Heating coil panel

A technology for heating coils and coils, which is applied to coil devices, induction heating, electric heating fuels, etc., can solve the problems of small temperature difference, uneven heat distribution, concentration, etc., and achieve the effects of convenient use, high heating efficiency, and rapid centralized heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

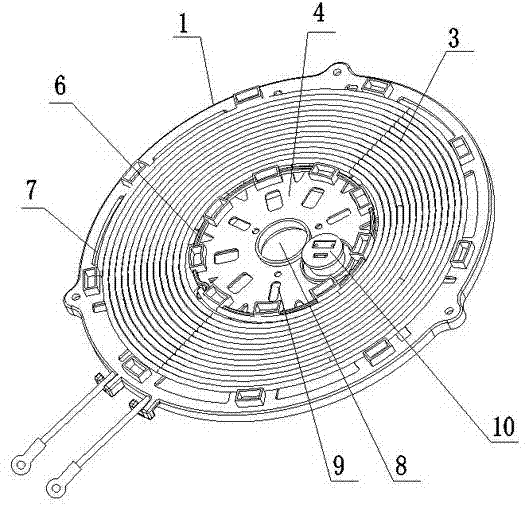

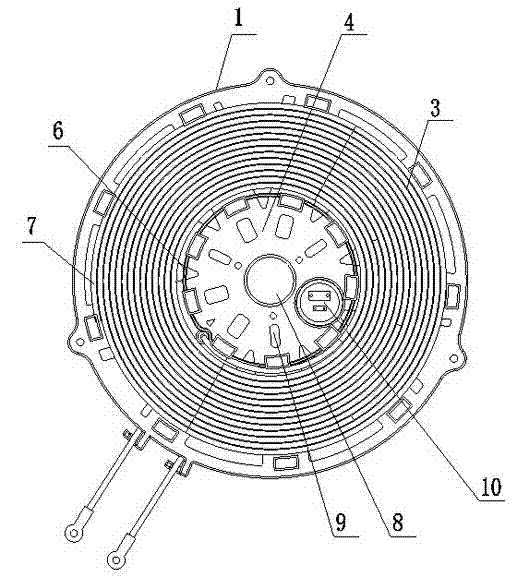

[0033] like figure 1 , 2 As shown in . and 3, a heating coil disk adopts a dense winding method to surround the heating coil 3, including a circular coil chassis 1, and its disk surface is composed of radial support bars, a central circle and an outer ring. The central circle is It is the winding central area 4, and the outer ring is the winding area. In the center of the winding central area 4, there is a circular through hole 8 for installing an external drive motor, and a circle of cooling holes is arranged around the hole 8. 10. There is also a temperature control switch assembly 10 fixed near the edge of the central area 4 of the winding, which consists of a thermistor temperature probe and a thermal fuse that automatically forcibly burns and powers off after reaching a certain limit temperature; if in actual application If required, a heating supplement can be added in the central area of the winding.

[0034] In order to facilitate the passage of the heating coil 3 ...

Embodiment 2

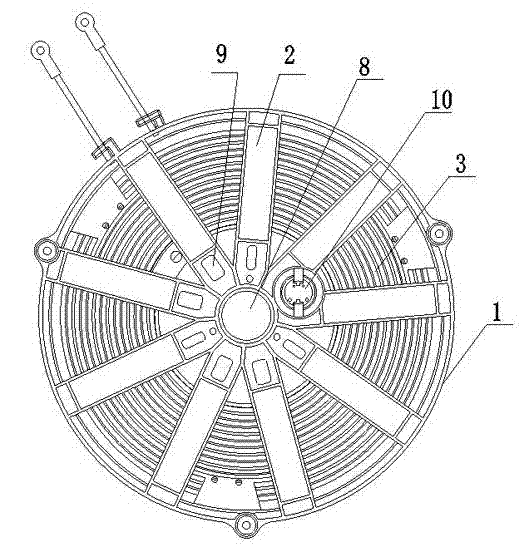

[0038] like Figure 5 , 6 As shown in and 7, a heating coil adopts a loose winding method to surround the heating coil, including a circular coil chassis 1, and its disk surface is composed of radial support bars, a central circle and an outer ring. The central circle is the winding The resistance central area 4, the outer ring is the winding area, wherein, the center of the winding central area 4 has a circular through hole 8 for installing an external drive motor, and a circle of cooling holes 10 is arranged around the hole 8. A temperature control switch assembly 10 is also fixed near the edge of the central area 4 of the winding, which consists of a thermistor temperature probe and a thermal fuse that automatically burns and powers off when it reaches a certain limit temperature; if there is a demand in practical applications , a heating supplementary device can be added in the central area of the winding.

[0039] In order to facilitate the passage of the heating coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com