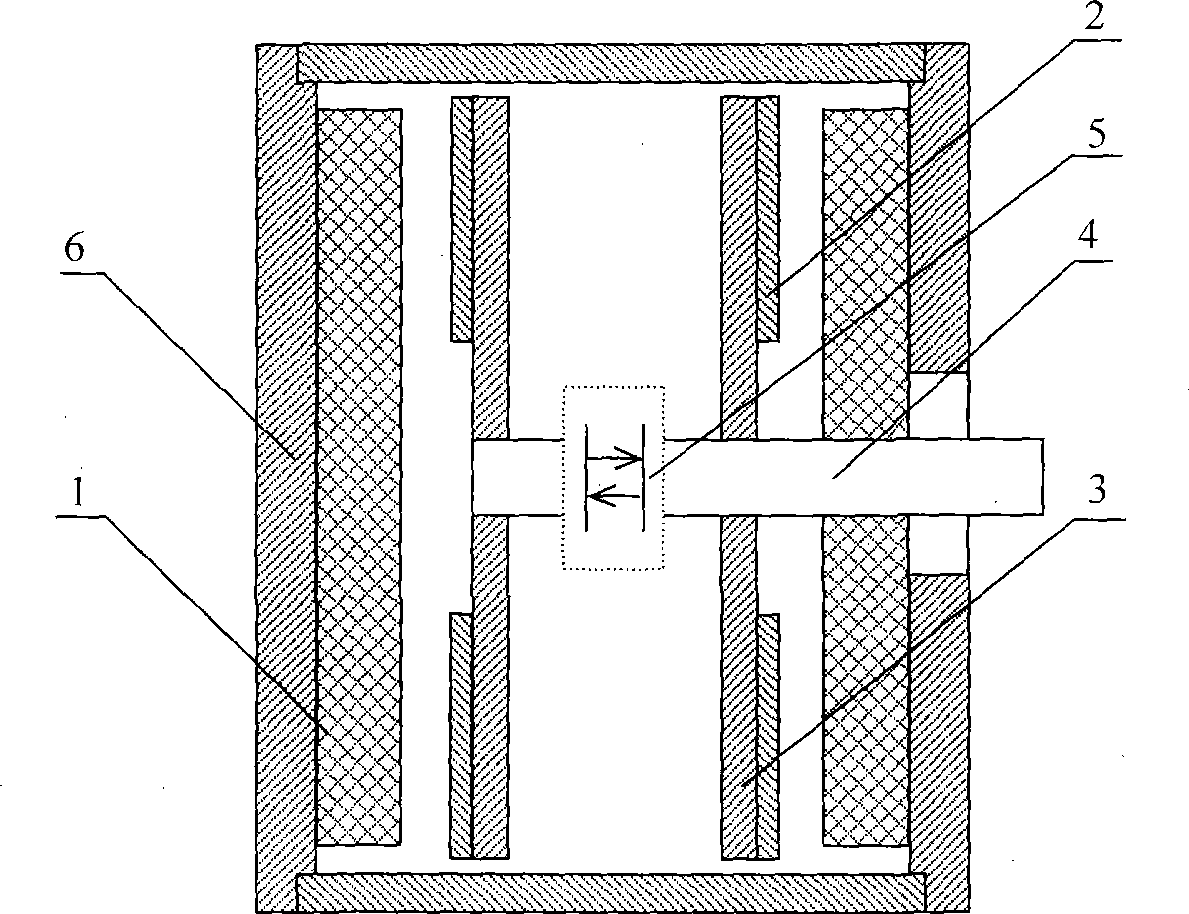

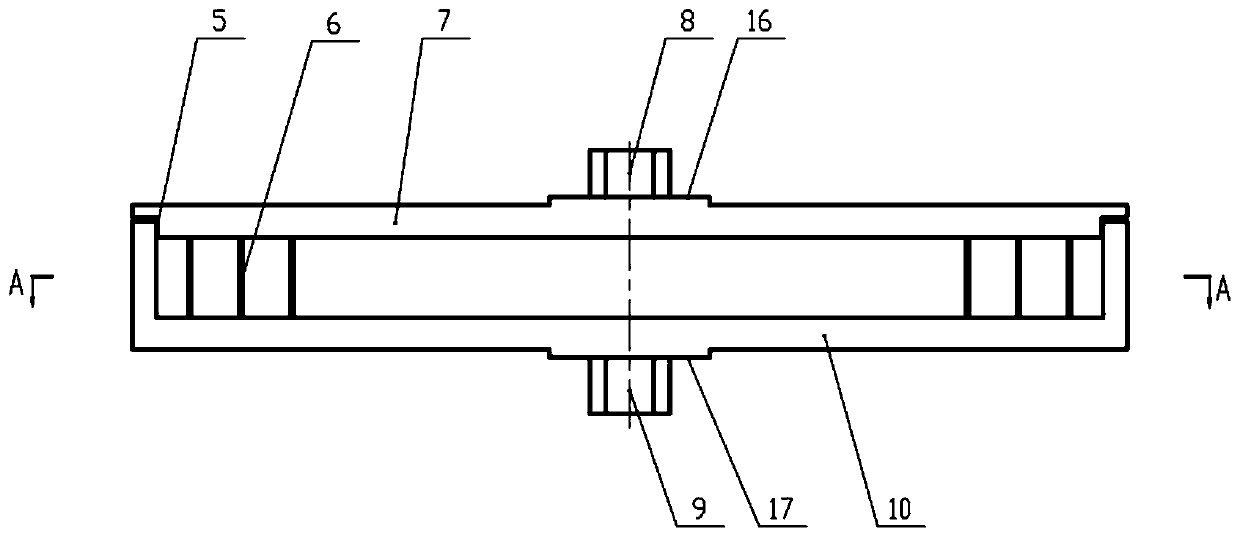

Air gap variant eddy speed regulating induction motor and working mode

InactiveCN101488691AWith soft startWith overload protectionMechanical energy handlingMagnetic circuit shape/form/constructionElectrical conductorElectric machine

A variable air gap vortex flow speed regulating induction motor can achieve the aim of transmitting torque from an electric motor to a load by the interaction of air gap field between an electrical conductor and a winding. The variable air gap vortex flow speed regulating induction motor comprises a stator, a rotor, an air gap regulating component and the like, and is characterized in that the stator (1) comprises an iron core and the winding, wherein, the iron core is fixed on an end cover (6); the rotor includes a copper disc (2) and a back yoke (3), and is fixed on an output rotating shaft (4) which can change the air gap distance between the stator (1) and the copper disc (2) by the air gap regulating component (5); the motor adopts a disc structure, and the intensity of the air gap field can be conveniently regulated by regulating the air gap regulating component on the output rotating shaft, thus achieving the aim of regulating the rotating speed and the torque of the motor and leading the motor to start at underload and operate at full load.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

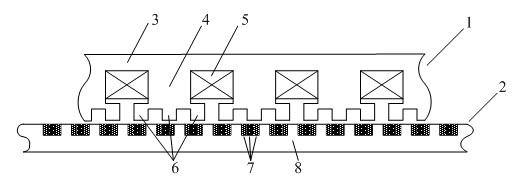

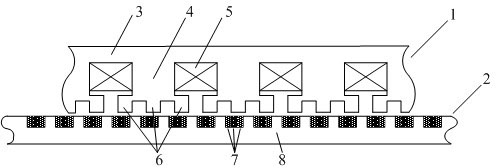

Permanent magnet vernier linear motor for urban rail transits

The invention relates to a permanent magnet vernier linear motor for urban rail transits, which comprises a motor primary (1), and a motor secondary (2) separated from the motor primary (1) through an air gap; the motor primary (1) comprises a flat primary iron core (3), an armature winding (5), flux modulation poles (6), wherein primary teeth (4) protruding out of the periphery of the primary iron core are arranged on the primary iron core (3), the armature winding (5) is wound on the primary teeth (4), and protruding small tooth portions on the primary teeth (4)are flux modulation poles (6), the motor primary (1) is mounted on a train; the motor secondary (2) comprises permanent magnets (7) and a secondary iron core (8), wherein permanent magnets (7) are embedded in the secondary iron core (8) along a horizontal direction in gaps with a same distance, and the motor secondary (2) is arranged on the train rail. The motor can improve the stability of the linear motor for urban rail transits during low velocity operation, the motor efficiency is improved, and high theoretical and practical values are provided.

Owner:SOUTHEAST UNIV

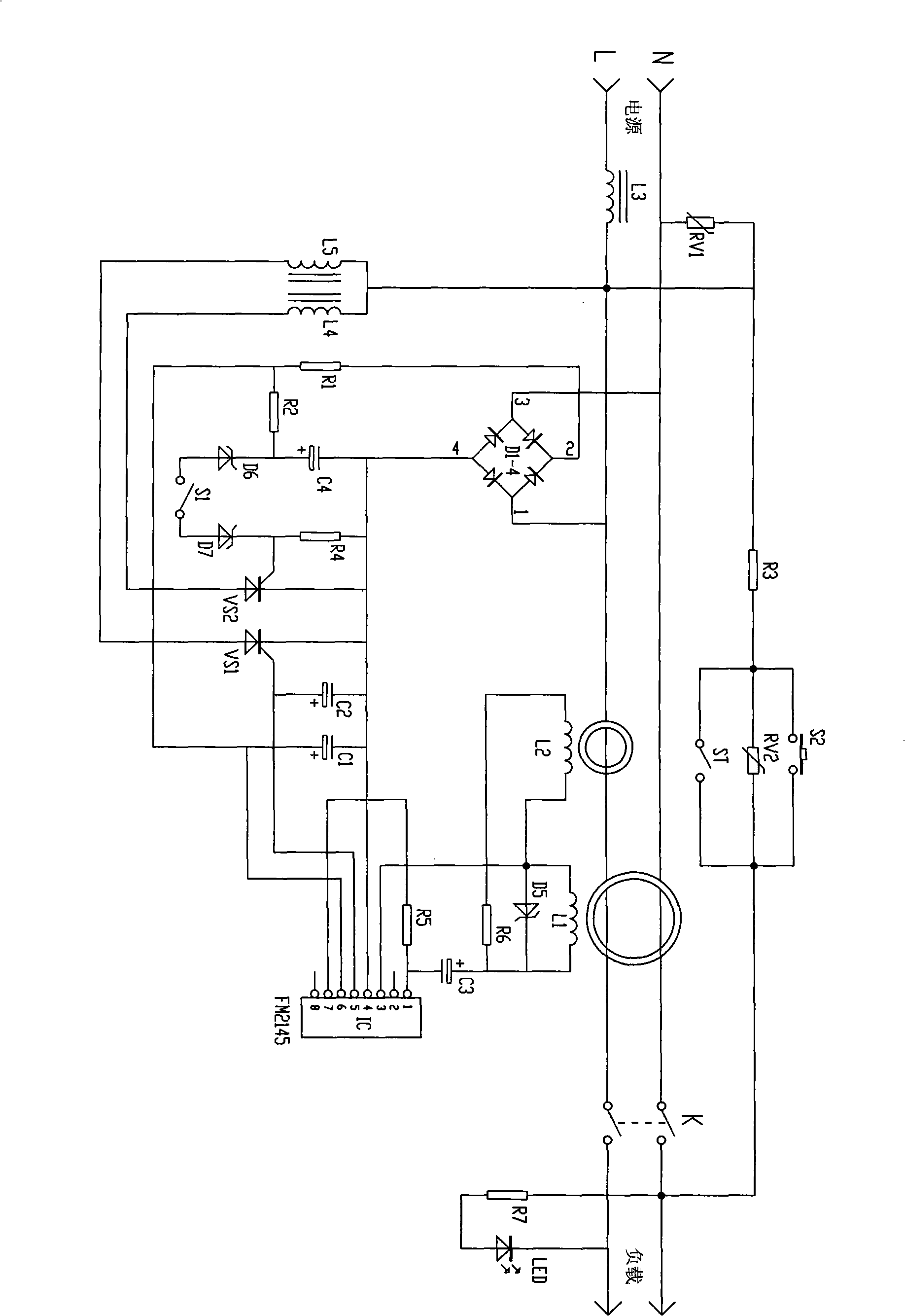

Control circuit of multifunctional protection socket

InactiveCN101316038AWith leakage protectionWith overload protectionCoupling device detailsArrangements responsive to excess currentShort circuit protectionEngineering

The invention discloses a control circuit for a multi-functional protection socket, comprising a signal processing chip IC, a zero sequence current transformer L1, a controllable silicon VS1, a releasing coil L5, a rectifier circuit, a testing circuit, an indicator circuit, a piezoresistor RV1 and other resistor-capacitor unit. The control circuit is characterized in that the control circuit also comprises an over-current transformer L2, a recovery coil L4, a controllable silicon VS2, a short circuit coil L3, a temperature switch ST and a piezoresistor RV2. As the invention has the functions of electric leakage protection, over-load protection, over-heat protection, short circuit protection, over-voltage protection, anti-thunder, etc., the control circuit has wider protection range, and can protect the lives and the possessions of people more effectively and safely.

