Patents

Literature

64results about How to "Reduce dynamic stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

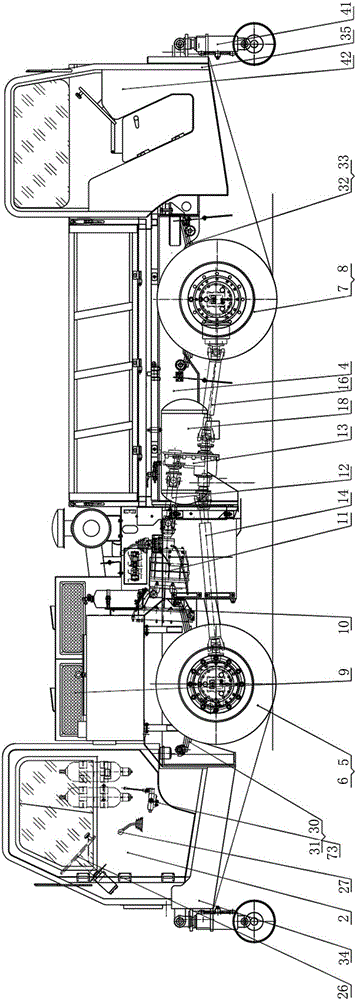

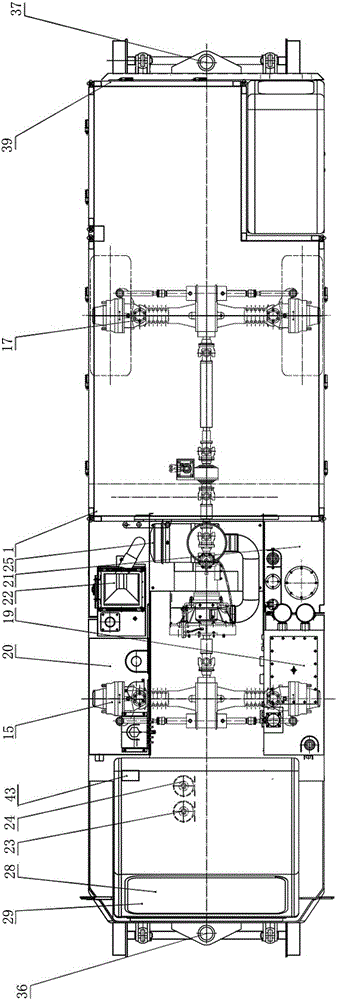

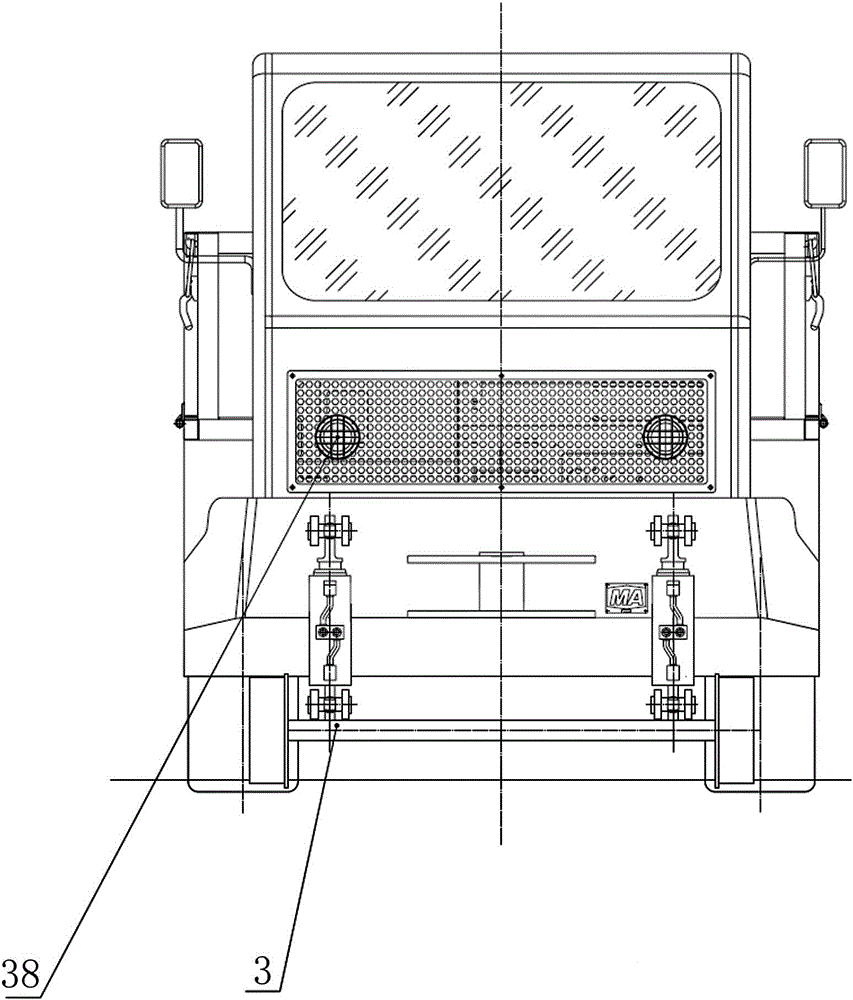

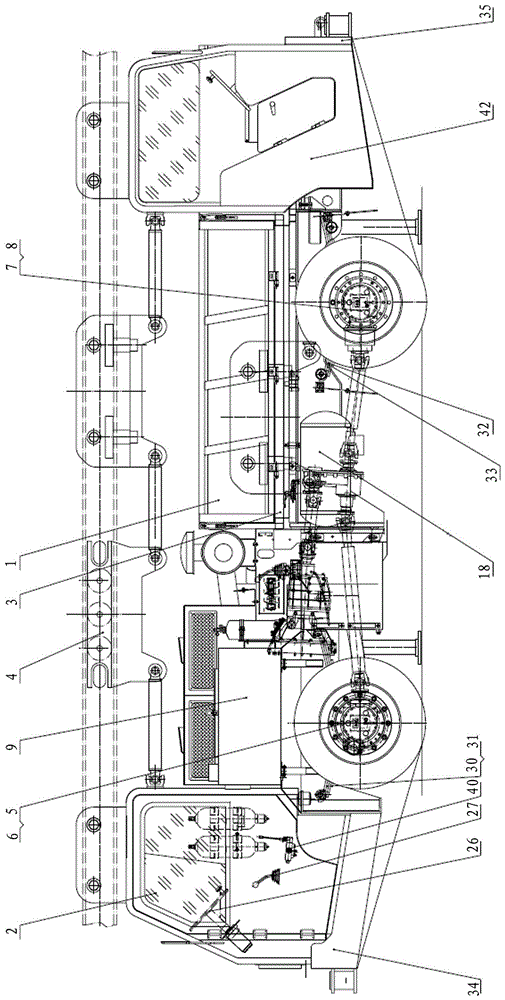

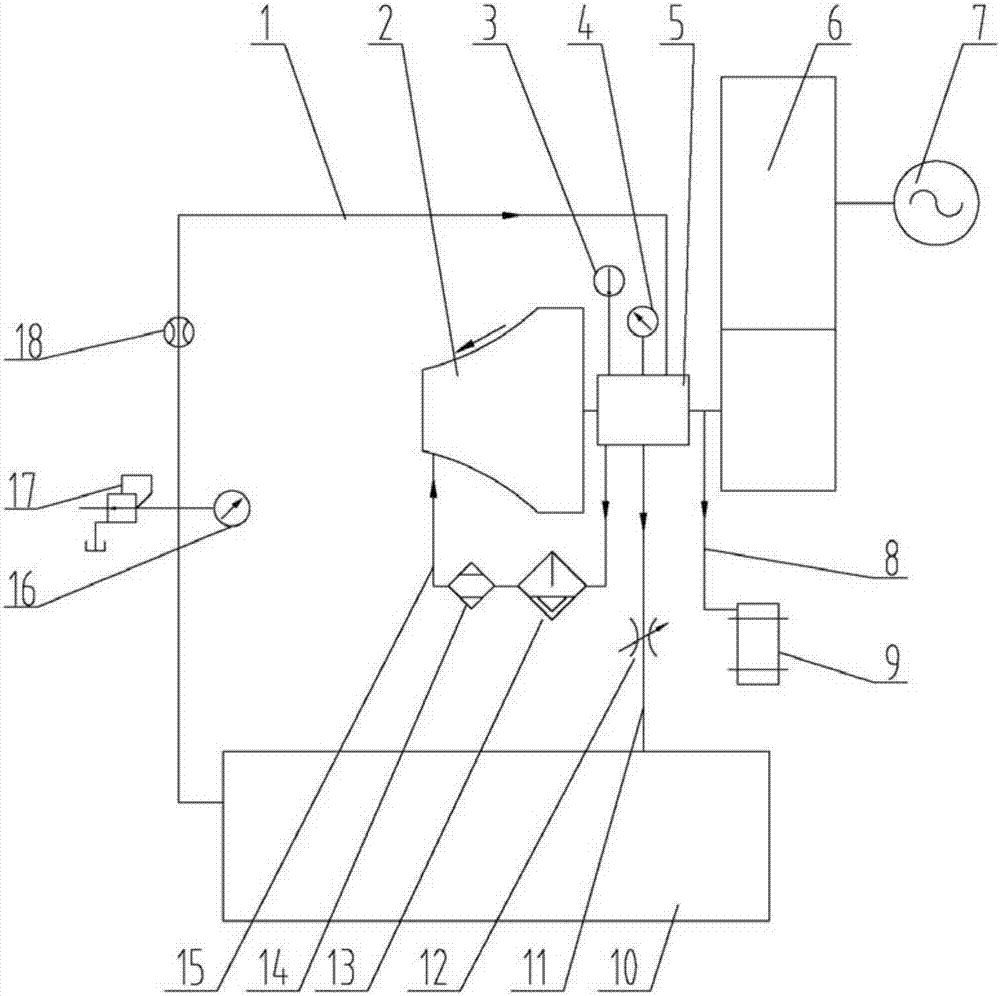

Explosion-proof diesel engine road-rail vehicle for coal mine underground roadway

ActiveCN105172500AImprove powerSmall turning radiusRail and road vehiclesItem transportation vehiclesTransfer caseAir filter

The invention belongs to the technical field of design and manufacturing of coal mine underground auxiliary transportation equipment, solves the technical problems that in the coal mine transportation field, no traction engine capable of realizing trackless or tracked reloading is provided, and unidirectional driving is not conducive to health and safe driving, and provides an explosion-proof diesel engine road-rail vehicle for a coal mine underground roadway. The road-rail vehicle comprises a carriage, a main cab, a vice cab, front wheels, rear wheels, a frame, suspensions, transmission shafts, a transfer case, drive axles, a clutch, a hydraulic oil tank, a fuel tank, a waste gas treatment tank, a feed water tank, an air filter, a gas tank, a diesel engine, a hydraulic mechanism, a pneumatic mechanism, wheeltrack guiding devices, a quick change-over device and traction connection devices. The road-rail vehicle is provided with a mode switching system, so that the switching of a trackless working mode and a tracked working mode can be realized; four-wheel driving and bidirectional driving are adopted; and the road-rail vehicle is reasonable in design, compact in structure, small size, strong in climbing ability, and flexible, can shuttle in a narrow coal mine underground roadway, and freely and conveniently run forwards and backwards.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

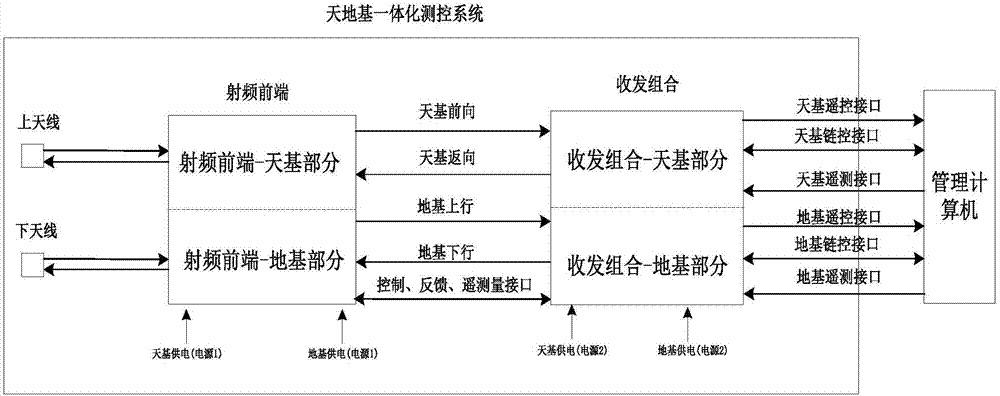

Ground-space-based integral measurement and control system applied to terrestrial space

ActiveCN107959526AAchieve full coverageQuick captureRadio transmissionTransmission switchingControl system

The invention discloses a ground-space-based integral measurement and control system applied to a terrestrial space. The system includes a ground measurement and control station; a relay satellite; anair vehicle including an upper antenna, a lower antenna, a radio frequency front end, a transceiving assembly and an air vehicle management computer, wherein the upper antenna and the lower antenna are used for receiving and transmitting of ground-base uplink and downlink signals and space-based forward and backward remote control signals; the radio frequency front end is used for performing filtering hybrid amplification on signals and outputting the signals; the transceiving assembly is used for conversion through modulation and demodulation and for receiving CCSDS remote measurement framesor acquiring positioning information according to remote measurement parameters of the transceiving assembly itself and calculating the optimal direction transmission of the space-based forward remote control signals; the air vehicle management computer is used for transmitting the received positioning information and the calculated optimal direction of the space-based forward remote control signals to the radio frequency front end for transmission switching between the upper antenna and the lower antenna and transmitting selected space-based backward remote control signals to the relay satellite. According to the invention, a ground-based and a space-based remote measurement and remote control links can be implemented at the same time and whole course coverage of flight tasks is realized.

Owner:BEIJING SATELLITE INFORMATION ENG RES INST

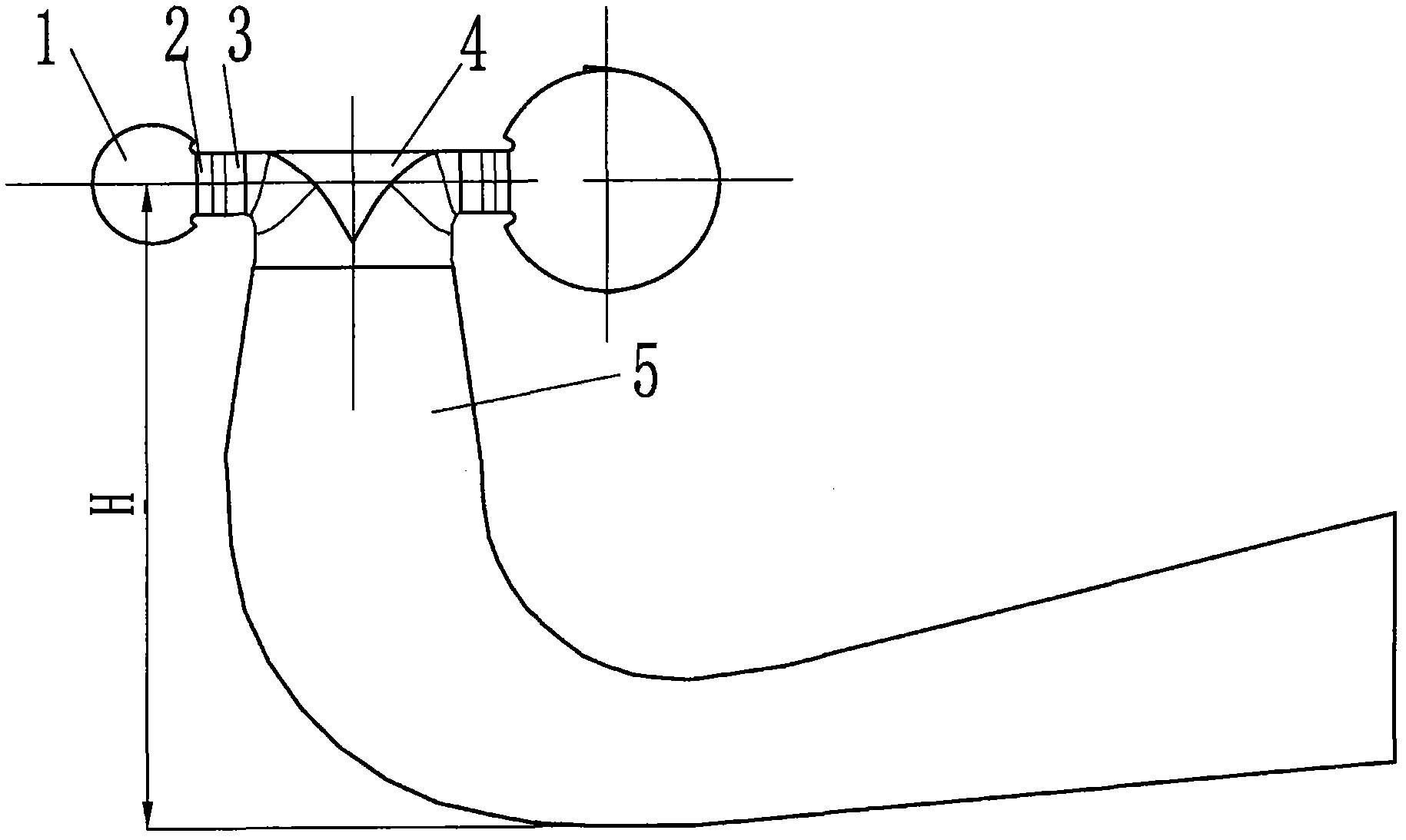

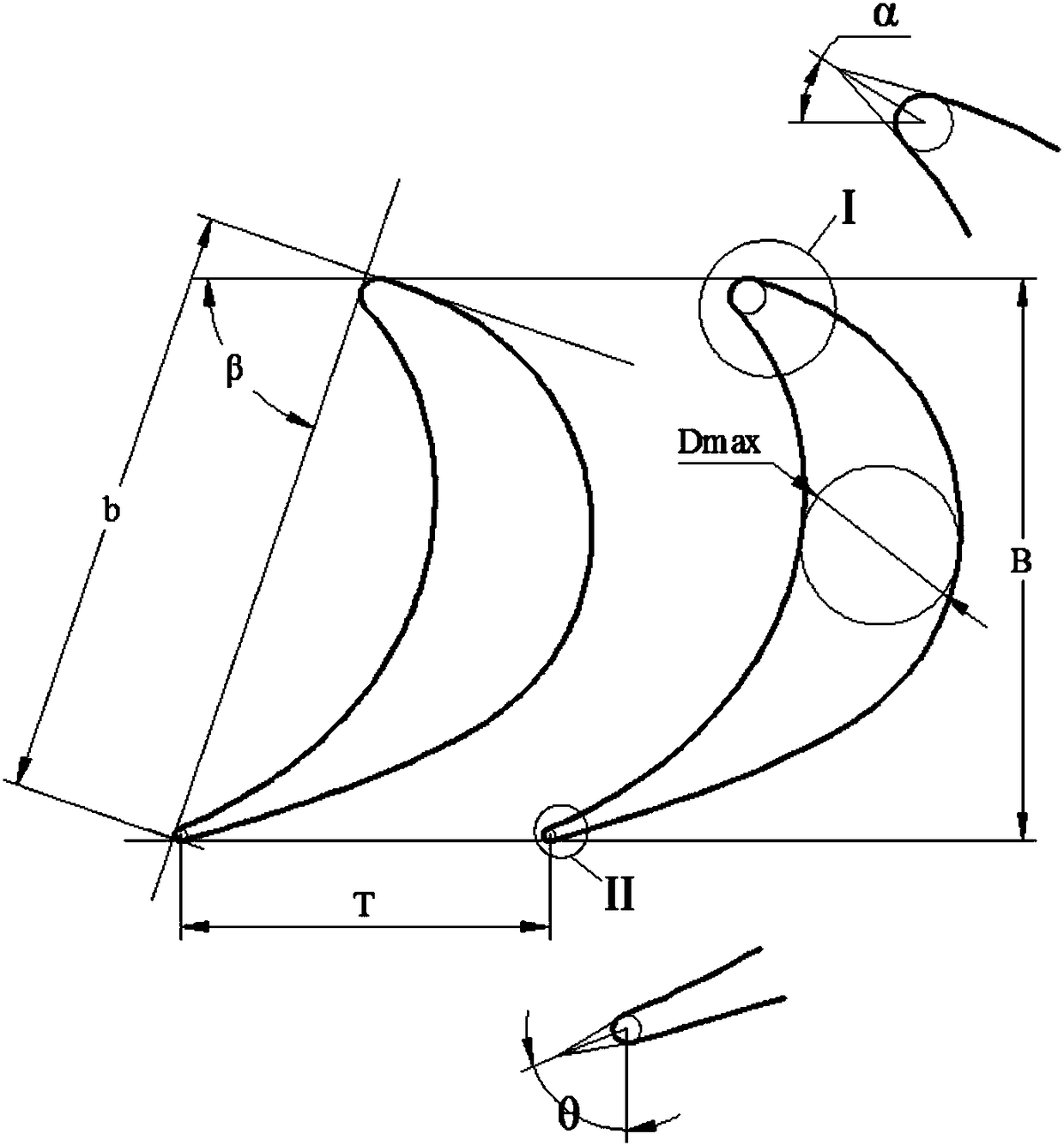

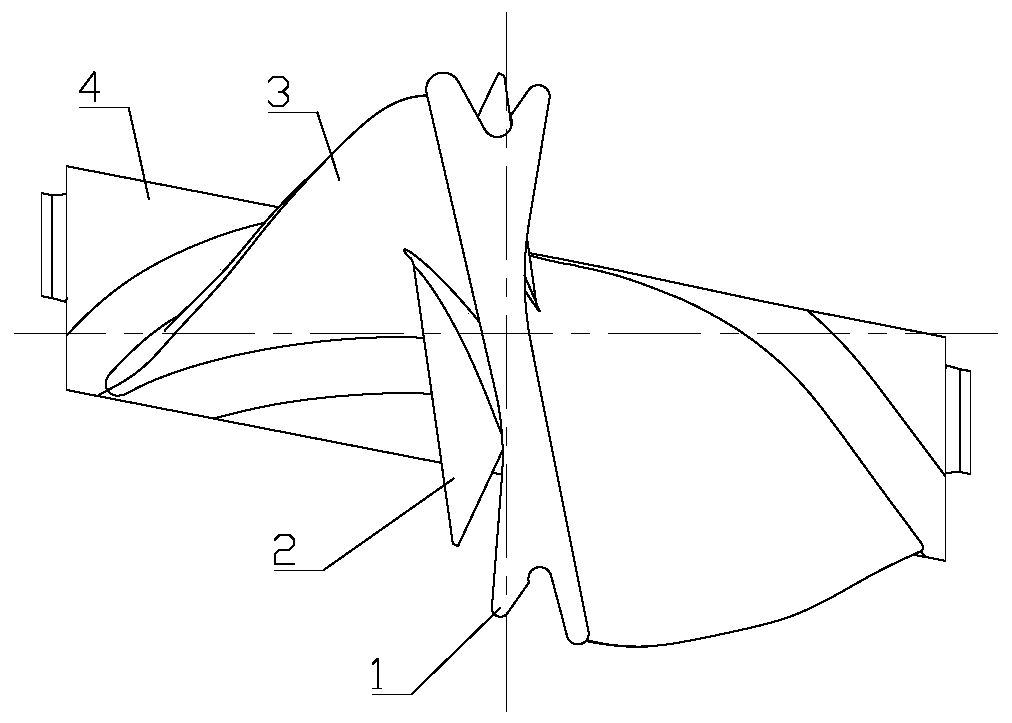

Radial-axial flow turbine employing novel guide blade and runner blade profile

InactiveCN102011672AImprove efficiencyImprove running stabilityHydro energy generationReaction enginesTurbine bladeFriction loss

The invention belongs to the technical field of fluid machinery and engineering equipment, and in particular relates to a radial-axial flow turbine, in particular to a radial-axial flow turbine employing a novel guide blade and runner blade profile. The turbine comprises a volute, a fixed guide blade, a movable guide blade, a runner and an exhaust water pipe; the shape of a nose baffle of the volute and the shape of the movable guide blade are designed, and a brand-new guide blade profile, so the flow is smoother, and the resistance loss in a flow channel is lower; the height difference between an upper crown and a lower ring surface, the length of a straight cone of the exhaust water pipe and a flow angle of outlet liquid of the turbine blade are newly designed; and a novel thickness change rule is adopted for the runner blade from an inlet to an outlet. The novel turbine improves the efficiency, reduces the vibration and pressure fluctuation, improves the mechanical strength of the runner, and reduces dynamic stress of the runner blade. Therefore, the probability for generating cracks on the runner blade is greatly reduced, and the operating stability of the turbine is improved.

