Shock-absorption expansion filling material used for filling deep goaf and preparation method

A filling material and goaf technology, which is used in the field of shock absorption and expansion filling materials and preparation, can solve the problems of filling failure, and achieve the effects of reducing landslides, reducing impacts, preventing and controlling rock bursts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

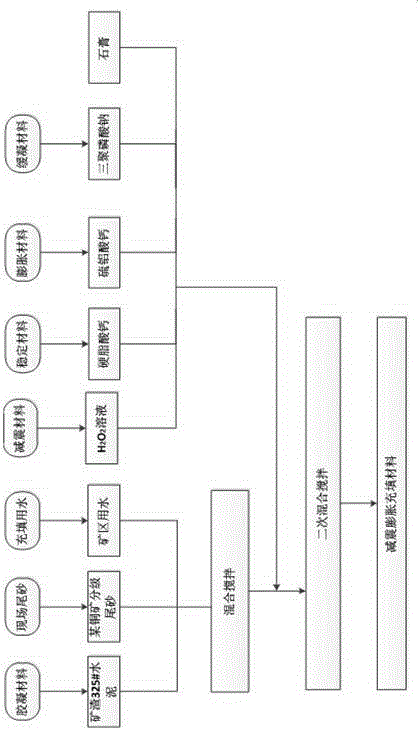

Method used

Image

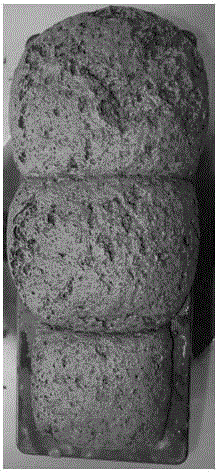

Examples

Embodiment 1

[0041] Slag No. 325 cement 500.00Kg, mine graded tailings 2000.00Kg, filling water 1231.00Kg, hydrogen peroxide solution with a mass concentration of 27.5% 18.80Kg, calcium stearate 10.00Kg, calcium sulfoaluminate 40Kg, sodium tripolyphosphate 5Kg , Gypsum 10Kg.

[0042] The preparation method of the shock-absorbing expansion filling material includes the following steps: Note that the following formulas are existing formulas.

[0043] (1) Determination of moisture content of tailings: The moisture content of tailings is different due to different storage conditions, so it is necessary to measure the moisture content of tailings. The moisture content determination method is: first weigh the weight of the container m 1 , with an accuracy of 0.1g (the same below), weigh the weight of the tailings and the container immediately after sampling the tailings m 2 (The sample must be weighed immediately after sampling to reduce the influence of water evaporation), put the sample in a...

Embodiment 2

[0055] Slag No. 325 cement 400.00Kg, mine graded tailings 2400.00Kg, filling water 1379.00Kg, hydrogen peroxide solution 18.00Kg, calcium stearate 10.00Kg, calcium sulfoaluminate 60Kg, sodium tripolyphosphate 8Kg, gypsum 12Kg.

[0056] The expansion rate of a shock-absorbing expansion filling material prepared according to the above components is 14.38%, the expansion start time is 0.4h, and the expansion termination time is 21.0h; the filling material is initially set at 1.5h, and finally set at 38.0h; 3d The compressive strength is 0.4MPa, and the strength of 28d is 2.1MPa; the sound wave propagation velocity of 28d is 1393.5m / s, and the stress wave is attenuated by 31.5% after passing through the filling body.

Embodiment 3

[0058] Slag No. 325 cement 300.00Kg, mine graded tailings 2400.00Kg, filling water 1330.00Kg, hydrogen peroxide solution 18.80Kg, calcium stearate 6.00Kg, calcium sulfoaluminate 100Kg, sodium tripolyphosphate 10Kg, gypsum 14Kg.

[0059] The expansion rate of a shock-absorbing expansion filling material prepared according to the above components is 21.15%, the expansion start time is 0.3h, and the expansion termination time is 24.0h; the filling material is initially set at 1.9h, and finally set at 42.0h; 3d The compressive strength is 0.3MPa, and the strength of 28d is 1.7MPa; the sound wave propagation velocity of 28d is 1164.0m / s, and the stress wave is attenuated by 48.52% after passing through the filling body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com