Owner:汲怀利 +1

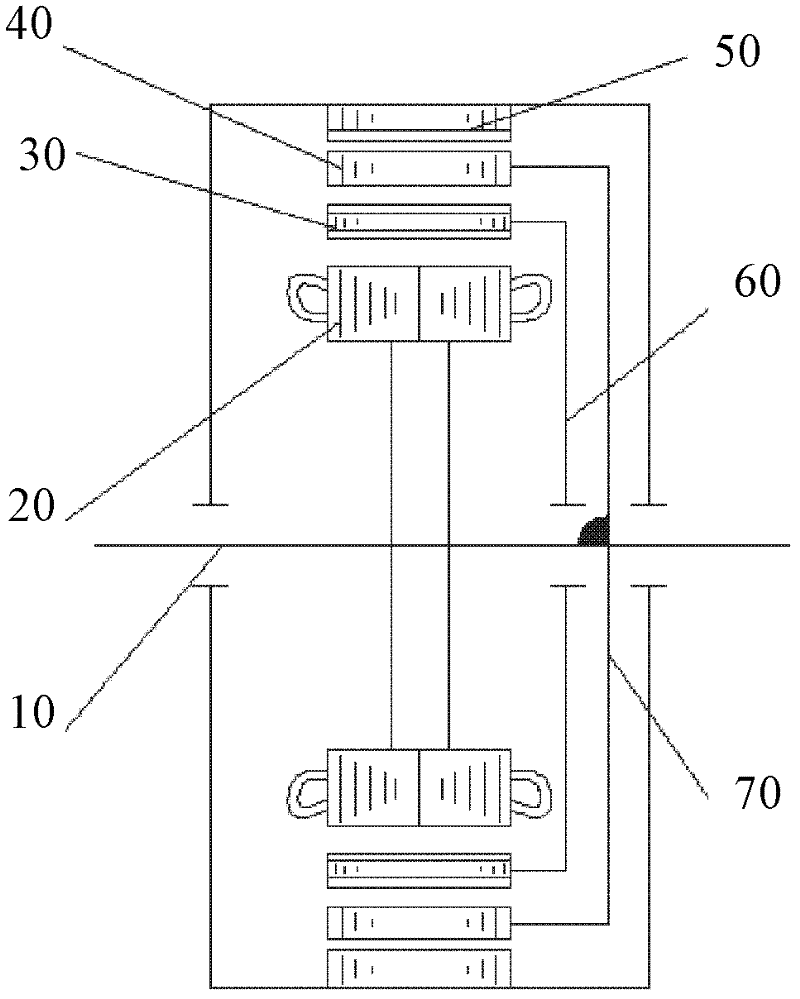

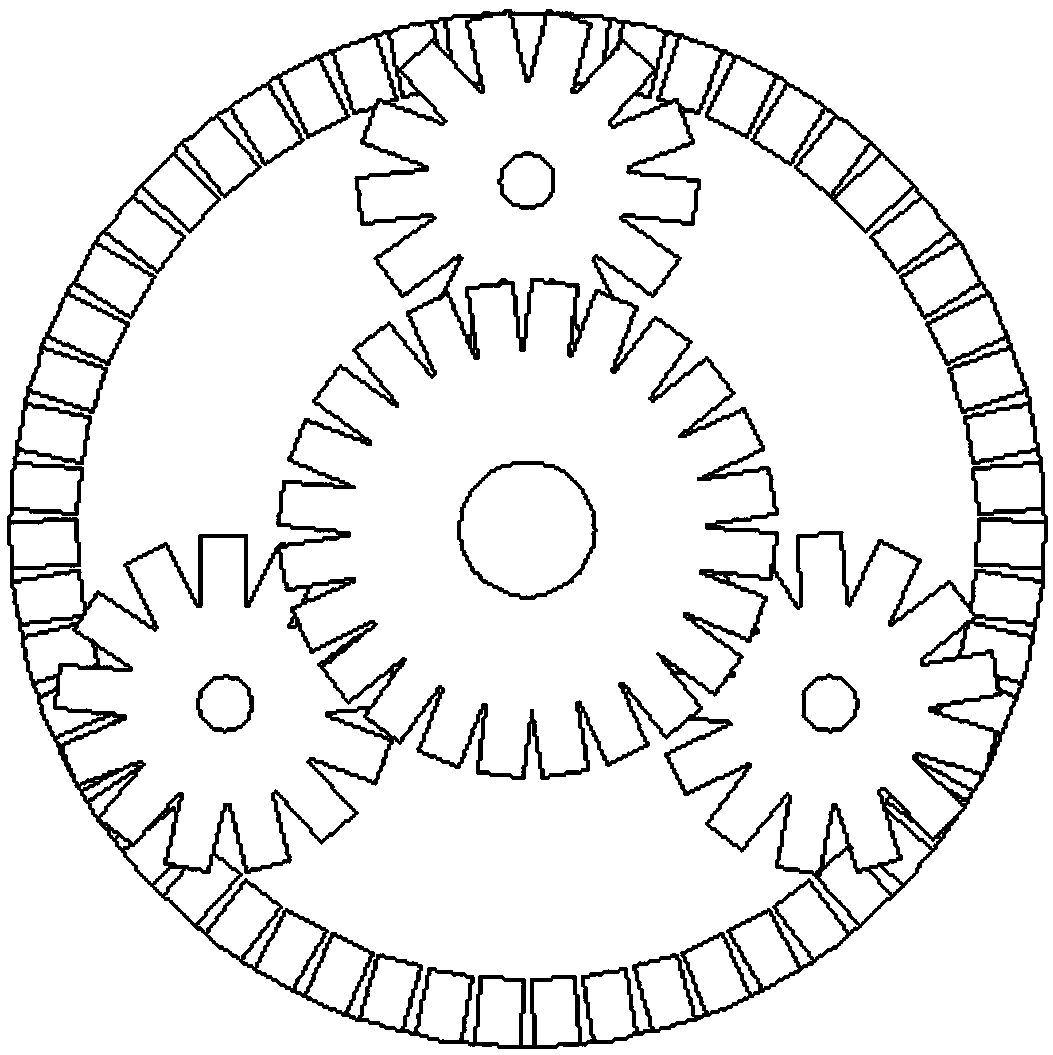

Magnetic gear-type composite hub motor

InactiveCN102647060AWith overload protectionReduce noiseDynamo-electric brakes/clutchesMagnetic circuit rotating partsLow speedMagnetic modulation

The invention provides a magnetic gear-type composite hub motor. The magnetic gear-type composite hub motor comprises a motor mandrel, an inner stator, a high-speed inner rotor, a magnetic modulation ring, and a low-speed outer rotor, wherein the inner stator, the inner rotor, the magnetic modulation ring, and the outer rotor are arranged around the motor mandrel in sequence, and are sequentially nested along the radial direction of the motor mandrel; the inner stator is fixed in the motor mandrel; the inner rotor is supported by an inner rotor support assembly and can rotate around the motor mandrel; the inner rotor support assembly is arranged on both sides of the inner rotor along the axial direction of the motor mandrel; the magnetic modulation ring is fixed on the motor mandrel through a magnetic modulation ring fixing panel; the magnetic modulation ring fixing panel is arranged on both sides of the magnetic modulation ring along the axial direction of the motor mandrel; the outer rotor is supported by an outer rotor support assembly and can rotate around the motor mandrel; the outer rotor support assembly is arranged on both sides of the outer rotor along the axial direction of the motor mandrel. The magnetic gear-type composite hub motor provided by the invention has high structural strength and rigidity, large rotation accuracy and output torque, is compact in structure, high in efficiency, small in vibration, and is suitable for direct-driven hub motor.