Owner:TSINGHUA UNIV +1

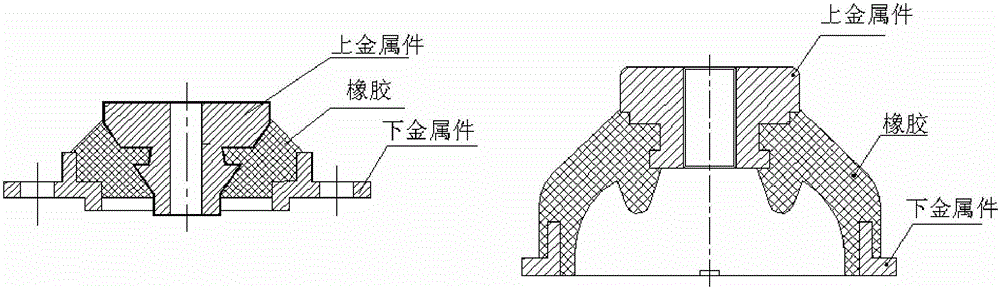

Automobile shock-reducing rubber spring and preparation process thereof

The invention discloses an automobile shock-reducing rubber spring and a preparation process thereof, and relates to the technical field of production of automobile rubber. The automobile shock-reducing rubber spring comprises the following components in parts by weight: 100Phr of natural rubber, 3-7Phr of zinc oxide, 0.5-3.5Phr of an anti-aging agent RD, 2-5Phr of an anti-aging agent 4010NA, 1-3Phr of a dispersant, 1-3Phr of stearic acid, 35-50Phr of carbon black, 2-5Phr of an accelerant, 7-13Phr of paraffin, 4-9Phr of aromatic hydrocarbon oil, 1-3Phr of sulfur S8 and 2-5Phr of a coupling agent. The invention also discloses a preparation process of the automobile shock-reducing rubber spring, and the preparation process comprises twelve process steps of plastifying, standing, mixing, slice discharging, strip cutting, metal frame treatment, surface treatment, rubber cement spraying, vulcanization, trimming, checking and warehousing. The rubber spring produced by the method disclosed by the invention is excellent in mechanical property, good in fatigue resistance and shock-reducing property, wide in material source and low in preparation cost.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

