Belt offset detection apparatus

A technology for offset detection and detection devices, which is applied in the direction of conveyor control devices, transportation and packaging, conveyors, etc., can solve problems such as damage to offset detection devices, system failures, and easily damaged angle sensors, so as to reduce accuracy requirements, Good shock absorption function, easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

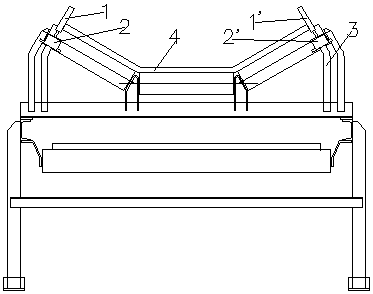

[0015] given in the present invention figure 1 In the embodiment, the first detection device 2 and the second detection device 2' with the same structure are correspondingly installed on the conveyor belt support frame 3; the first guide roller 1 and the second guide roller 1' are installed on the first detection device respectively. On the rotating shafts of the device 2 and the second detection device 2', the first guide roller 1 and the second guide roller 1' are in contact with the left and right sides of the belt 4 respectively.

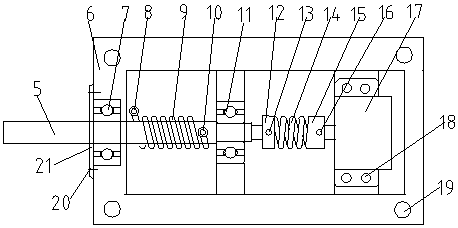

[0016] exist figure 2 In the shown embodiment of the detection device, the first shaft hole and the second shaft hole are respectively installed in the left end of the housing wall of the detection device housing 6 and the center of the inner partition of the housing, and the first bearing 7 and the second bearing 11 are respectively installed in the second shaft hole. In the first hole and the second hole, the transmission shaft 5 is inserted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com