Owner:SHANGHAI JIAO TONG UNIV

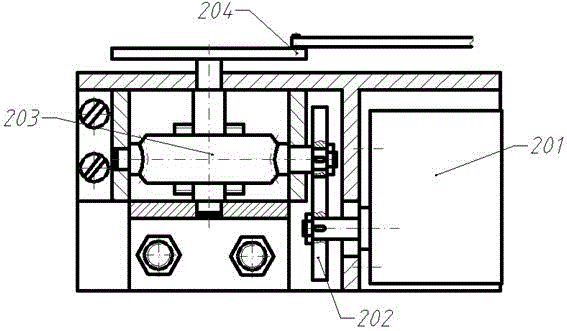

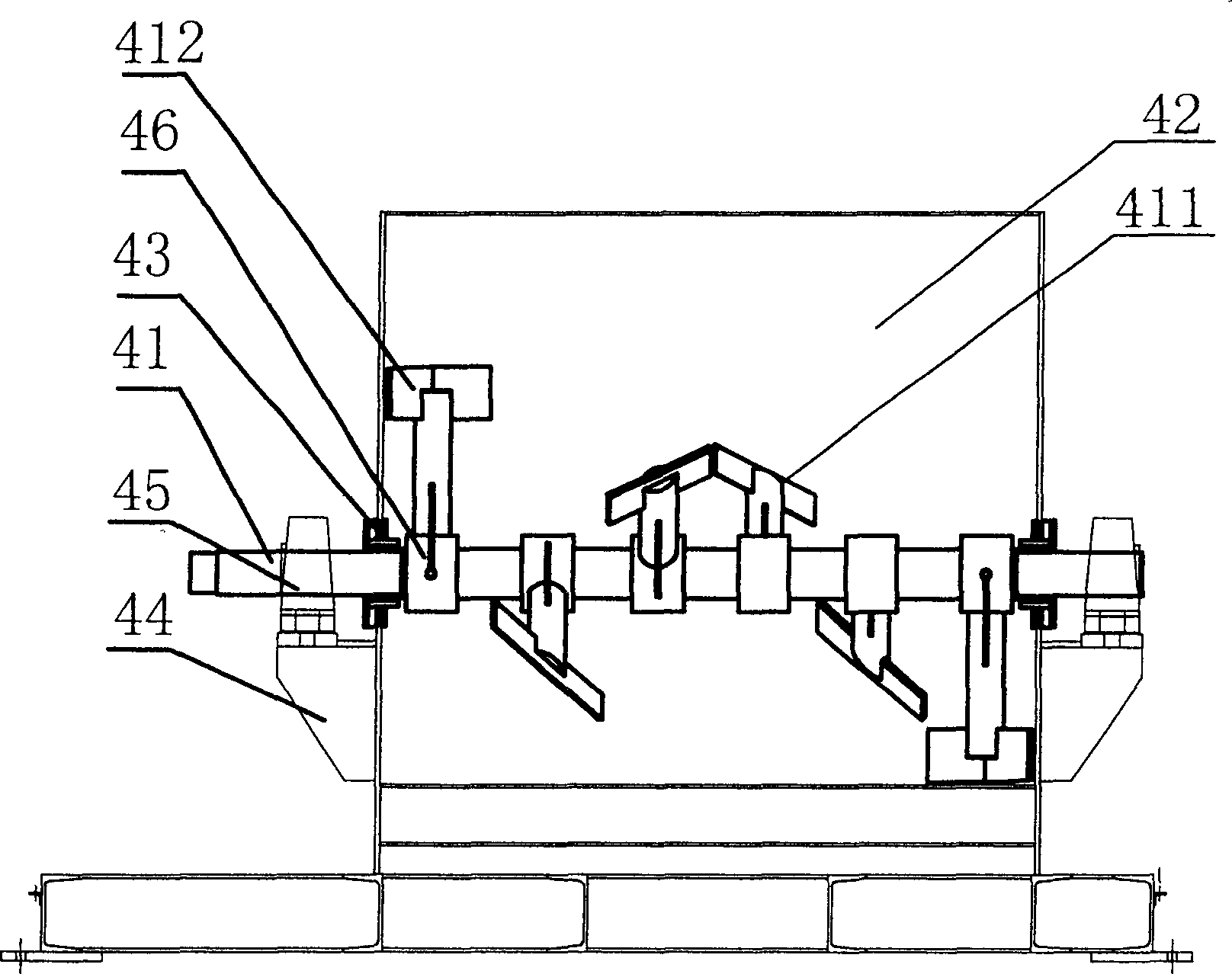

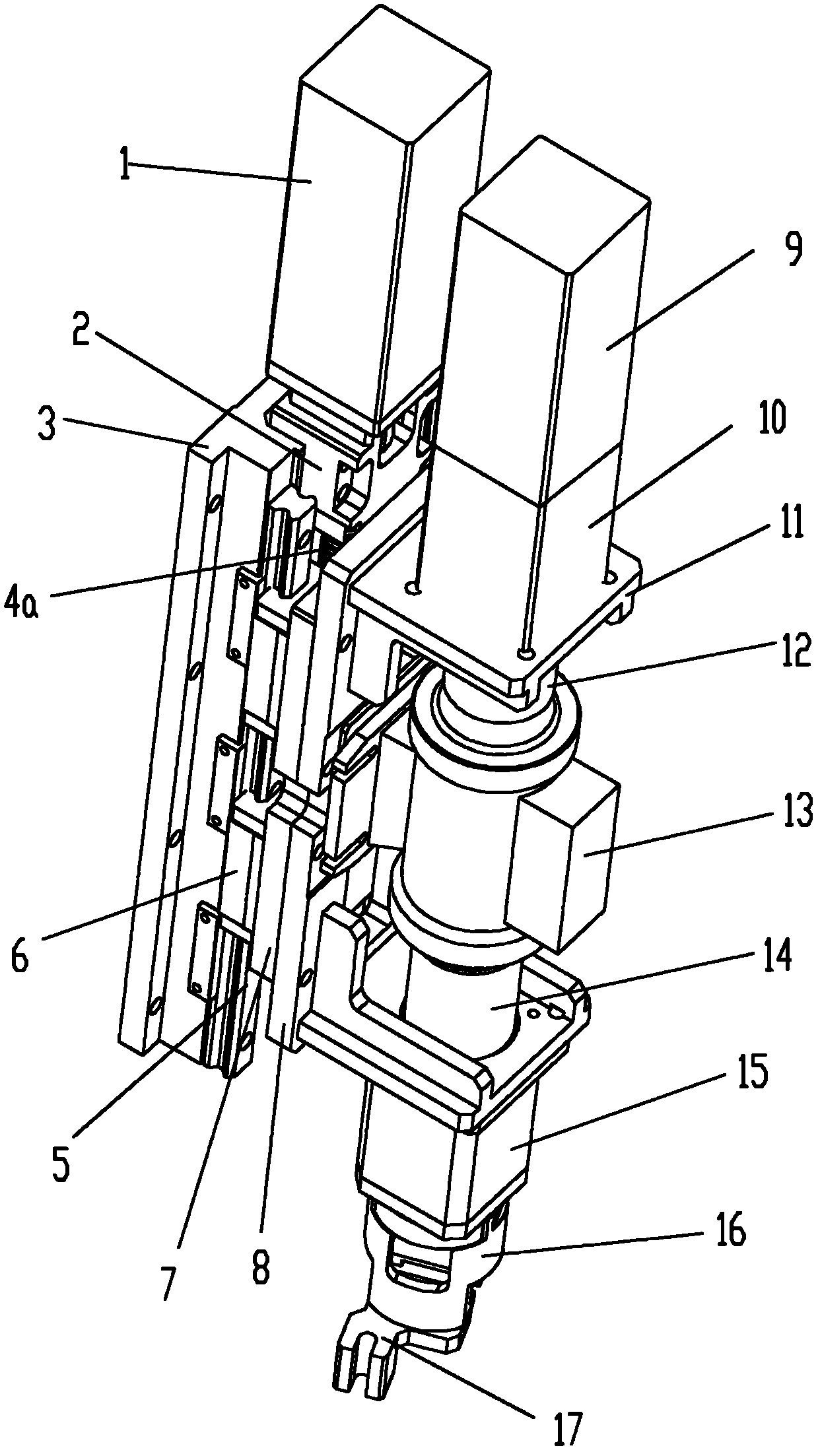

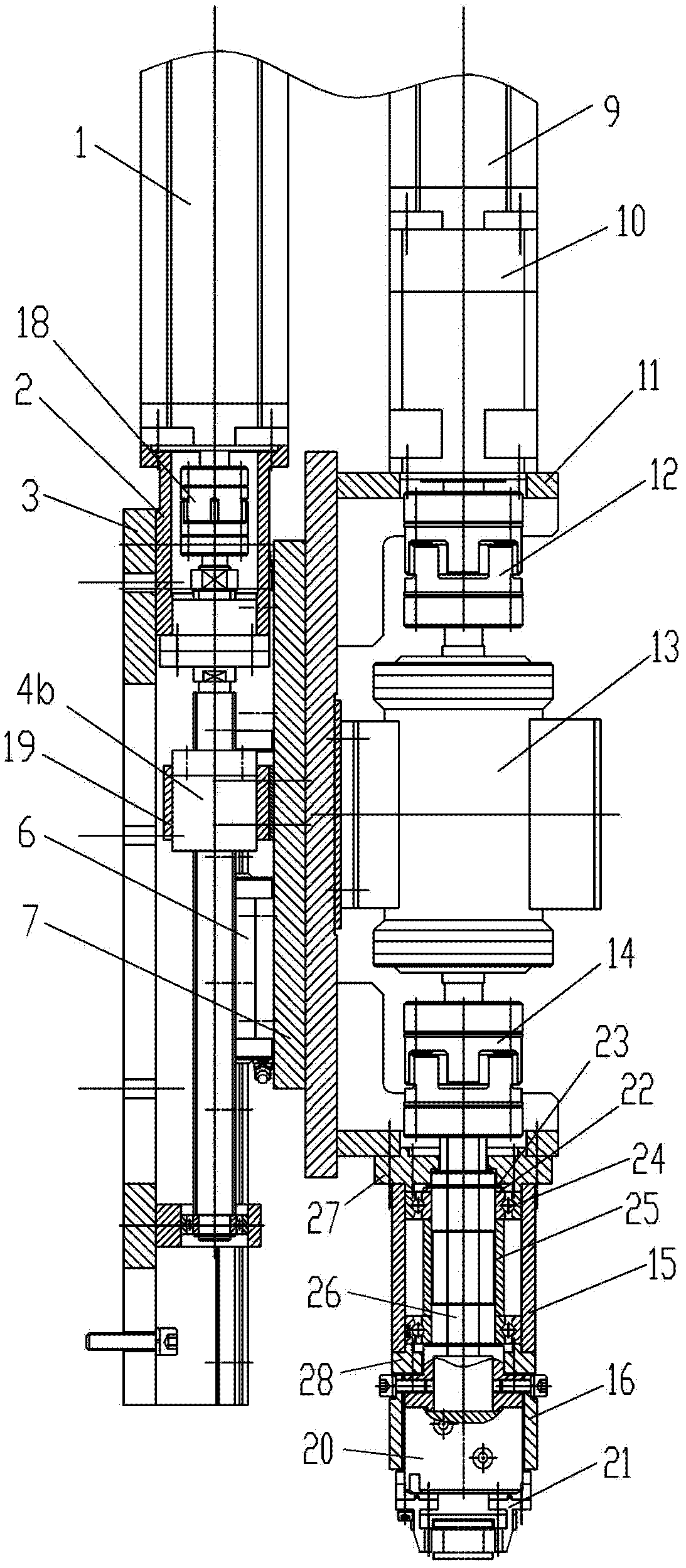

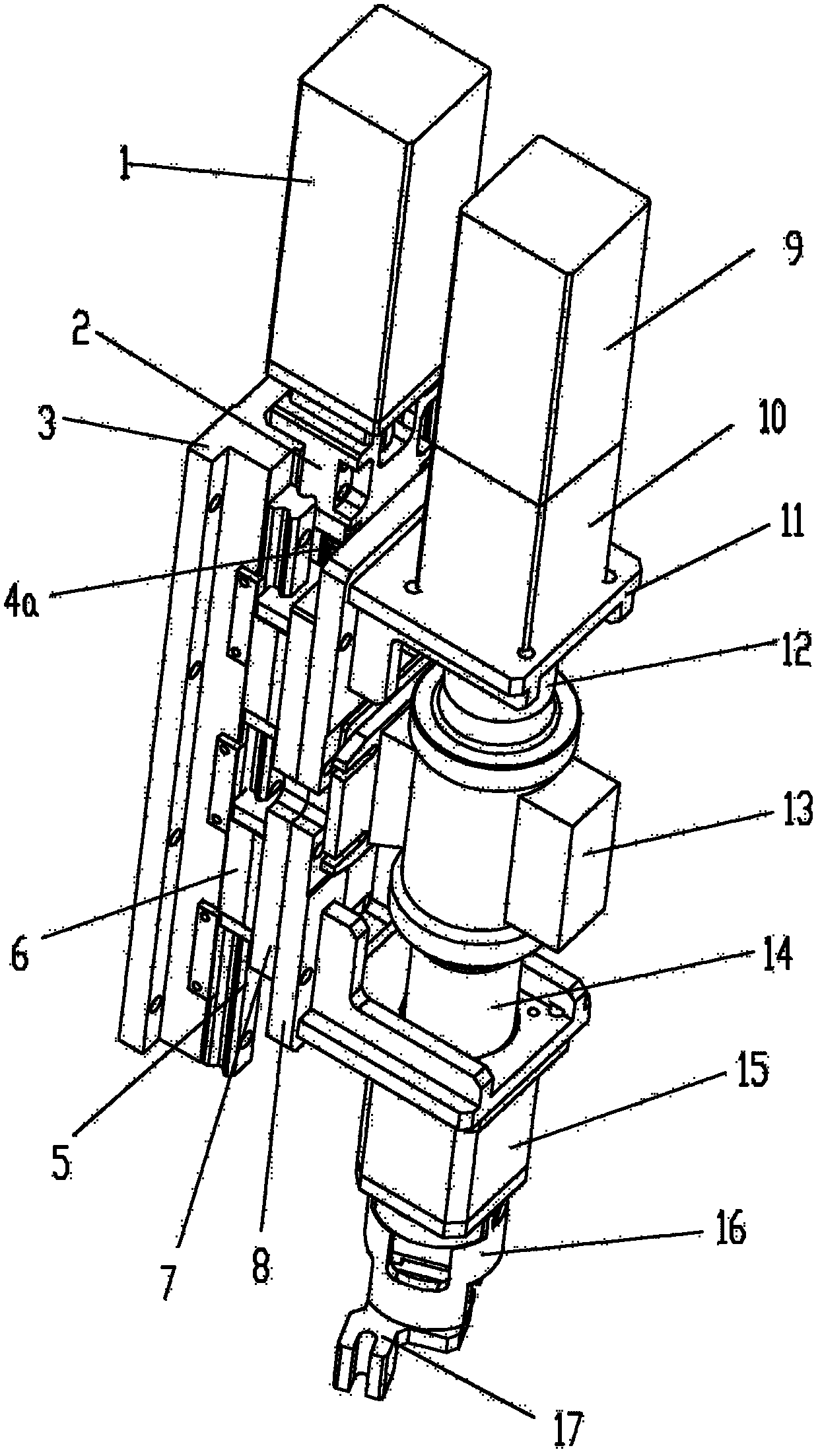

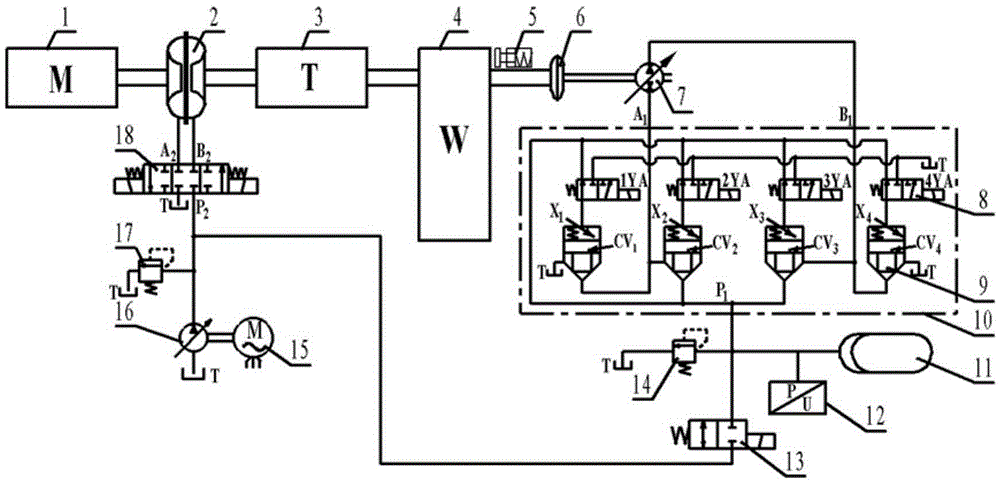

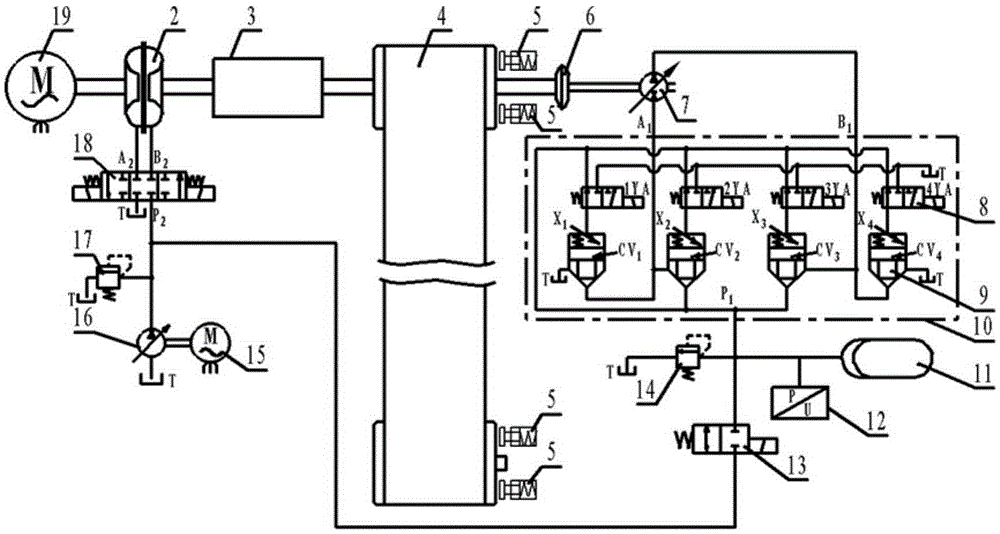

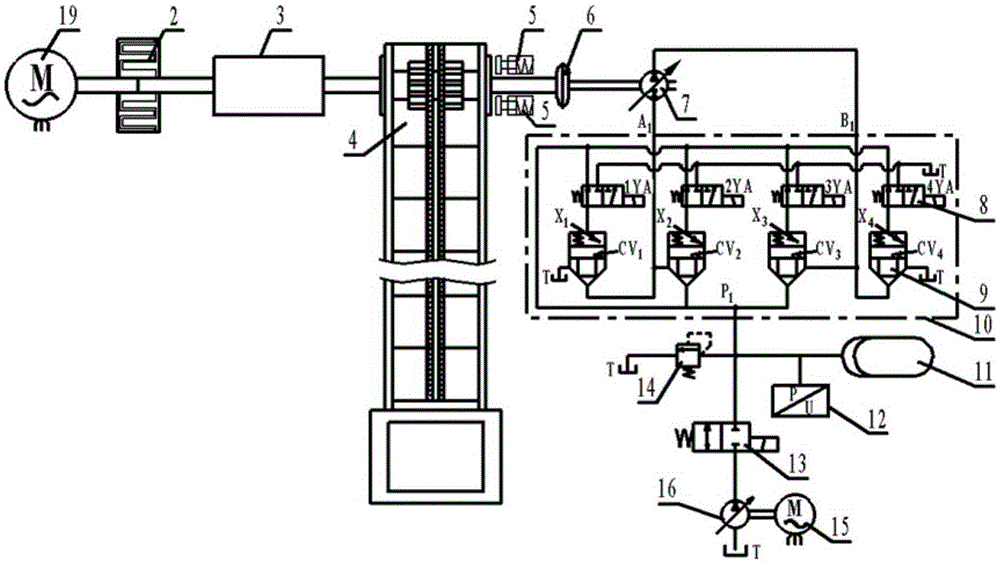

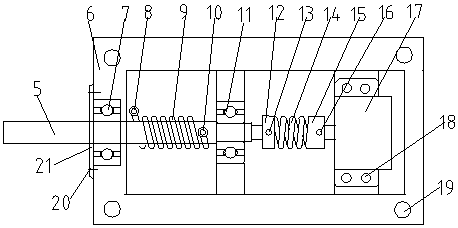

On-line loading test stand shift mechanism of manual transmission

ActiveCN102384845ARealize automatic shiftingSimple structureMachine gearing/transmission testingMotor driveDrive shaft

The invention discloses an on-line loading test stand shift mechanism of a manual transmission.The on-line loading test stand shift mechanism is characterized in that a gear selection unit is arranged and has a working principle that a gear selection servo motor drives a screw sliding table to slide along the axial direction of a ball screw; a gear shift unit has a working principle that a gear shift servo motor drives a gear shift shifting head through a transmission shaft to rotate for a set angle; the transmission shaft in the gear shift unit and the ball screw in the gear selection unit are in the same axial direction; the gear shift unit is supported by a gear shift unit support plate; the gear shift unit support plate is fixedly connected with the screw sliding table; and the screw sliding table drives the gear shift unit to slide along the axial direction of the ball screw. The on-line loading test stand shift mechanism has the advantages of simple structure and high control precision and can act accurately and reliably, and the manual transmission can automatically shift gears.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

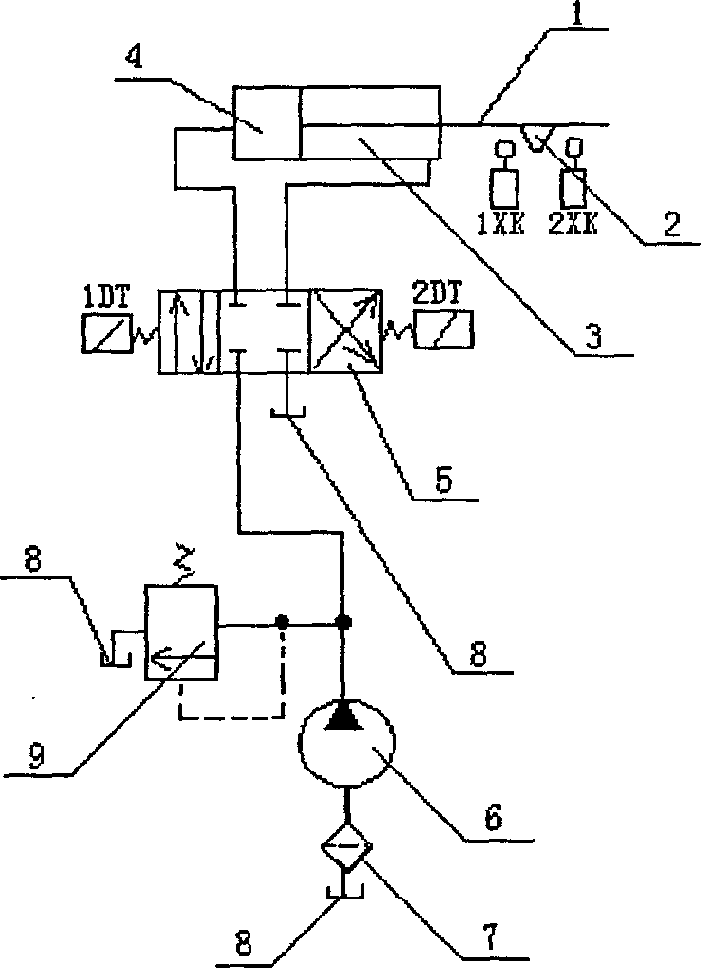

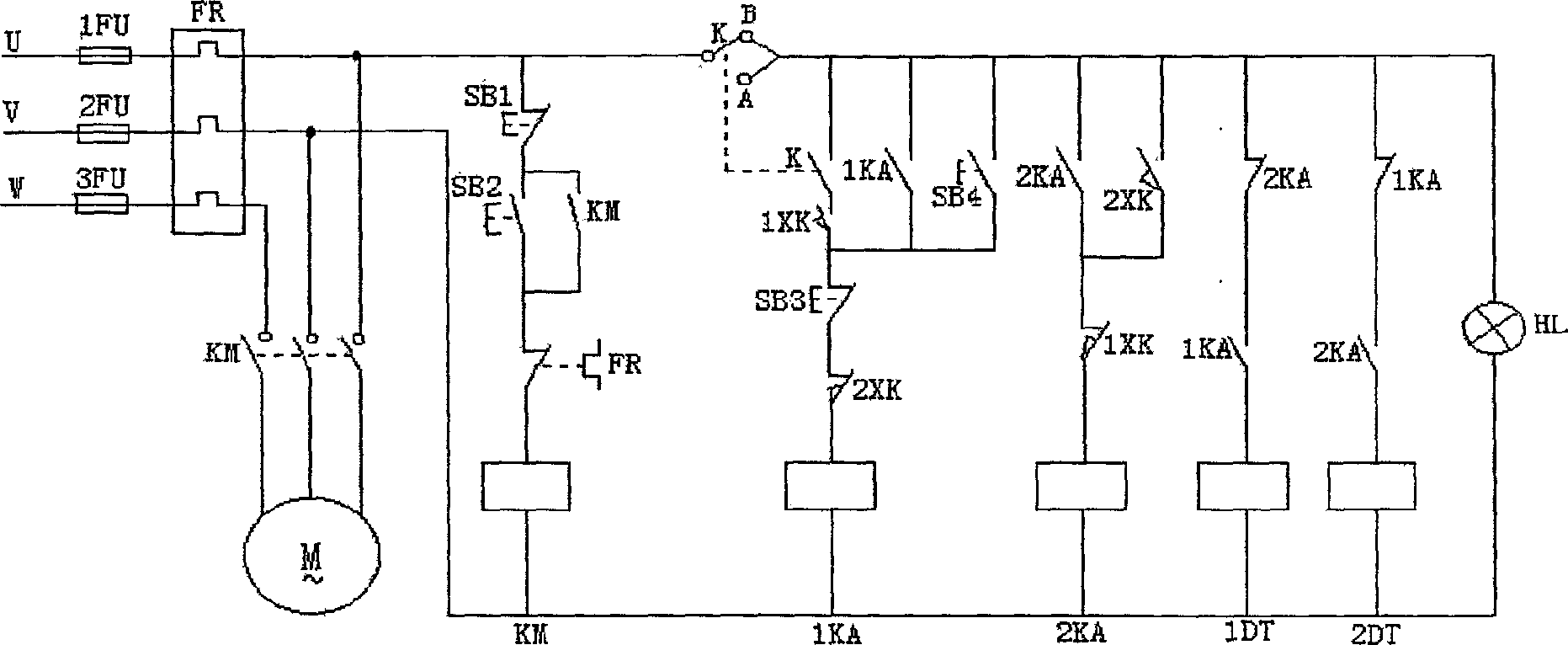

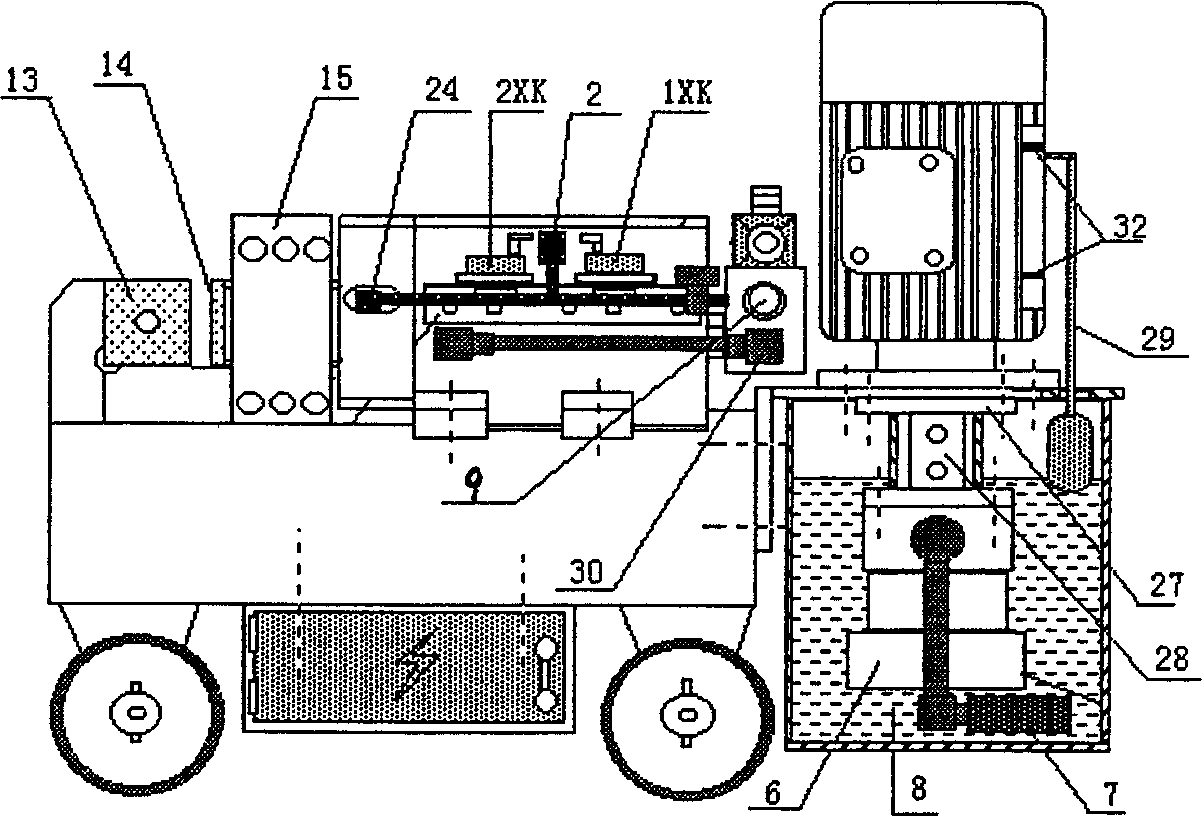

Hydraulic steel bar cutting machine

The hydraulic steel bar cutting machine includes machine base, cutter seat, hydraulic cylinder with piston rod, piston rod guiding seat, cutter fixed on the piston rod, sealing part between the piston rod and the hydraulic cylinder; motor driven oil pump connected via oil divider to the front cavity and the back cavity of the hydraulic cylinder, oil returning pipe connected between oil divider and oil tank; electromagnetic change-over valve with two electric magnets to control the front cavity and the back cavity separately; two stroke switches for limiting the range of the piston rod and corresponding touch blocks on the piston rod; and one circular control mechanism comprising the two stroke switches and the two electric magnets.