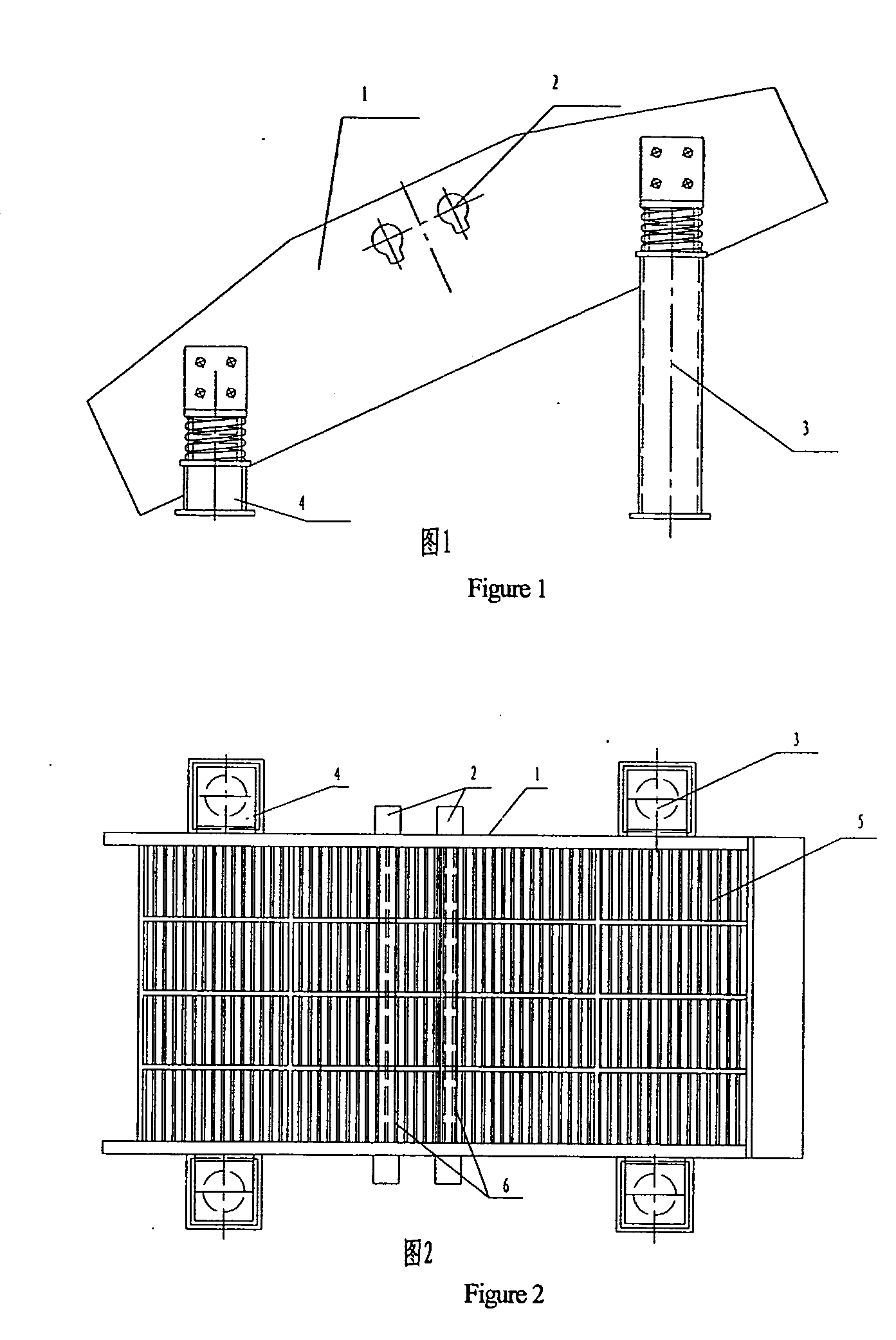

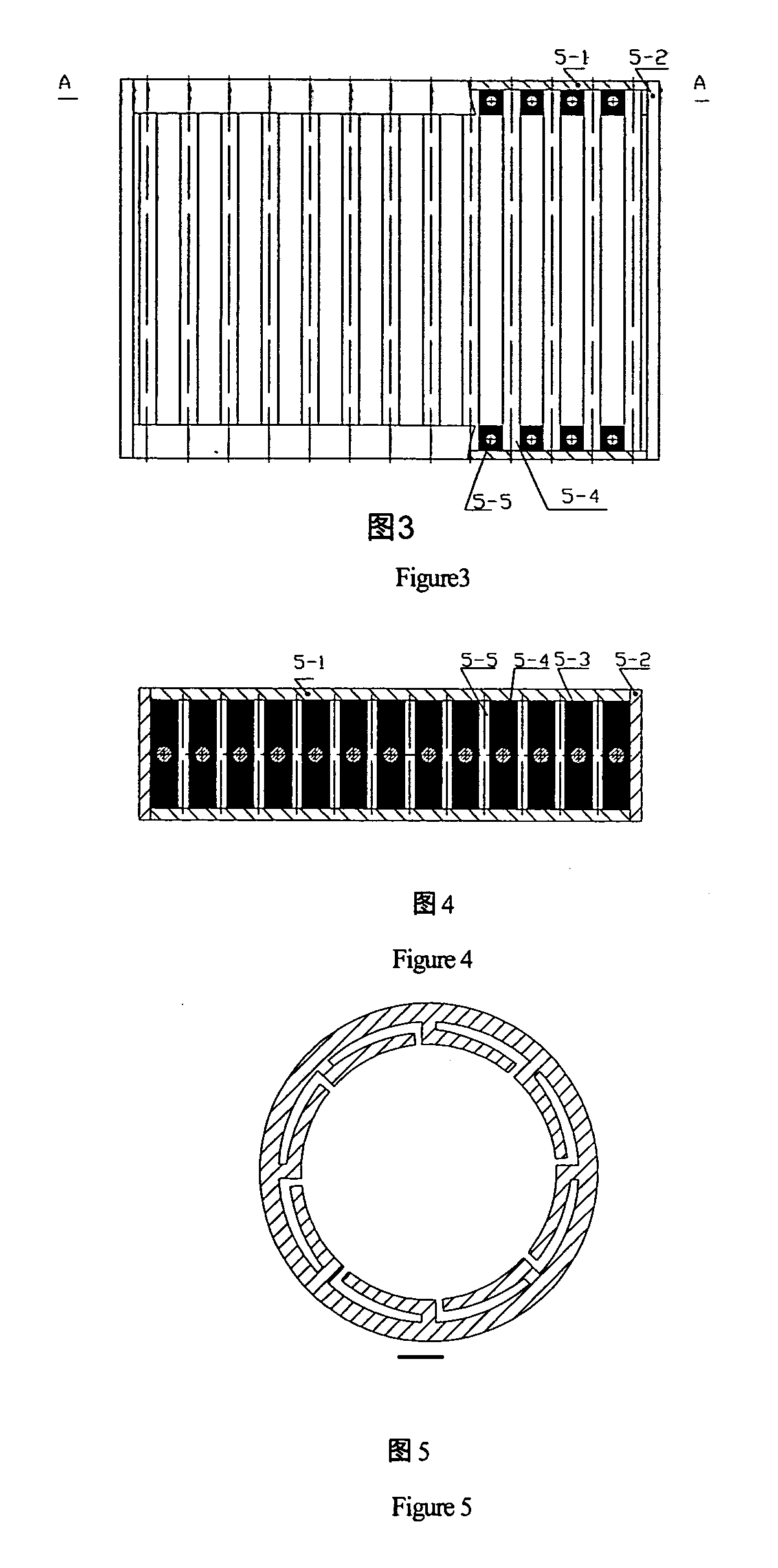

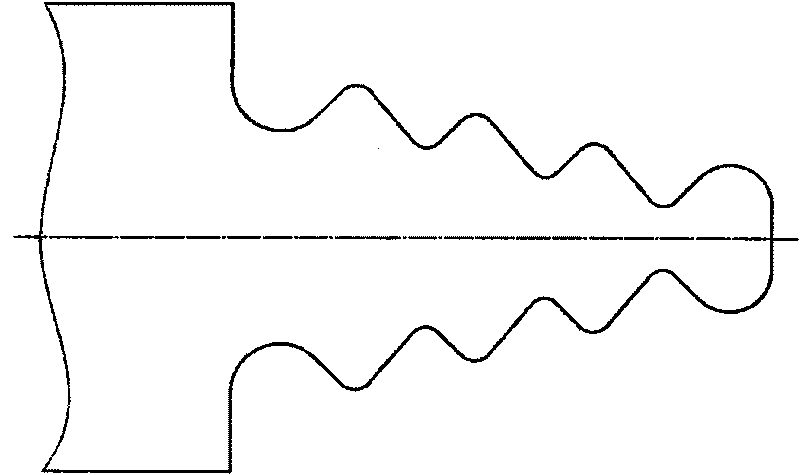

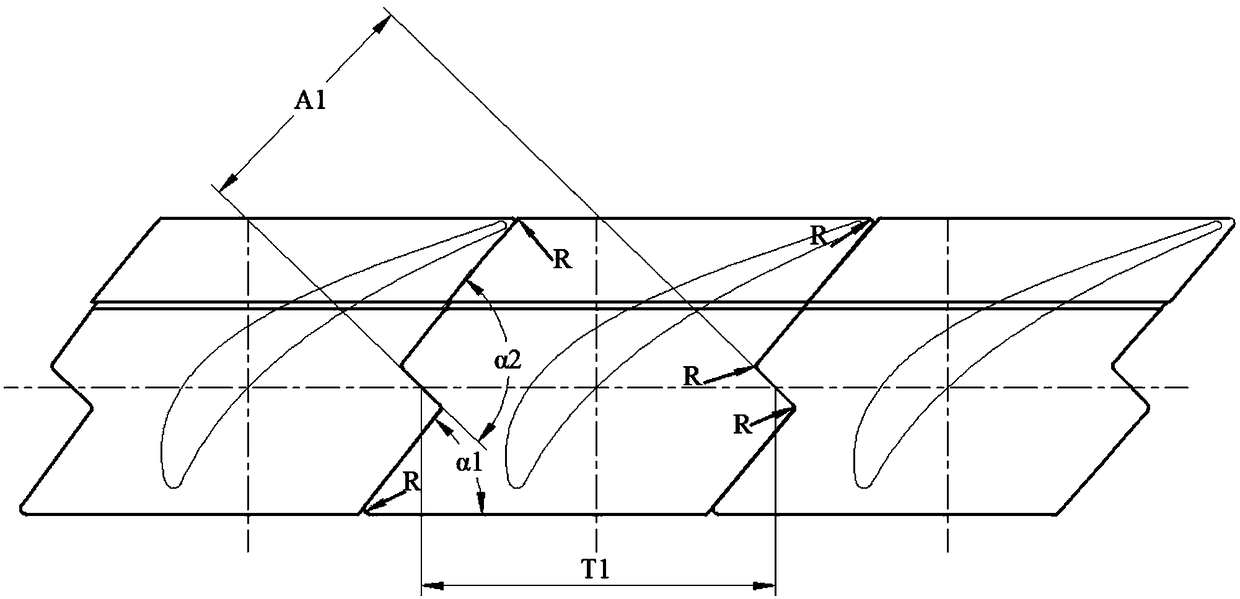

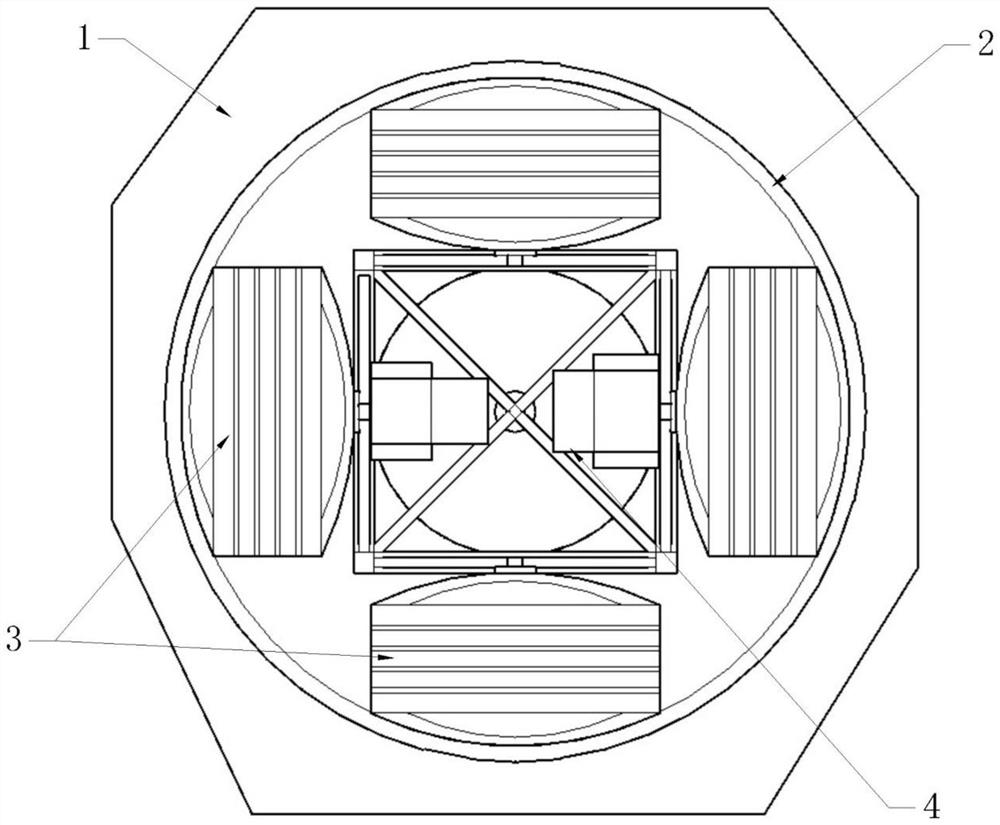

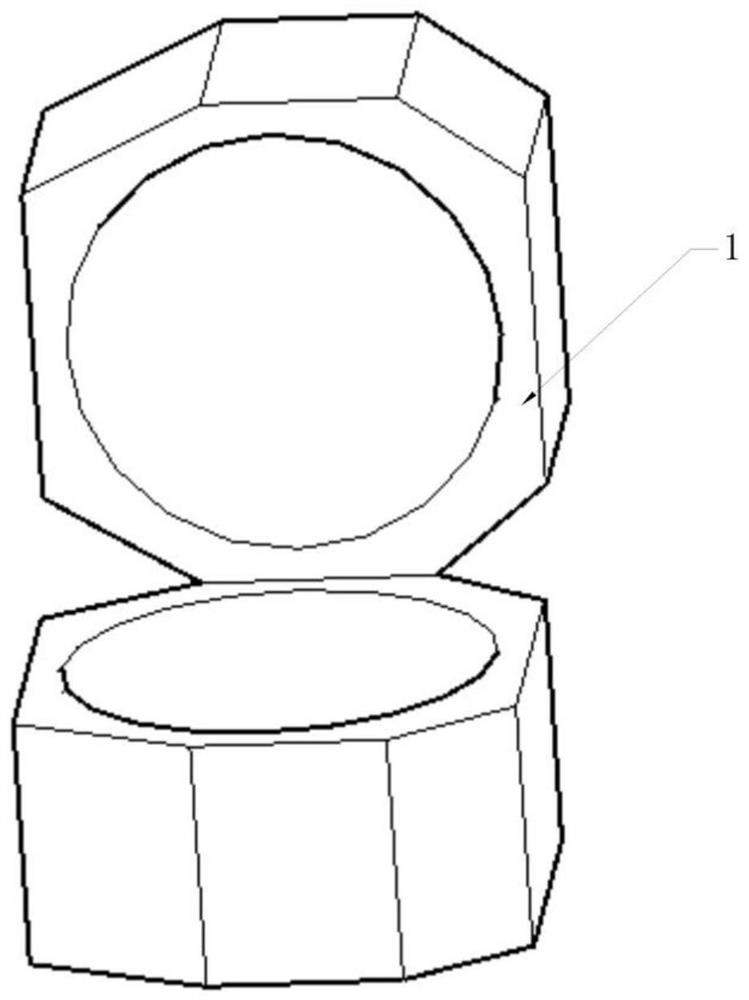

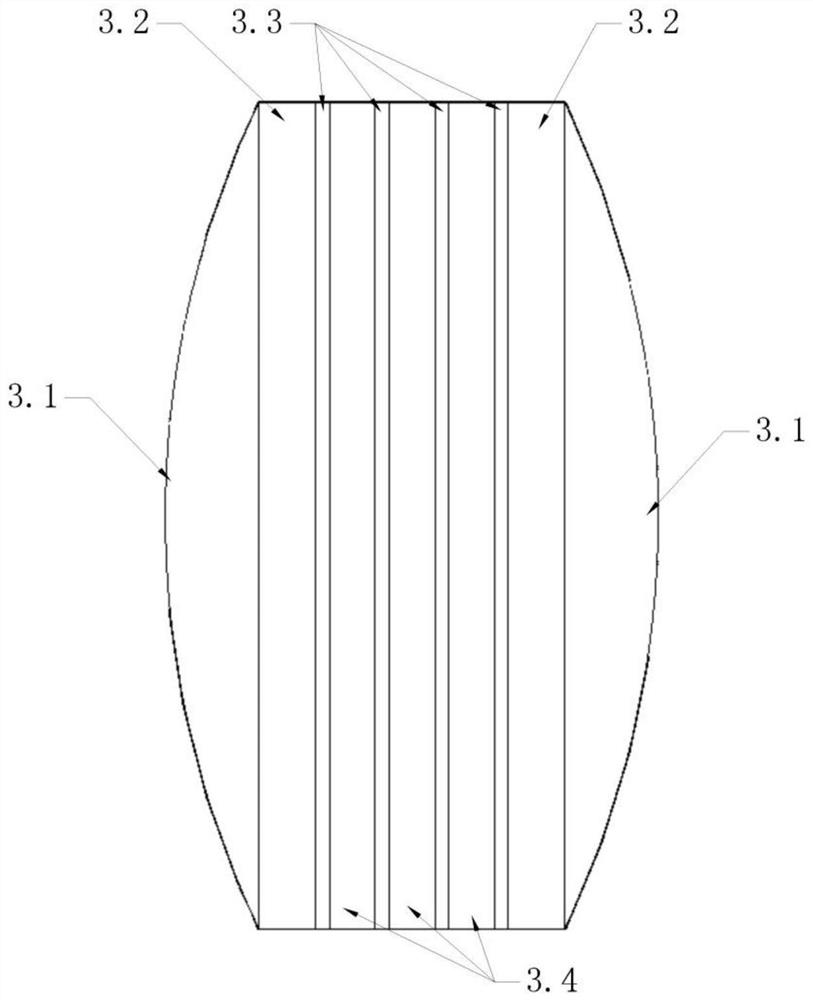

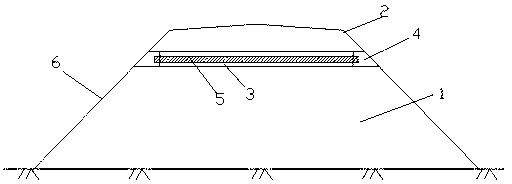

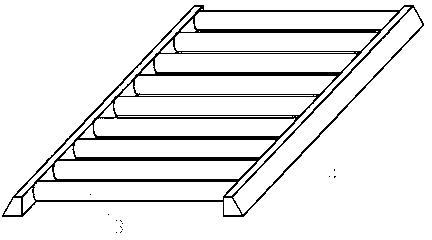

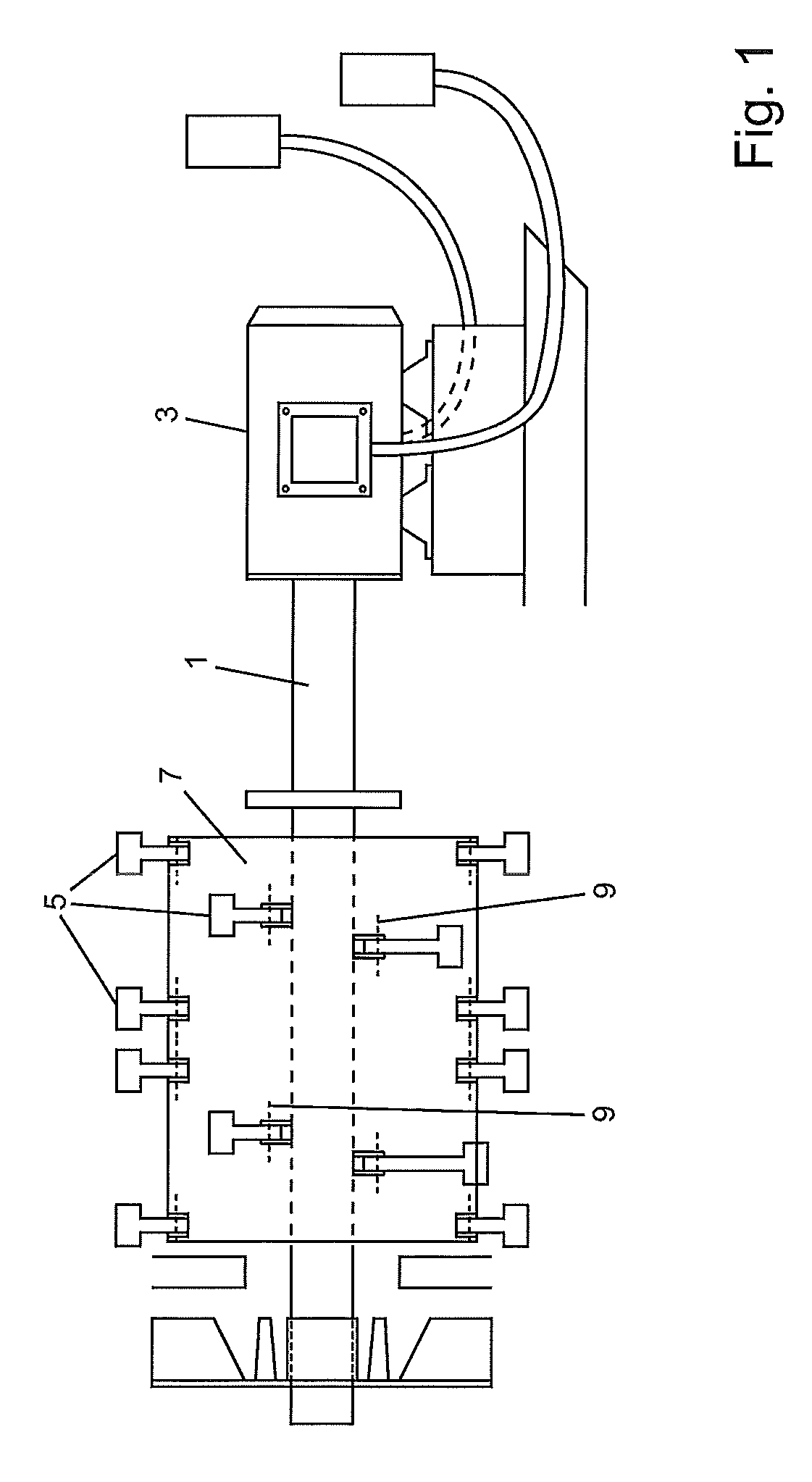

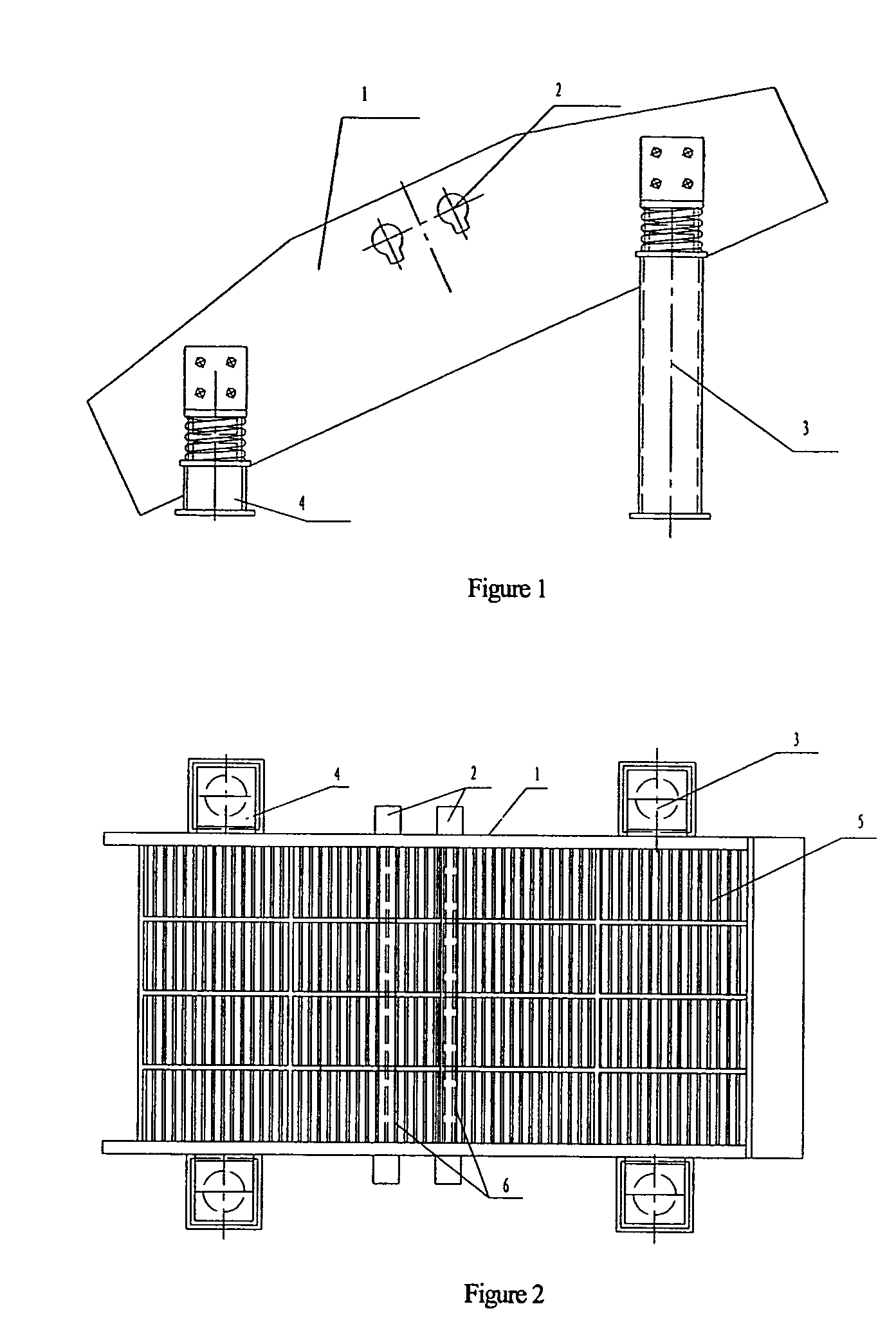

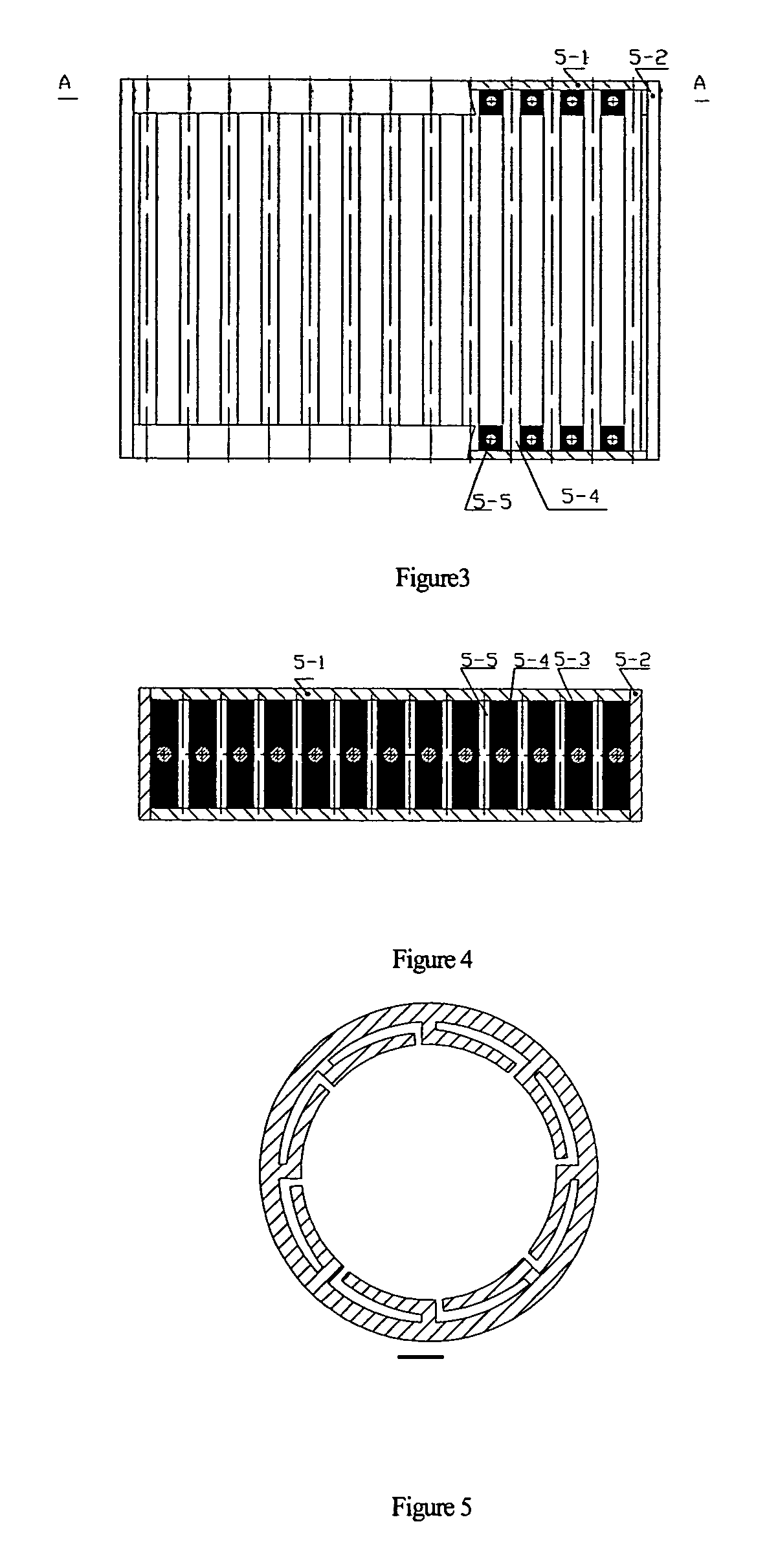

Elastic sieving technique and corresponding large-sized elastic vibration screen

InactiveUS20070261999A1Reduce power consumptionSimple and easy to and maintainSievingScreeningResonanceElastic vibration

An elastic sieving method and corresponding large-sized elastic vibration screen The present invention utilizes a screening surface and a separate sieving machine. A screen mat located on the sieve box is connected to multiple small rectangular screens. While the machine is vibrating, the resonation of screen rods located on the screen mat connected by small rectangular screens are initiated to screen the material and to cause the vibration of the whole vibration screen and realize the conveyance and lamination of materials. Because the screening surface is in a state of resonance, the vibration strength is strong enough to prevent the screen meshes from becoming plugged, allowing for high sieving efficiency. A bearing in the sieving mechanism is installed with a vibration damping ring, placing the bearing in a resonant state, allowing for a low dynamic stress level, which satisfies the process requirement for large-sized vibration screen excitation units with a screening surface as wide as 4800 mm. Thus, the production efficiency of vibration screen is high, the structure of the machine is simple and easy to repair and maintain, and energy consumption is reduced. Furthermore, the dynamic stress level of the sieving machine is low, the reliability is high, and the vibrations are stable. These properties allow the present invention to have a wide range of practical applications, including uses in the coal, metallurgic, chemical and environmental protection fields.

Owner:CHINA UNIV OF MINING & TECH

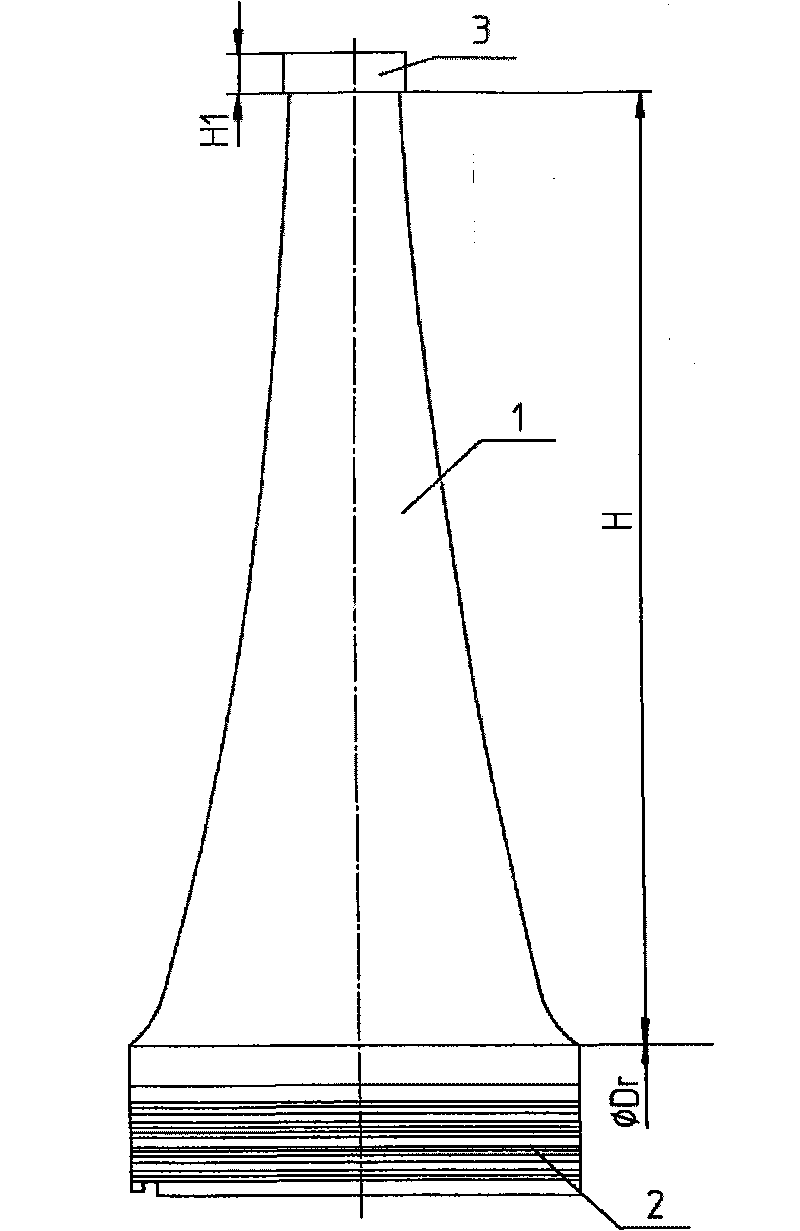

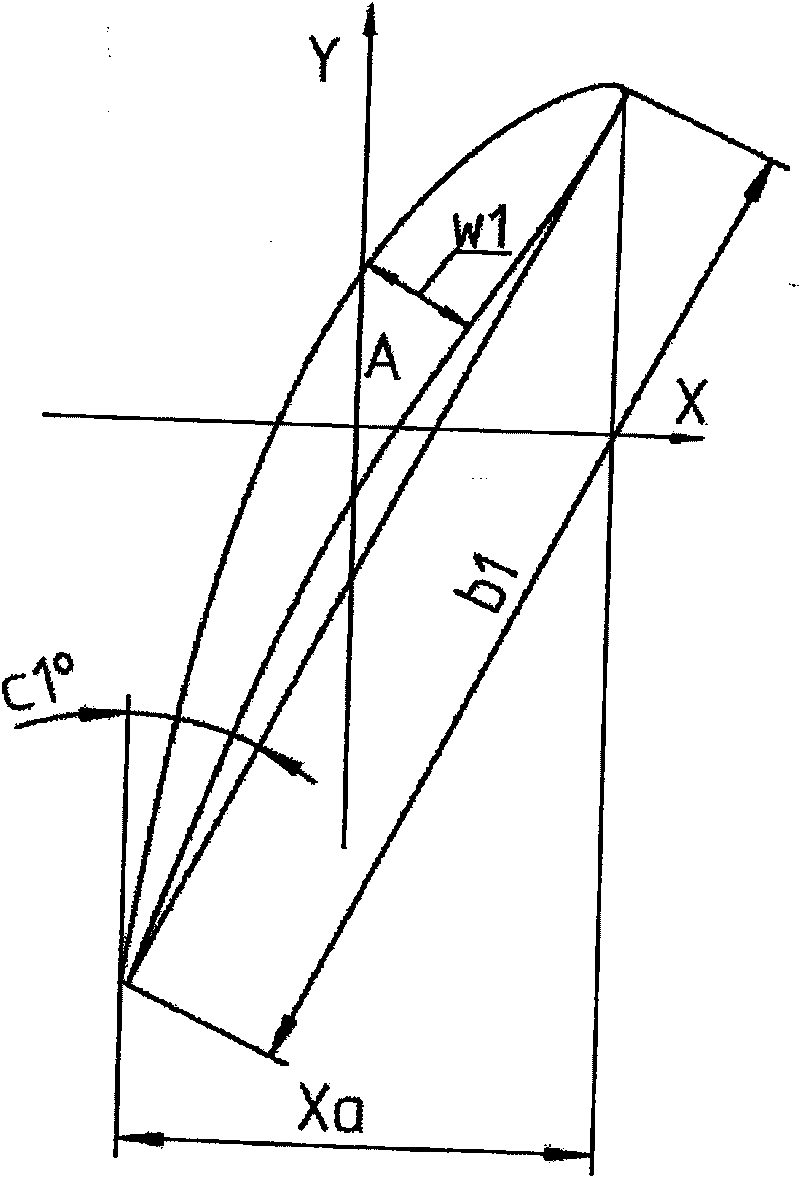

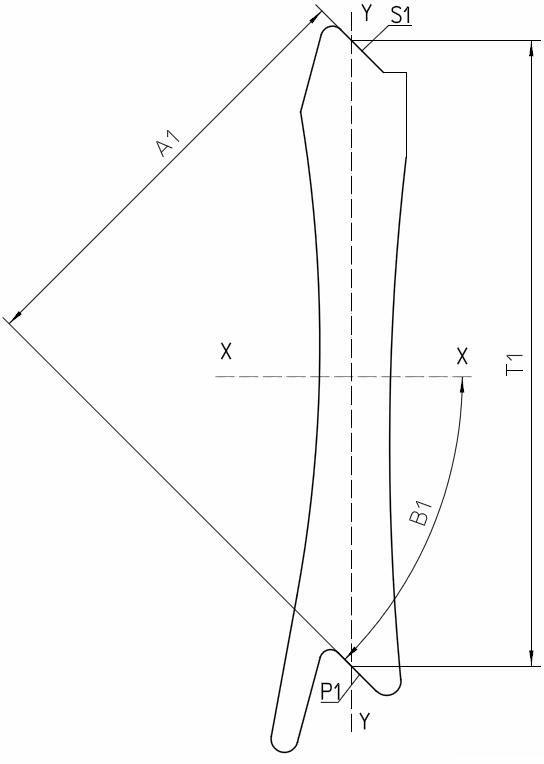

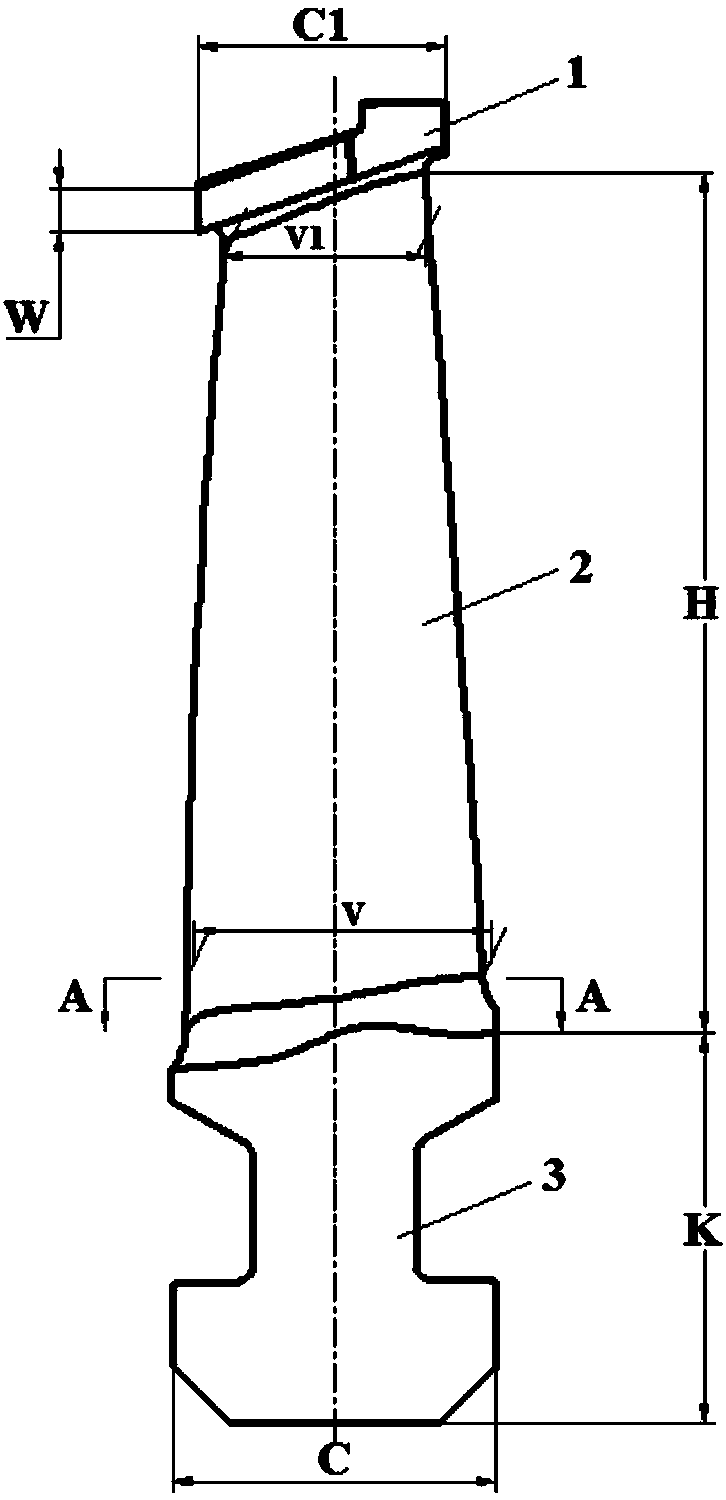

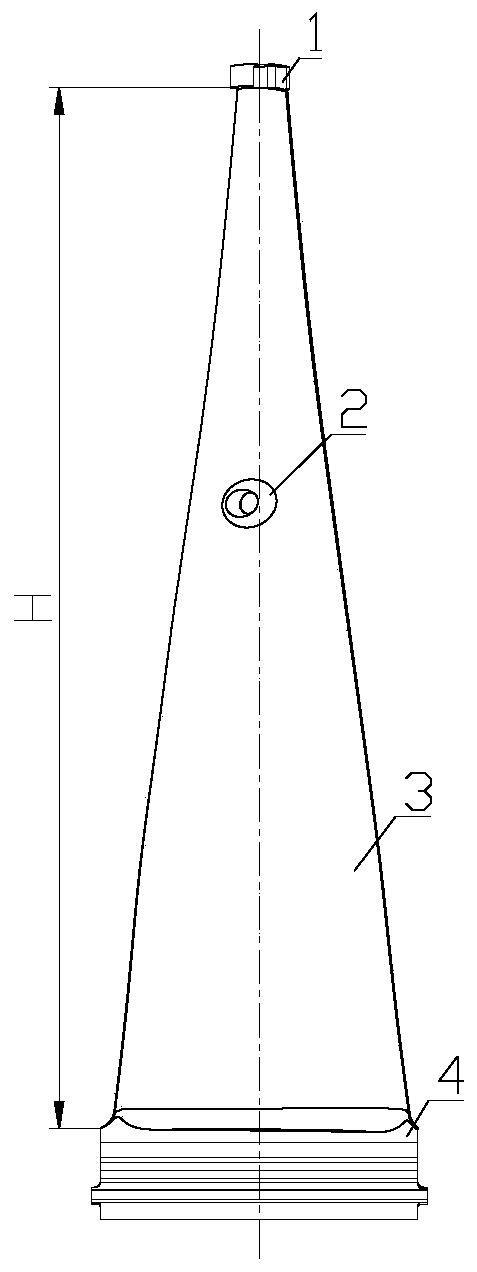

Last-stage moving blade of air-cooled feed pump steam turbine

ActiveCN101737091AIncrease dynamicsReduce dynamic stressBlade accessoriesMachines/enginesEffective heightEngineering

The invention discloses a last-stage moving blade of an air-cooled feed pump steam turbine, comprising a blade body, wherein the blade body is an abnormal-shaped body formed by overlapping a plurality of characteristic sections according to a specific rule, the effective height of the blade body is H=365.0mm, and the root diameter of the blade body is Dr=906.8mm. The last-stage moving blade comprises the following characteristic parameters: an established angle c1, a chord length b1, a maximum thickness w1, an axial width Xa and a sectional area A. The overlapping rule of the sections is that the sections are in continuous and smooth transition along a blade height direction from a root end to a top end. The relative value of the blade height H is monotonically increased from 0.0 to 1.0; the established angle c1 is monotonically decreased from 81.830 to 13.670. The changing rule of the chord length b1 is no more than 1.61 and no less than 1.0; the changing rule of the maximum thickness w1 is no more than 2.265 and no less than 1.0; the changing rule of the axial width Xa no more than 3.75 and no less 1.0; and the changing rule of the sectional area A is no more than 4.58 and no less than 1.0. The invention has good dynamic property, small dynamic stress and good damping characteristic and is especially suitable for a 1000MW supercritical unit air-cooled steam turbine.

Owner:DONGFANG TURBINE CO LTD

Renovation method for treating mud pumping of plate-type ballastless track railway roadbed

The invention discloses a renovation method for treating mud pumping of a plate-type ballastless track railway roadbed. Drilling is conducted on the surface layer of a foundation bed through a special horizontal drilling machine, and then the method that hot air is injected into grouting hole passageways is adopted; accumulated water in a mud pumping disease area is subjected to treatment, and grouting is conducted in grouting holes after accumulated water treatment is completed; before grouting, telescopic seams of a base plate, cracks of the side edges and orifices of the opposite sides of the grouting holes are subjected to sealing treatment, and then grouting is successively conducted in the hole passageways according to a certain sequence; a uniform and compact water insulation layer with the certain strength is formed between the base plate and the surface layer of the foundation bed after grouting is completed; and the water insulation layer can obstruct water of cracks on the upper portion from invading into the surface layer of the foundation bed and can also block fine particle soil in the surface layer of the foundation bed on the lower portion to move upwards. According to the novel renovation method for treating mud pumping of the plate-type ballastless track railway roadbed, the mud pumping disease of the plate-type ballastless track railway roadbed can be well governed.

Owner:ZHEJIANG UNIV

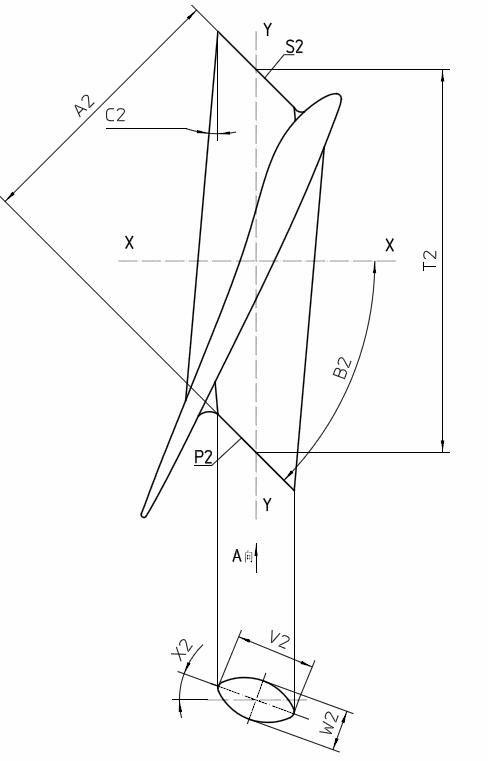

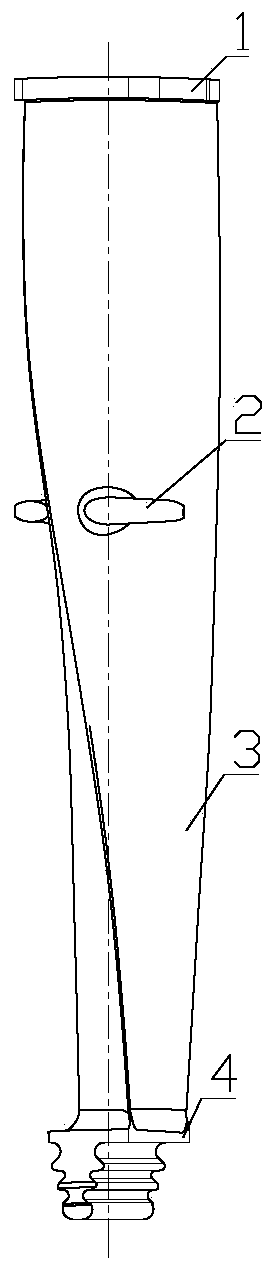

Last stage blade for half speed nuclear power steam turbine

ActiveCN102108882AIncrease dynamicsImprove aerodynamic performanceBlade accessoriesMachines/enginesNuclear powerEffective height

The invention discloses a last stage blade for a half speed nuclear power steam turbine. A blade body is a special body formed by laminating a plurality of characteristic sections according to a specific rule, and has the effective height H and root diameter Dr; a characteristic parameter installation angle c1, a chord length b1, the maximum thickness W1, an axial width Xa and a sectional area A are provided; the laminating rule of the sections is that the sections are continuously and smoothly transited from the root end to the top end along the blade height direction; a relative value of the blade height H is monotonously increased to 1.0 from 0.0; correspondingly, the installation angle c1 is monotonously decreased to 10.8 degrees from 80.99 degrees; a change rule of the sectional area A is that A is more than or equal to 1 and less than or equal to 5.564; a change rule of the axial width Xa is that Xa is more than or equal to 1.0 and less than or equal to 8.437; a change rule of the chord length b1 is that b1 is more than or equal to 1.0 and less than or equal to 1.556; and a change rule of the maximum thickness W1 is that W1 is more than or equal to 1.0 and less than or equal to 3.131. The dynamic stress of the blade can be greatly reduced, the rigidity of the blade can be improved and the blade safety requirement can be met; and the blade is suitable for nuclear power steam turbines with the rated speed of 1,500 rpm, and particularly suitable for nuclear power steam turbines with the back pressure of 3-6kPa, the power of 1,000-1,700MW and the rotating speed of 1,500rpm.

