Magnetic gear-type composite hub motor

An in-wheel motor and gear-type technology, applied in the field of magnetic gear-type compound in-wheel motors, can solve the problems of low stiffness, strength and rotation accuracy, high noise and vibration, etc., to reduce noise and vibration, reduce vibration, and eliminate additional bending. moment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

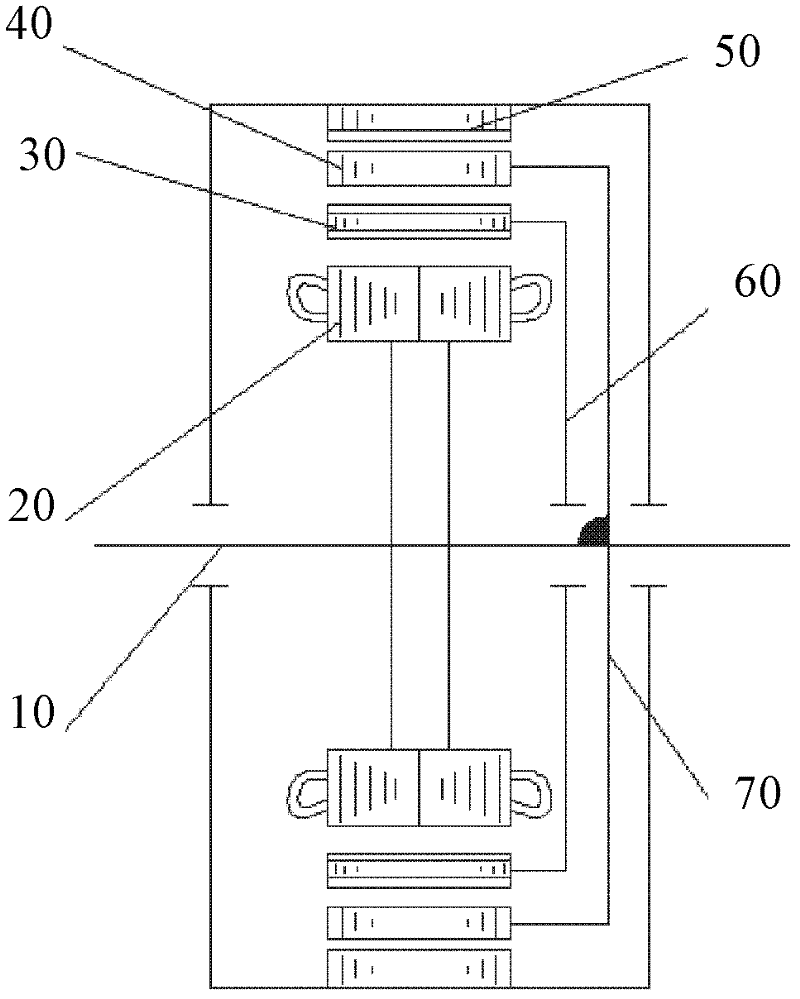

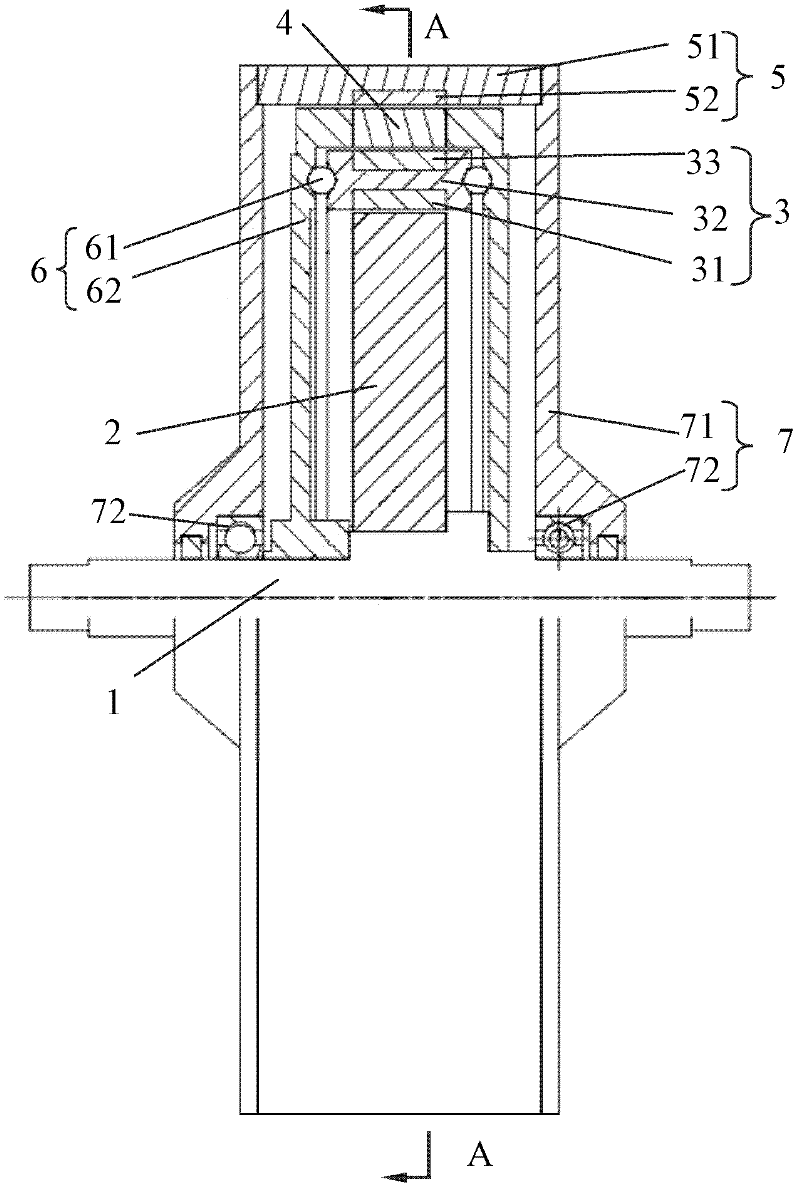

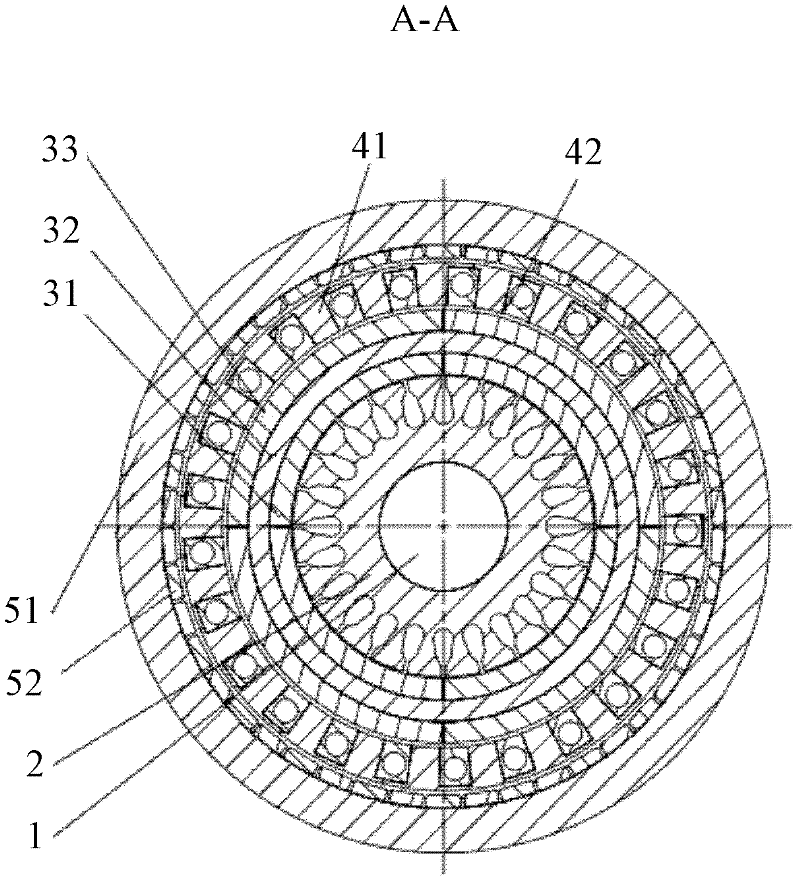

[0023] Such as figure 2 and image 3 As shown, the magnetic gear type composite hub motor in the first preferred embodiment of the present invention includes a motor mandrel 1, an inner stator 2, a high-speed inner rotor 3, a magnetic ring 4, a low-speed outer rotor 5, and an inner rotor support assembly 6 and the outer rotor support assembly 7. The inner stator 2 , the high-speed inner rotor 3 , the magnetizing ring 4 and the low-speed outer rotor 5 are arranged coaxially around the motor shaft 1 and nested in sequence along the radial direction of the motor shaft 1 .

[0024] The inner stator 2 and the high-speed inner rotor 3 constitute an ordinary motor, while at the same time, the high-speed inner rotor 3, the magnetic adjustment ring 4 and the low-speed outer rotor 5 constitute concentric magnetic gears. Therefore, the high-speed inner rotor 3 is the rotor of an ordinary motor. It is also the rotor of the magnetic gear, and the magnetic gear compound in-wheel motor in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com