Owner:张永生

Mechanical soft starting auxiliary driving device

ActiveCN105298993AVersatilityAuxiliary drive for soft startActuator accumulatorsFluid-pressure actuator componentsClutchEnergy recycling

The invention discloses a mechanical soft starting auxiliary driving device. The mechanical soft starting auxiliary driving device comprises a prime motor, a mechanical soft starting device, a speed changing device, a working mechanism, a gate control system, a clutch, a second driving motor, a hydraulic pump, a second safe valve, a three-position four-way control valve, a controller, a power device, a combined reversing valve, an energy accumulator, a pressure sensor, a two-position two-way control valve and a first safe valve. When the working mechanism starts, the power device is in the hydraulic motor working condition to assist in starting of the working mechanism, and when the working mechanism brakes, the power device is in the pump working condition to assist in braking. By means of the mechanical soft starting auxiliary driving device, the effects of soft starting and soft stopping of common driving devices can be achieved, moreover, auxiliary braking and braking energy recycling can be achieved through an energy recycling device, the energy consumption of the working mechanism in the starting and stopping process is reduced, and the problem that the common existing driving devices cannot achieve energy saving effect basically is solved.

Owner:TAIYUAN UNIV OF TECH

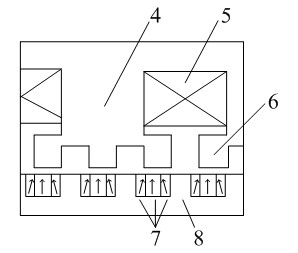

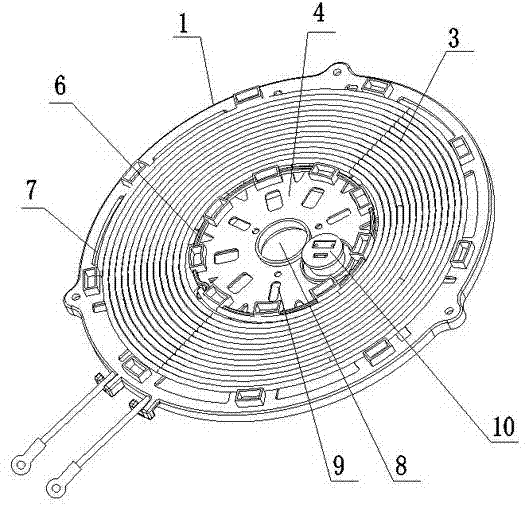

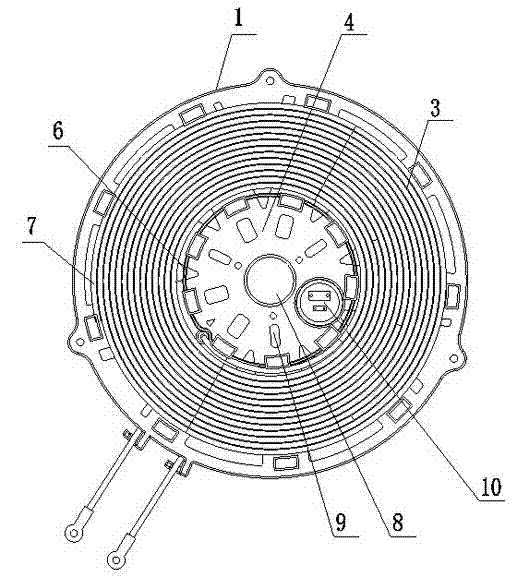

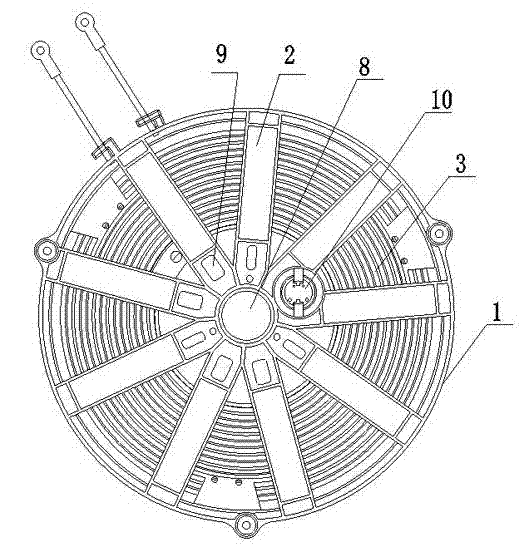

Heating coil panel

InactiveCN103118450AEvenly distributedSpread evenlyDomestic stoves or rangesCoil arrangementsEngineeringArea coverage

The invention relates to the electromagnetic induction heating field, in particular to a heating coil panel used for induction cookers. The heating coil panel comprises a coil base panel, and a magnetic stripe, wire slots and heating coils wound in the wire slots which are all arranged on the coil base panel, and further comprises a terminal convenient for coiling of the heating coils, wherein the terminal is composed of an input terminal and an output terminal. The heating coil panel is characterized in that, a winding centre area and a coiling area are arranged on the coil base panel from the centre to the periphery, wherein the diameter of the winding centre area is at least 70mm, a plurality of wire slots are arranged in the coiling area, the wire slots are separated by a plurality of wire slot separation plates, at least one layer of heating coils wound around the wire slots is arranged in the coiling area, more than two layers of heating coils overlapped up and down are arranged in the coiling area, and as the number of layers of the coils increases, distances from the heating coils to the center of the coil base panel gradually increase, and therefore the heating coils are in a ladder shape with the width gradually increasing from top to down. The heating coil panel is large in the outer ring, large in heating area coverage, rapid and uniform in heat spread, and high in heating efficiency.

Owner:浙江乐太电器有限公司

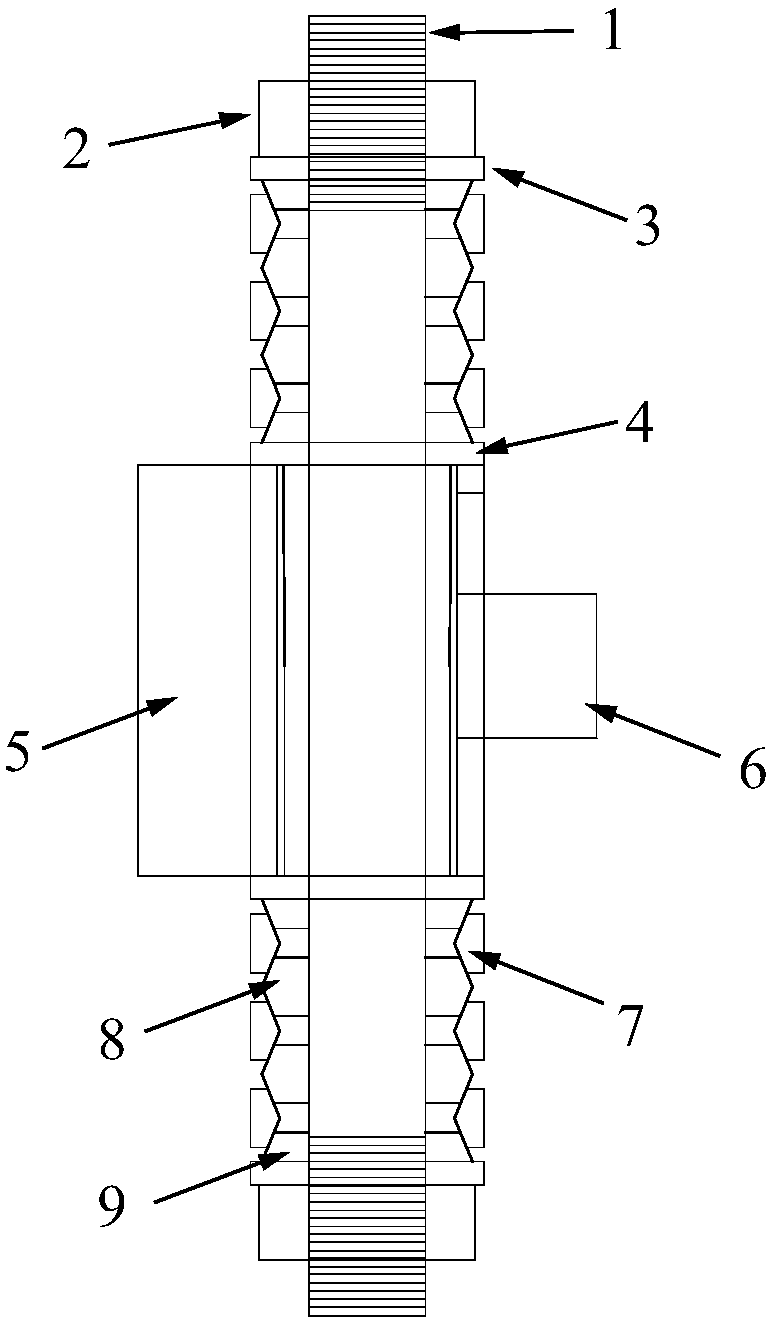

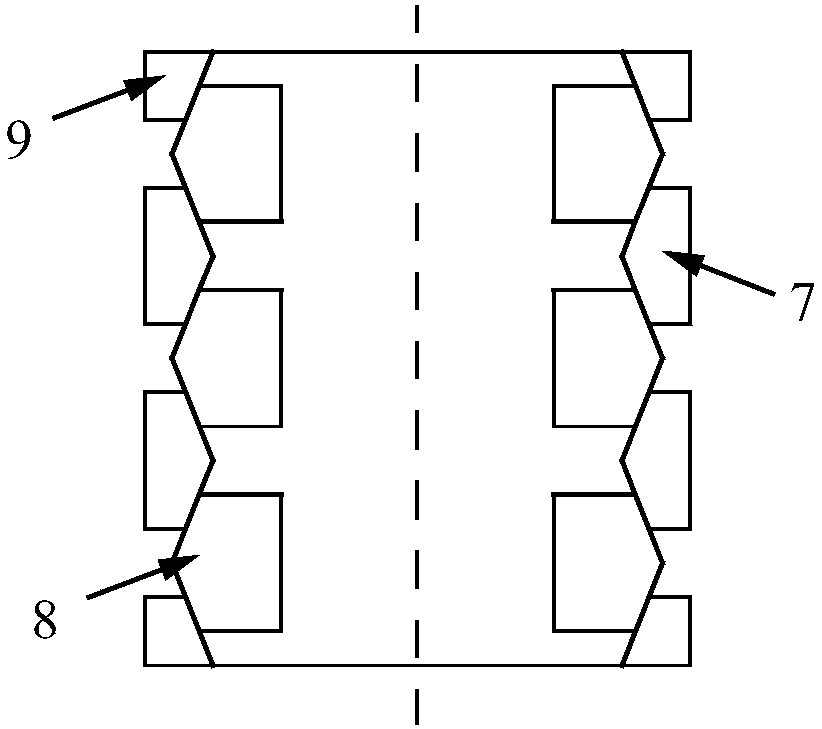

Earthquake non-loss and self-resetting energy-dissipation device for swing core

ActiveCN108590302ASimple structureThe mechanism of action is clearProtective buildings/sheltersShock proofingRelative displacementEngineering

The invention discloses an earthquake non-loss and self-resetting energy-dissipation device for a swing core. The earthquake non-loss and self-resetting energy-dissipation device for the swing core comprises a core screw, a compound connecting piece arranged on the core screw in a sleeving mode, limiting pieces arranged at two ends of the core screw, and ring spring groups which are arranged on the core screw in a sleeving mode and separately located between the two ends of the compound connecting piece and the two limiting pieces. The compound connecting piece comprises a first connecting piece and a second connecting piece, wherein the second connecting piece is arranged on the outer side of the middle portion of the core screw in a sleeving mode and can move in the axial direction of the core screw, and the first connecting piece is arranged on the outer side of the second connecting piece in a sleeving mode to enable the first connecting piece and the second connecting piece to generate relative displacement in the axial direction of the core screw. Compared with the prior art, the earthquake non-loss and self-resetting energy-dissipation device is simple in structure, clear inmechanism and stable in self-resetting energy dissipation performance, all components remain elasticity in the earthquake process, repair nor replacement is not needed after an earthquake, no economic loss is generated, and extensive application value is achieved.