Owner:DONGFANG TURBINE CO LTD

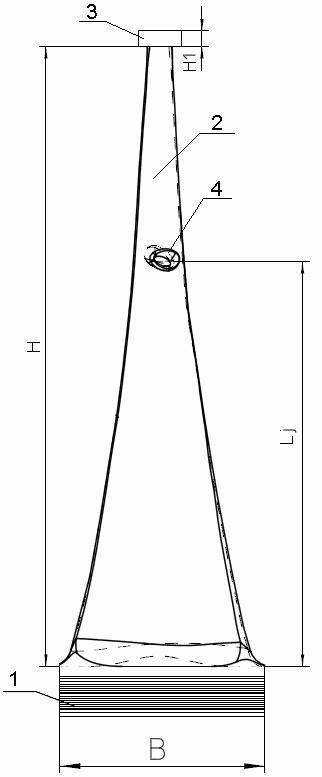

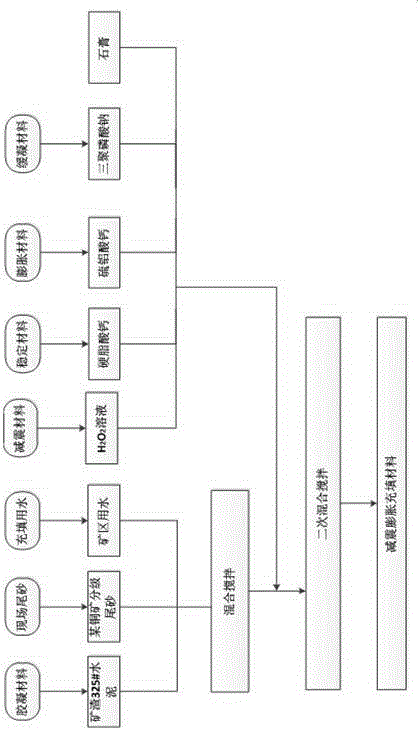

Shock-absorption expansion filling material used for filling deep goaf and preparation method

InactiveCN105152595AStress Migration ReliefPrevention and Control of RockburstsGypsumCalcium aluminates

The invention discloses a shock-absorption expansion filling material used for filling a deep goaf and a preparation method in order to solve the problem that filling cannot realize roof contact after the underground goaf is filled with a conventional filling material. The shock-absorption expansion filling material is composed of a base material and other material, and the base material comprises, in percent by mass, 53.60%-64.89% of mine tailings, 7.44%-14.60% of a gelling material, and the balance water. The other material is prepared from the following raw materials in percent by mass: 3.75%-8.75% of hydrogen peroxide, 2.00%-6.00% of a stabilizing material, 8.00%-12.00% of calcium sulphoaluminate, 1.00%-3.00% of a retarding material, and 2.00%-4.00% of gypsum. The preparation method comprises selection of the materials, proportioning of the ingredients, molding and molding maintenance. Because of the special pore structure, the shock-absorption expansion filling material possesses the advantages of obvious shock absorption performance, relatively good fluidity, excellent expansion performance and the like, and is especially applicable to filling of the metal mineral deep goaf.

Owner:LANZHOU ENG & RES INST OF NONFERROUS METALLURGY

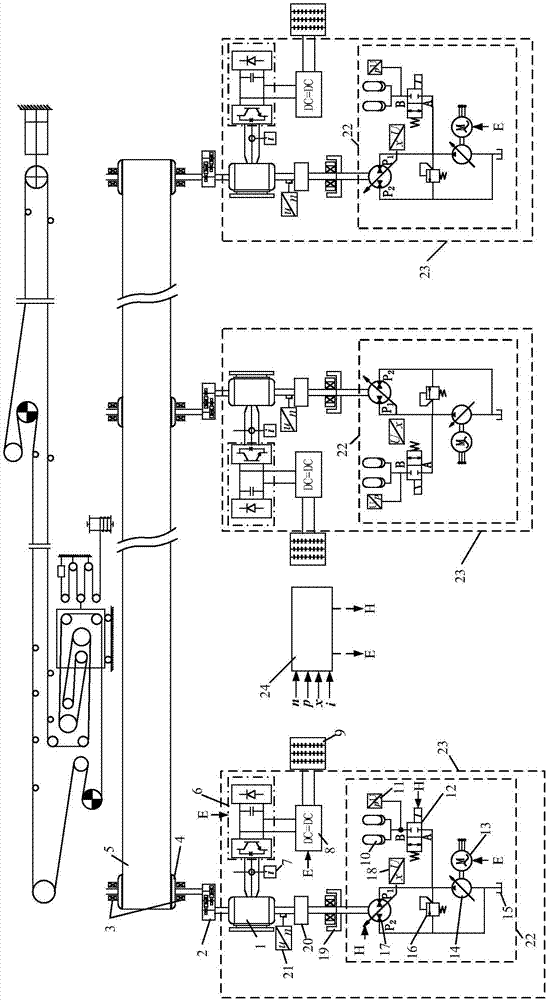

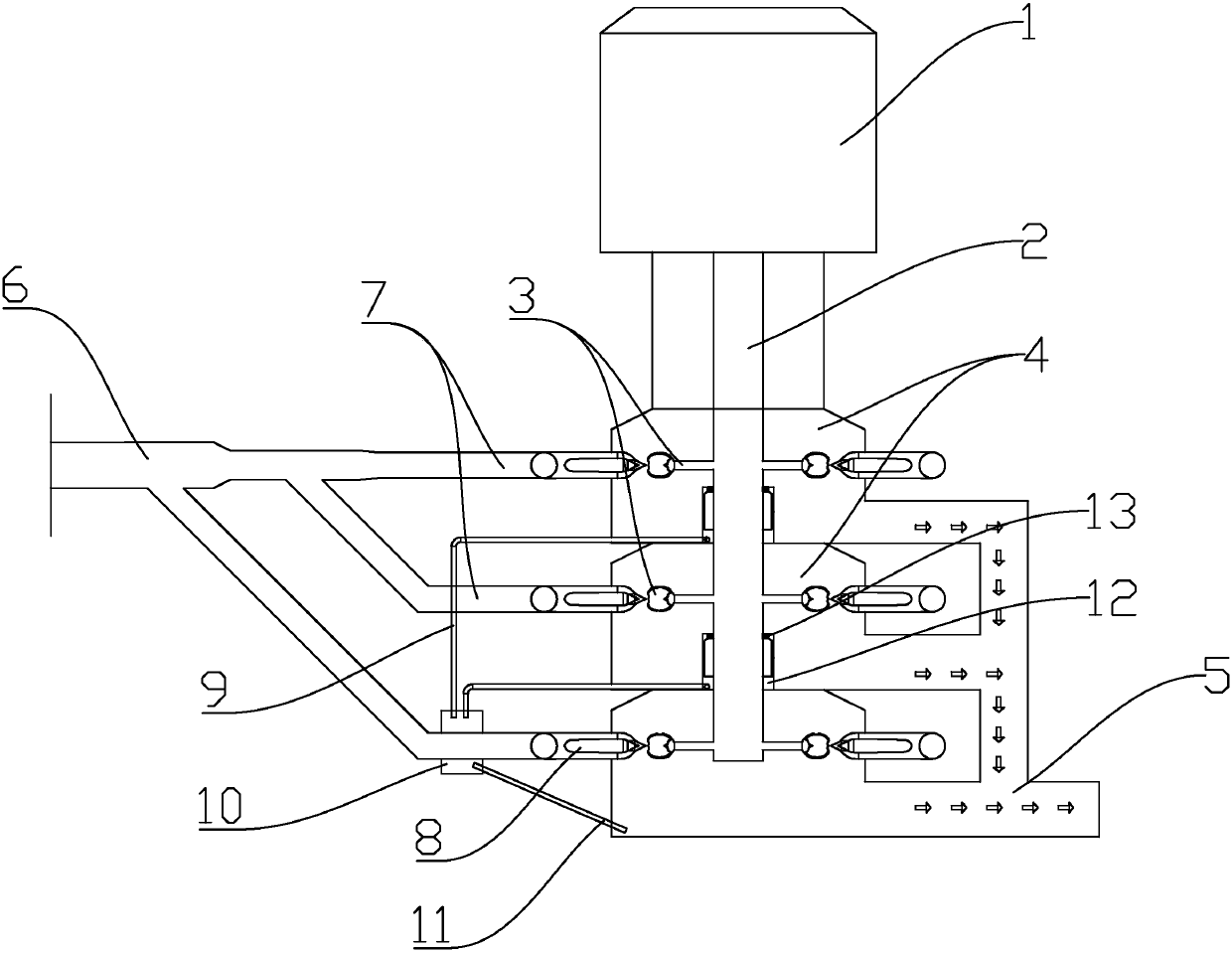

Hybrid-driven long-distance belt conveyor

InactiveCN107444847AReduce volumeOptimize layoutConveyorsControl devices for conveyorsReduction driveDrive motor

The invention discloses a hybrid-driven long-distance belt conveyor. The hybrid-driven long-distance belt conveyor comprises speed reducers, gate control systems, driving rollers and a conveying belt. The hybrid-driven long-distance belt conveyor further comprises kinetic potential storage and transportation circuit and motor combination drive systems, supercapacitor sets and controllers. By recycling kinetic energy of the belt conveyor in the braking process, electro-hydraulic hybrid drive of the long-distance belt conveyor is achieved. According to the hybrid-driven long-distance belt conveyor disclosed by the invention is high in energy utilization rate, impact and vibration of an operating mechanism are eliminated, dynamic stresses of the operating mechanism are reduced, the degree of fatigue is lowered and the service life of main drive motors and the operating mechanism is prolonged.

Owner:TAIYUAN UNIV OF TECH

Low-pressure stage moving blade for variable-speed mass-flow industrial steam turbine

PendingCN108119187AImprove aerodynamic performanceAerodynamic performance is sufficientBlade accessoriesMachines/enginesThree stageEngineering

The invention designs a low-pressure stage moving blade for a variable-speed mass-flow industrial steam turbine. The low-pressure stage moving blade for the variable-speed mass-flow industrial steam turbine is taken as a tail three-stage blade of a low-pressure stage and comprises a blade body, a surrounding belt and a blade root. The low-pressure stage moving blade is characterized in that the blade body, the surrounding belt and the blade root are stamped into a whole from top to bottom, wherein a molded line of the blade body is a variable section twisted blade, the sectional area of the twisted blade gradually decrease from the root to the top, and two adjacent cross sections are relatively twisted. The structure has the characteristics that the molded line of the blade body is a variable section twisted molded line and is formed by a plurality of characteristic sections according to a characteristic rule, and the two adjacent cross sections are relatively twisted. The low-pressurestage moving blade can safely work at a backpressure of 5kPa-40kPa and a rotation speed of 2400rpm-4000rmp, has the characteristics of high variable-speed and variable-load efficiencies, good strength vibration performance, high mass flow, stable structure, convenience in machining and assembling and can be widely applied to heavy-load variable-speed industrial steam turbines.

