Low-temperature-resistant durable vibration rubber shock absorber

A rubber shock absorber, rubber shock absorption technology, applied in the direction of spring/shock absorber, spring, spring assembly composed of several springs, etc., can solve the problem of insufficient installation space, limited bonding strength, inapplicability Lightning suppressor damping and vibration reduction, to achieve the effect of improving durable vibration reliability characteristics, improving low temperature resistance characteristics, and realizing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

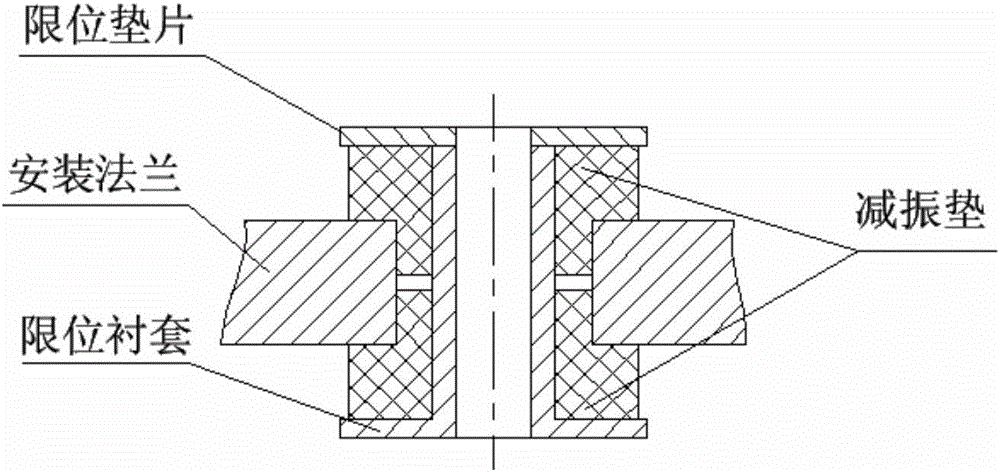

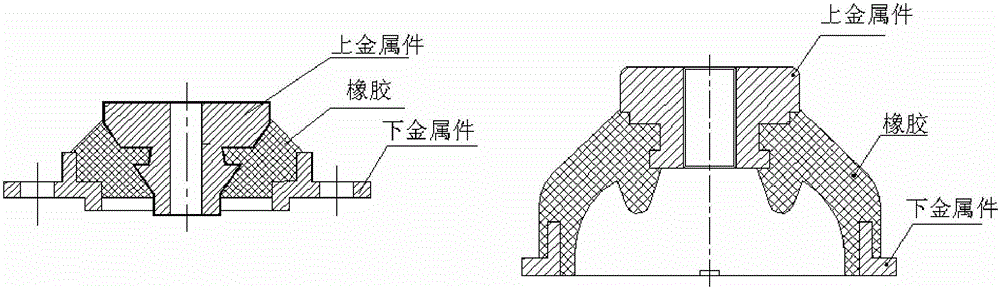

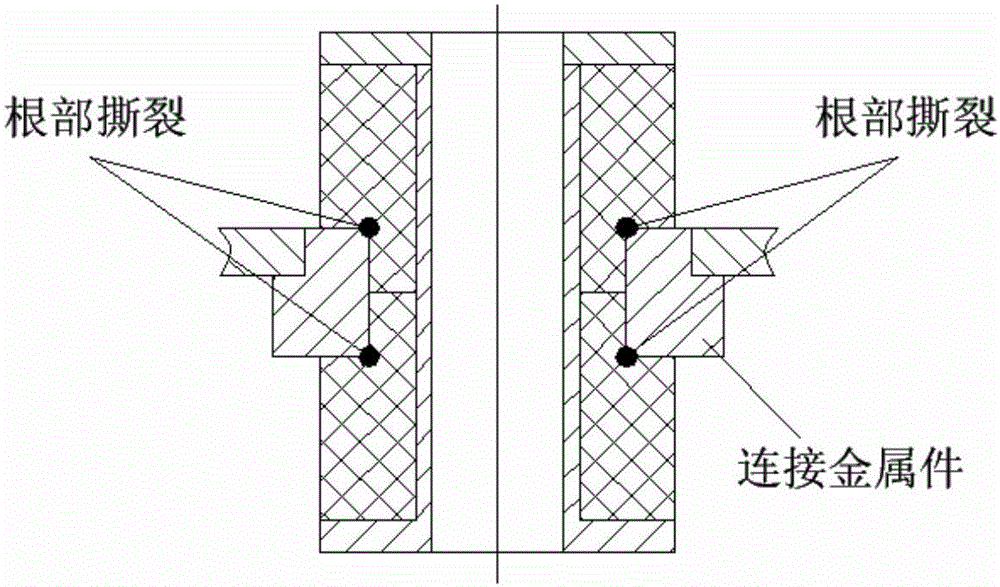

[0028] This embodiment is applied to the damping and vibration reduction of the lightning suppressor of a certain type of aircraft. The total weight of the lightning suppressor and its mounting plate is about 160g, and the mounting plate of the lightning suppressor is a thin plate structure with a thickness of 1mm. Under the action of durable random vibration load under the condition, the base of the lightning suppressor appeared fatigue fracture. By designing and installing connectors, the gap between the two T-shaped rubber damping pads 1 in this embodiment is 1mm, and the height of the shock absorber installation area 5-1 of the ring structure in this embodiment is 4mm, which expands the lightning suppressor The shock absorber installation space of the installation plate structure, in this embodiment, the natural rubber layer is vulcanized on the annular inner wall of the shock absorber installation area 5-1, the material is natural rubber, the thickness is 1mm, and the elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com