Mechanical soft starting auxiliary driving device

A technology of auxiliary drive and soft start, which is applied in the direction of fluid pressure actuation devices, mechanical equipment, fluid pressure actuation system components, etc., can solve the problems of increasing fault points, reducing reliability, and high price, so as to improve braking deceleration performance, elimination of shock and vibration, and reduced fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

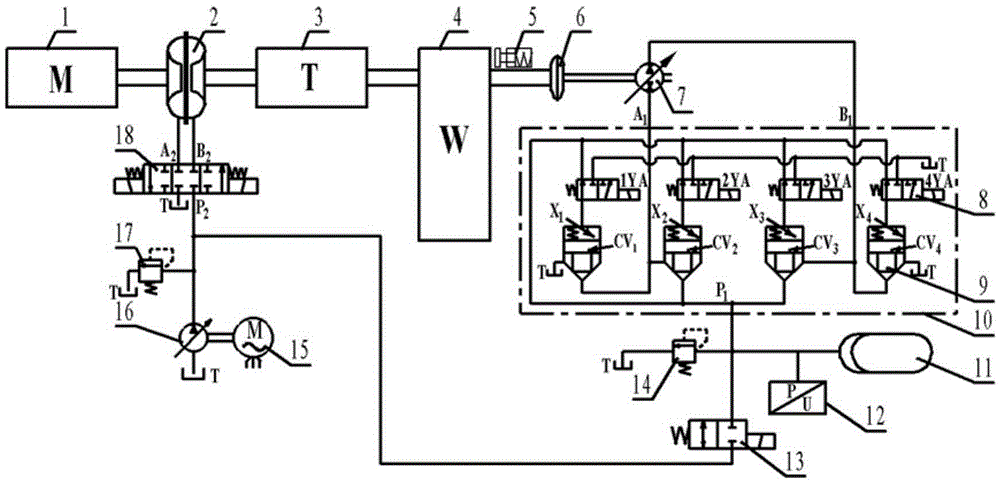

[0024] Such as figure 1 As shown, the mechanical soft start auxiliary driving device in this embodiment includes a prime mover 1, a mechanical soft start device 2, a transmission device 3, a working mechanism 4, a gate control system 5, a clutch 6, a second driving motor 15, a hydraulic pump 16. The second safety valve 17, the three-position four-way control valve 18 and the controller, the mechanical soft start device is connected with the prime mover and the speed change device, the speed change device is connected with the working mechanism, and the start and stop of the working mechanism are passed by the mechanical soft start device The speed change device is controlled, and the gate control system is installed on the working mechanism; the second drive motor is connected to the hydraulic pump, and the hydraulic pump is connected to the mechanical soft start device through the three-position four-way control valve, and the controller realizes the control of the entire syst...

