Vertical Shaft Multistage Pelton Turbine

A water turbine and impact technology, applied in impact engines, hydroelectric power generation, mechanical equipment, etc., can solve problems such as limiting the capacity of a single unit of the unit, and achieve the effect of reducing the size of the plane layout, making it easier to be safe, and reducing dynamic stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

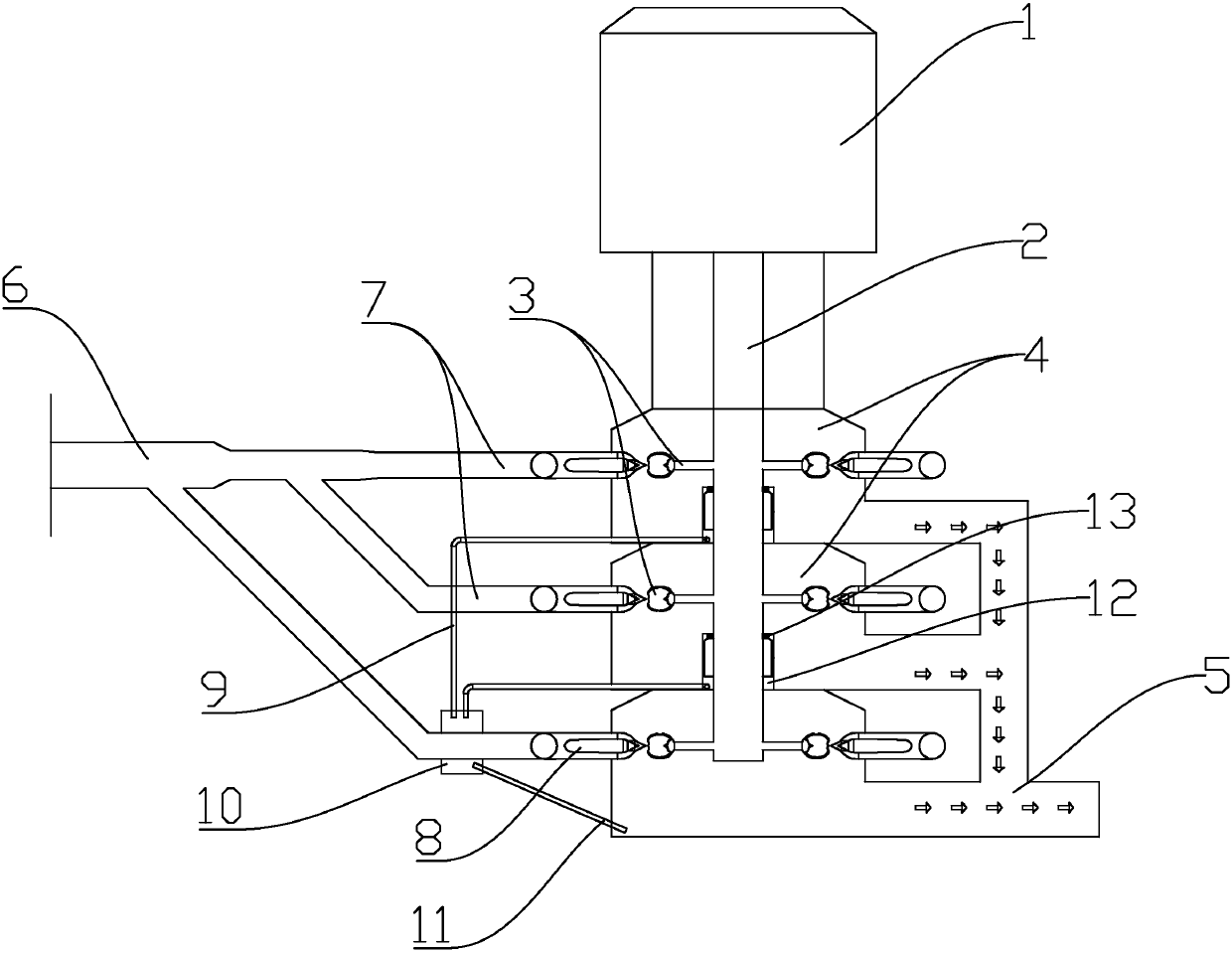

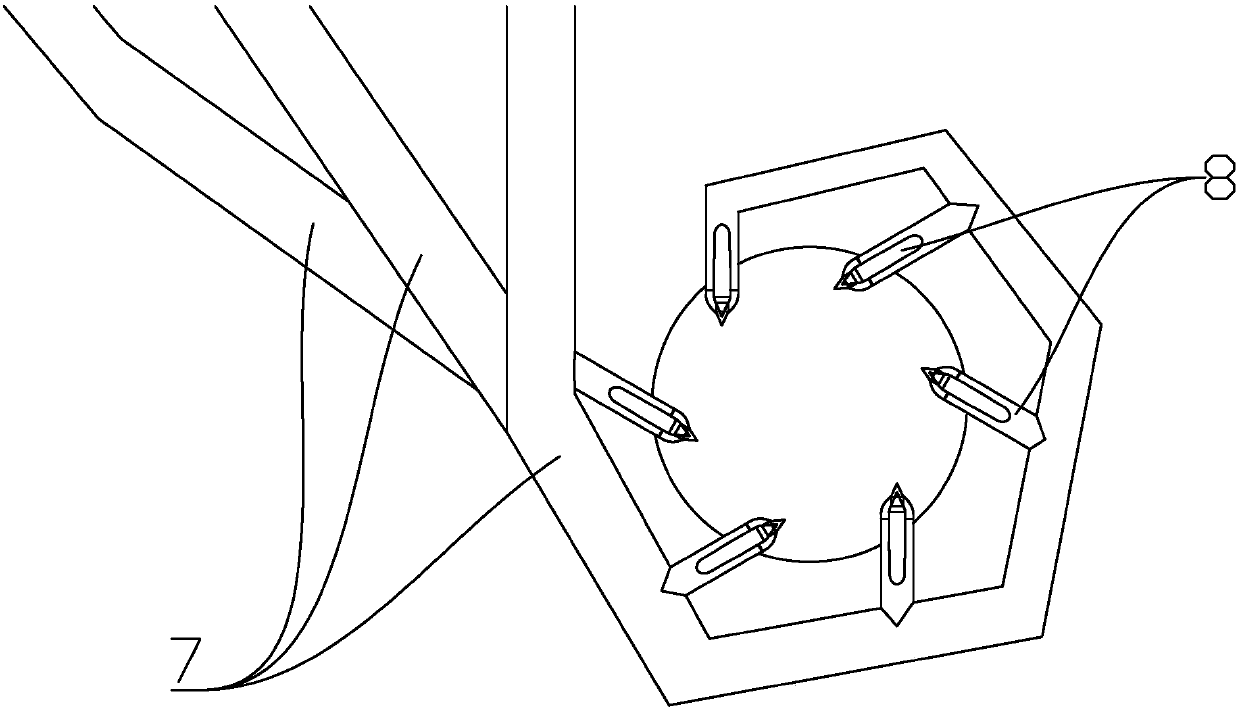

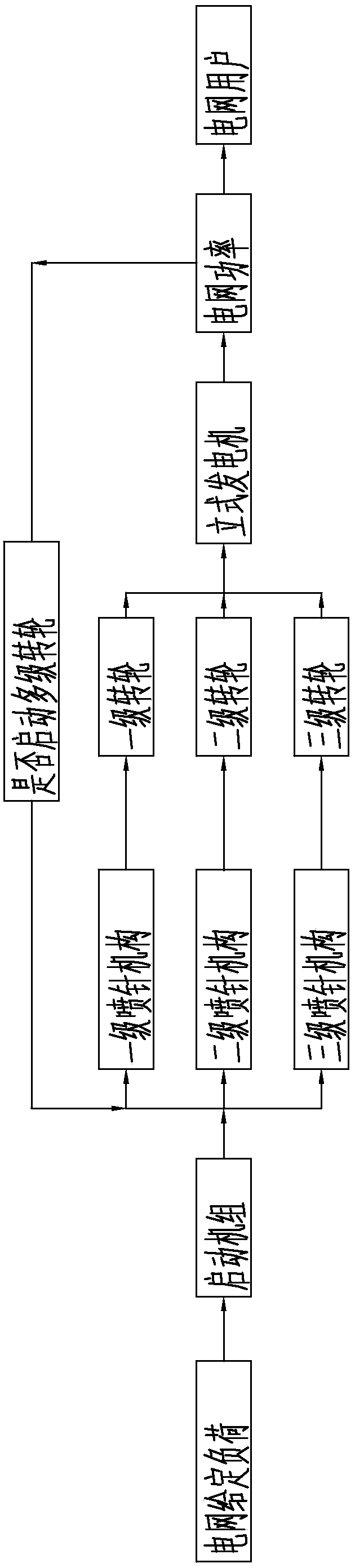

[0015] Embodiment 1: as figure 1 , figure 2 As shown, this embodiment is a vertical shaft three-stage impact turbine, including a water inlet pipe 6, a generator 1, a main shaft of the turbine 2, a runner chamber 4, a water distribution ring pipe 7, a nozzle pipe and a spray needle 8. Wherein there are three runner chambers 4 , and the three runner chambers 4 are arranged up and down on the same straight line, and the runner chambers 4 are connected to the tailwater channel 5 . The generator 1 is installed above the three runner chambers 4, the main shaft 2 of the water turbine is connected with the generator 1, and the lower end of the main shaft passes through the three runner chambers 4 sequentially from top to bottom, and in each runner chamber 4 A vertical shaft bucket type runner 3 is arranged on the main shaft 2 of the water turbine. Corresponding to each runner chamber 4 in this example, a water distribution annular pipe 7 is arranged outside the chamber, and the an...

Embodiment 2

[0018] Embodiment 2: This embodiment is a vertical shaft two-stage impact water turbine, and the only difference from Embodiment 1 is that this embodiment adopts the structure of two runner chambers 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com