Low-pressure stage moving blade for variable-speed mass-flow industrial steam turbine

An industrial steam turbine, low-pressure stage technology, applied in the direction of machines/engines, blade support elements, mechanical equipment, etc., can solve the problem of low efficiency of the last 3-stage moving blade profile, increased water vapor collision loss, increased steam leakage loss, etc. problems, to achieve the effect of being conducive to dynamic frequency modulation, broad market application prospects, and simple blade mode shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below through implementation in conjunction with the accompanying drawings.

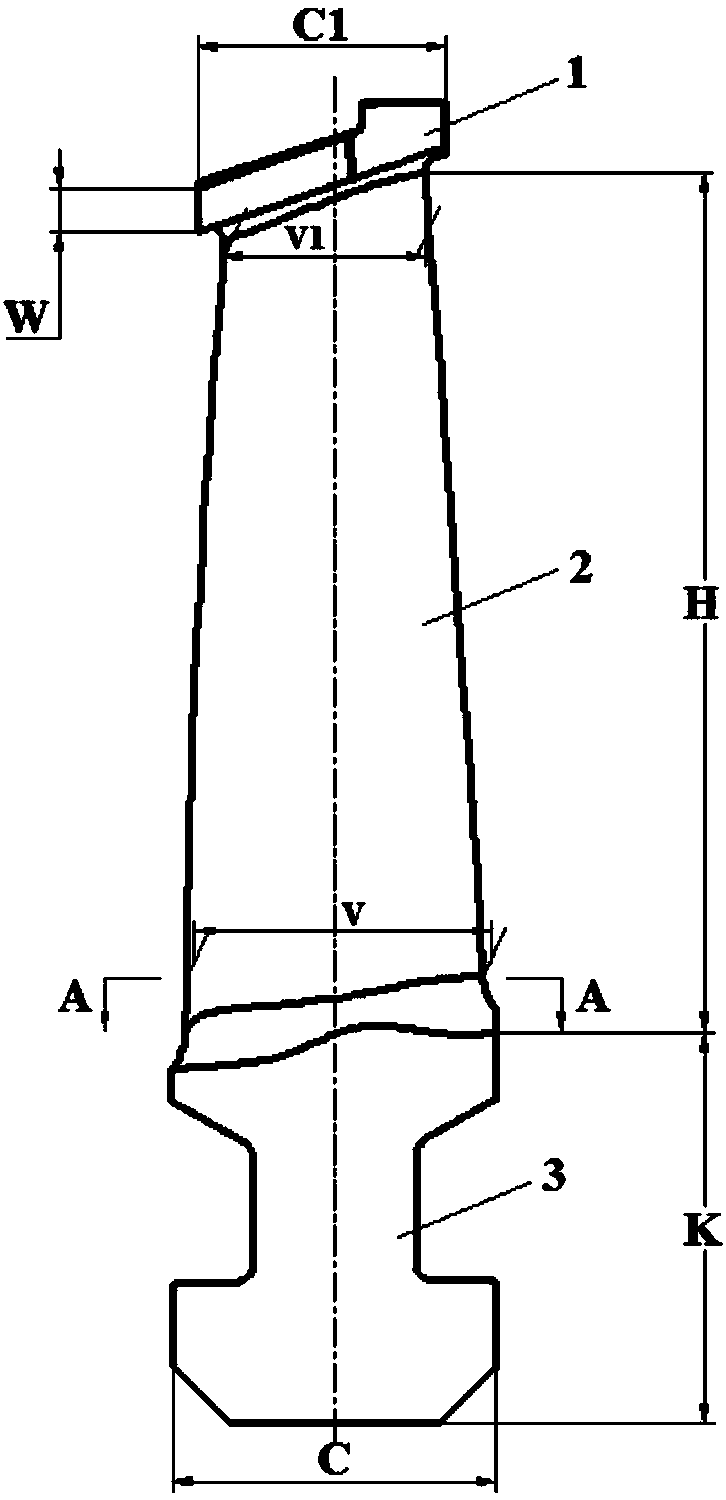

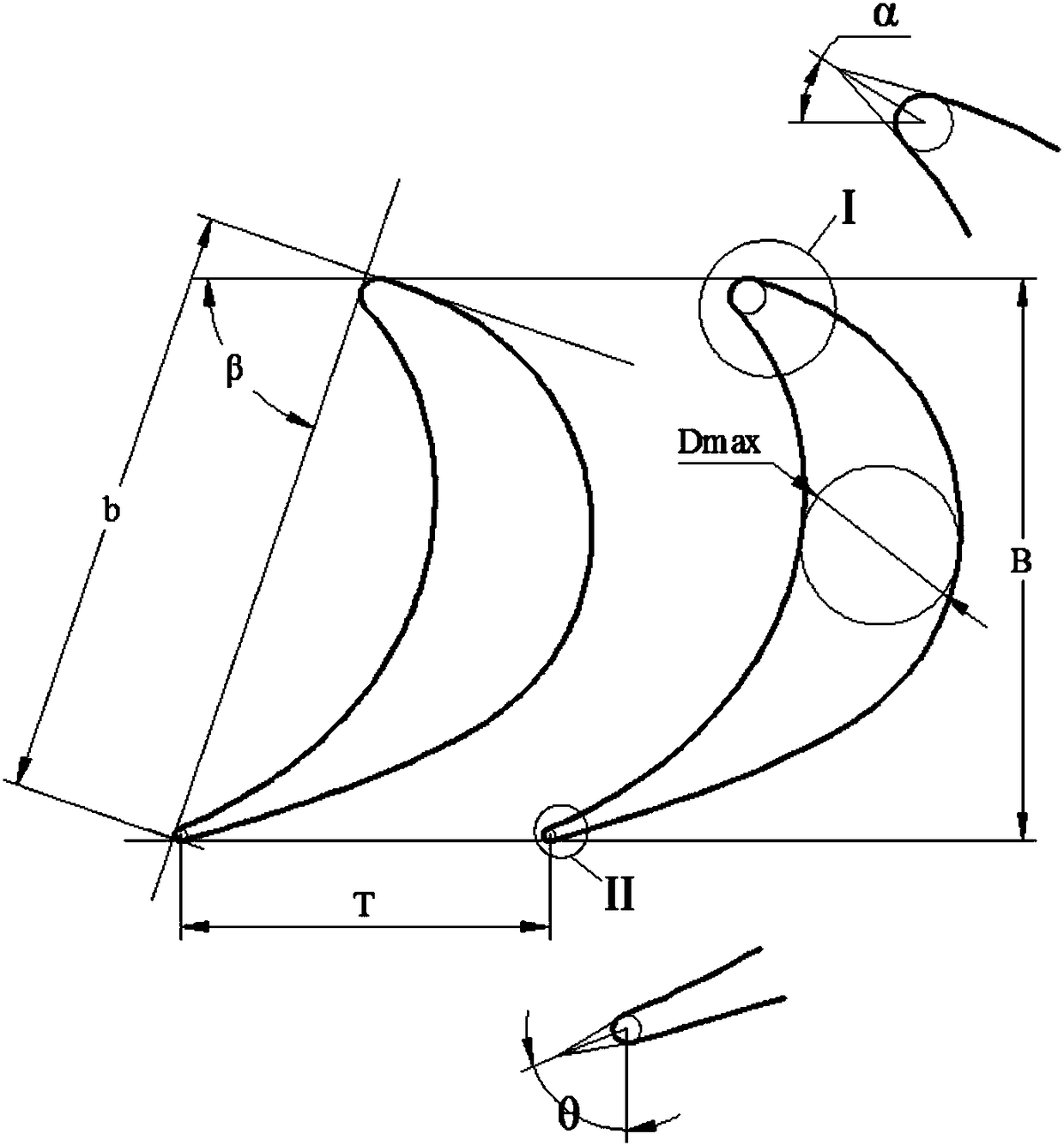

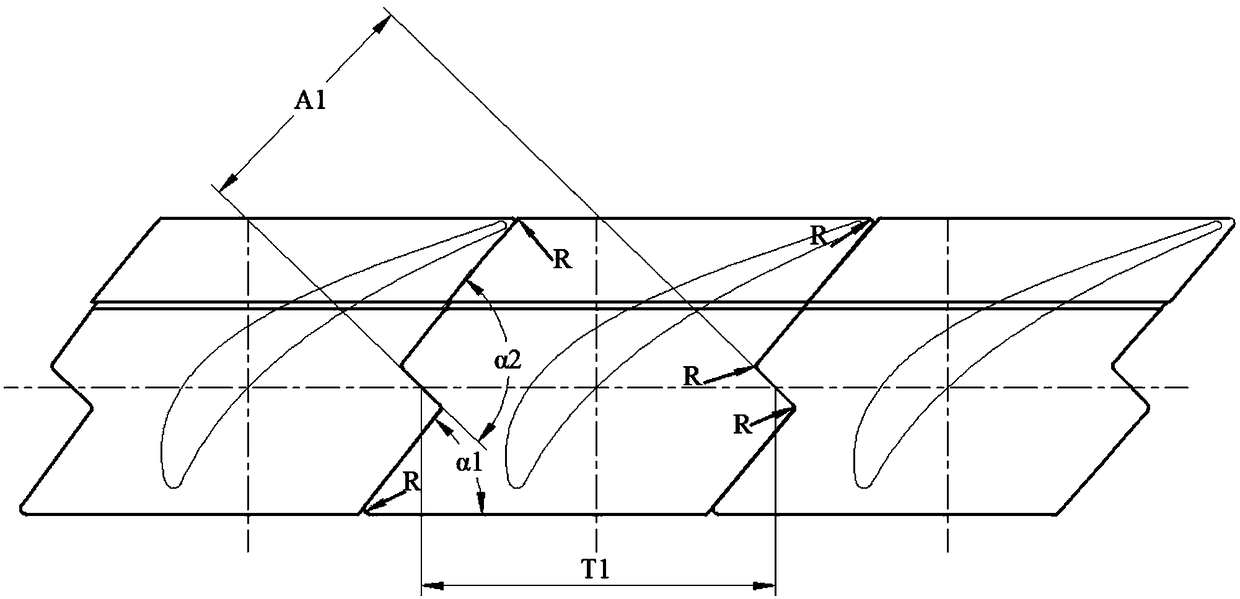

[0017] Such as figure 1 with image 3 As shown, the low-pressure stage moving blade of the variable-speed and high-flow industrial steam turbine of the present invention includes the blade body 2, the shroud 1 and the blade root 3, and the blade body 2, the shroud 1 and the blade root 3 are forged from top to bottom Integrate, the 2-shaped line of the blade body is a twisted blade with variable cross-section, and the cross-sectional area from the root to the top gradually decreases, and there is relative twist between two adjacent cross-sections, and the blade is formed by superimposing several characteristic cross-sections according to specific rules , the contour line of the characteristic section is a closed curve surrounded by the inner arc curve and the back arc curve, and the superposition law of the section is a continuous smooth transiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com