Embodiment 2

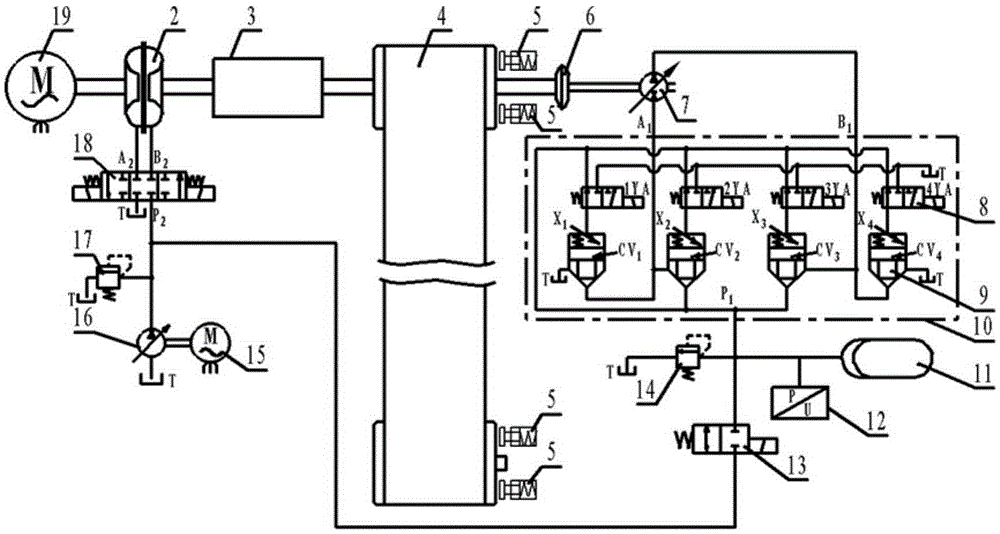

[0035] Such as figure 2 As shown, the working mechanism in the mechanical soft start auxiliary drive device in this embodiment is a belt conveyor, the prime mover 1 is replaced by a drive motor 19, the mechanical soft start device 2 is a speed-regulating type hydraulic coupling, and the speed change device 3 is reducer.

[0036] The speed-regulating hydraulic coupler 2 is connected with the driving motor 19 and the reducer 3, and the reducer 3 is connected with the belt conveyor 4, and the start and stop of the belt conveyor 4 are passed by the speed-regulating hydraulic coupler 2 through the reducer 3 control, the gate control system 5 is installed on the belt conveyor 4; the second drive motor 15 is connected to the hydraulic pump 16, and the hydraulic pump 16 is connected to the speed-regulating hydraulic coupler 2 through the three-position four-way control valve 18, and the controller To realize the control of the whole system, it also includes the power unit 7, combine...

Embodiment 3

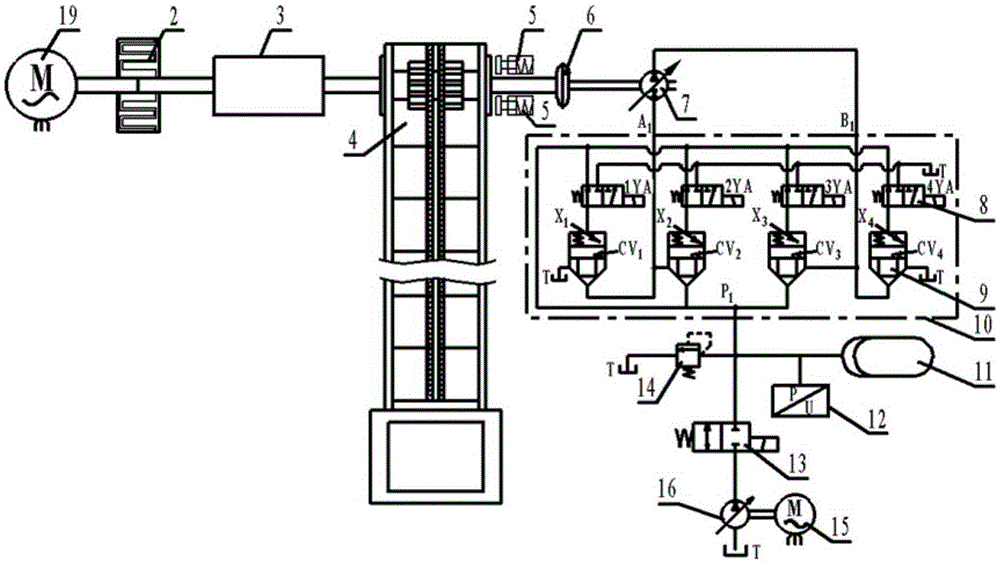

[0041] Such as image 3 As shown, the working mechanism of the mechanical soft start auxiliary drive device in this embodiment is a scraper conveyor, the prime mover 1 is replaced by a drive motor 19, the mechanical soft start device 2 is a viscous clutch, and the speed change device 3 is a reducer. The difference from the mechanical soft start auxiliary driving device in Embodiment 1 is that the second safety valve 17 and the three-position four-way control valve 18 are removed.

[0042] Since the fluid-viscous clutch transmission is based on Newton's law of internal friction, the normal work does not need to be controlled by filling and discharging fluid, so the second safety valve and three-position four-way control valve are removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com