Owner:TONGJI UNIV

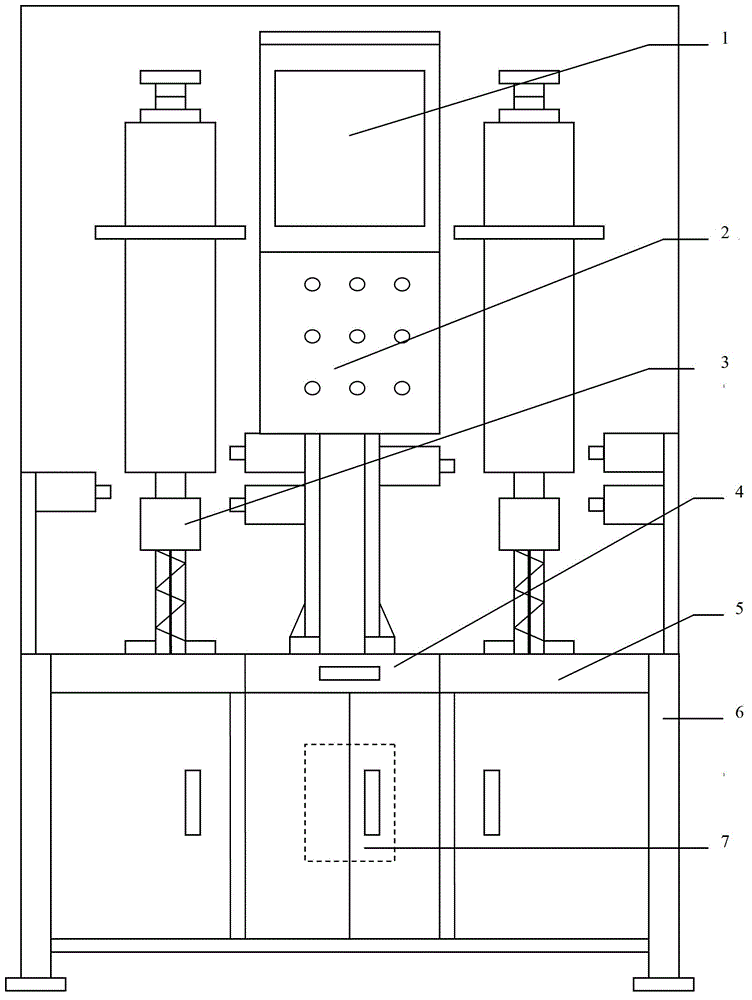

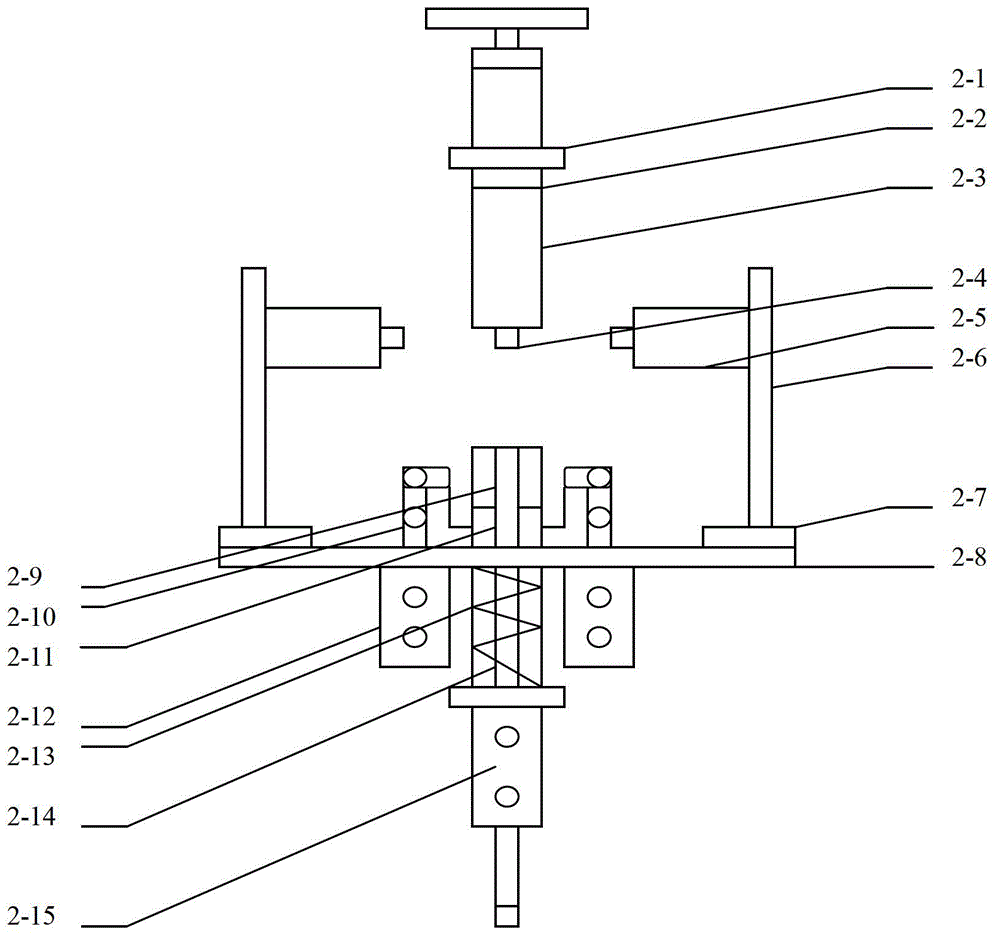

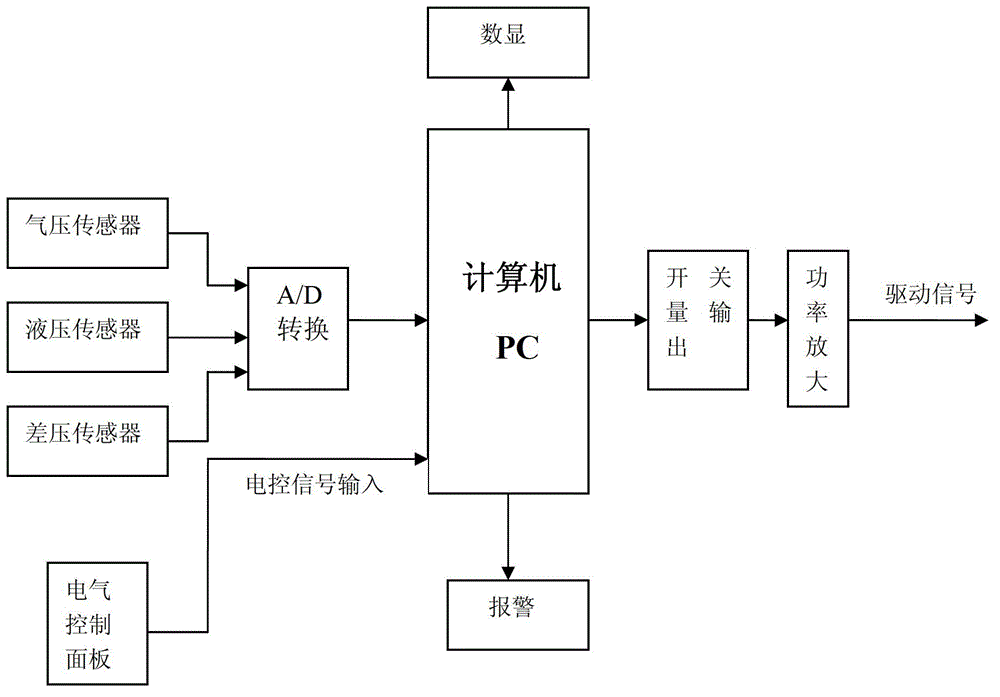

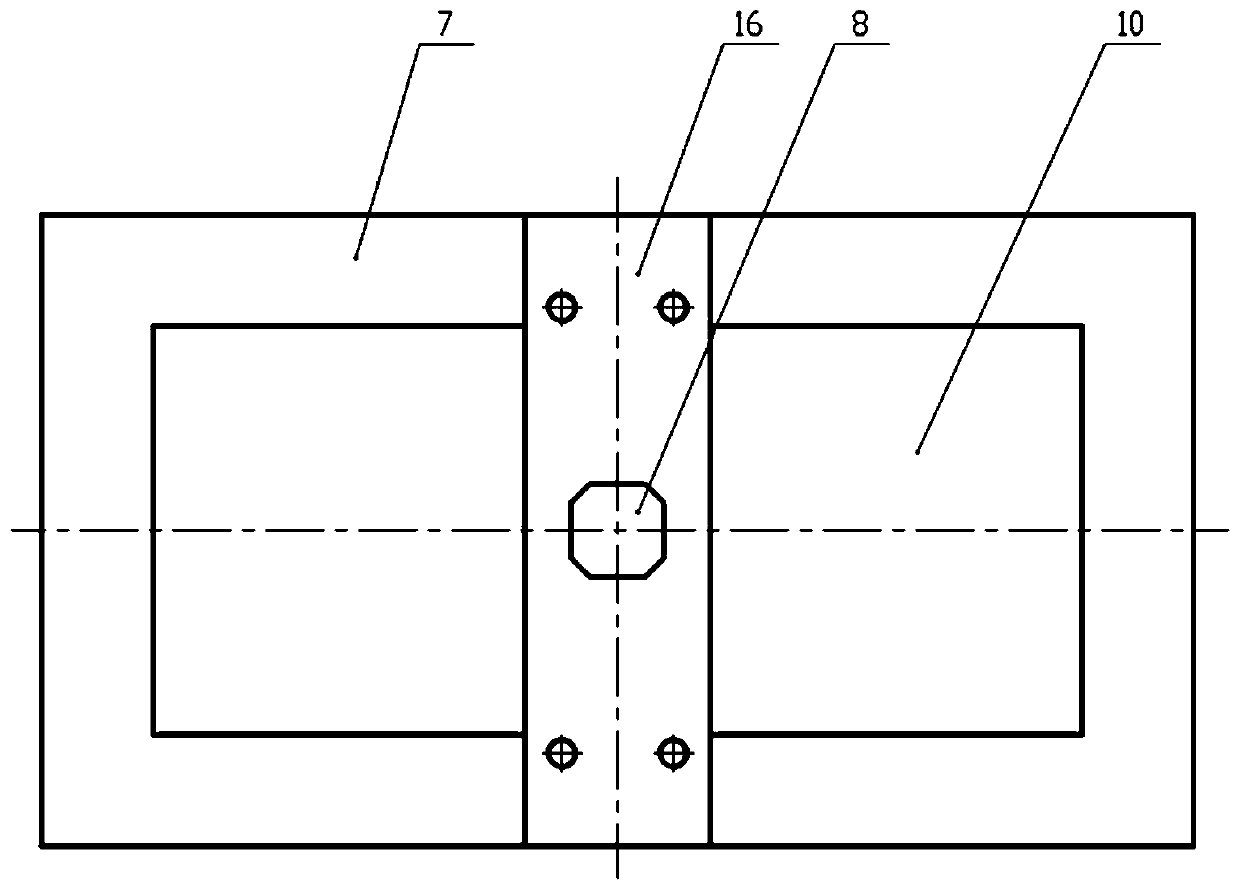

Double-station online detection platform for tightness of clutch booster

ActiveCN102865975AImprove general performanceRealize double-station online monitoringMeasurement of fluid loss/gain rateLiquid-crystal displayTest-and-set

The invention discloses a double-station online detection platform for the tightness of a clutch booster. The conventional apparatus is low in stability and test accuracy. The double-station online detection platform comprises a liquid crystal display, a fast insertion box, clamping and test devices, a keyboard area, a control box, a rack and a personal computer (PC). The PC, the keyboard area and the control box are arranged in the rack. The liquid crystal display is arranged at a central position above the rack. The quick insertion box is arranged below the liquid crystal display. A plurality of fast insertion joints are arranged on the fast insertion box, comprise interfaces for controlling the advance and retreat of downward pressing cylinders and side sealing cylinders, and are connected with corresponding advance and retreat interfaces of the downward pressing cylinders and the side sealing cylinders respectively. A plurality of control switches are arranged in the control box, and control the opening and closing states of a plurality of electromagnetic valves respectively. The clamping and test devices are arranged on the two sides of the liquid crystal display. The keyboard area is used for controlling the PC to operate, selecting contents to be tested and setting the time of a test flow. A detection process of the double-station online detection platform is automatic, the clutch booster can be fast clamped, a judgment of qualification is automatically made, and a sound and light alarm is automatically given.

Owner:HANGZHOU WOLEI INTELLIGENT TECH

Mine handheld hydraulic drilling rig based on multi-action inner curve radial hydraulic motor

The invention discloses a mine handheld hydraulic drilling rig based on a multi-action inner curve radial hydraulic motor. The drilling rig comprises a rig body upper casing, a rig body lower casing, the multi-action inner curve radial hydraulic motor, a coupling, a drill pipe and a drill bit. Handholding rods are mounted on left and right sides of the rig body upper casing to control the hydraulic drilling rig by the aid of holding force of palms; high-pressure oil enters the multi-action inner curve radial hydraulic motor from an oil inlet in a central area of the rig body upper casing and pushes pistons and cross beams in the multi-action inner curve radial hydraulic motor to press towards the inner curve surface of a stator, rollers are located on the cross beams, are directly contacted with the inner curve surface of the stator and act mutually to produce axial force to push a rotor to rotate so as to drive the drill pipe to rotate to drive the drill bit to drill holes. The mine handheld hydraulic drilling rig has the advantages that stress balance is realized, the handholding rods of the drilling rig are easy to hold, the torque is large, the safety is high and the like.

Owner:ANHUI UNIV OF SCI & TECH

Design method of magnetic type planet gear

The invention provides a design method of a magnetic type planet gear mechanism. The design method of the magnetic type planet gear mechanism is used for solving the technical problem of magnetic typeplanet gear transmission. The magnetic type planet gear mechanism comprises a magnetic sun gear, a magnetic center gear, a magnetic planet gear, a small transmission shaft, a large transmission shaftand a sleeve, the center gear and the magnetic planet gear are axially connected in parallel, and the magnetic sun gear is correspondingly in axial series connection with the magnetic center gear andthe magnetic planet gear; magnetic poles of axially opposite magnetic tooth blocks are different, so that axial attraction is generated, off-axial opposite magnetic poles are the same, so that axialmutex force is generated, automatic core adjustment is realized, and an incomplete axial coupling area is formed; and the acting force between the magnetic tooth blocks is compensated mutually throughthe magnitude of the attraction and the mutex force, and stable torque transmission is formed. The design method of the magnetic type planet gear mechanism has the beneficial effects that noise and vibration generated by mechanical meshing are removed fundamentally, and the reliability of a transmission system is increased; the torque density is high and a fixed peak value is achieved, the returndifference of transmission is decreased, automatic decoupling is carried out during overload, transmission connection is cut off, and a prime motor is protected.

Owner:UNIV OF JINAN

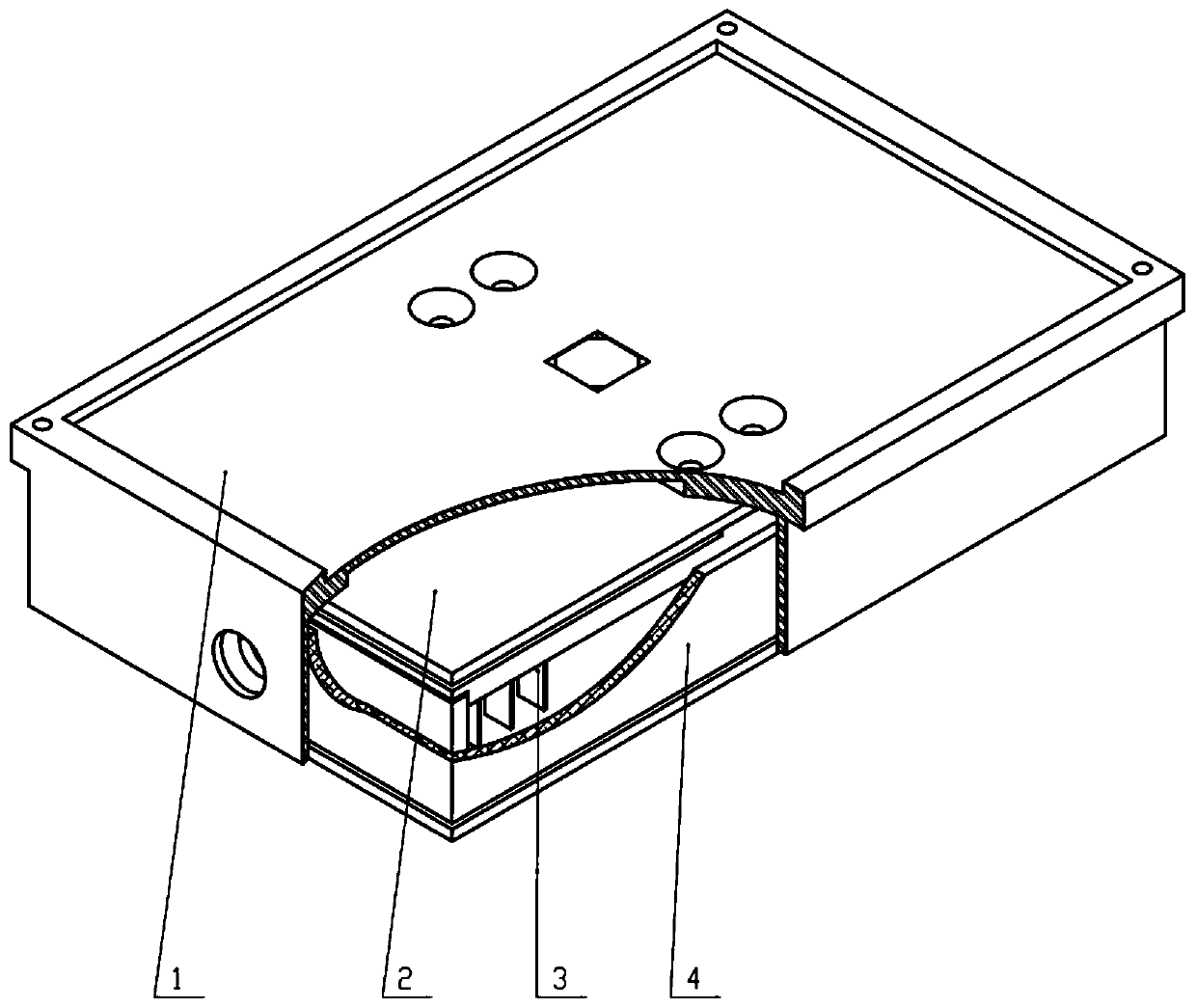

Surface frictional resistance wind tunnel measurement method based on box type frictional resistance balance

