Existing railway roadbed micropile reinforcing structure under operation condition

A technology for strengthening structures and existing railways, applied in infrastructure engineering, roads, tracks, etc., can solve the problems of difficult to guarantee the quality of rotary jet piles, prone to cracking or broken piles, poor adaptability of roadbed filling, etc. Reliable pile quality, convenient construction, and the effect of reducing dynamic stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the drawings and examples.

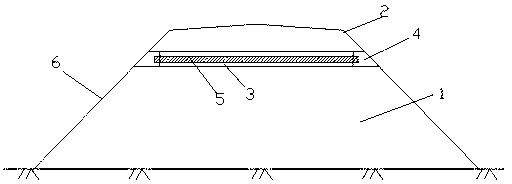

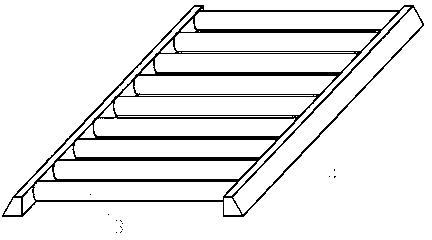

[0024] figure 1 It is a structural schematic diagram of the existing railway subgrade micro pile reinforcement structure under the operating conditions of the present invention; figure 2 It is a structural schematic diagram of the connection between the reinforced concrete pile and the connecting beam of the present invention. Such as figure 1 and figure 2 As shown, under the operating conditions of the present invention, the existing railway embankment micro-pile reinforcement structure is composed of small-diameter reinforced concrete piles 3 and connecting beams 4 . The two ends of the reinforced concrete pile 3 are connected by connecting beams 4 to form a pile row.

[0025] The small-diameter reinforced concrete pile 3 is set on the embankment slope at a distance of 1 to 2m from the embankment surface, and is formed by inserting bars 5 into boreholes drilled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com