Owner:HANGZHOU STEAM TURBINE

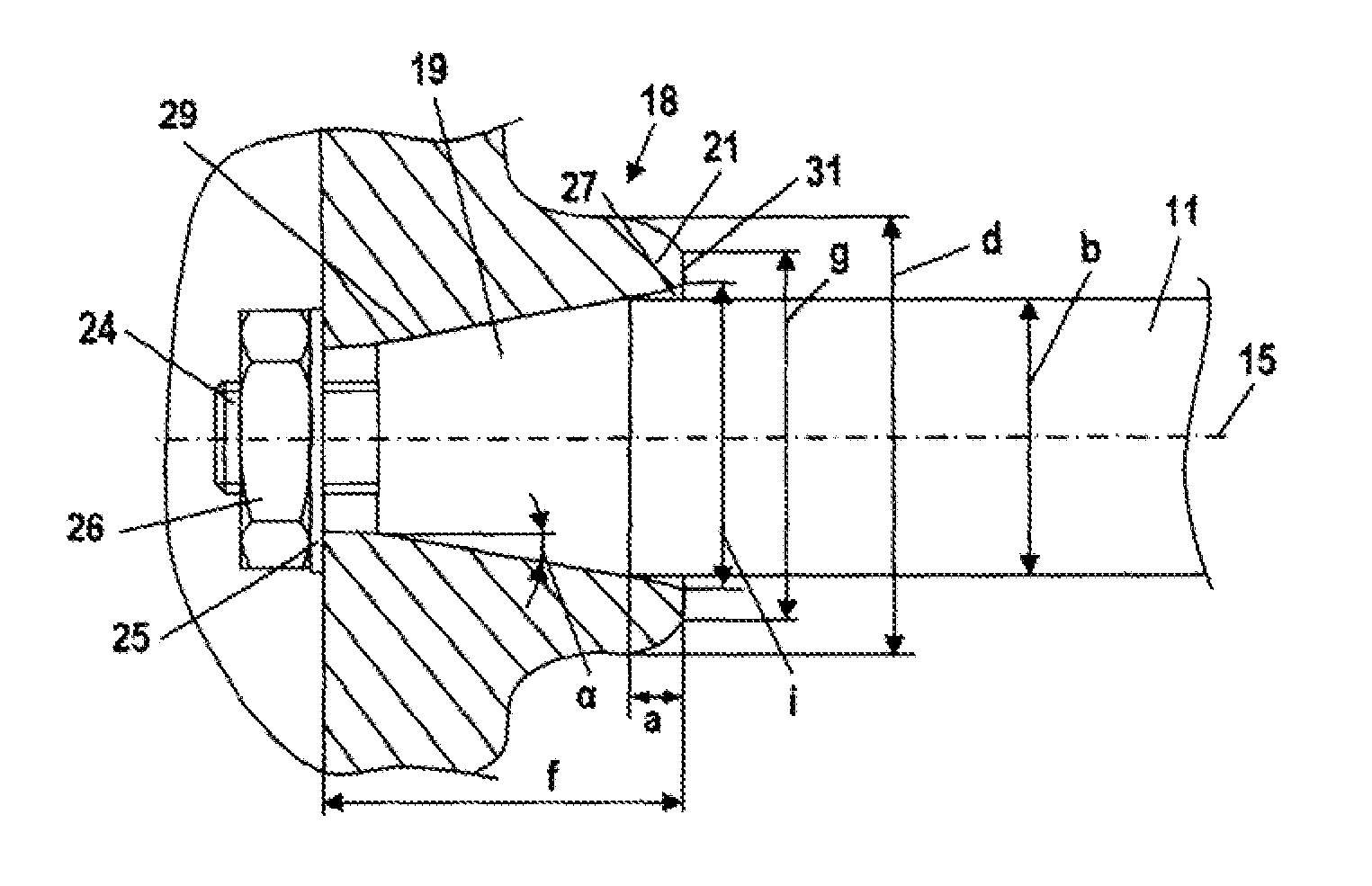

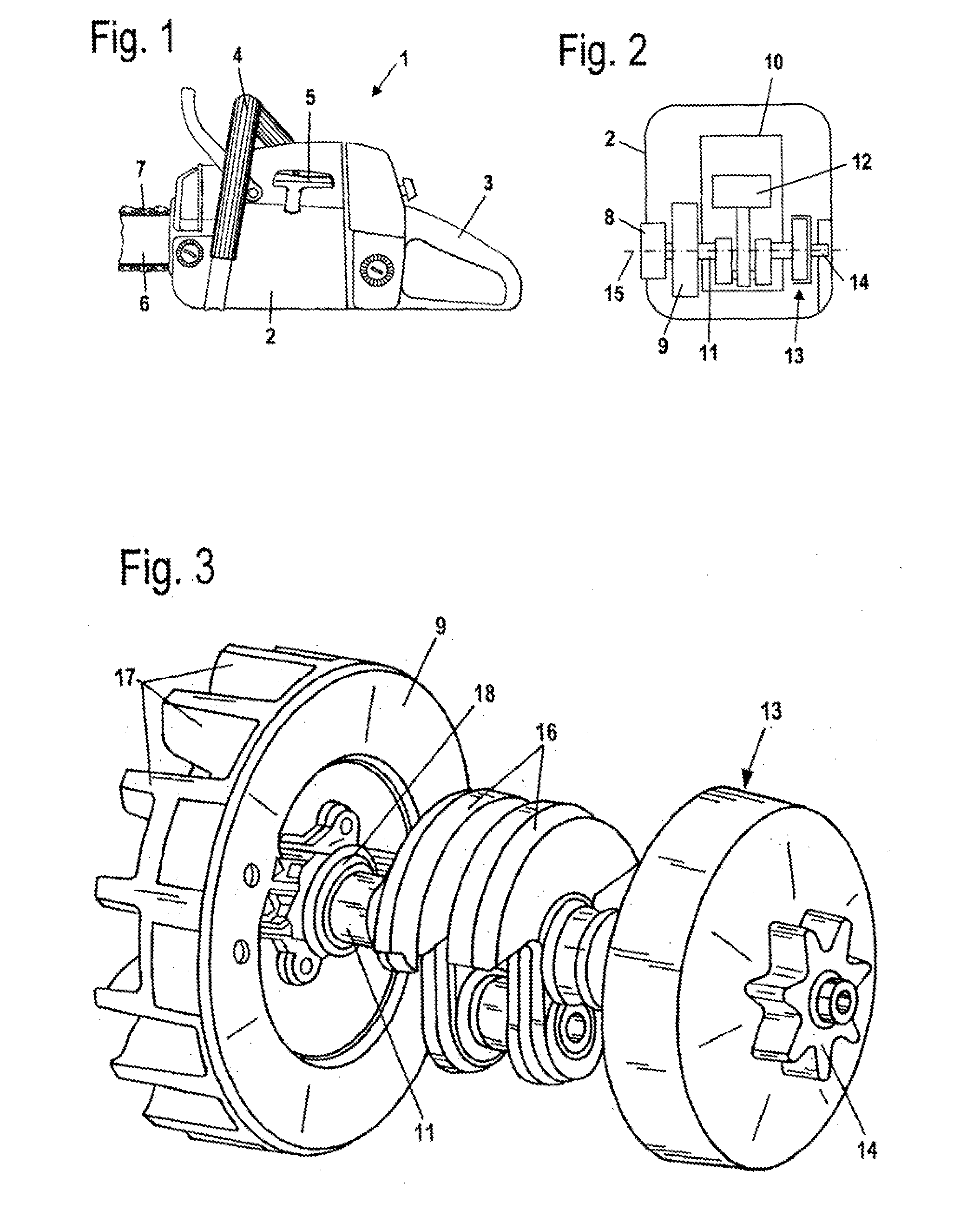

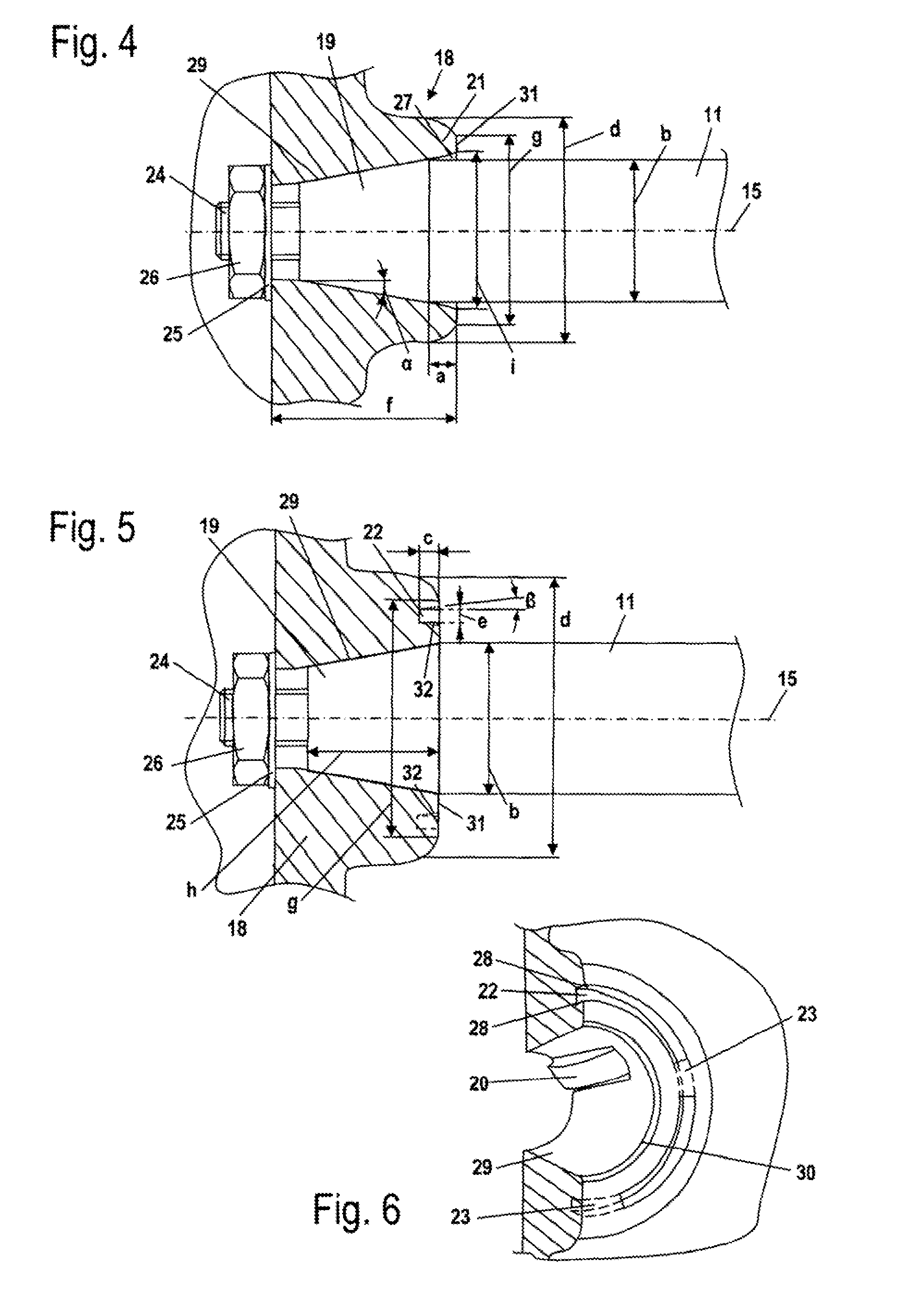

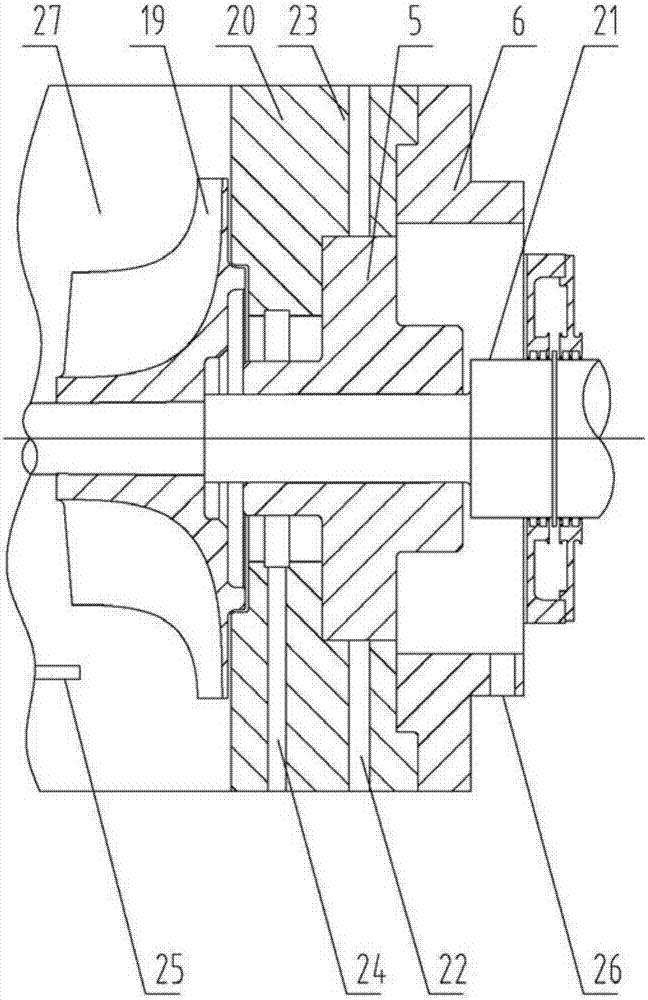

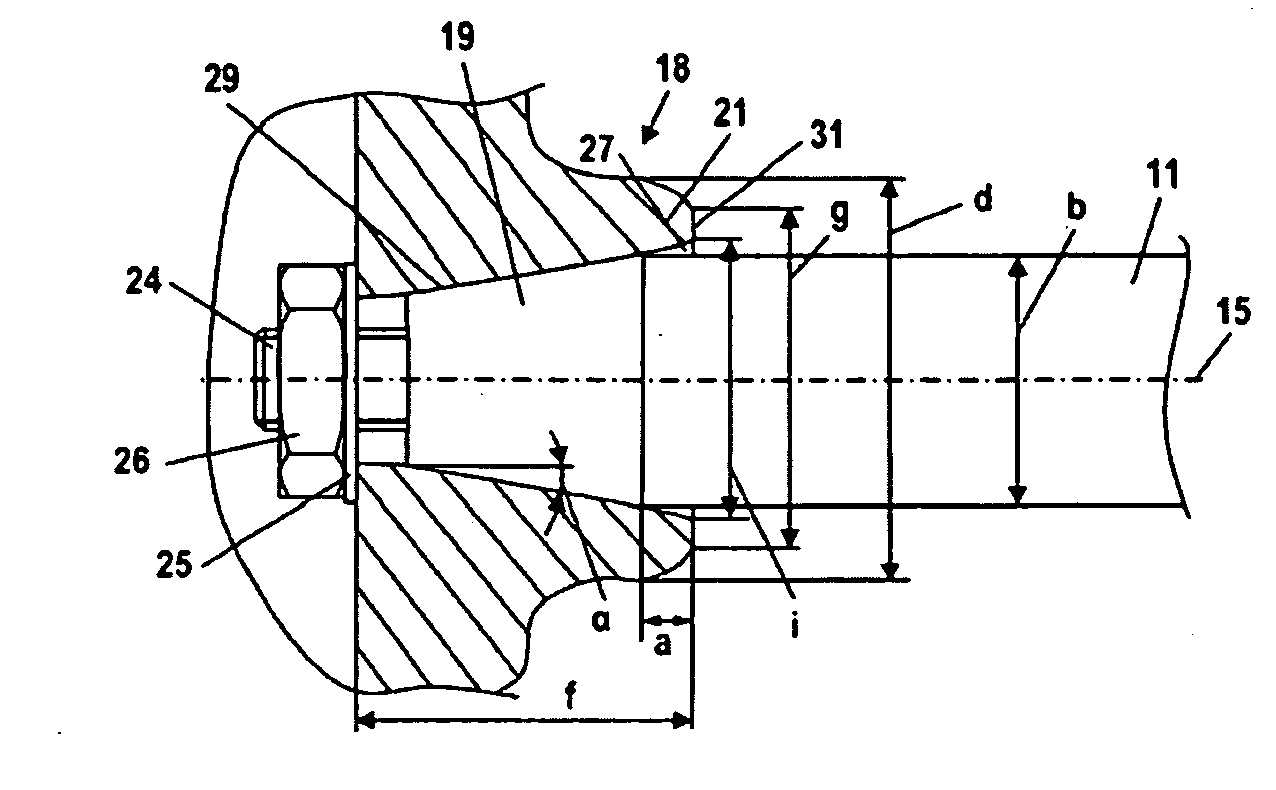

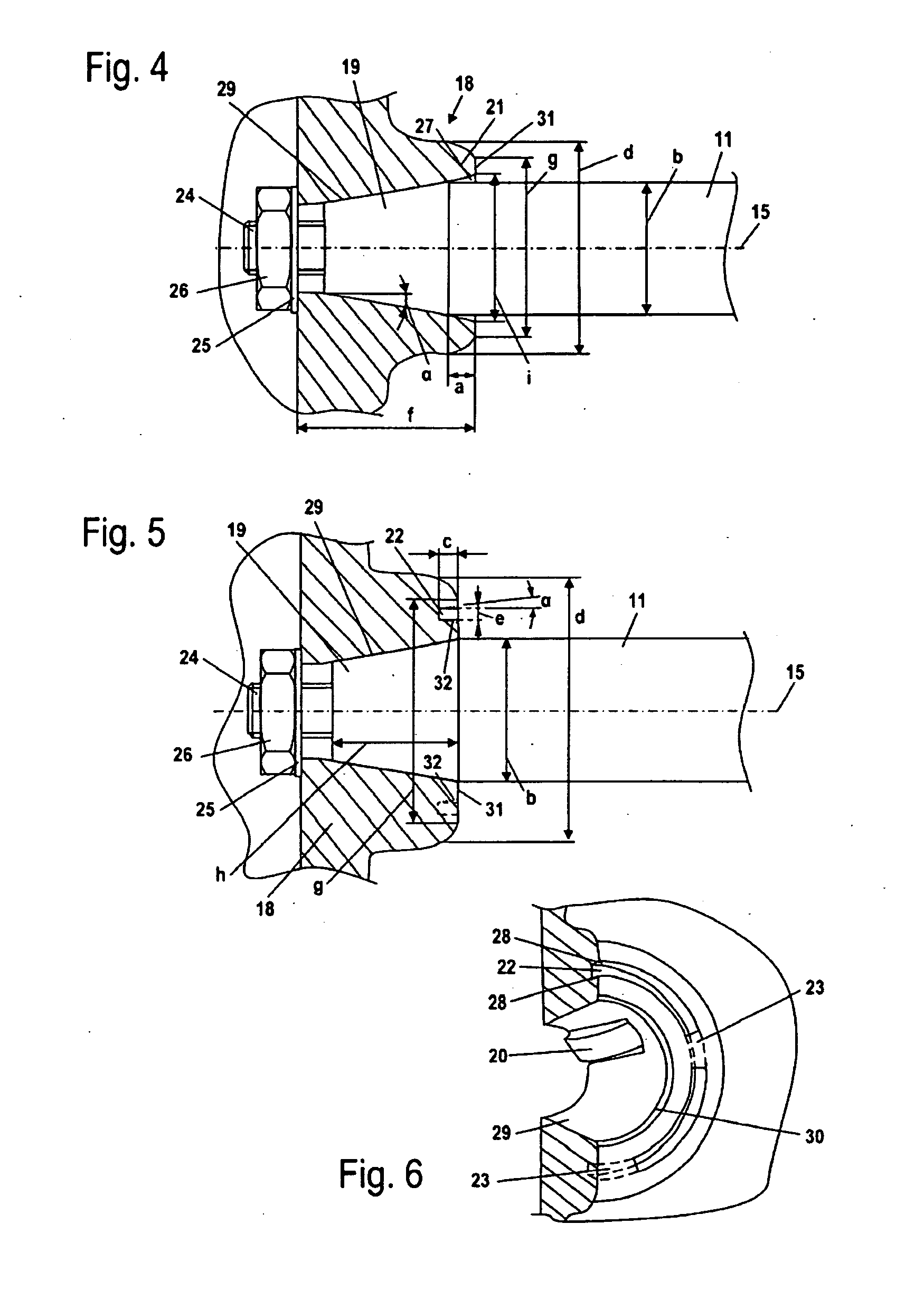

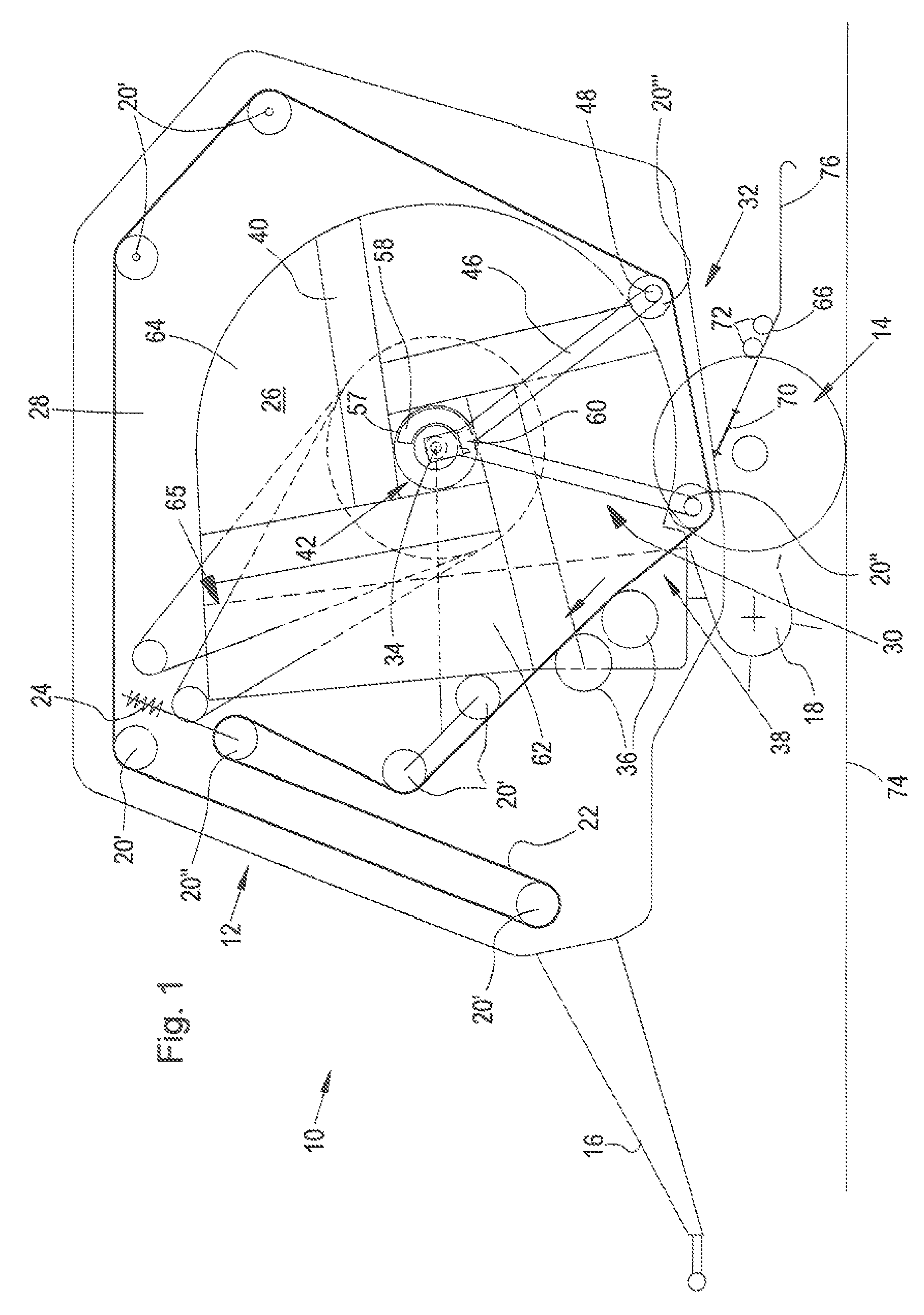

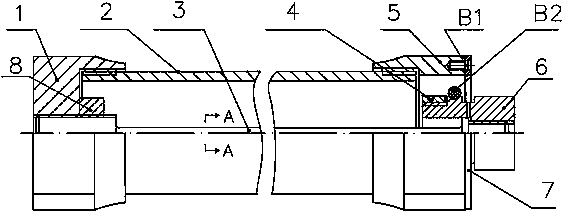

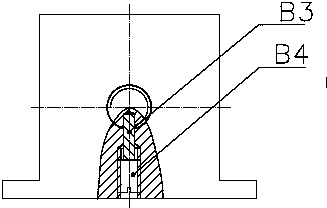

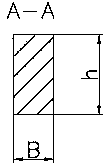

Shaft/Hub Connection and Manually Guided Implement

InactiveUS20110182660A1Reduce dynamic fatigue stressReduce dynamic stressRod connectionsCouplings for rigid shaftsClassical mechanicsStructural engineering

A shaft / hub connection between a shaft rotatably driven about an axis of rotation, and a hub disposed on the shaft so as to be non-rotatable relative thereto. The hub has a conical opening and an end face at that end of the hub having the greatest inner diameter. The hub also has at least one relief groove that extends into the hub from the end face thereof. A conical shaft extension on the shaft extends into the conical opening of the hub and is held in the hub via a conical pressure connection.

Owner:ANDREAS STIHL AG & CO KG

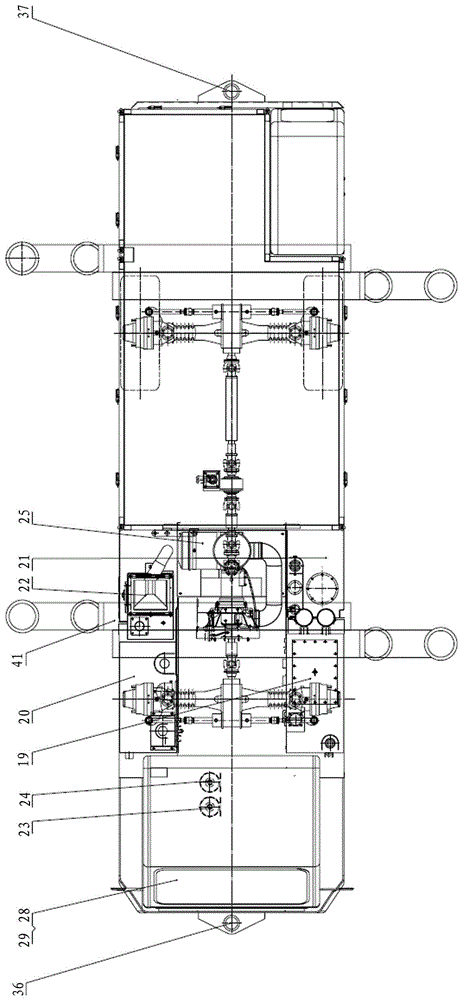

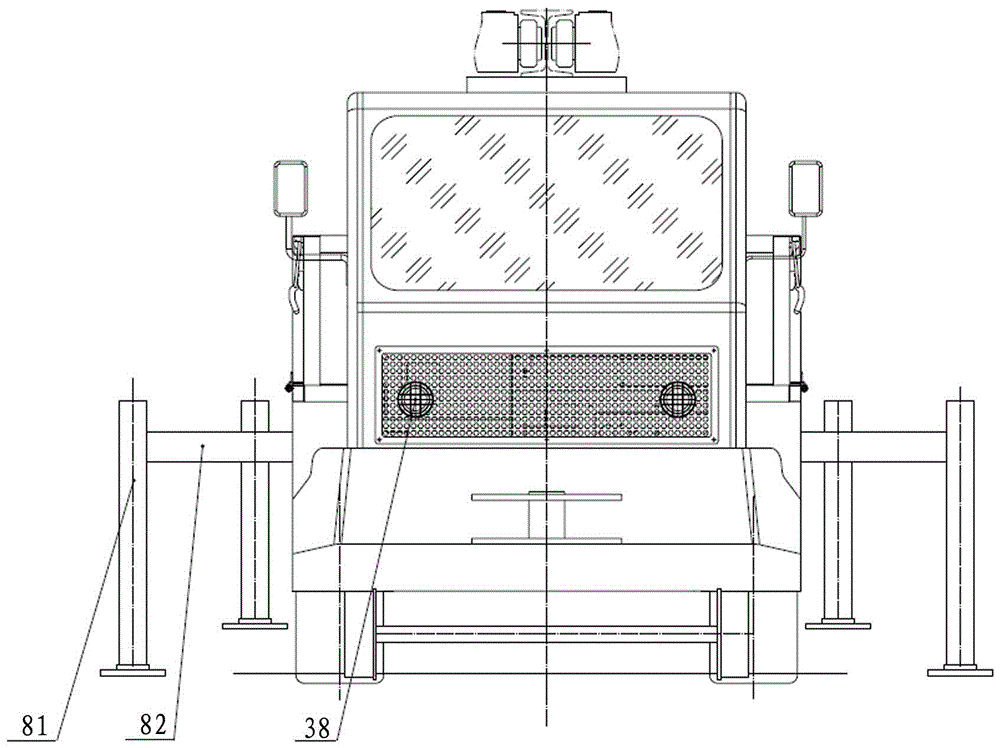

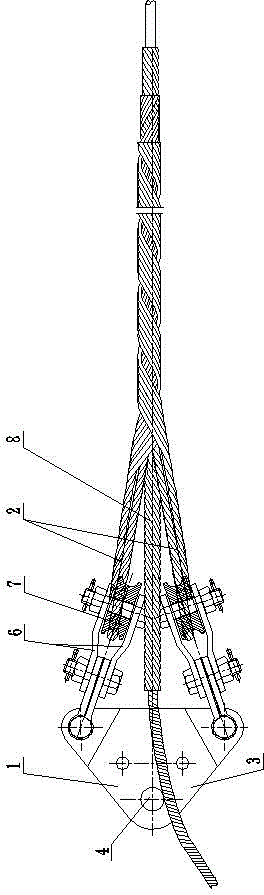

Explosion-proof diesel engine air-ground vehicle for coal mine underground roadway

The invention belongs to the technical field of design and manufacturing of coal mine underground auxiliary transportation equipment, solves the technical problems that in the coal mine underground auxiliary transportation field, no tool car capable of realizing railless or monorail crane reloading is provided, and provides an explosion-proof diesel engine air-ground vehicle for a coal mine underground roadway. The air-ground vehicle comprises a carriage, a main cab, a vice cab, front wheels, rear wheels, a frame, suspensions, transmission shafts, a transfer case, drive axles, a clutch, a hydraulic oil tank, a fuel tank, a waste gas treatment tank, a feed water tank, an air filter, a gas tank, a diesel engine, an explosion-proof protector, a hydraulic mechanism, a pneumatic mechanism, a transmission mechanism, a quick change-over device and a monorail crane driving device. The air-ground vehicle is provided with a mode switching system, so that the switching of a trackless working mode and a monorail crane working mode can be realized; four-wheel driving and bidirectional driving are adopted; and the air-ground vehicle is reasonable in design, compact in structure, small in size and strong in climbing ability, is flexible, safe, stable and reliable, can shuttle in a narrow coal mine underground roadway, and can freely and conveniently run forwards and backwards.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

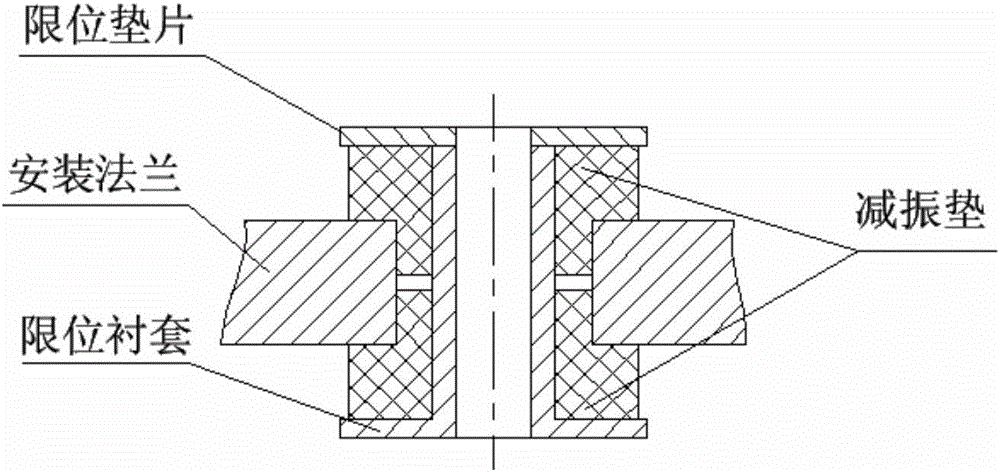

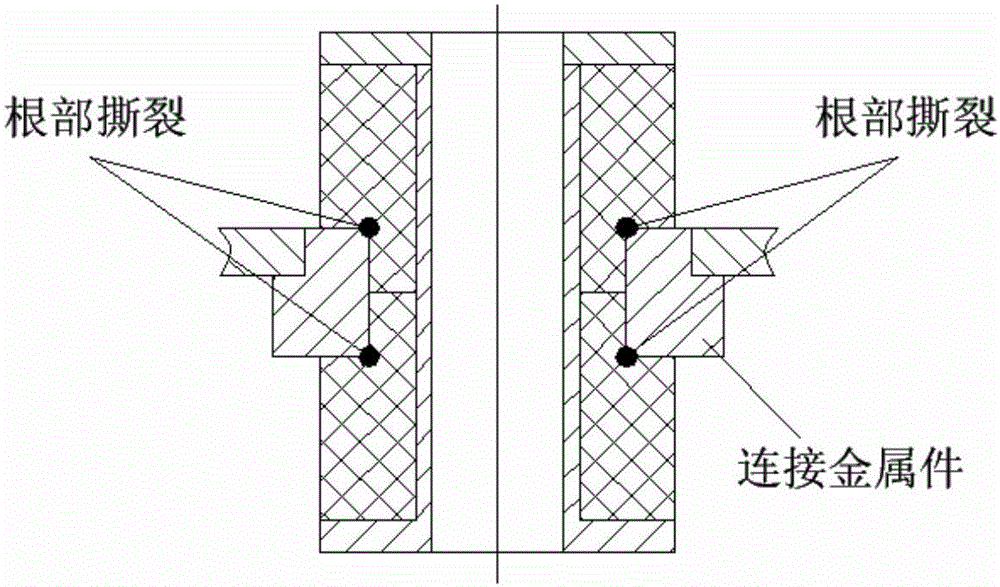

Low-temperature-resistant durable vibration rubber shock absorber

InactiveCN105114500AIncrease local thicknessLarge installation spaceMultiple spring combinationsRubber materialEngineering

A low-temperature-resistant durable vibration rubber shock absorber comprises an installation connecting element, a rubber shock-absorbing pad, a limiting bush, a limiting gasket and the like. According to the low-temperature-resistant durable vibration rubber shock absorber, vibration and impact energy is converted into heat and deformation energy of a rubber material through deformation of a rubber part, and accordingly a shock-absorbing function is achieved on a lightning suppressor. Besides, the shock absorber can bear the torsional bending function caused by inconsistent vibration, so that a lightning suppressor installation plate is in a rigid modal at low frequency, and damage caused by torsional bending of the installation plate to the suppressor is avoided. The designed installation connecting element effectively increases the thickness of the lightning suppressor installation plate, and space is provided for design and installation of the shock absorber. Damping rubber is vulcanized in an installation hole, used for assembling the shock absorber, of the installation connecting element, contact stress of the damping rubber and the rubber shock-absorbing pad is reduced, and durability of the shock absorber is effectively improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

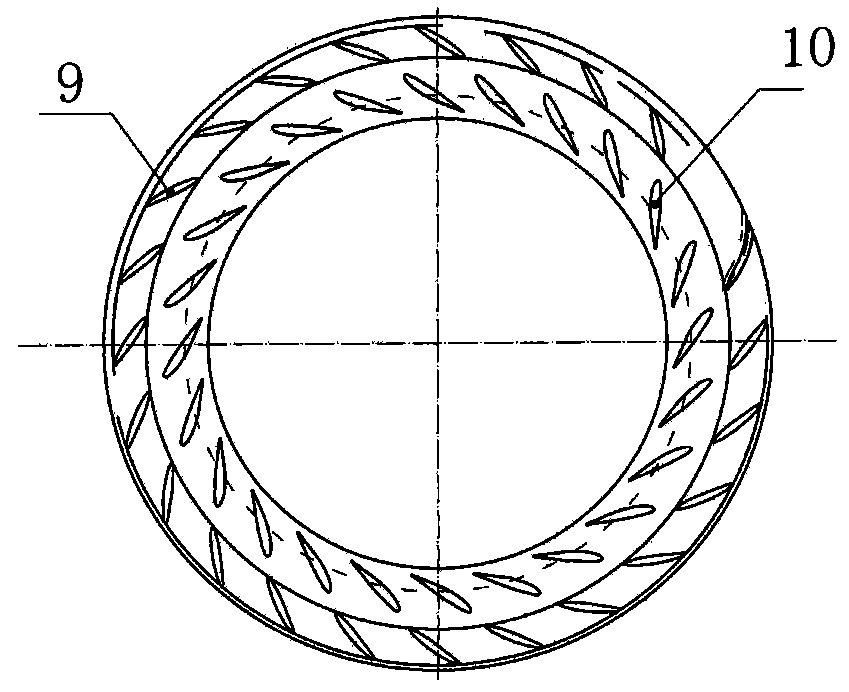

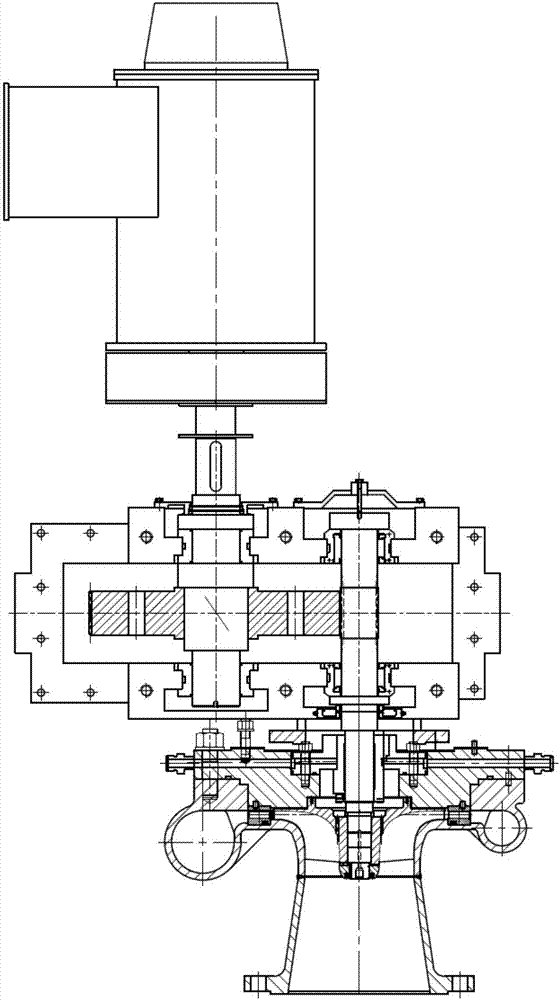

Organic Rankine cycle kilowatt power generation device

ActiveCN107355271AReduce dynamic stressImprove rigidityBlade accessoriesLeakage preventionOrganic Rankine cycleCoupling

The invention relates to an organic Rankine cycle kilowatt power generation device. The device comprises a radial inflow turbine, a reduction gearbox, a coupling and a generator; a high-speed shaft of the reduction gearbox is directly connected with the radial inflow turbine; and a low-speed shaft of the reduction gearbox is connected with the generator through the coupling. The device is characterized in that the radial inflow turbine comprises a volute, an impeller, a nozzle blade grid, a sealing shell and a sealing system; the sealing shell is fixedly mounted on the reduction gearbox; the volute is mounted on the sealing shell through a bolt; the impeller is positioned in the volute, and is fixedly mounted on the high-speed shaft of the reduction gearbox; the nozzle blade grid is fixedly mounted in a channel formed by the volute and the sealing shell; and the nozzle blade grid is annular, and is positioned at the outer periphery of the impeller. The device enables a power unit system to achieve compactness, high efficiency and reliability, and meanwhile, achieves zero leakage of organic working mediums.