ActiveCN111175016AReduce the effect of temperatureImprove anti-interference abilityAerodynamic testingFlight vehicleData acquisition

The invention discloses a surface frictional resistance wind tunnel measurement method based on a box type frictional resistance balance. According to the method, a special box type frictional resistance balance is used. The method comprises the following steps: 1, ; processing and calibrating the box type frictional resistance balance; inputting a resistance calculation formula of the box-type frictional resistance balance into a wind tunnel data collection system; design processing test model, a test model is installed in a wind tunnel, a box-type frictional resistance balance is installed in the wind tunnel, a measuring part is fixed on an upper connecting cover of the box-type frictional resistance balance, the width of a narrow slit among a model front cover plate, the measuring partand a model rear cover plate is adjusted, a balance line is connected to a wind tunnel data collection system, and the posture of the test model is adjusted to carry out a wind tunnel test. The box type frictional resistance balance special for the method has good temperature response capability and has overload protection and heat insulation protection functions. The method is low in cost, good in benefit, easy to operate, and especially suitable for accurate measurement of aircraft surface frictional resistance in high-speed and hypersonic wind tunnels.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

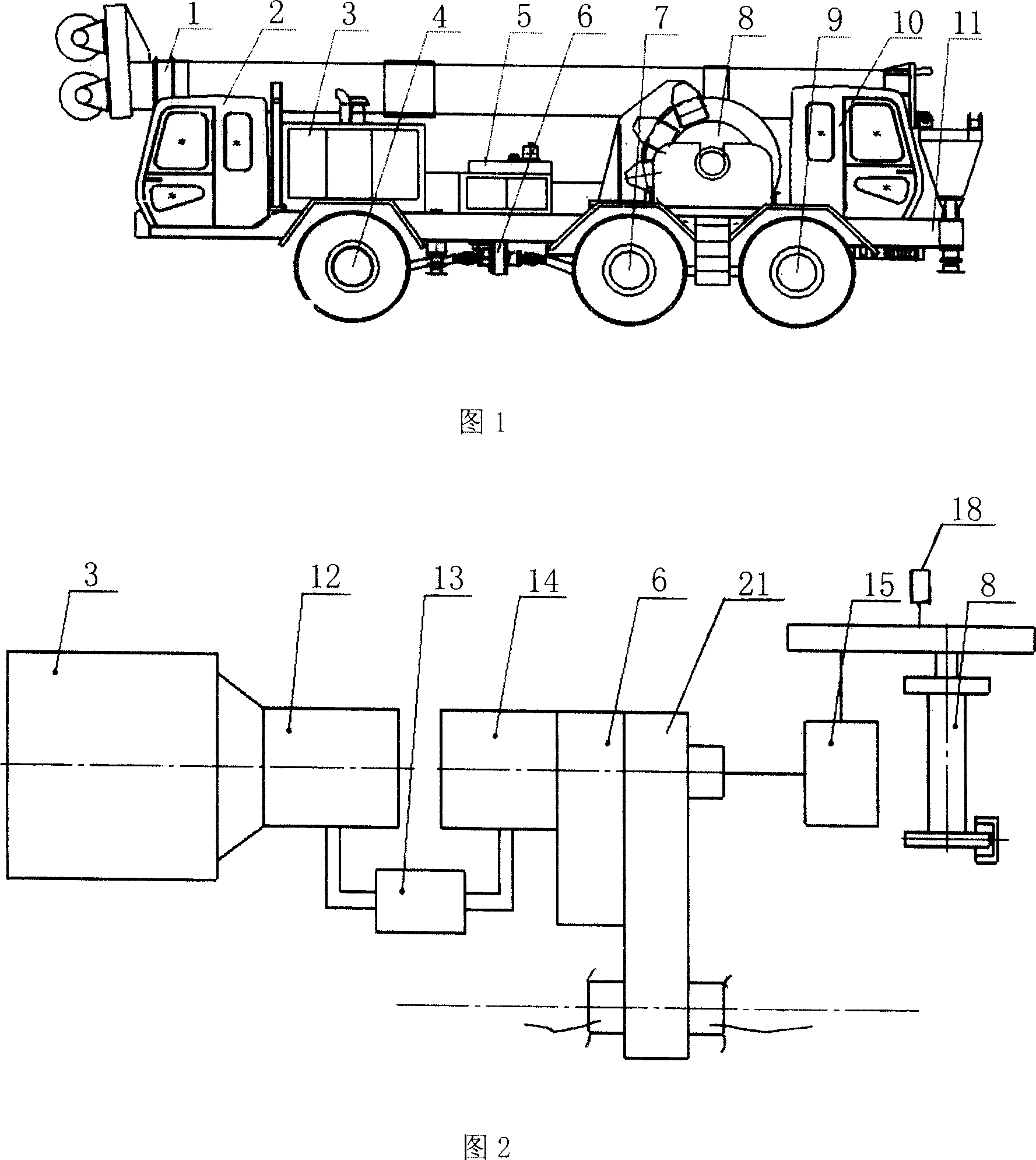

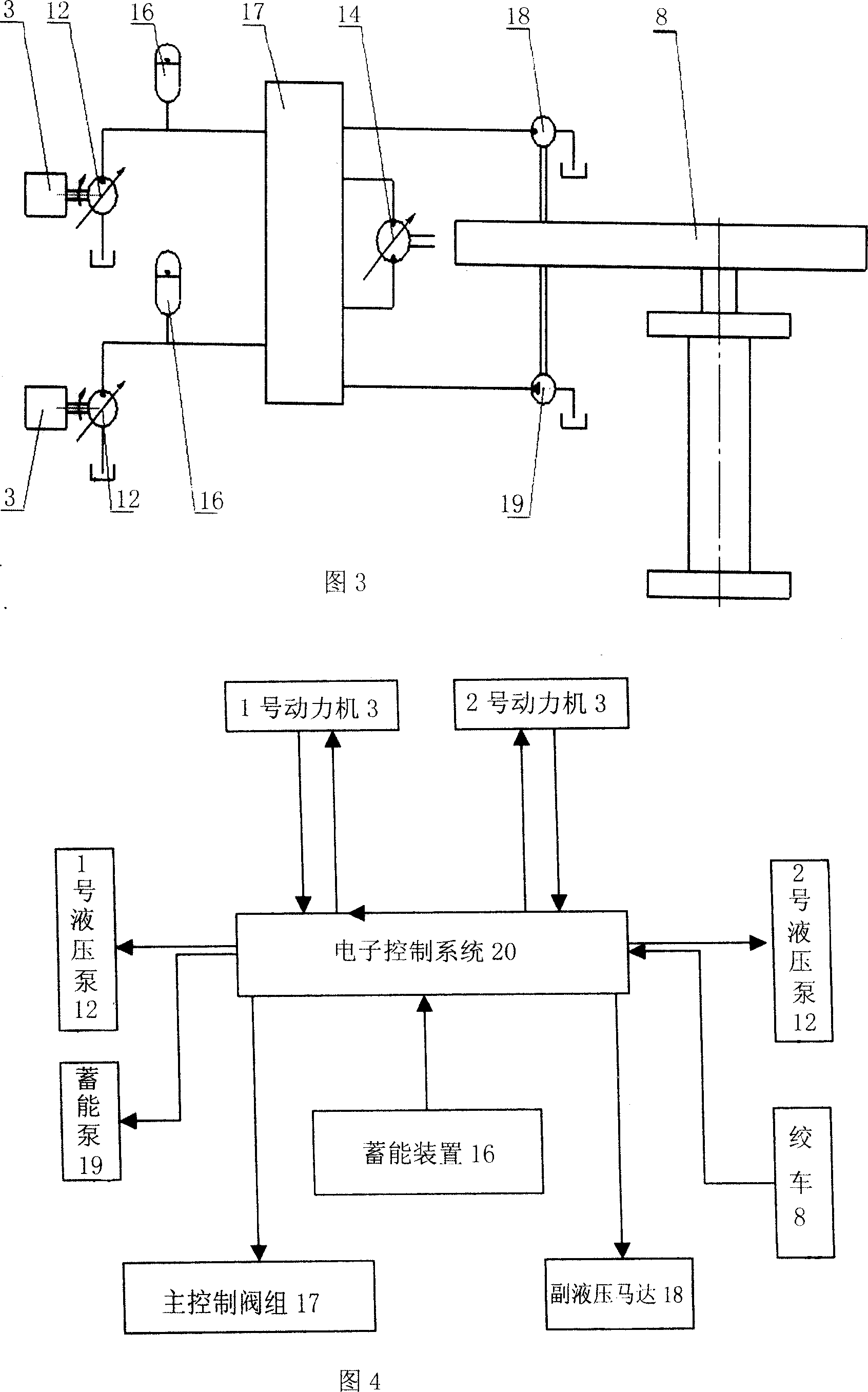

Hybrid power well repairing machine

InactiveCN1987039ATo achieve the purpose of energy saving and environmental protectionTo achieve the purpose of energy savingDrilling rodsDerricks/mastsVehicle frameHydraulic pump

A well repairing truck is composed of truck frame, driver cab, engine system, front, middle and back bridges, hydraulic oil tank, speed varying gear, winder, operating cab, the drive system consisting of power output unit, speed variator, primary and secondary hydraulic motors, commutation valve, hydraulic pump, power unit, winder, etc, the hydraulic system consisting of winder, primary and secondary hydraulic motors, energy accumulating pump, master control valve set, energy accumulator, hydraulic pump and power unit, and the electronic control system.

Owner:SHENGLI OIL FIELD SHENGLI POWER MACHINERY GRP

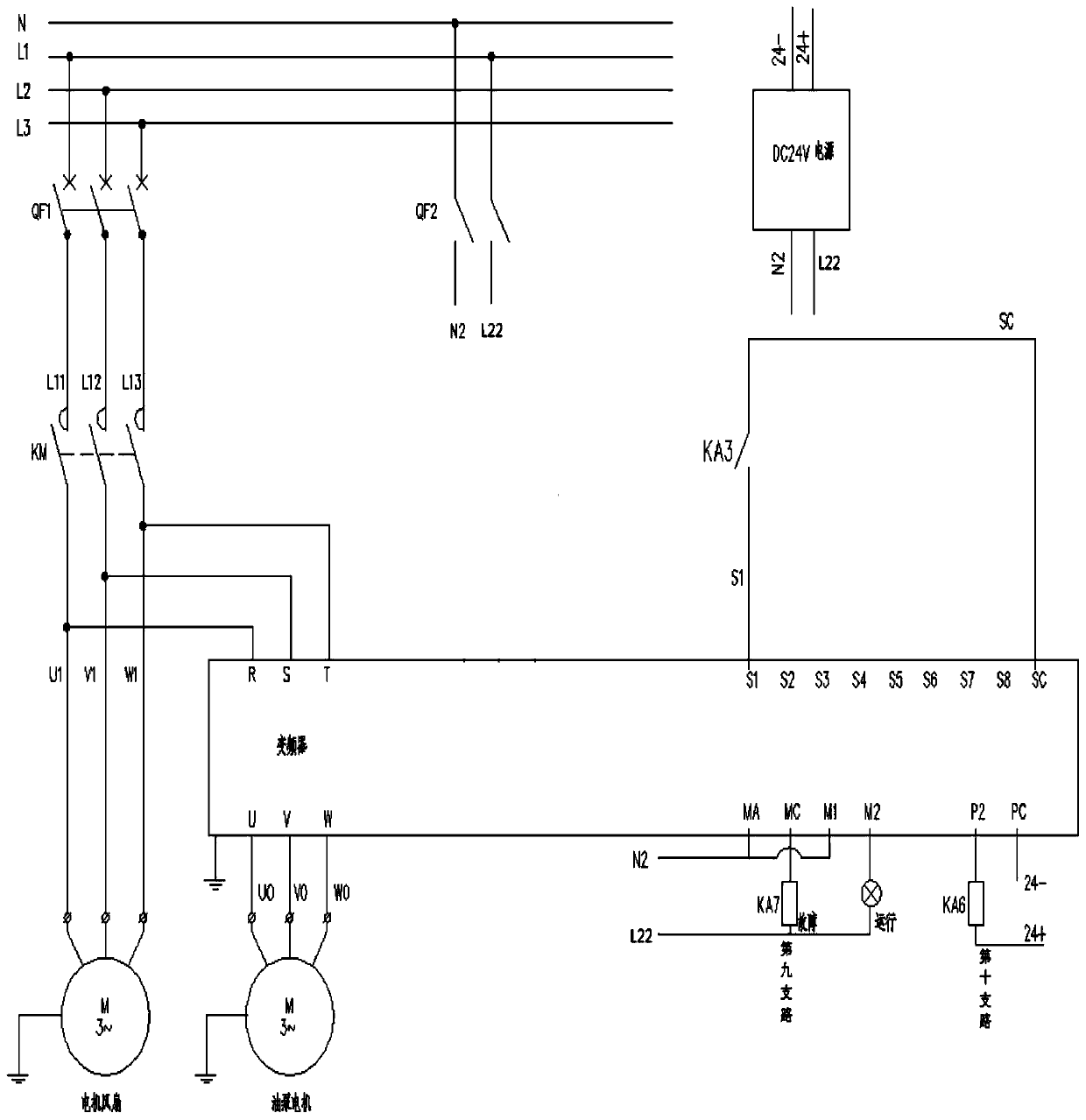

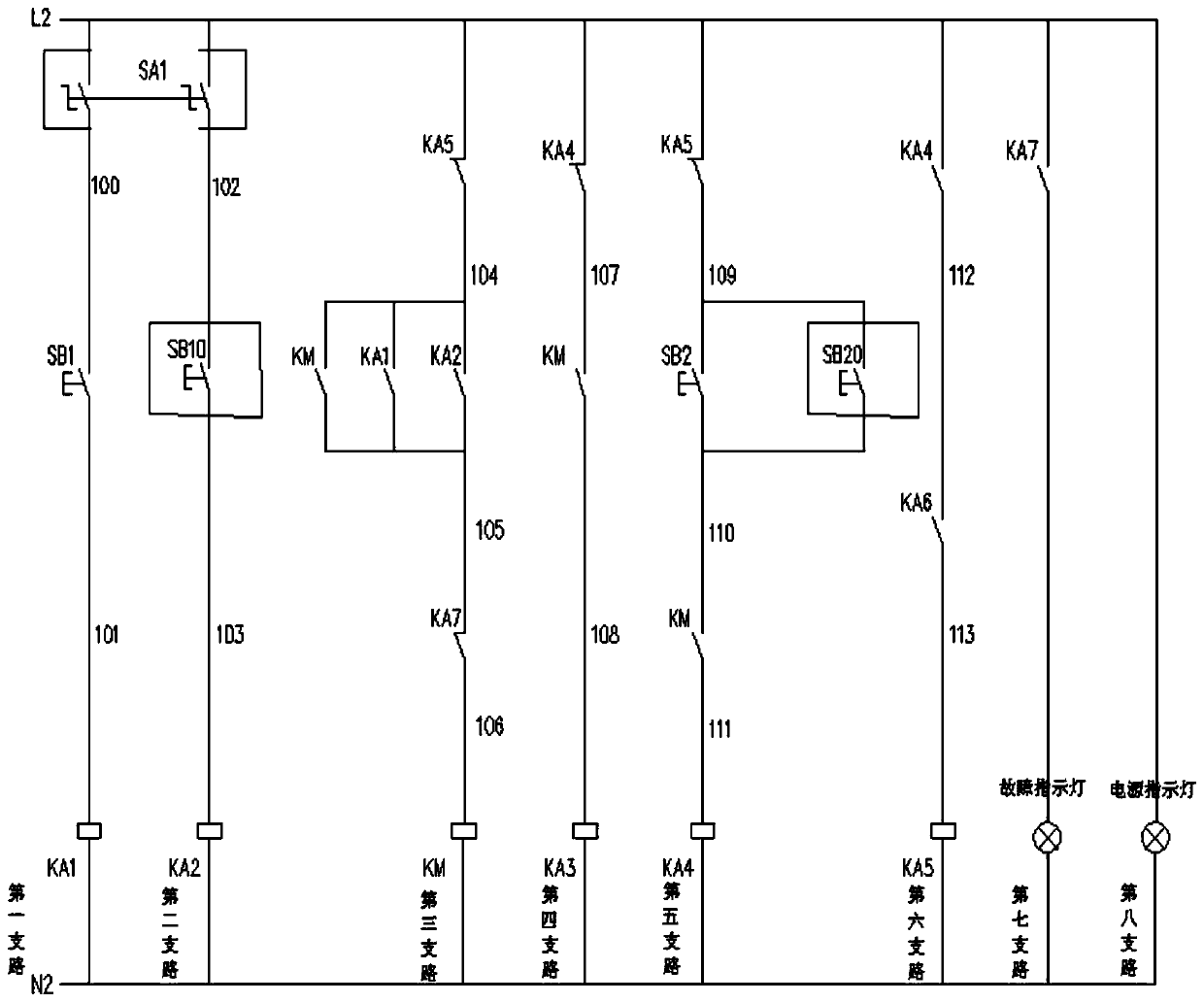

Blower main oil pump switching control circuit, starting-up control method and switching control method

PendingCN110474595AShorten the timeWith overload protectionAC motor controlPump componentsLow voltage circuitsFrequency changer

The invention discloses a blower main oil pump switching control circuit, a starting-up control method and a switching control method. The control circuit includes a major loop and a control loop connected to the major loop; the major loop includes a low-voltage circuit breaker QF1, a contactor KM, a motor cooling fan, an oil pump motor and a frequency converter; a three-phase four-wire power supply is respectively connected to three upper ports of the low-voltage circuit breaker QF1, and the three lower ports of the low-voltage circuit breaker QF1 are connected to three upper ports of the contactor KM; the three lower ports of the contactor KM are respectively connected to the input end of the frequency converter and the motor cooling fan; and the output end of the frequency converter isconnected to the oil pump motor. Thus, the electric oil pump motor can have longer down time during switching and can be rapidly started up when oil pressure reduces, the restarting up of a unit caused by the unit outage of main / standby oil pumps during switching can be avoided, so that influences on the whole technological system cannot be caused, switching time after the starting-up of the unitis finished can be shortened.

