Hydraulic steel bar cutting machine

A steel bar cutting machine and hydraulic technology, which is applied in the field of hydraulic steel bar cutting machines, can solve the problems of large volume of motorized steel bar cutting machines, low working efficiency of manual steel bar cutting machines, inconvenient operation, etc., and achieves low noise, good lubrication and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

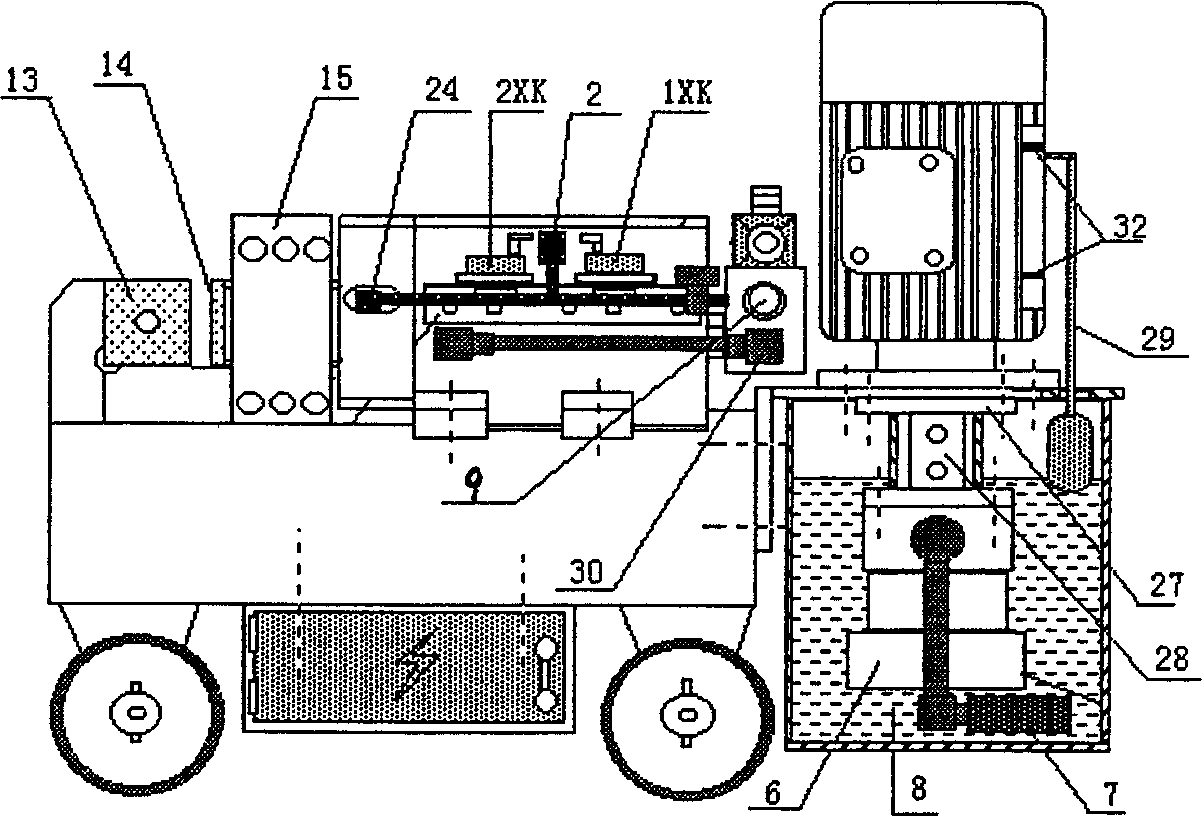

[0020] Referring to the attached picture:

[0021] The hydraulic steel bar cutting machine of the present invention comprises a machine base 17, a knife seat 13, a hydraulic cylinder 16 with a piston rod 1, a piston rod guide seat 15, and a cutting blade 14 is fixed on the piston rod. There is a seal 26 between the hydraulic cylinders 16 .

