A wind-driven direct-drive generator that adjusts the windward angle of the sail according to the wind direction

A windward angle and generator technology, which is applied to wind turbines, wind turbines, and combinations of wind turbines at right angles to the wind direction, can solve problems such as the inability to adjust the load, the low utilization rate of wind power, and the inability to combine motors, so as to increase wind energy. Utilization, low cost, effect of increasing mechanical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

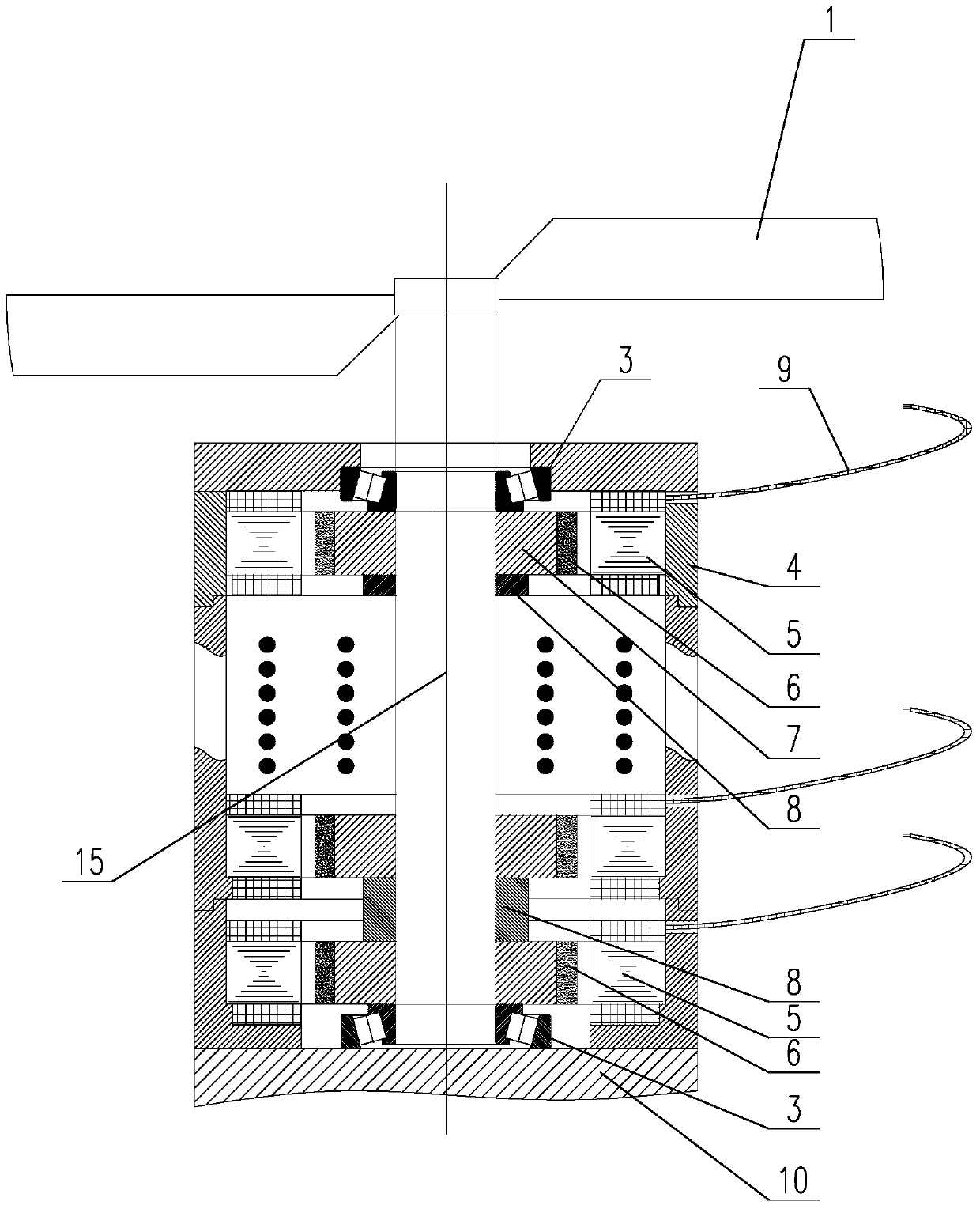

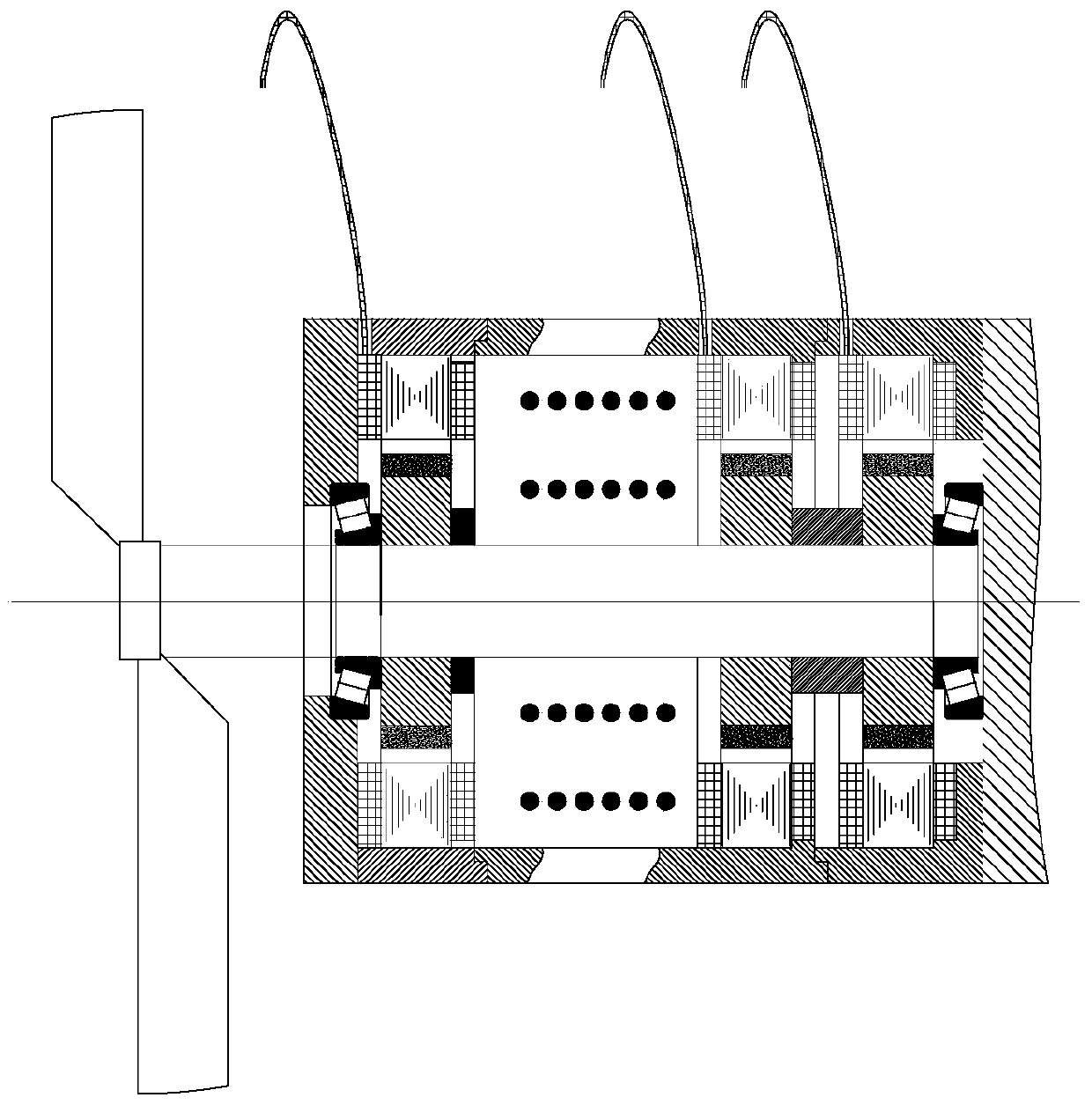

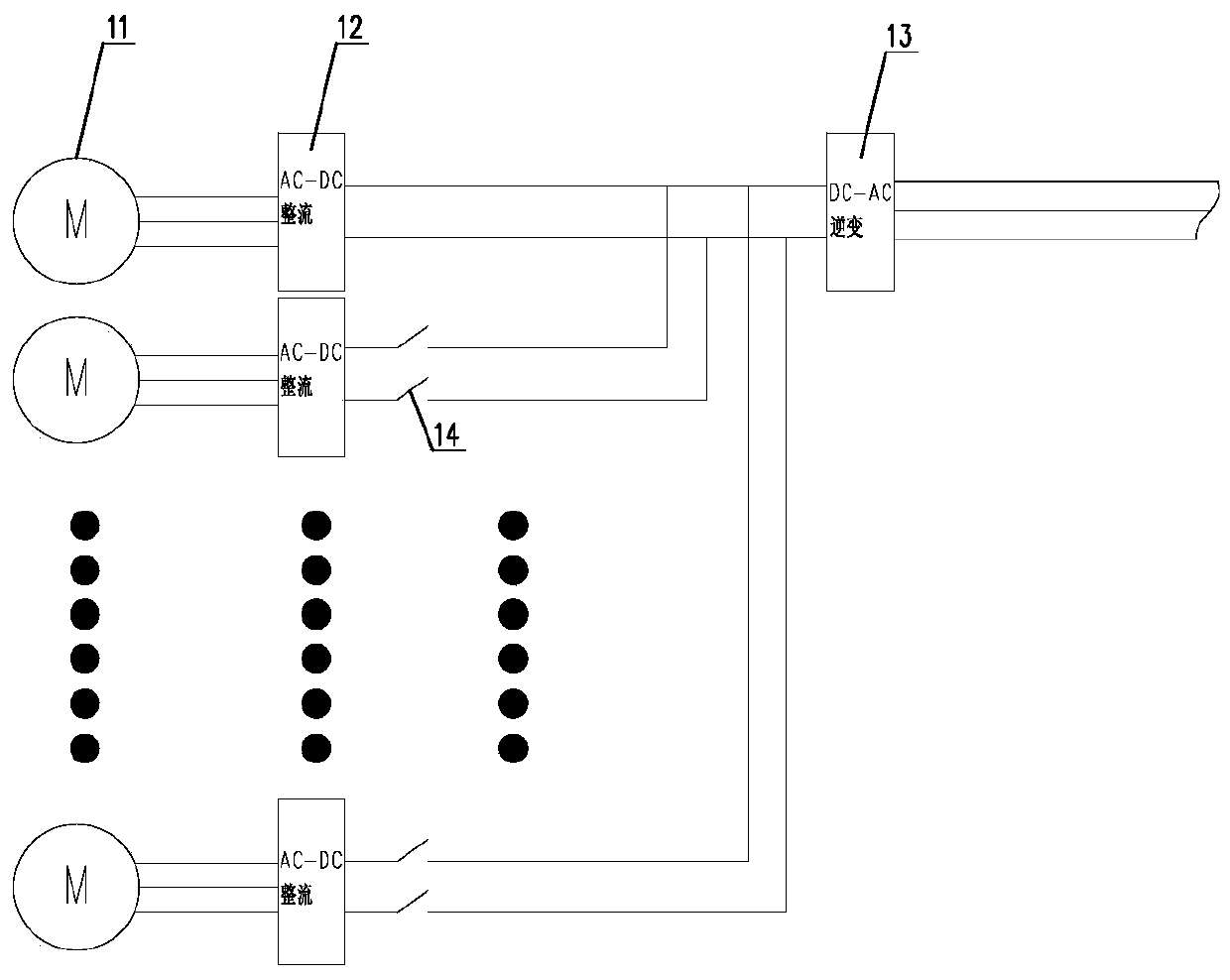

[0041] Such as figure 1 and image 3 As shown, the motor rotor of the generator unit includes: a rotor yoke 7 and a permanent magnet 6 ; the rotor yoke 7 is fixed on the power input shaft 15 , and the permanent magnet 6 is fixed