Owner:ACADEMY OF AEROSPACE PROPULSION TECH

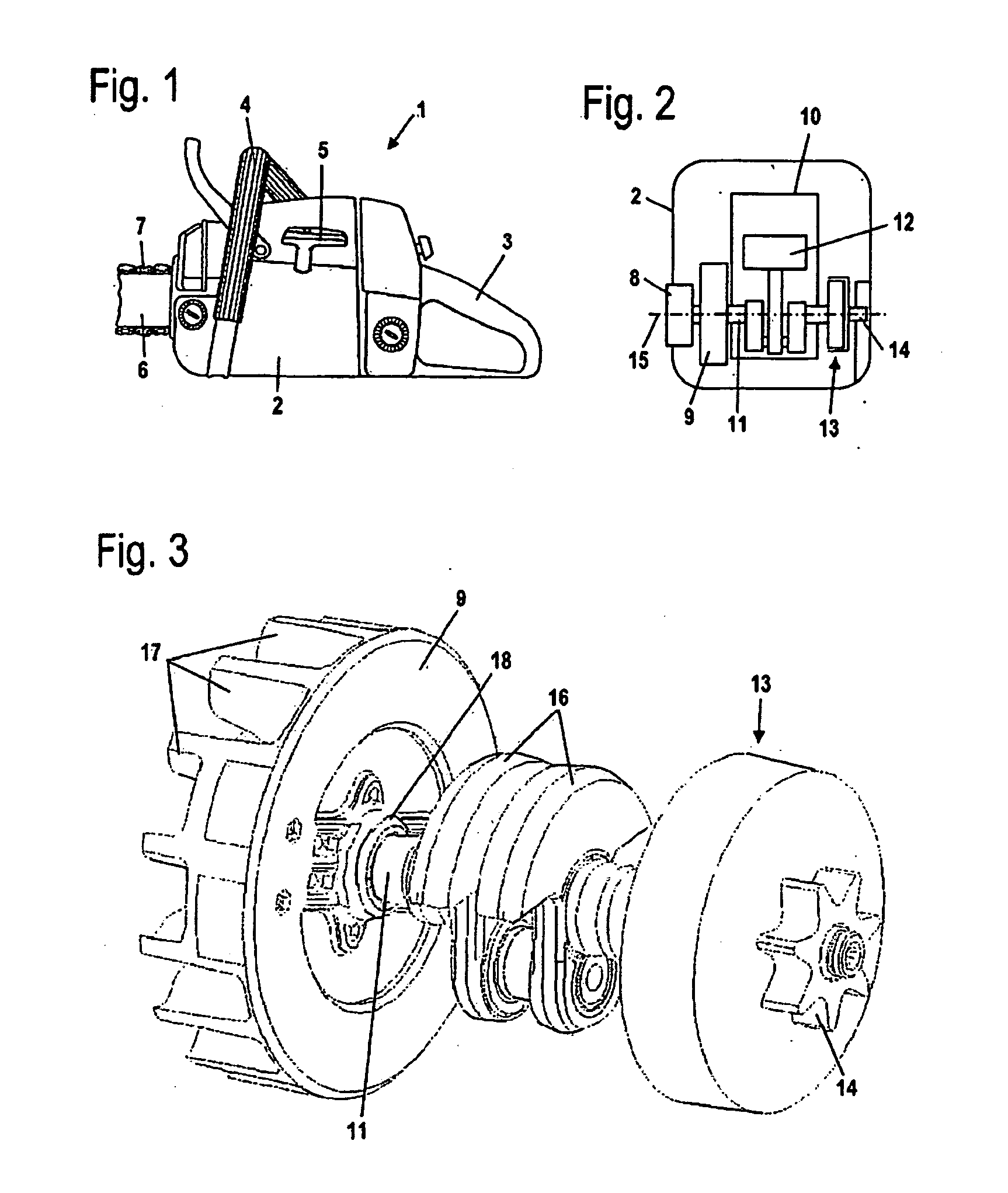

Shaft/hub connection and manually guided implement

InactiveUS20090028630A1High strengthReduce overall outer diameterHubsCouplings for rigid shaftsStress relievingEngineering

A shaft / hub connection between a shaft rotatably driven about an axis of rotation, and a hub disposed on the shaft so as to be non-rotatable relative thereto. A conical shaft extension on the shaft extends into a conical opening of the hub and is held in the hub via a conical pressure connection. The hub is provided with a stress-relieving or antifatigue arrangement for reducing the dynamic fatigue stresses that occur on the hub during operation. The shaft / hub connection is advantageously utilized for connecting the crankshaft of the internal combustion engine of a manually guided implement with a flywheel.

Owner:ANDREAS STIHL AG & CO KG

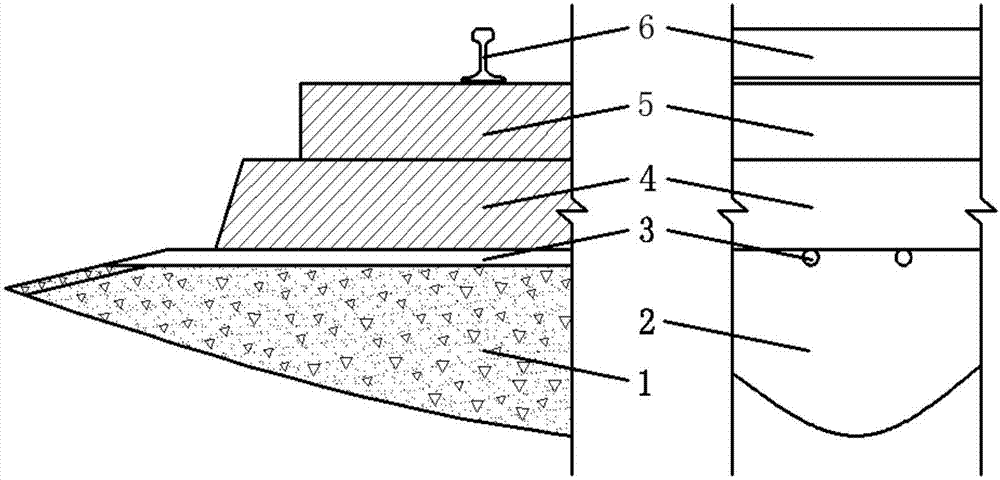

Intelligent coarse particles for vibration reduction and power generation

ActiveCN112663407AReduce dynamic stressGuaranteed StrengthPiezoelectric/electrostriction/magnetostriction machinesBallastwayEnergy harvesterEngineering

Intelligent coarse particles for vibration reduction and power generation sequentially comprise a concrete shell, a steel shell, a plurality of piezoelectric vibration reduction energy harvesters and an electric energy collection and conversion structure from outside to inside, and the two ends of each piezoelectric vibration reduction energy harvester abut against the steel shell and the electric energy collection and conversion structure correspondingly and are used for converting stress of the concrete shell and the steel shell into electric power. The electric energy collection and conversion structure converts electric power into stable electric energy and stores the electric energy. On the premise that the strength and rigidity are guaranteed, the concrete shell is printed through the 3D printing technology, the vibration force of an external structure is received, the piezoelectric effect is utilized, and the piezoelectric vibration reduction energy harvester, the energy converter and the energy storage element inside are combined to collect, convert and store vibration energy into electric energy; dynamic stress of an external structure can be directly reduced, the service life of the external structure is prolonged, harmonic oscillator vibration energy can be converted into electric energy through piezoelectric materials, waste can be turned into wealth, and the device is a green energy source.

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +1

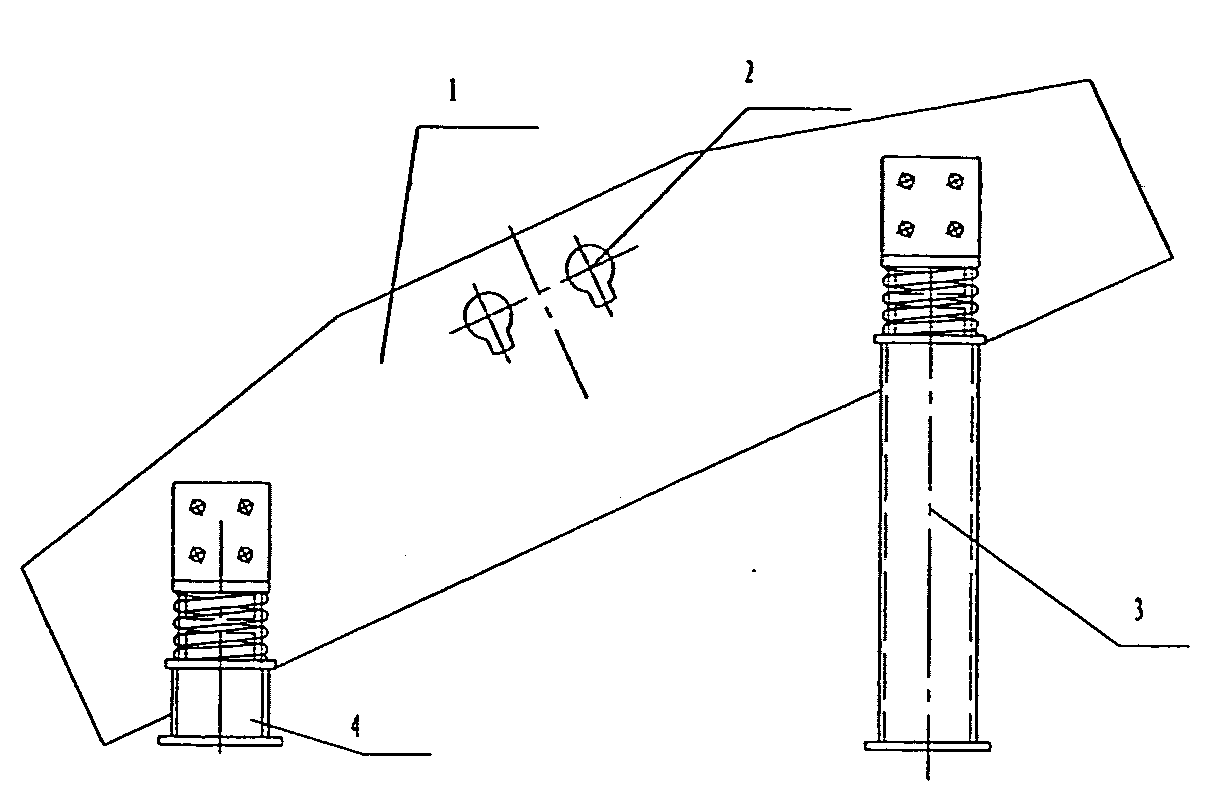

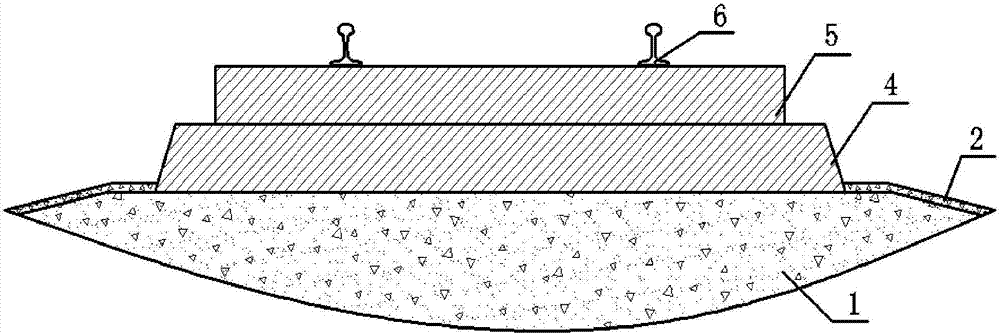

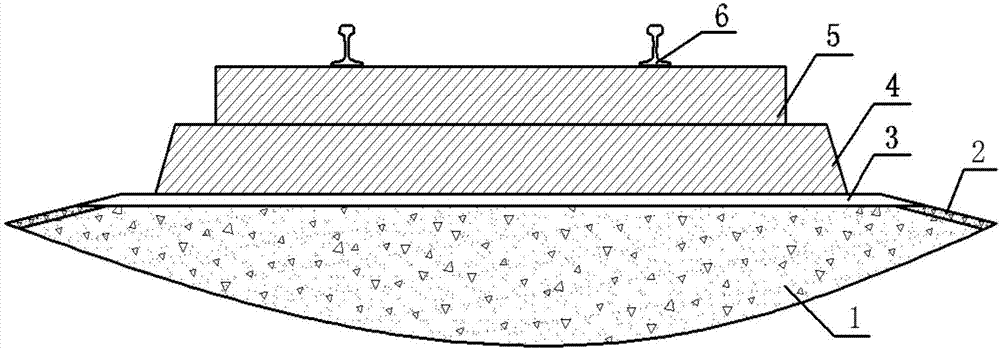

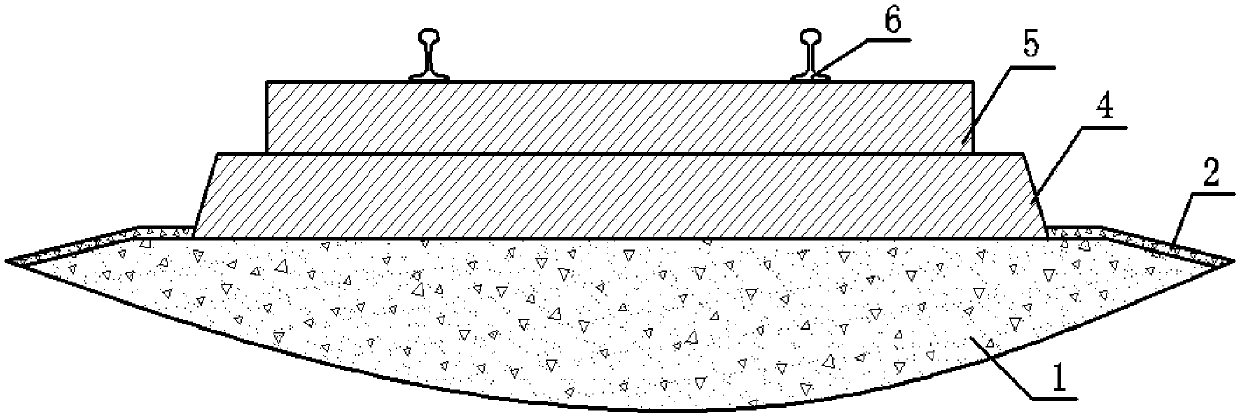

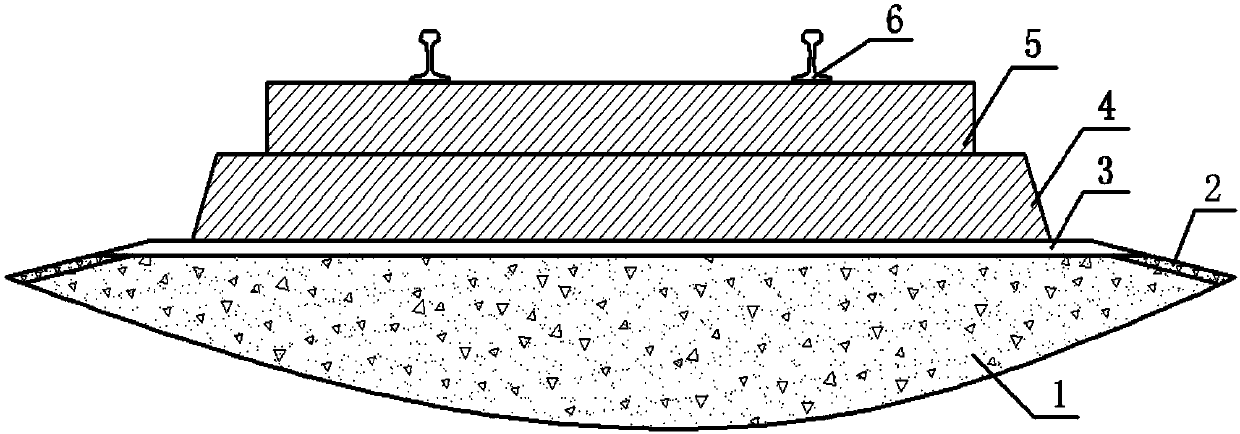

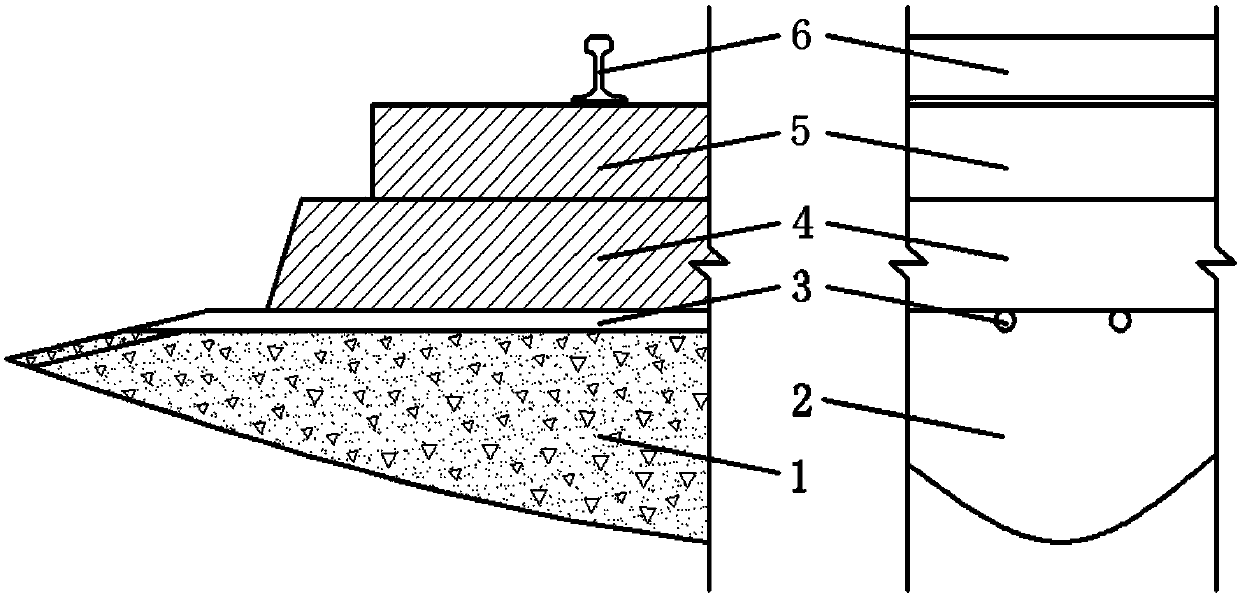

Existing railway roadbed micropile reinforcing structure under operation condition

InactiveCN103276638AReduce dynamic stressImprove carrying capacityRailway tracksFoundation engineeringReinforced concreteRebar

The invention discloses an existing railway roadbed micropile reinforcing structure under the operation condition. The structure is composed of a small-diameter reinforced concrete pile and connection beams at two ends of the reinforced concrete pile which is horizontally installed in a roadbed. Reinforcement cages or steel pipes or preformed piles are inserted into drill holes and mortar pouring is conducted to constitute the small-diameter reinforced concrete pile, and the drill holes are horizontally formed in the side slope of an embankment in a continuous mode or at intervals; the connection beams are of reinforced concrete structures and arranged at two ends of the small-diameter reinforced concrete pile, and reinforcing steel bars in the connection beams are connected with the reinforcement cages or the steel pipes or the preformed piles in the small-diameter reinforced concrete pile. The existing railway roadbed micropile reinforcing structure under the operation condition has the advantages of being strong in structural integrality, reliable in pile-forming quality, low in price, convenient to construct and the like.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

High-rotating-speed and high-load last-stage movable vane for industrial steam turbine

PendingCN109707461AImprove aerodynamic performanceImprove the vibration effectBlade accessoriesMachines/enginesSteam turbine bladeEngineering

The invention relates to the field of industrial steam turbine vanes and particularly discloses a high-load last-stage movable vane with the steam exhausting area being 1.3 m2. The high-load last-stage movable vane can meet the requirement for high-rotating-speed and high-load operation. The movable vane comprises a vane body, a vane root, a girdle used for enabling the vane to form whole-ring self-locking, and a boss. A molded line of the vane body is a variable cross section twisted vane. The height of the working portion is 393.05 mm. The axis width of the root portion of the working portion is 113.07 mm. The diameter of the root portion is 662.44 mm. The change rule of pitch and chord length ratio T / b from the vane root cross section to the vane top cross section is 0.28<=T / b<=0.89. The change rule of pitch and vane type cross section axial width ratio T / B from the vane root cross section to the vane top cross section is 0.28<=T / B<=3.9. The steam exhausting area of the vane body is1.3 m2. A fir type oblique vane root is adopted as the vane root. The axial width is 120 mm. The total height of the vane root is 34.20 mm. The high-rotating-speed and high-load last-stage movable vane with the steam exhausting area being 1.3 m2 has the advantages of being high in pneumatic efficiency, good in strength performance, reasonable in structure, convenient to assemble and the like, andcan be widely applied to a high-rotating-speed and high-load industrial steam turbine.

Owner:HANGZHOU STEAM TURBINE

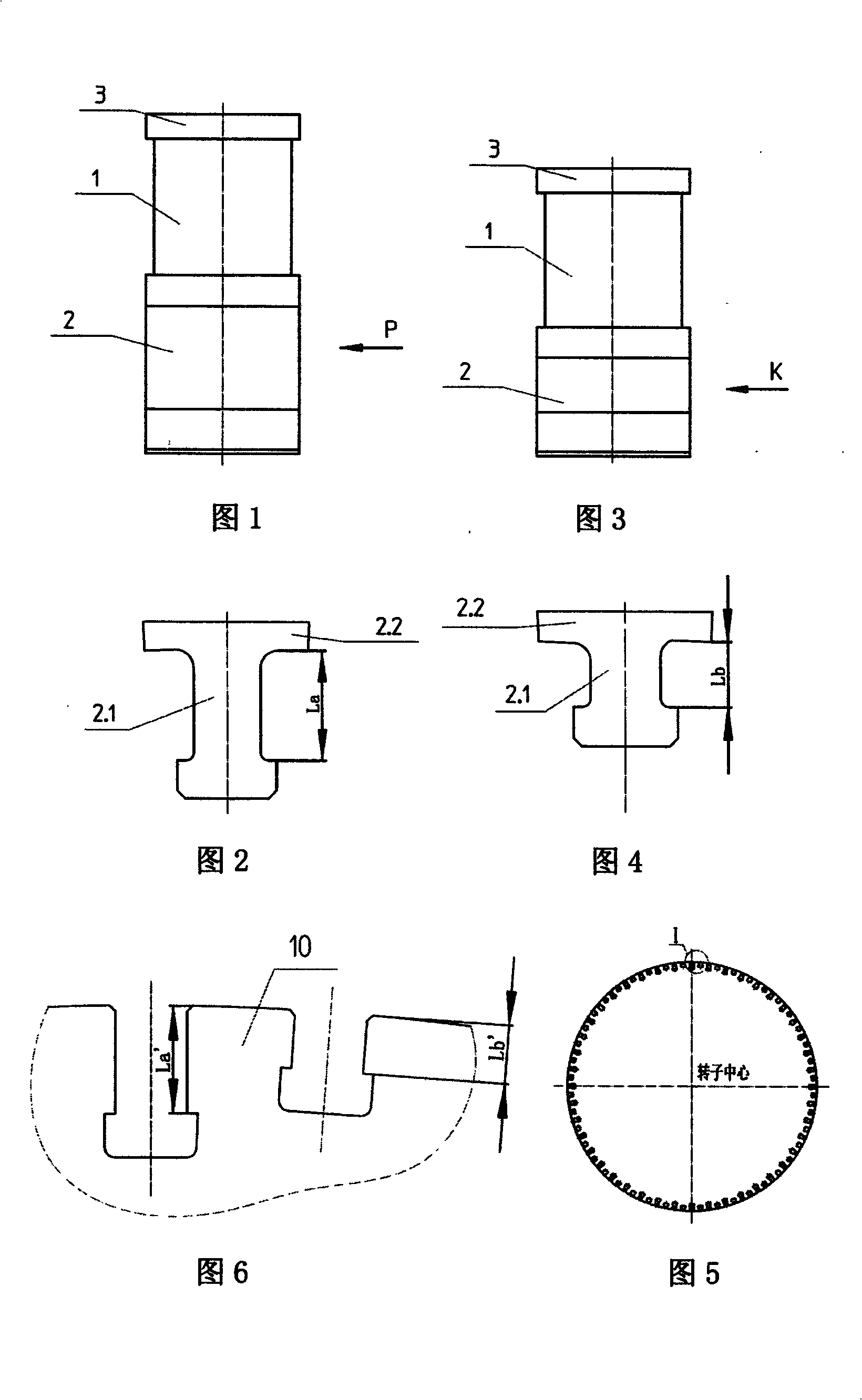

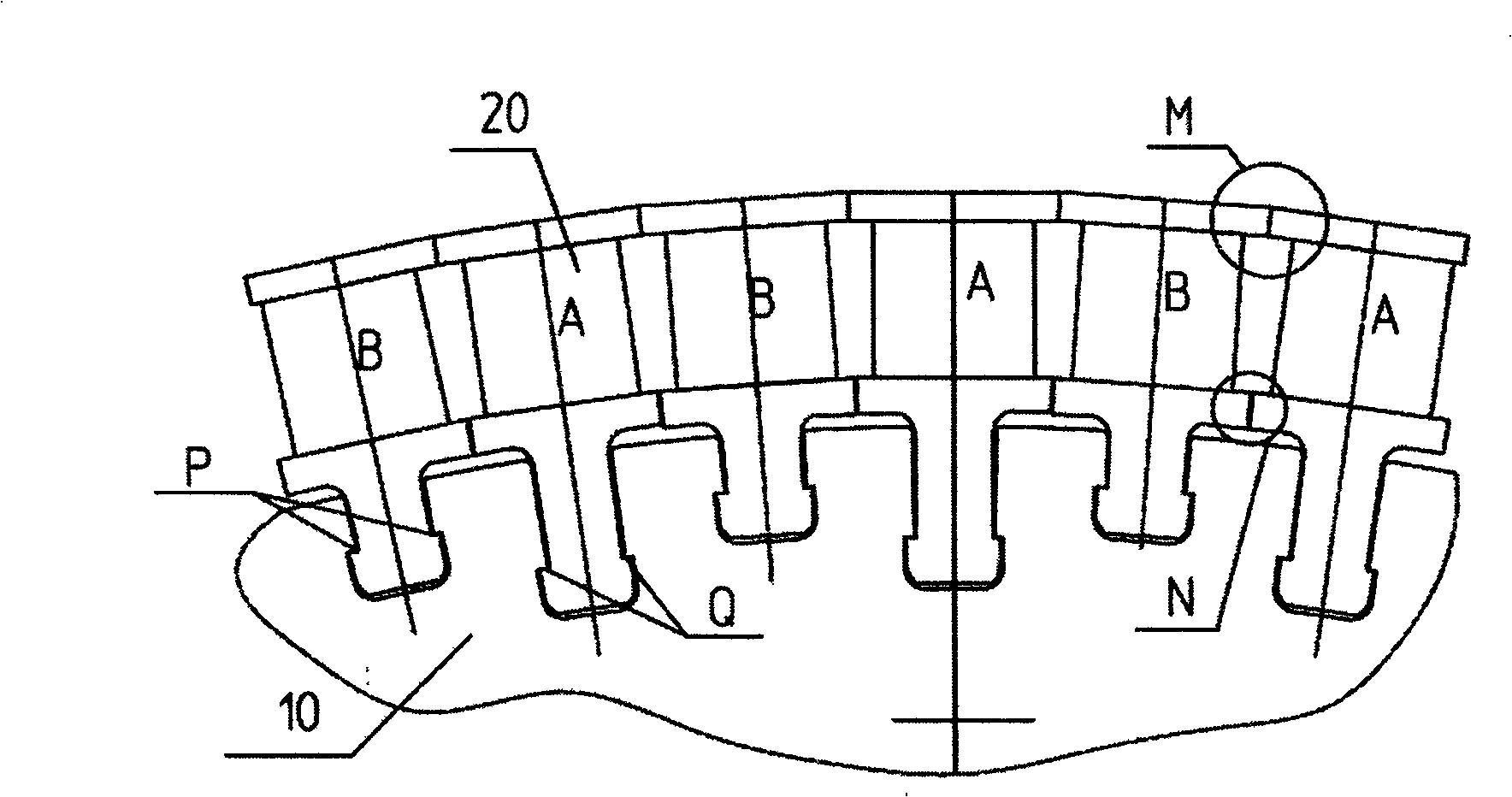

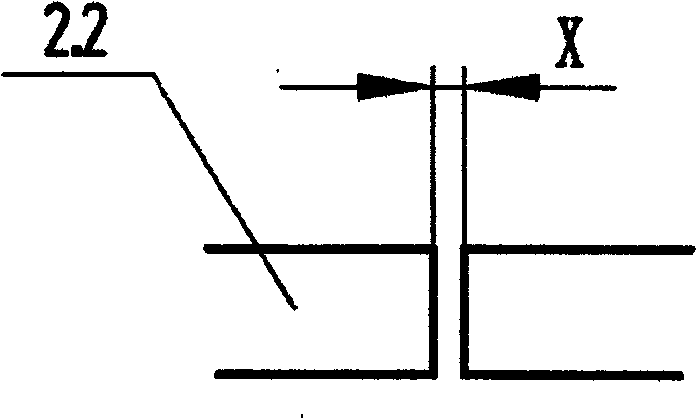

Full level steam turbine short movable vane without frequency modulation

The invention discloses an untuned short moving blade of a whole-stage steam turbine. A plurality of the short moving blades are assembled on an impeller to form the whole stage; each short blade is provided with a blade body, a blade root and a blade crown which have an integral structure; the blade root is provided with a molded line part and a midbody part; the stage blade is divided into two kinds; the molded line parts of the blade roots of two kinds of the blades have different heights; and two kinds of the blades are arranged at intervals on the impeller; clearance is reserved between the midbodies of the blade roots of two kinds of the blades; the blade crown is provided with a damping structure; and the blade root is an axial mounting type blade root. Through adjusting the relative difference of the inherent frequencies of two kinds of the blades, namely controlling the length difference of the dimensions L of the blade roots, the response and dynamic stress of the whole system are controlled within the safe range.