Owner:XIAN SHAANGU POWER

Integrated six-dimensional force sensor with double-I-shaped cross beam structure

ActiveCN111103084ASmall coupling between dimensionsHigh measurement sensitivityMeasurement of force componentsPhysicsStrain gauge

The invention provides an integrated six-dimensional force sensor with a double-I-shaped cross beam structure. The integrated six-dimensional force sensor comprises a double-I-shaped cross beam and aplurality of resistance strain gauges. The double-I-shaped cross beam comprises an outer ring, four elastic bodies and an inner ring. The four elastic bodies are uniformly distributed between the outer ring and the inner ring in a spoke form, and the four elastic bodies are symmetrically distributed in a cross shape to form a cross beam which is used for sensing stress; each elastic body comprisesa first I-shaped component and a second I-shaped component which are perpendicular to each other so that cross beams of the first I-shaped component and the second I-shaped component respectively form a horizontal plate and a vertical plate which are perpendicular to each other; and a plurality of resistance strain gauges are respectively arranged on the upper and lower surfaces of the horizontalplate and the two side surfaces of the vertical plate. The sensor has the advantages of simple structure, convenience in processing, small inter-dimensional coupling, high sensitivity, high overloadresistance and the like, the mechanical structure of the sensor and the signal control circuit are integrated for integrated design, and the sensor can be flexibly and conveniently integrated at the tail end of a robot actuating mechanism.

Owner:SHANGHAI JIAO TONG UNIV

Magnetic levitation planetary transmission speed control machine

InactiveCN103269147AHigh torque transmissionReduce dosageDynamo-electric gearsAviationProduction line

The invention discloses a magnetic levitation planetary transmission speed control machine, and aims at providing a magnetic levitation planetary transmission speed control machine which is large in transmission torque, high in magnetic utilization rate, environment-friendly and pollution-free, is provided with an overload protection function and based on a Halbach-type permanent magnetic array. The magnetic levitation planetary transmission speed control machine comprises a shaft I, a shell, a shaft II and a permanent magnet, wherein an inner gear ring is arranged in the shell, the inner gear ring is provided with a permanent magnet installation frame I, two ends of the shell are respectively provided with an end cover, the center of the end cover on one end of the shell is connected with an input connecting shaft through a bearing, the center of the end cover on the other end of the shell is connected with the shaft II through a bearing, one end of the shaft I is installed in the center of the input connection shaft, the other end of the shaft I is installed in the center of the shaft II, the shaft I is provided with an eccentric shaft through a key, the eccentric shaft is connected with a planetary wheel through a bearing, and the planetary wheel is provided with a permanent magnet installation frame II. The magnetic levitation planetary transmission speed control machine not only can be used for reduction application, but also can be used for the acceleration application, and particularly applicable to the pollution-free food production line, the aviation field and the wind power generation field.

Owner:苏大卫 +1

Belt offset detection apparatus

PendingCN107792616AEasy to installGuaranteed safe operationConveyorsControl devices for conveyorsDrive shaftCoupling

A belt offset detection apparatus is characterized in that a first detection device and a second detection and a second detection device sharing the first detection device are correspondingly arrangedon a supporting rack; a first conduction roller and a second conduction roller are arranged on a rotating shaft of the first detection device and a rotating shaft of the second detection device in respective; the first conduction roller contacts with the left side of a belt and the second conduction roller has contact with the right side of the belt; transmission shafts equipped with a first bearing and a second bearing are disposed in holes of a housing; each transmission shaft is covered with one torsion spring; the left end of each torsion spring is fixed on the inner wall of the housing via a first screw; a right end of each torsion spring is fixed on each transmission shaft via a second screw; an angle sensor is fixed on an installation seat disposed in the housing in the right end via first bolts; two ends of a flexible coupler are assembled to the right end of the transmission shaft and the left end of a shaft of the angle sensor via a first pin roll and a second pin roll; anda housing cover is fixed on the housing via a second bolt, and then the belt offset detection device is formed.

Owner:湖北华电襄阳发电有限公司

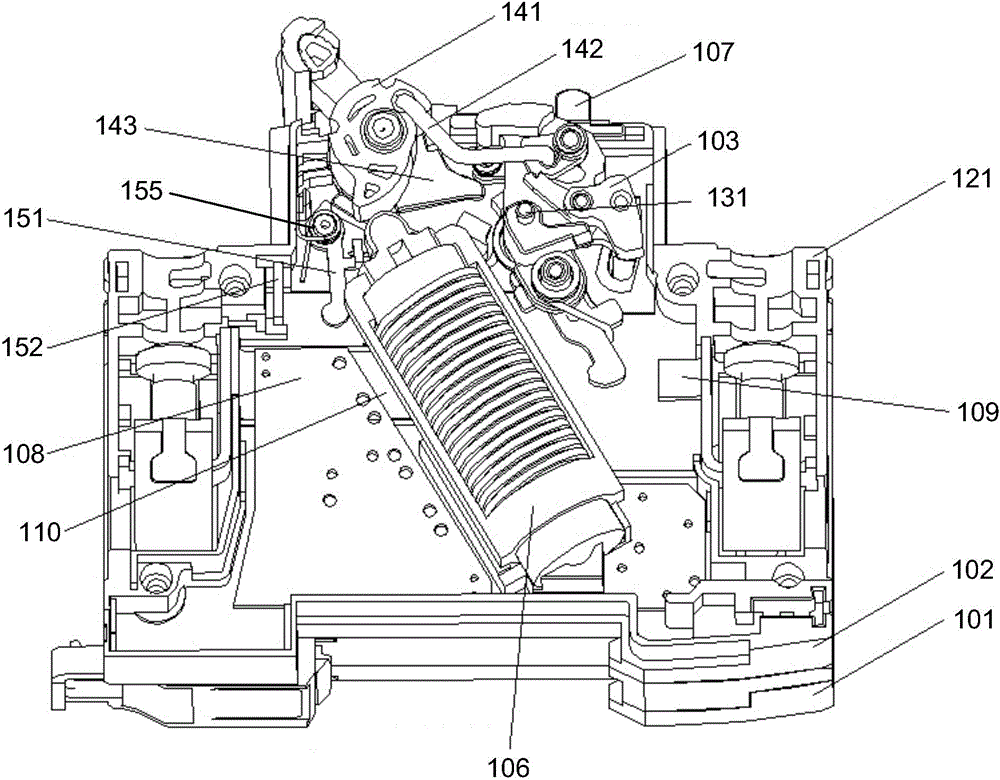

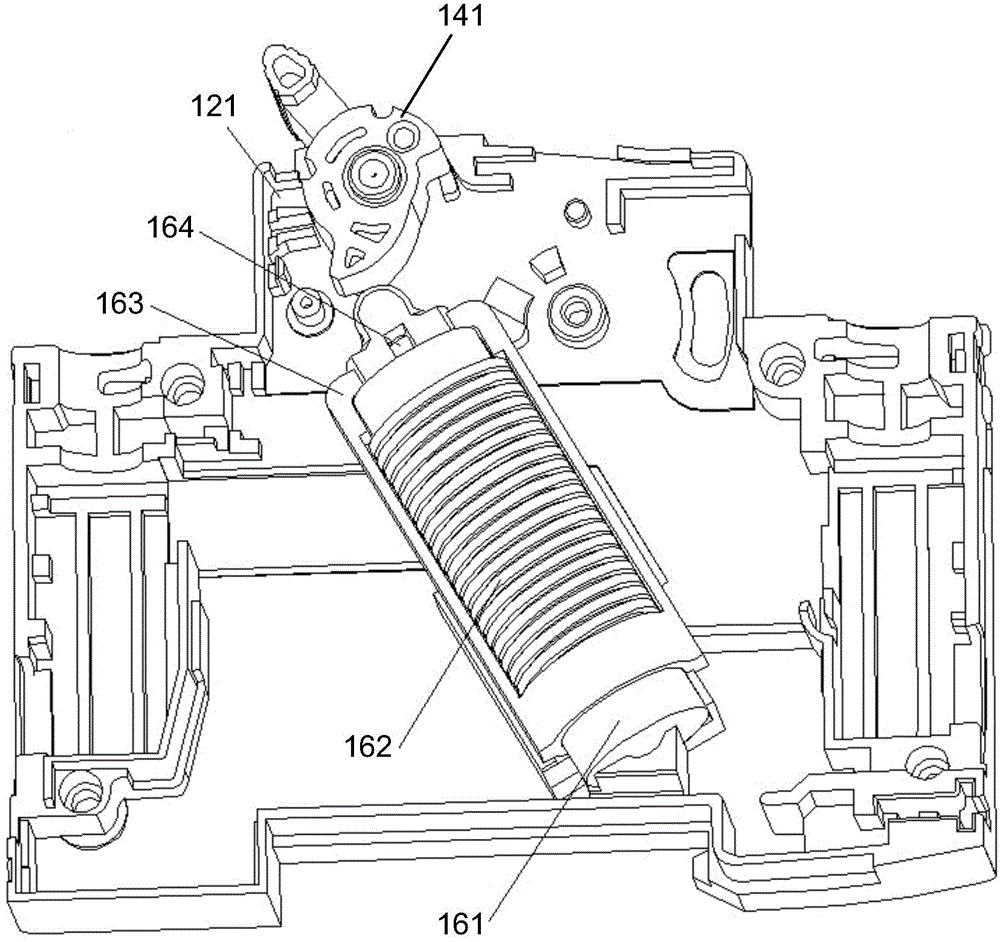

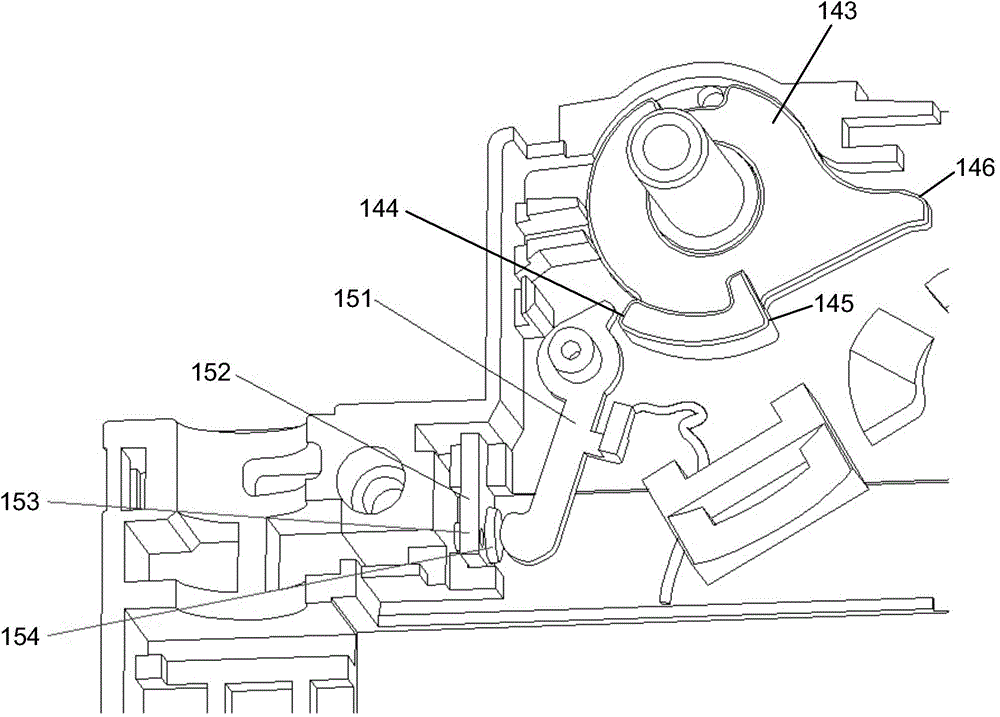

Circuit breaker and automatic closing device thereof

ActiveCN104681368AWith overload protectionWith short circuit protectionProtective switch operating/release mechanismsHeat sensitiveAutomatic testing

The invention discloses an automatic closing device of a circuit breaker. An automatic closing mechanism comprises a heat-sensitive element and a reset spring; after the heat-sensitive element is electrified, the automatic closing mechanism is enabled to push a handle of the circuit breaker to perform closing operation; after the heat-sensitive element is diselectrified, the reset spring enables the automatic closing mechanism to be reset. An auxiliary contact set is connected in series in a circuit used for supplying power to the heat-sensitive element. A rotary plate transmission mechanism is rotationally mounted on a base of the circuit breaker; when being in a first position, the rotary plate transmission mechanism does not interact with the auxiliary contact set; when being in a second position, the rotary plate transmission mechanism drives the auxiliary contact set to be switched off; the rotary plate transmission mechanism rotates to the second position from the first position in response to a trigger signal. A switching shift rod performs switching between an automatic position and a manual position; when being switched to the automatic position, the switching shift rod does not interact with the rotary plate transmission mechanism; when the switching shift rod is switched to the manual position, the trigger signal is generated. The trigger signal is further generated by the closing operation of the handle.