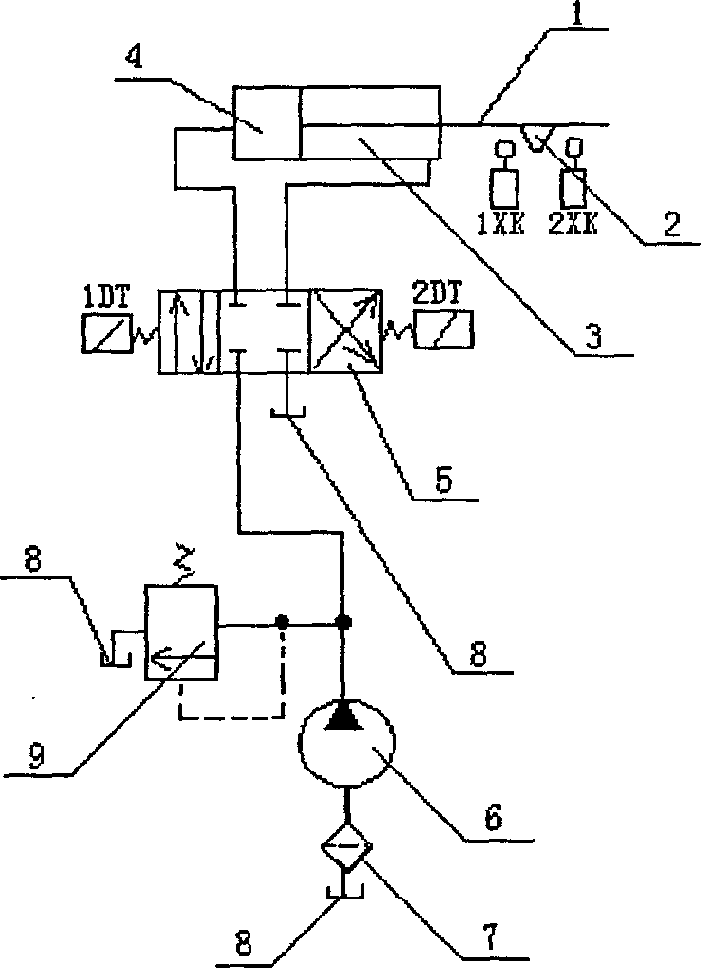

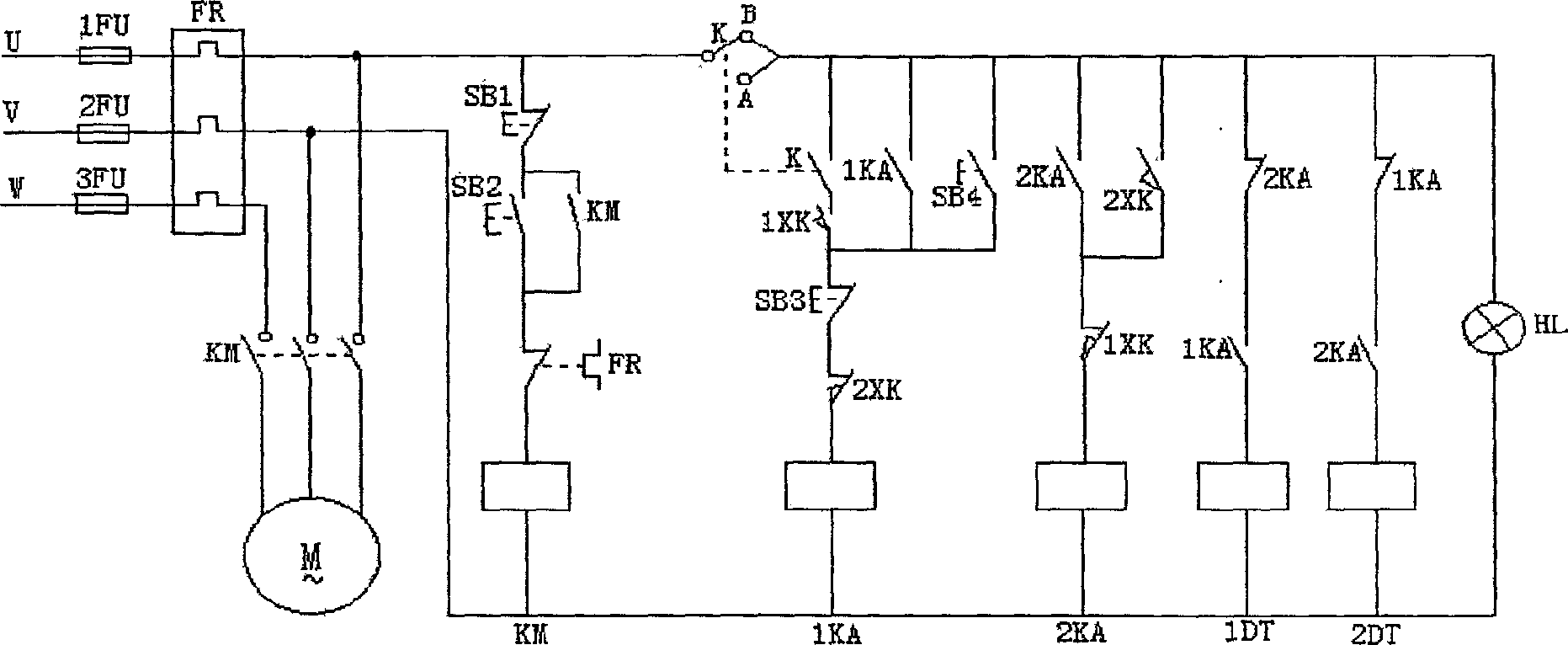

[0022] It also includes an oil pump 6 driven by a motor 21. The output pipe of the oil pump 6 is connected to the front chamber 3 and the rear chamber 4 of the hydraulic cylinder through the oil separator 18; ;

[0023] The electromagnetic reversing valve 5 for switching the oil circuit is installed on the oil distributor 18, and the electromagnetic reversing valve 5 has a first electromagnet 1DT for controlling the oil delivery pipeline in the rear chamber 4 of the hydraulic cylinder and a first electromagnet 1DT for controlling the oil delivery pipeline in the front chamber 3 of the hydraulic cylinder. Two electromagnets 2DT;

[0024]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com