Owner:DONGFANG TURBINE CO LTD

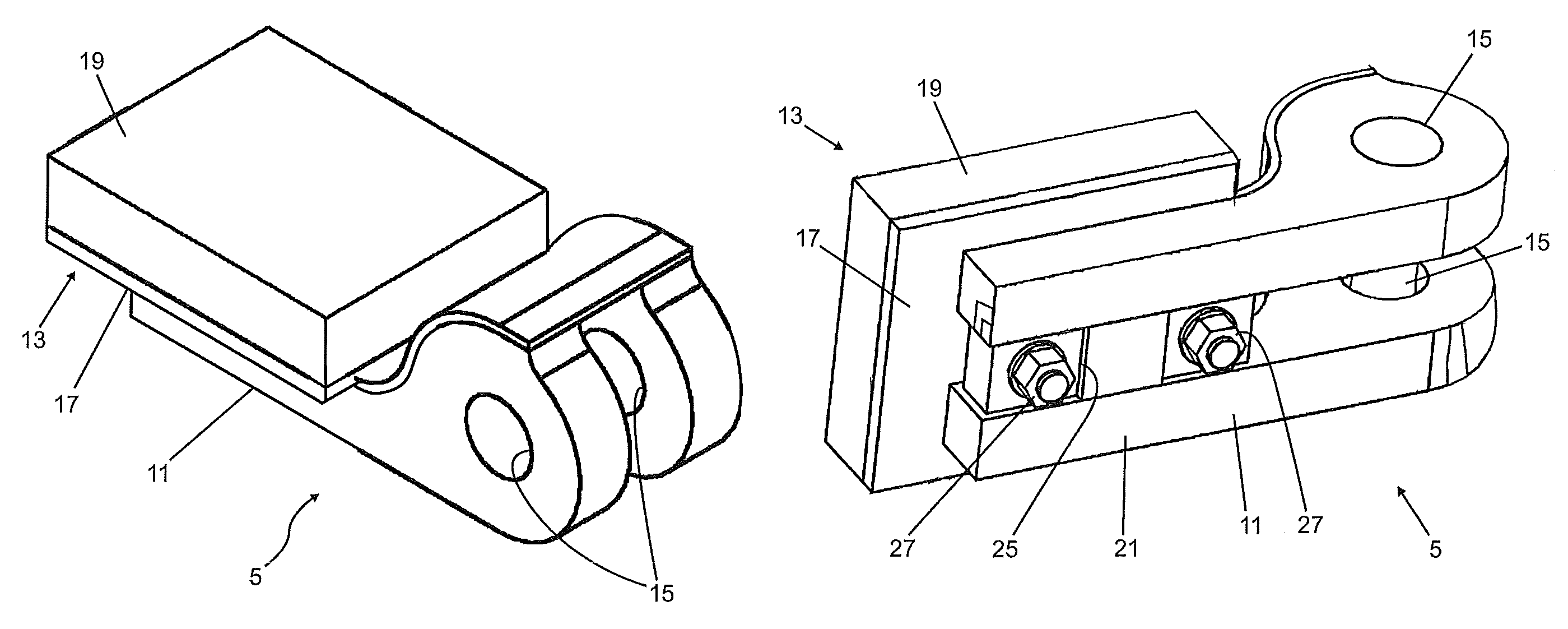

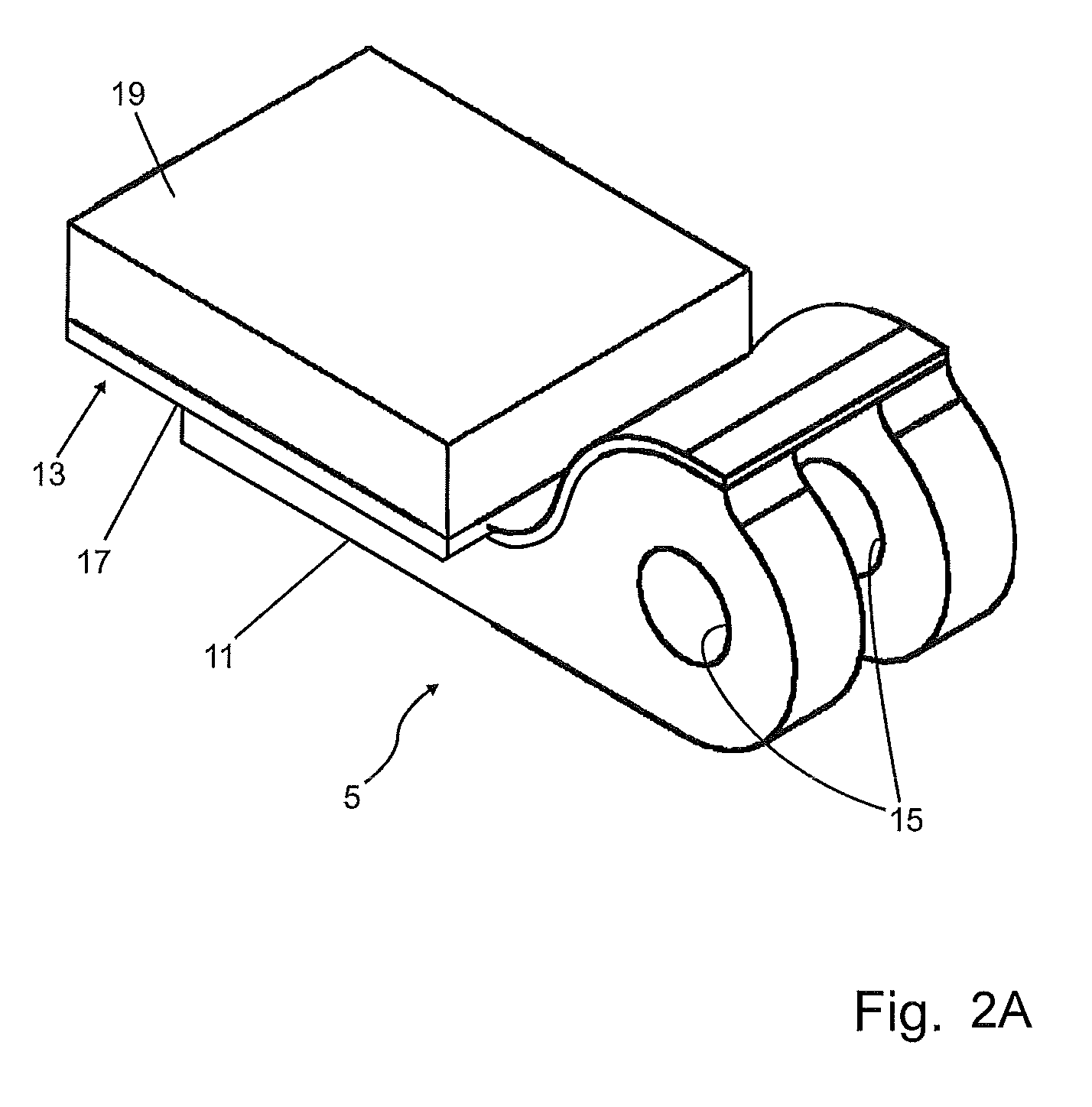

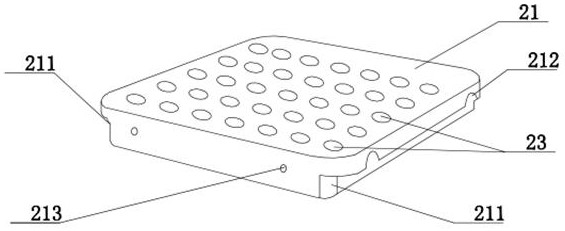

Hammer of a beater mill

A hammer (5) for a beater mill used to process coal, biomass material and other materials is provided having a hammer body (11), an impeller head (13) at a first end of the hammer body (11), and a bore (15) at a second opposite end of the hammer body (11). The impeller head (13) is detachably connected to the hammer body (11) by a base plate 17. Base plate (17) has a first side with a protrusion (21) and at least one bolt (29) protruding therefrom and a second opposed planar side with a crushing member (19). Protrusion (21) and at least one bolt (29) detachably connects impeller head (13) to first end of hammer body (11).

