Margarine production system and process flow thereof

A production system and margarine technology, which is applied in the production/processing of edible oil/fat, etc., can solve the problems of high energy consumption, difficulty in controlling the temperature of cream at the outlet of the quencher, and complicated operation, so as to reduce energy consumption and initial investment. Costs and O&M expenses, the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

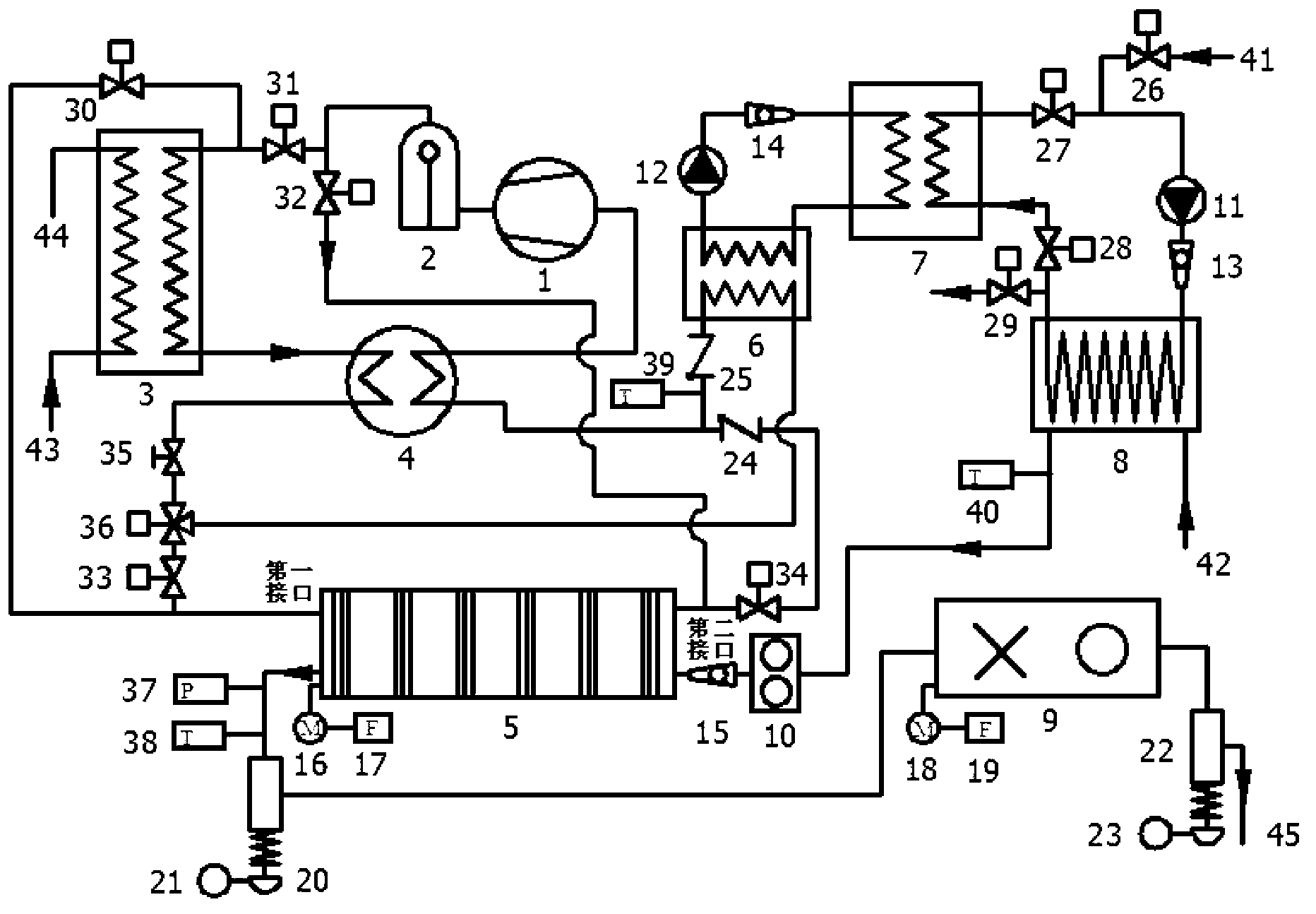

[0027] see figure 1, an energy-saving margarine production system, including a cream quenching circulation system, a cold storage and precooling circulation system, and a cream pressure control system; an electromagnetic three-way valve 36 is provided after the outlet of the regenerator 4 of the cream quenching refrigeration circulation system , the first outlet of the electromagnetic three-way valve 36 communicates with the evaporator in the cream quencher 5, and the other outlet communicates with the cold recovery heat exchanger 6, and the two outlets are connected in parallel to the compressor 1 through the regenerator 4 The suction port of the cold storage and precooling circulation system mainly includes a cold recovery heat exchanger 6, a cold storage device 7 and a cream precooler 8; the cream pressure control system mainly includes a variable plunger pump 10, a cream q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com