Refrigerating system of three-stage flash-evaporation ejection economizers

The technology of a refrigeration system and an economizer is applied to the refrigeration system field of a three-stage flash ejection economizer. and use-value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

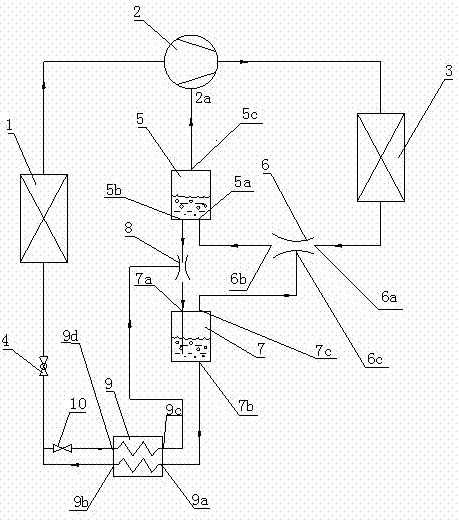

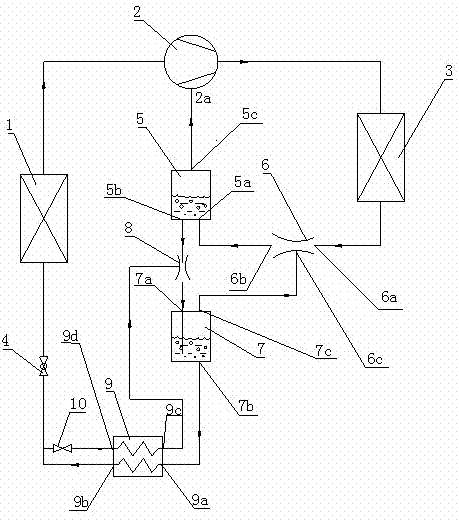

[0013] See figure 1 , a refrigeration system of a three-stage flash ejector economizer, including an evaporator 1, a compressor 2, a condenser 3, a first-stage high-pressure flash tank economizer 5, a first-stage ejector 6, and a second-stage flash tank The economizer 7, the secondary ejector 8 and the tertiary flash tank economizer 9; the evaporator 1, the compressor 2 and the condenser 3 are connected in sequence; the high pressure inlet 6a, the low pressure outlet 6b and the suction of the primary ejector Port 6c communicates with the liquid outlet of condenser 3, the inlet 5a of the primary high-pressure flash tank economizer, and the gas outlet 7c of the secondary flash tank economizer; the gas outlet 5c of the primary high-pressure flash tank economizer is connected to The compressor 2 is connected, and its liquid outlet 5b is connected with the inlet 7a of the secondary high-pressure flash tank economizer through the secondary ejector 8; the liquid outlet 7b of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com