Scroll compressor

A scroll compressor and movable scroll technology, applied in the field of scroll compressors, can solve the problems affecting the refrigeration efficiency of the scroll compressor and the high degree of superheat of the refrigerant, and achieve the effects of improving the efficiency of the refrigeration cycle and reducing the noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

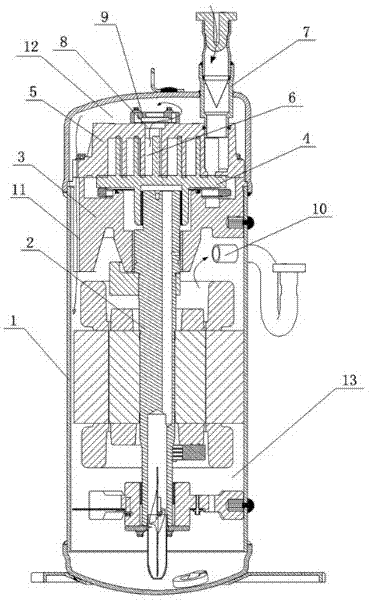

[0012] See figure 1 , a scroll compressor, including a shell 1, a crankshaft 2 set in the shell 1, a frame 3 set on the crankshaft 2, a movable scroll 4 set on the top of the crankshaft 2 and above the frame 3, and a set The fixed scroll 5 above the movable scroll 4 and meshed with the movable scroll 4 communicates with the compression chamber 6 formed on the fixed scroll 5 and meshed with the movable scroll 4 and the fixed scroll 5 The suction pipe 7, the exhaust hole 8 arranged on the top of the fixed scroll 5 and communicated with the central compression chamber 6, the exhaust check mechanism 9 arranged on the top of the fixed scroll 5 and communicated with the exhaust hole 8 and arranged on the machine The exhaust pipe 10 below the frame 3, the suction pipe 7 and the exhaust pipe 10 all extend out of the housing 1;

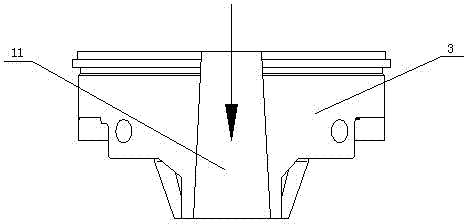

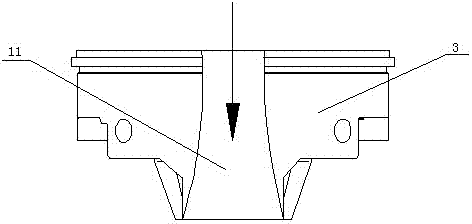

[0013] See figure 2 , image 3 , the outer wall of the frame 3 is provided with an exhaust channel 11, the exhaust channel 11 is a gradually expanding str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com