on the rotor yoke 7 . A rotor spacer 8 is arranged between two adjacent generator units, and the rotor spacer 8 is arranged between two adjacent generator units and fixed on the power input shaft 15 . The motor stator 5 is connected with a motor lead wire 9 , and the motor lead wire 9 is drawn out through a through hole on the motor housing 4 and connected to an AC-DC rectifier 12 . The output power of the generator unit is transmitted to the AC-DC rectifier 12; the output terminal of the AC-DC rectifier 12 of each generator unit is connected in parallel to the input terminal of the DC-AC inverter 13, and passes through the DC-AC inverter 13 Output after inversion, or increase to 10KV or higher output through a power frequency transformer.

Embodiment 2

[0043] Such as Figure 4 As shown, the sail shaft 1.1 and the power input shaft 15 can be fixedly connected when they are designed separately, or they can be set as one. The generator also includes a support beam 1.6, the support beam 1.6 is used to support the sail shaft 1.1, and the support beam 1.6 is connected to the sail shaft 1.1 through the sail top layer bearing 1.7;

Embodiment 3

[0045] Such as Figure 4 As shown, the angle adjustment mechanism 1.5 includes a servo motor, a reducer and a moment arm lever connected to the self-adaptive windward blade 1.3, which is used to automatically adjust the angle of each self-adaptive windward blade 1.3 through the magnitude of the moment of the moment arm In this technical solution, the servo motor is used as the control power, and the collection of wind direction can be analyzed and controlled by setting sensors on the sail structure, or combining the wind direction and wind force in the weather forecast of the local meteorological bureau.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com