Owner:SEARI ELECTRIC TECH +2

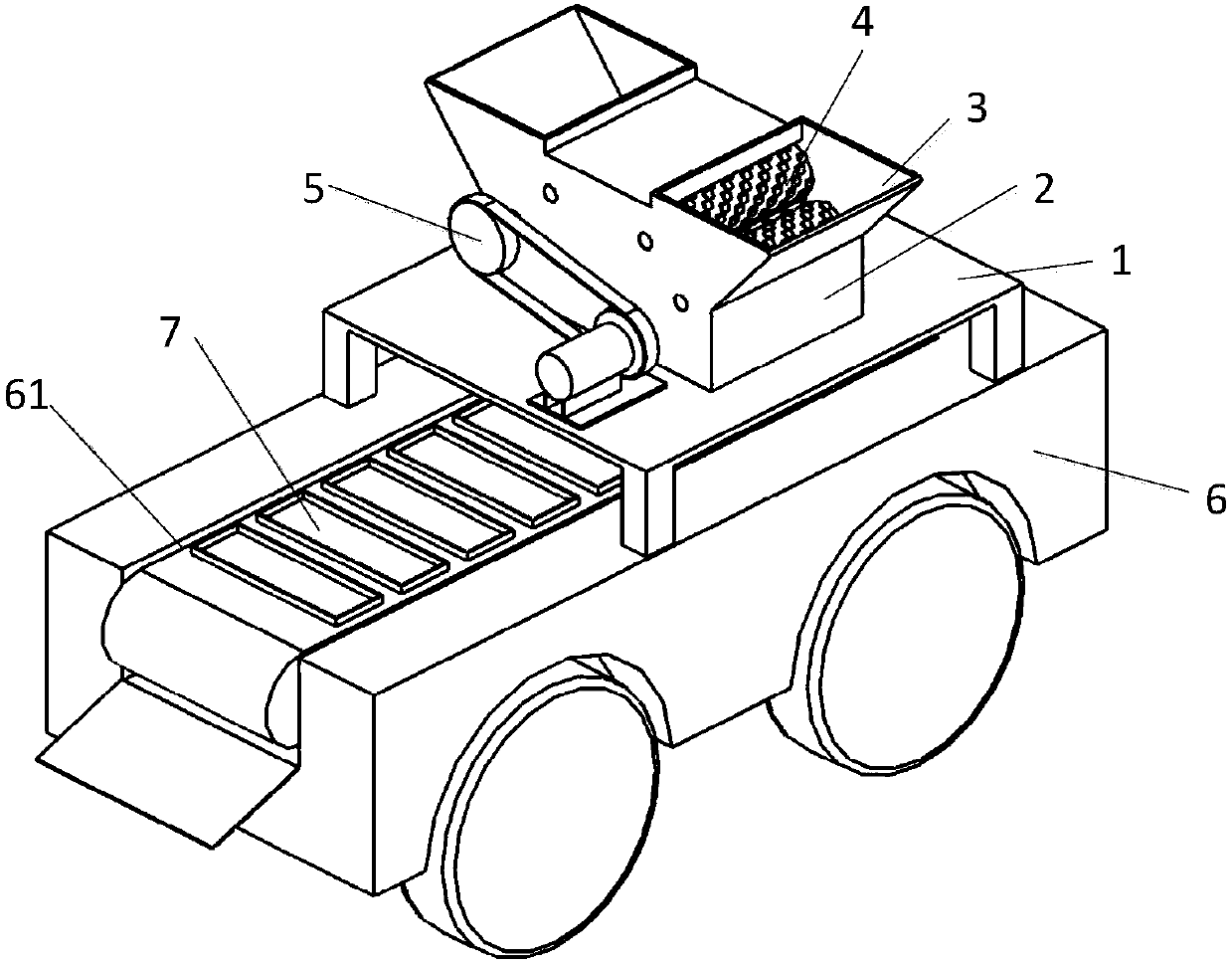

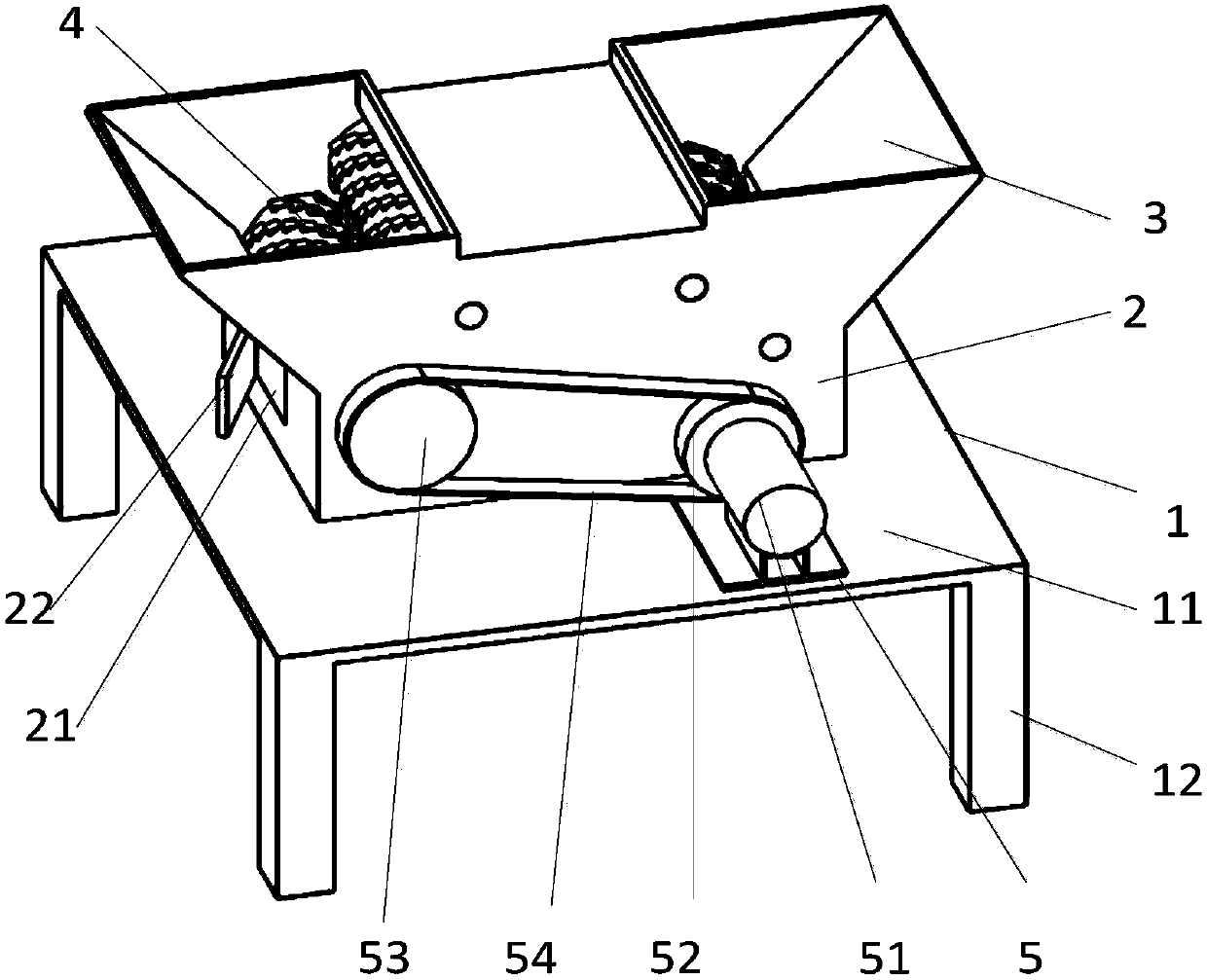

Wood crushing vehicle

InactiveCN107930832AEasy to moveRealize fixed-point dischargeWood working apparatusGrain treatmentsRaw materialAutomotive engineering

The invention discloses a wood crushing vehicle. The wood crushing vehicle comprises a rack, a shell, a material inlet, crushing rolls, driving devices, a vehicle body and a conveyer belt device, wherein the vehicle body is arranged below the rack; the upper end surface of the vehicle body is fixedly connected with the lower end surface of the rack; a downwards-concave rectangular groove is formedin the upper end surface of the vehicle body; the rectangular groove is arranged along the length direction of the vehicle body and is located right below a material discharging opening; the part, which is close to the tail part of the vehicle body, of the rectangular groove is not closed; the conveyer belt device is arranged in the rectangular groove; and wood bits discharged by the material discharging opening are conveyed from the vehicle head to the vehicle tail of the vehicle body. By adopting the wood crushing vehicle, the problems of a traditional crushing machine that when wood is placed in, a raw material needs to be pressed all the time by external force to finish continuous crushing of the wood; when only one material inlet is provided, material feeding for the crushing machineby multiple people in multiple directions cannot be realized; and production efficiency cannot be improved are solved. Through arrangement of the vehicle body, moving of the crushing device can be realized, so that flexibility is improved; and through arrangement of the conveyer belt device, fixed-site material output of the wood bits is realized, so that collection and packing are facilitated.

Owner:恭城福茂生油茶文化产业发展有限公司

Magnetic rheological soft startor

InactiveCN100359198CLower working temperatureSlip power increaseFluid clutchesEngineeringConductor Coil

A magnetic rheological soft starter is used in mechanical transmission. In order to eliminate impact of clutch during starting, new material magnetic rheological fluid (MRF) is introduced as the power transmission medium, and magnetic field electromagnetic winding produces is used in altering the rheological characteristic and controlling transmitted torque to reach the aim of smooth starting. For small structure, great torque and reduced heat produced during operation, the present invention makes driving part in cavity holding driven part, adopts two electromagnetic windings to control the rheological characteristic of MRF in radial and axial work gap, and mounts heat pipe to the end cap of the driving part to lower its temperature. The present invention is used mainly in soft starting of mechanical unit, power transmission, speed regulation and overload protection.

Owner:CHONGQING UNIV

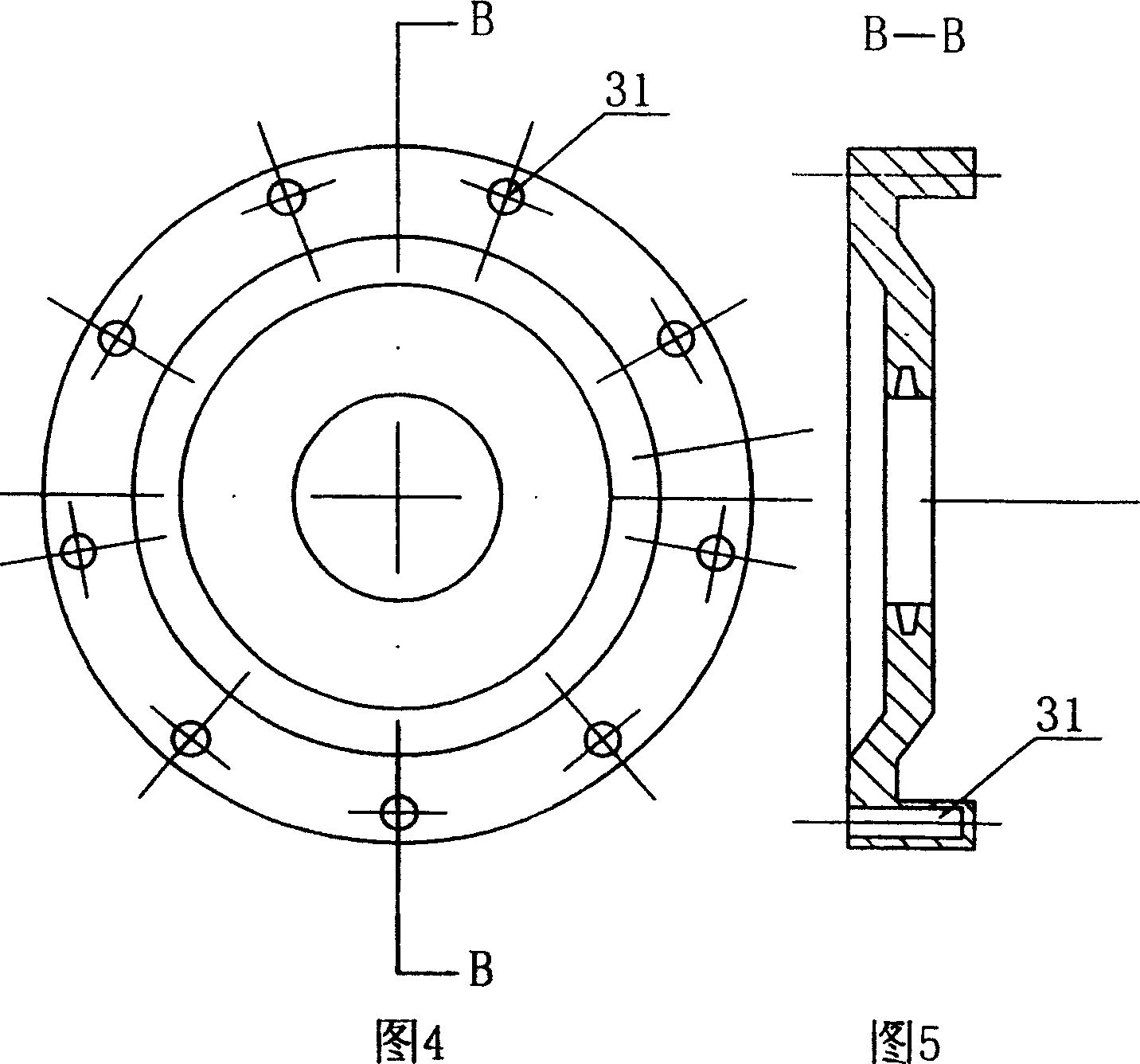

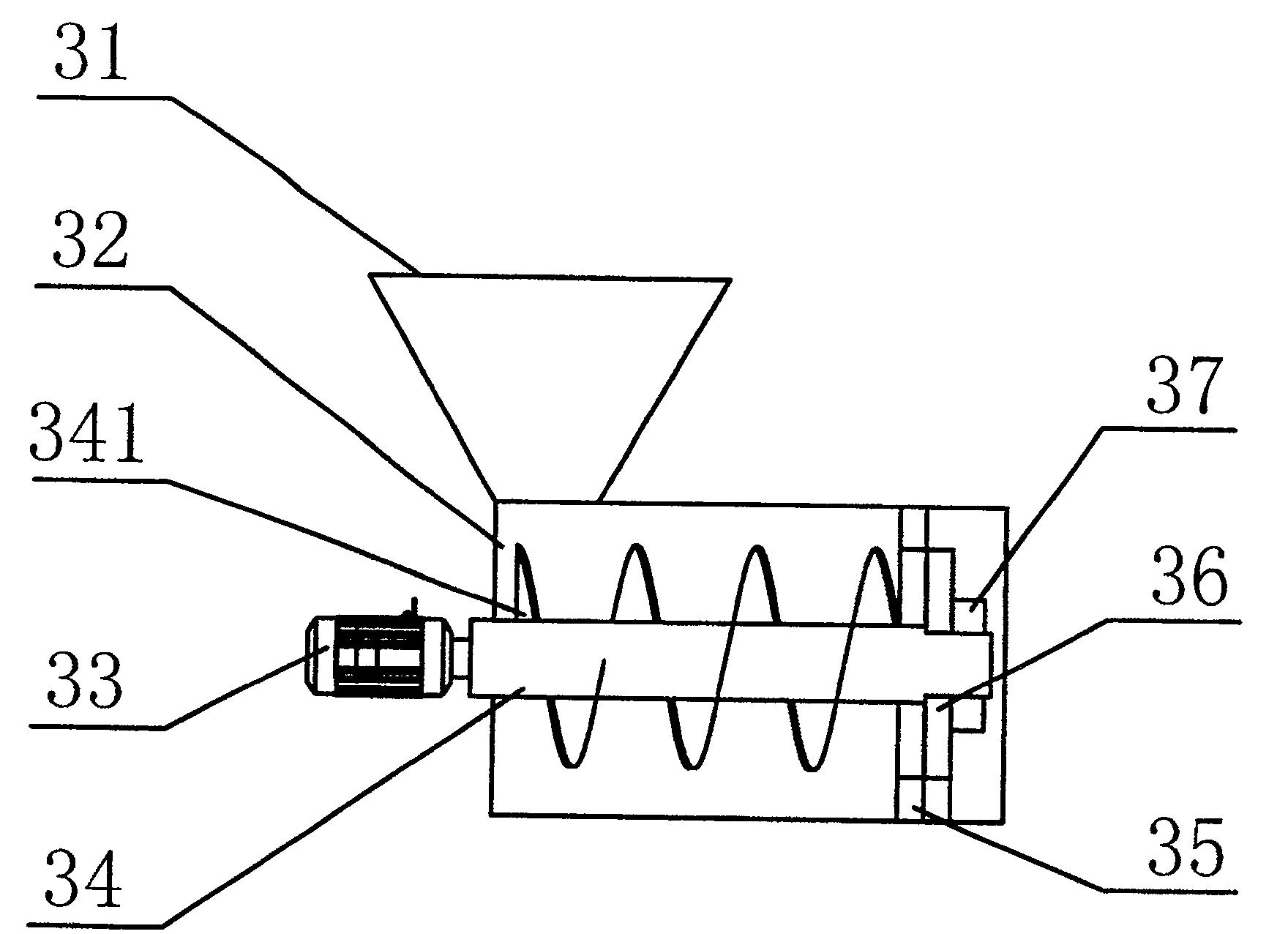

Multifunctional kitchen refuse treatment machine

InactiveCN100551561CWith overload protectionWith overcurrent fuse protectionSolid waste disposalEngineeringPower equipment

The invention relates to a multifunctional kitchen waste processor. It realizes the entire automatic workflow of crushing, filtering, stirring, heating, heat preservation, fermentation and deodorization of kitchen waste. The multifunctional food waste processor includes a casing for accommodating the various components of the equipment, a detection door is arranged on the top of the casing, and a crushing device connected with the casing is arranged at the upper end of one side of the casing. There is a stirring device between the discharging devices. The bottom of the stirring device is provided with a fermentation fungus material storage tank. A power device is provided at the lower end of one side of the casing. The middle end of the casing side is placed between the stirring device and the power device. There is a transmission device between them, and an electric control device is provided outside the power device and the transmission device. A discharge device is provided at the lower part of the front end of the casing corresponding to the detection door, a heat preservation device is provided between the power equipment, the base, and the discharge device, a heating device is arranged on the heat preservation device, and a connection with the casing is provided outside the casing. A deodorizing device connected to the upper part.

Owner:SHENZHEN SHENGDEYI HI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com