Owner:GENERAL ELECTRIC TECH GMBH

Elastic sieving technique and corresponding large-sized elastic vibration screen

Owner:CHINA UNIV OF MINING & TECH

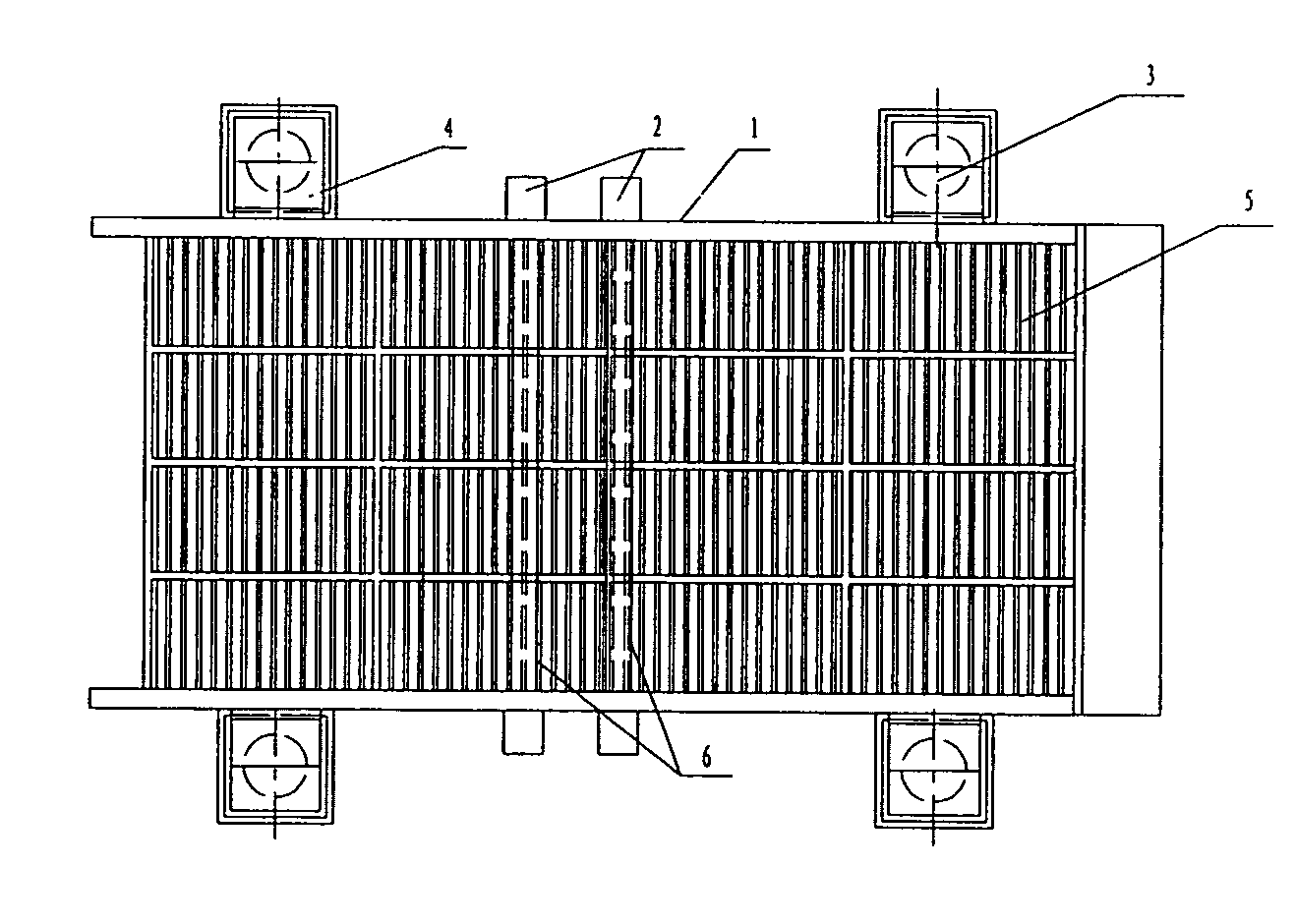

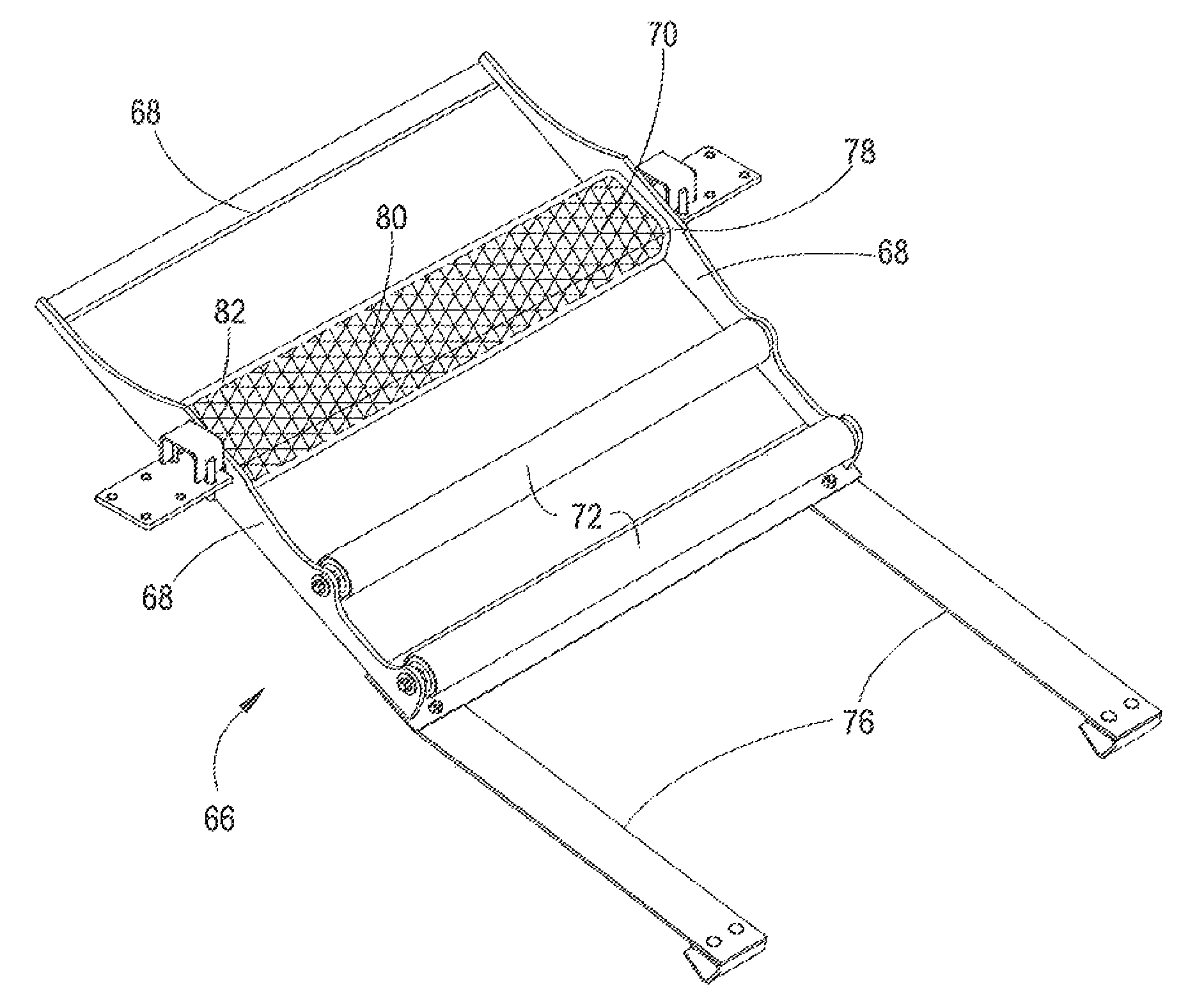

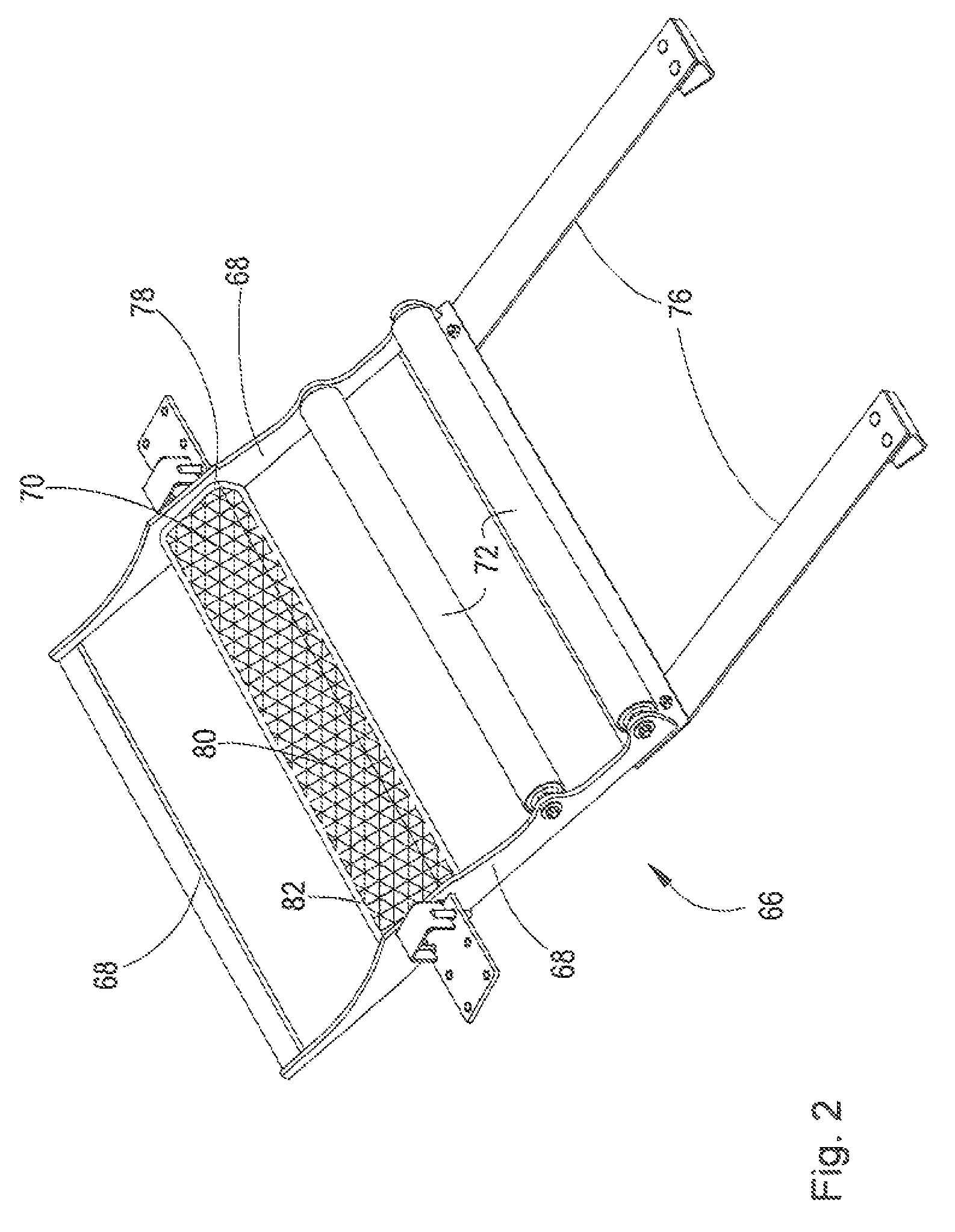

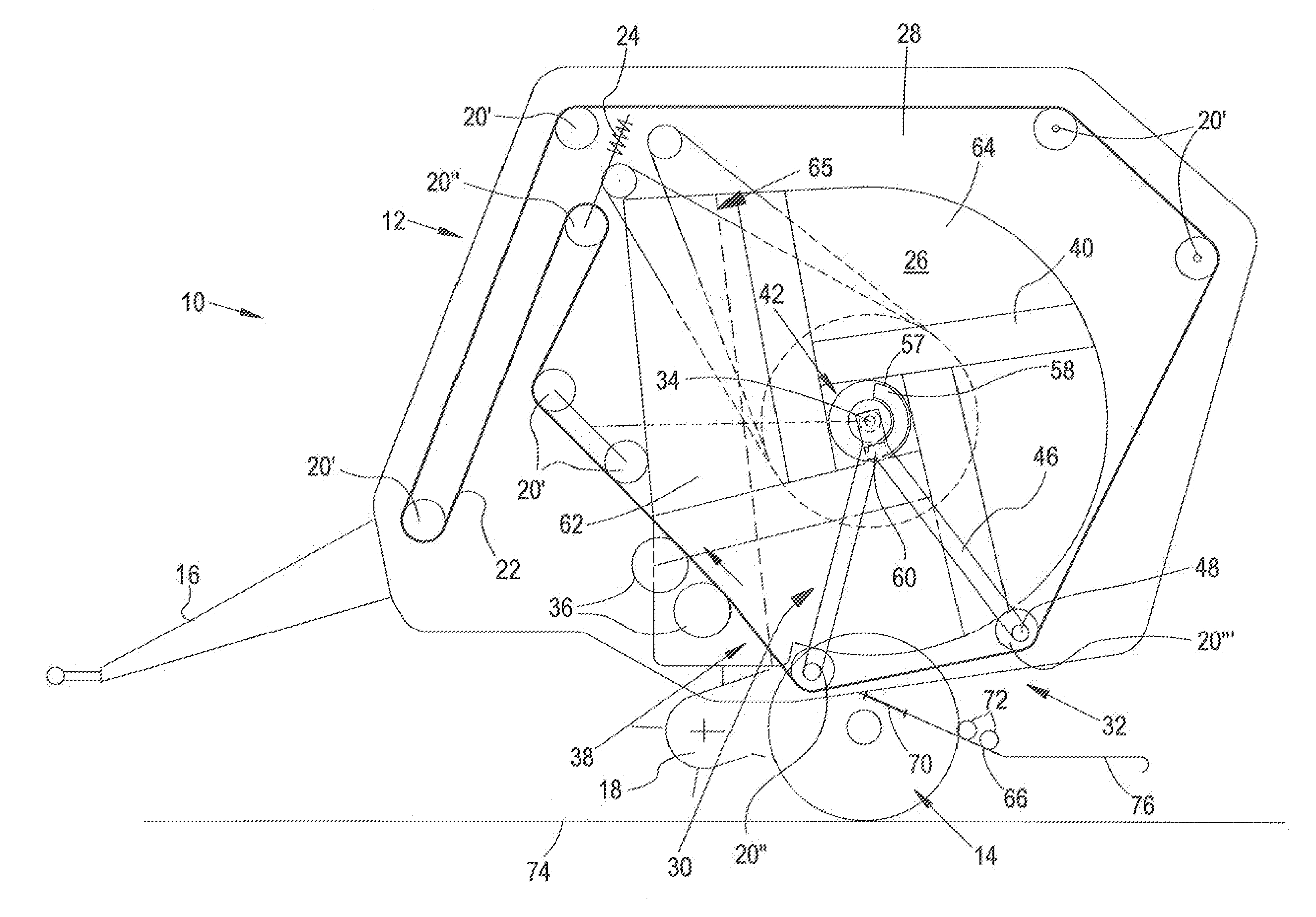

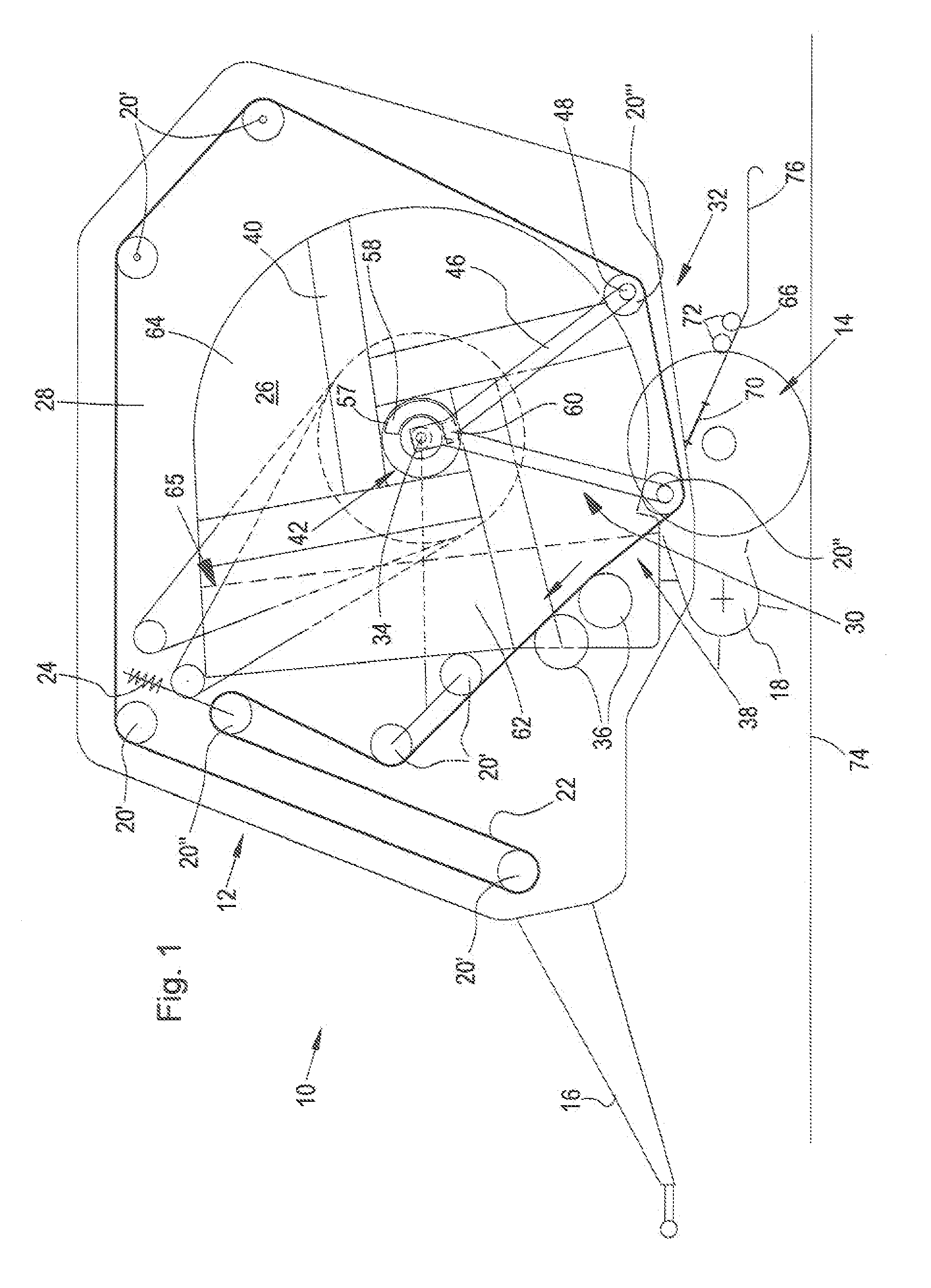

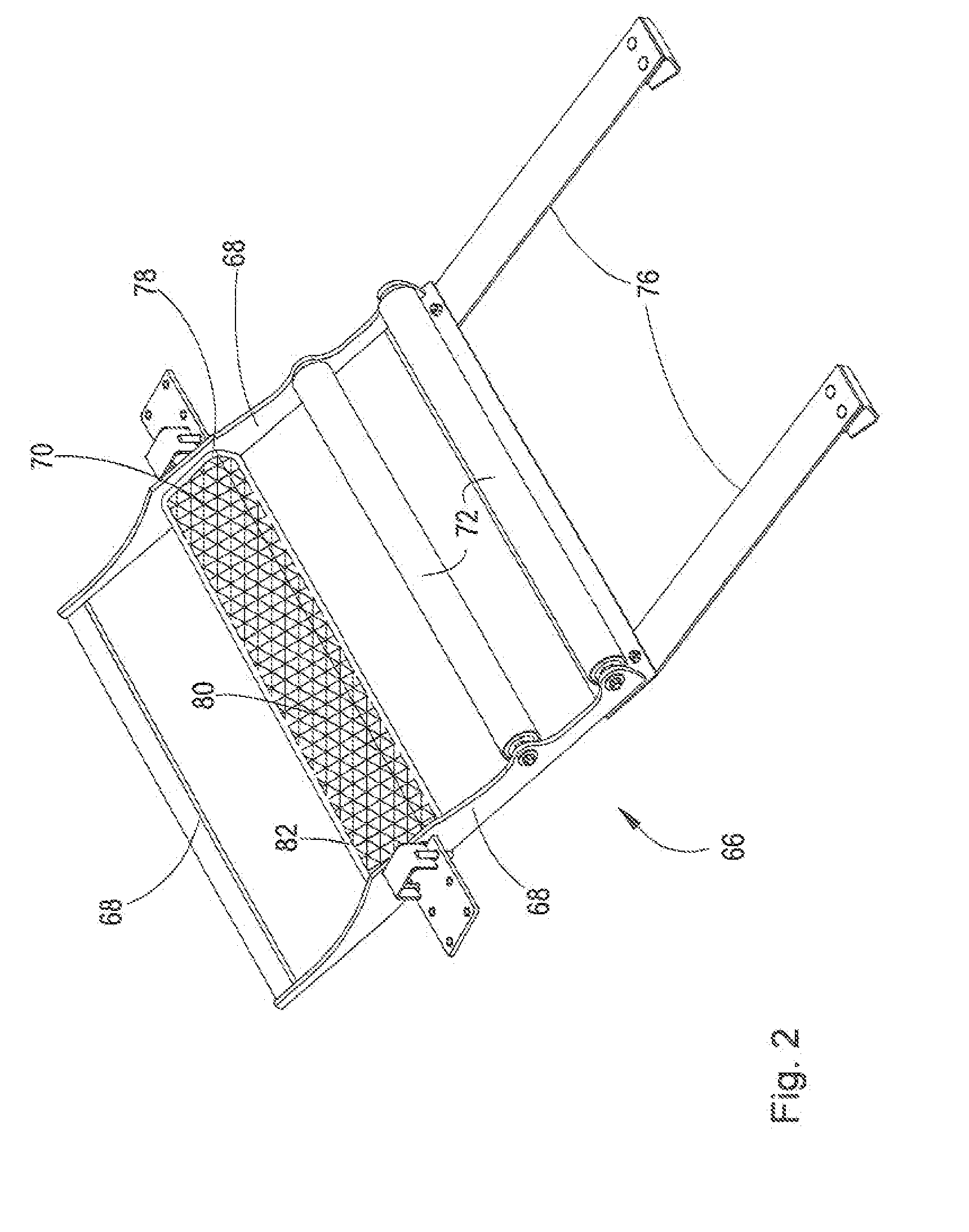

Round baler

A round baler is provided having a frame, a baling chamber on the frame for forming a round bale, an unloading area provided between the baling chamber and a ground surface and at least one depositing element which is arranged in the unloading area and which extends parallel to the rotational axis of the round bale and serves for supporting the round bale during an unloading operation. To reduce mechanical stress on the round bale caused by the depositing element and as a result to prevent damage to the round bale, a flat section is provided which, compared to the rollers otherwise usually used as depositing element, provides a higher contact surface for the round bale such that the surface pressure during the impact of the round bale can be decisively reduced compared to the use of a roller.

Owner:DEERE & CO

Round Baler

ActiveUS20140190360A1Reduce dynamic stressIncrease contact areaBalingPressesRotational axisEngineering

A round baler is provided having a frame, a baling chamber on the frame for forming a round bale, an unloading area provided between the baling chamber and a ground surface and at least one depositing element which is arranged in the unloading area and which extends parallel to the rotational axis of the round bale and serves for supporting the round bale during an unloading operation. To reduce mechanical stress on the round bale caused by the depositing element and as a result to prevent damage to the round bale, a flat section is provided which, compared to the rollers otherwise usually used as depositing element, provides a higher contact surface for the round bale such that the surface pressure during the impact of the round bale can be decisively reduced compared to the use of a roller.

Owner:DEERE & CO

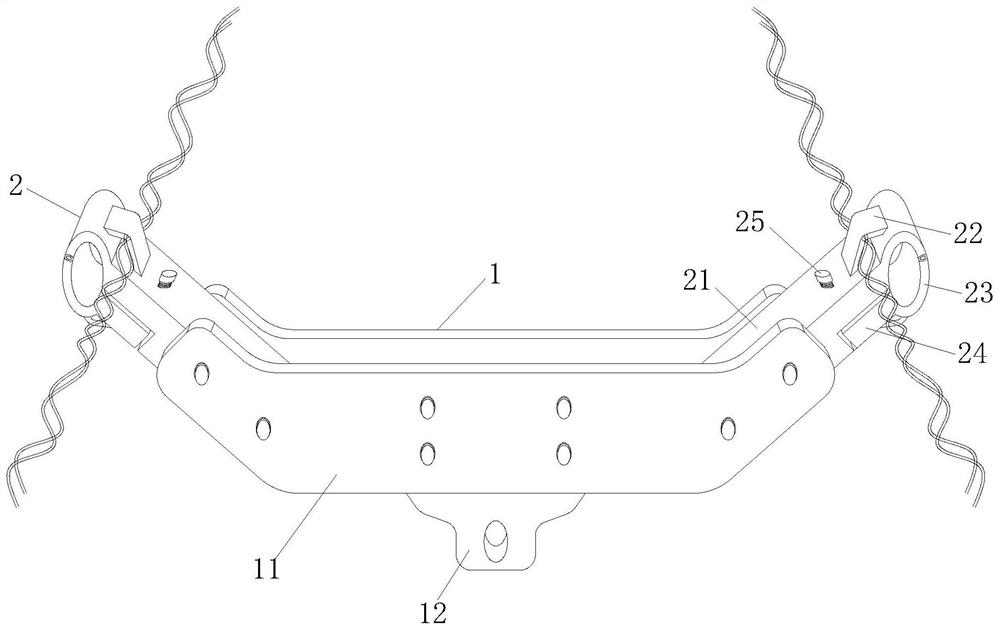

Pre-twisted spacer

PendingCN112821332AAffect performanceReduce difficultyMaintaining distance between parallel conductorsBraced frameElectric cables

The invention relates to the technical field of spacers, and discloses a pre-twisted spacer, which comprises a supporting frame, wire clamps and pre-twisted wires. The supporting frame is composed of two supporting plates and a connecting piece, the connecting piece is located between the two supporting plates, and the supporting plates and the connecting piece are connected through bolts; the two wire clamps are arranged at the two ends of the supporting frame respectively. The wire clamp comprises a wire frame, a positioning frame, a semicircular ring, a fixing block and a screw rod. When the pre-twisted spacer is installed, the wire clamp is opened and clamped on a cable, the screw rod is rotated to close the wire clamp, so that the wire clamp is hung on the cable and cannot clamp the cable, stress concentration cannot be formed, the performance of the cable cannot be influenced, the pre-twisted wire is matched to be wound on the cable, and the wire clamp is fastened on the cable, so that the installation of the spacer is completed.

Owner:GULIFA ELECTRIC +1

A treatment method for controlling the mud and slopping of the subgrade of slab ballastless track railway

The invention discloses a renovation method for treating mud pumping of a plate-type ballastless track railway roadbed. Drilling is conducted on the surface layer of a foundation bed through a special horizontal drilling machine, and then the method that hot air is injected into grouting hole passageways is adopted; accumulated water in a mud pumping disease area is subjected to treatment, and grouting is conducted in grouting holes after accumulated water treatment is completed; before grouting, telescopic seams of a base plate, cracks of the side edges and orifices of the opposite sides of the grouting holes are subjected to sealing treatment, and then grouting is successively conducted in the hole passageways according to a certain sequence; a uniform and compact water insulation layer with the certain strength is formed between the base plate and the surface layer of the foundation bed after grouting is completed; and the water insulation layer can obstruct water of cracks on the upper portion from invading into the surface layer of the foundation bed and can also block fine particle soil in the surface layer of the foundation bed on the lower portion to move upwards. According to the novel renovation method for treating mud pumping of the plate-type ballastless track railway roadbed, the mud pumping disease of the plate-type ballastless track railway roadbed can be well governed.

Owner:ZHEJIANG UNIV

Standard sample for verifying vibration testing capacity

The invention provides a standard sample for verifying the vibration testing capacity. The standard sample is connected with a left support and a right support through connecting barrels, and an opening of the right end of the right support is sealed by a cover plate. A resonance beam with a rectangular cross section is arranged at the center of each connecting barrel, the left end of the resonance beam is connected with the left support, and the long side of the rectangular cross section is perpendicular to a support bottom plane. The right end of the resonance beam is connected with a square mass block, the square mass block extends out of the cover plate, the side of the square mass block is parallel to the side of the resonance beam, and an upper plane is parallel to the support bottom plane. Due to the fact that the adopted fixing supports are provided with installing convex lugs, and vibration characteristics of a vertical table and a horizontal sliding table are respectively verified during testing. In addition, compared with existing standard samples, the standard sample is small in stress and high in stability.

Owner:南京捷诺环境技术有限公司

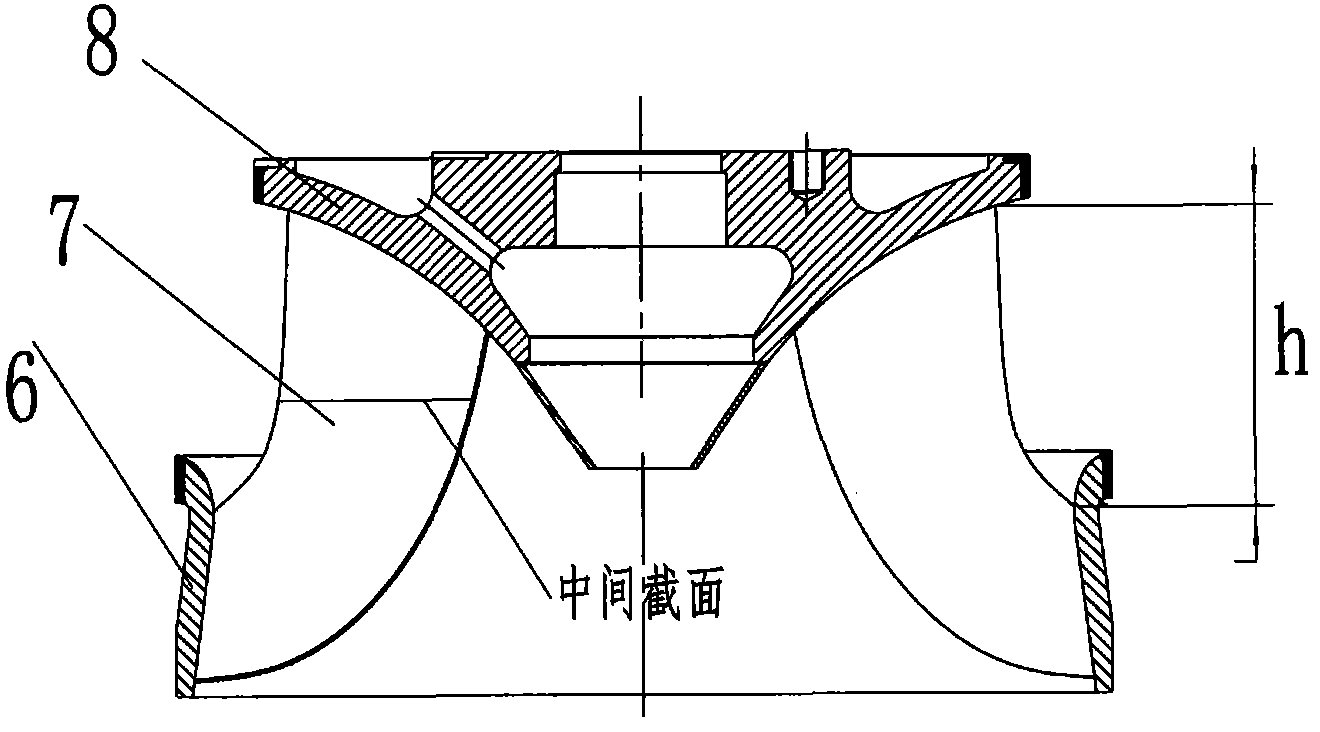

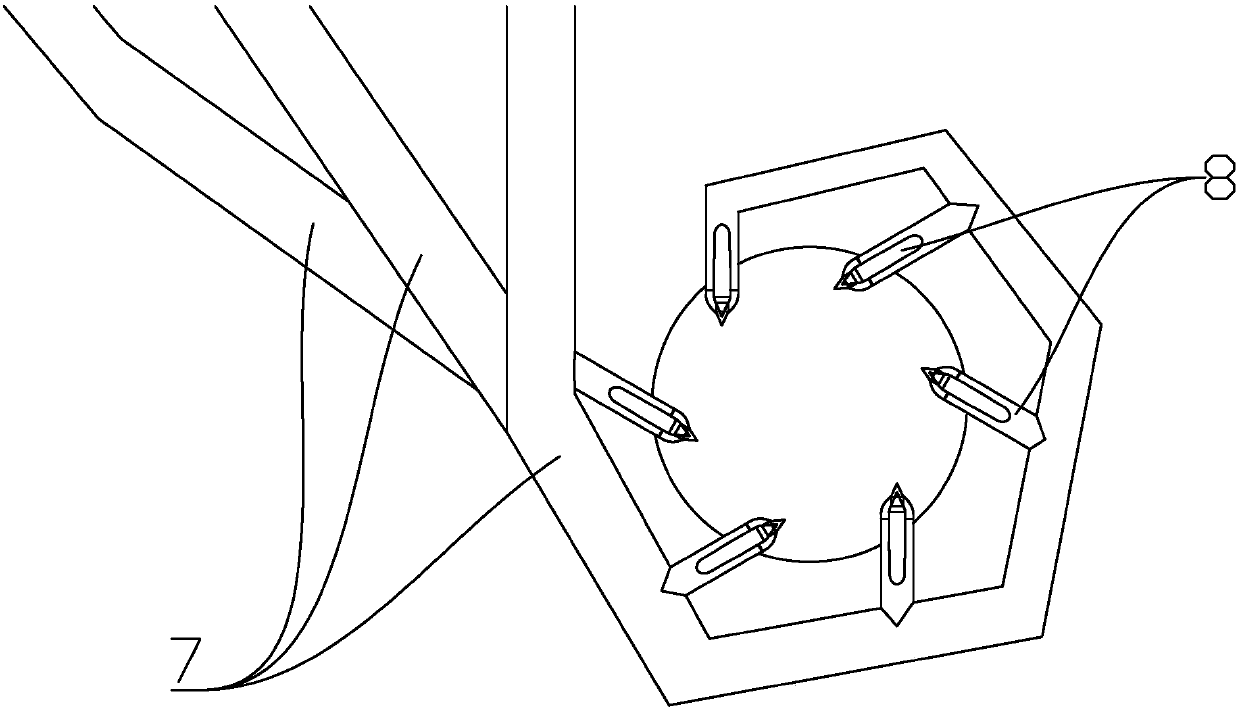

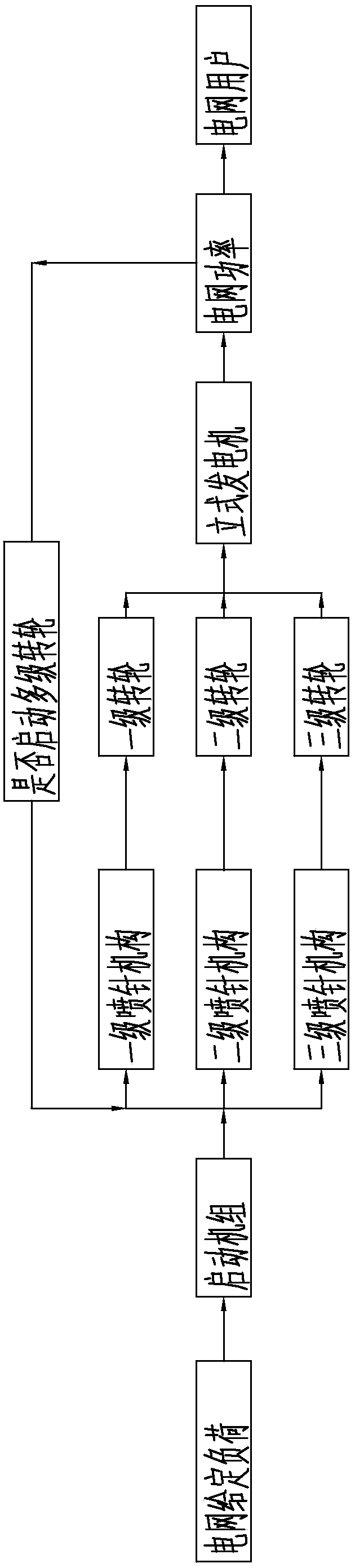

Vertical Shaft Multistage Pelton Turbine

ActiveCN105545571BAny load adjustmentSmall form factorFinal product manufactureHydro energy generationWater turbineWater channel

Owner:POWERCHINA HUADONG ENG COPORATION LTD

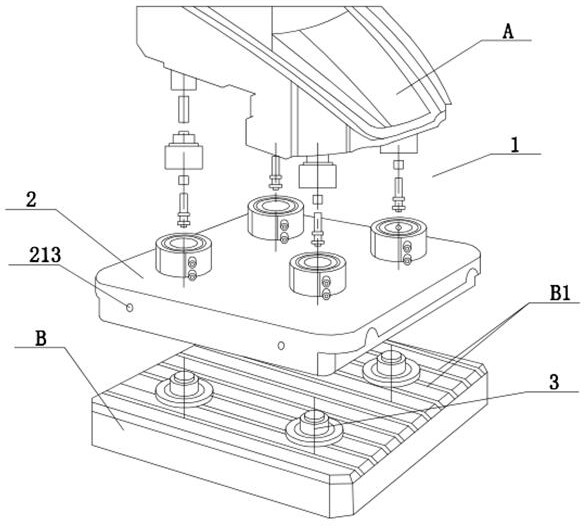

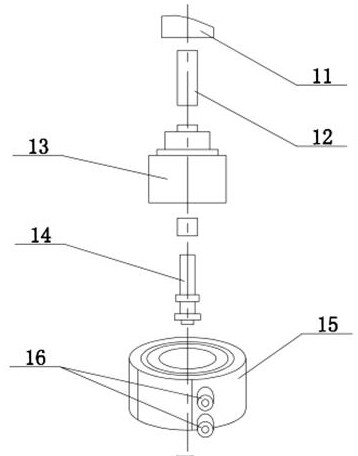

Workpiece clamp for numerical control machine tool machining

InactiveCN111922467AAvoid damageGuaranteed installationElectrical-based auxillary apparatusNumerical controlMachine

The invention discloses a workpiece clamp for numerical control machine tool machining, and relates to improvement of a machine tool machining auxiliary clamp, in particular to improvement of the workpiece clamp for numerical control machine tool machining. The workpiece clamp comprises a workpiece mounting piece, a connecting piece base and a base connecting piece, the top of the workpiece mounting piece is inserted into the bottom of a machined workpiece, the bottom of the workpiece mounting piece is fixed to the connecting piece base, and the connecting piece base is fixed to a machine toolbody through the base connecting piece; and during use, a base fixing column is inserted into the connecting piece base and is fixedly connected through a center guide column and an expansion ring, and a connecting center shaft is inserted into the machined workpiece. By the adoption of the technical scheme, the workpiece clamp has the advantages that mounting is rapid and convenient, the physical and mechanical characteristics of numerical control machining are utilized, and therefore the assembling rapidness and the machining stability can be guaranteed; and through assembling of the base,the clamping universality can be guaranteed, the cost of the tool clamp is greatly reduced, the clamping period of the workpiece can be shortened, and the working efficiency of the machine tool is improved.

Owner:东莞市铭旺模具有限公司

Combined pre-twisted tension-resistant wire clamp

InactiveCN105281270ALess likely to cause damageReliable clampingAdjusting/maintaining mechanical tensionStress concentrationEngineering

The invention relates to a combined pre-twisted tension-resistant wire clamp, and relates to components of overhead line equipment. The combined pre-twisted tension-resistant wire clamp comprises a connecting device and two pre-twisted wires. The connecting device comprises a triangular connecting board which is in the shape of an isosceles triangle. The top corner end of the triangular connecting board is provided with a hanging hole, and two bottom corner ends are respectively hinged with a hanging board. The other ends of the hanging boards are connected with two connecting boards which are symmetrically arranged in a non-contacting manner. A rotatably roller is connected with the other end of each of the two connecting boards. Each roller is connected with a pre-twisted wire. A holding force of the combined pre-twisted tension-resistant wire clamp can reach up to more than 100%of a puling breaking force of the twisted wire. The combined pre-twisted tension-resistant wire clamp is difficult to cause damages, great in holding force and light in weight, and can reduce dynamic stress. The stress which is born by the twisted wire is uniformly distributed on a larger combining surface, and a phenomenon of stress concentration does not exist, thereby ensuring the normal service life of a system.

Owner:江苏捷凯电力器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com