Hybrid power well repairing machine

A hybrid power and workover rig technology, applied in drilling equipment, drilling equipment and methods, earthwork drilling and mining, etc., can solve the problems of unavailability of potential energy, large power loss, power waste, etc., and achieve power saving, power reduction, wide vision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

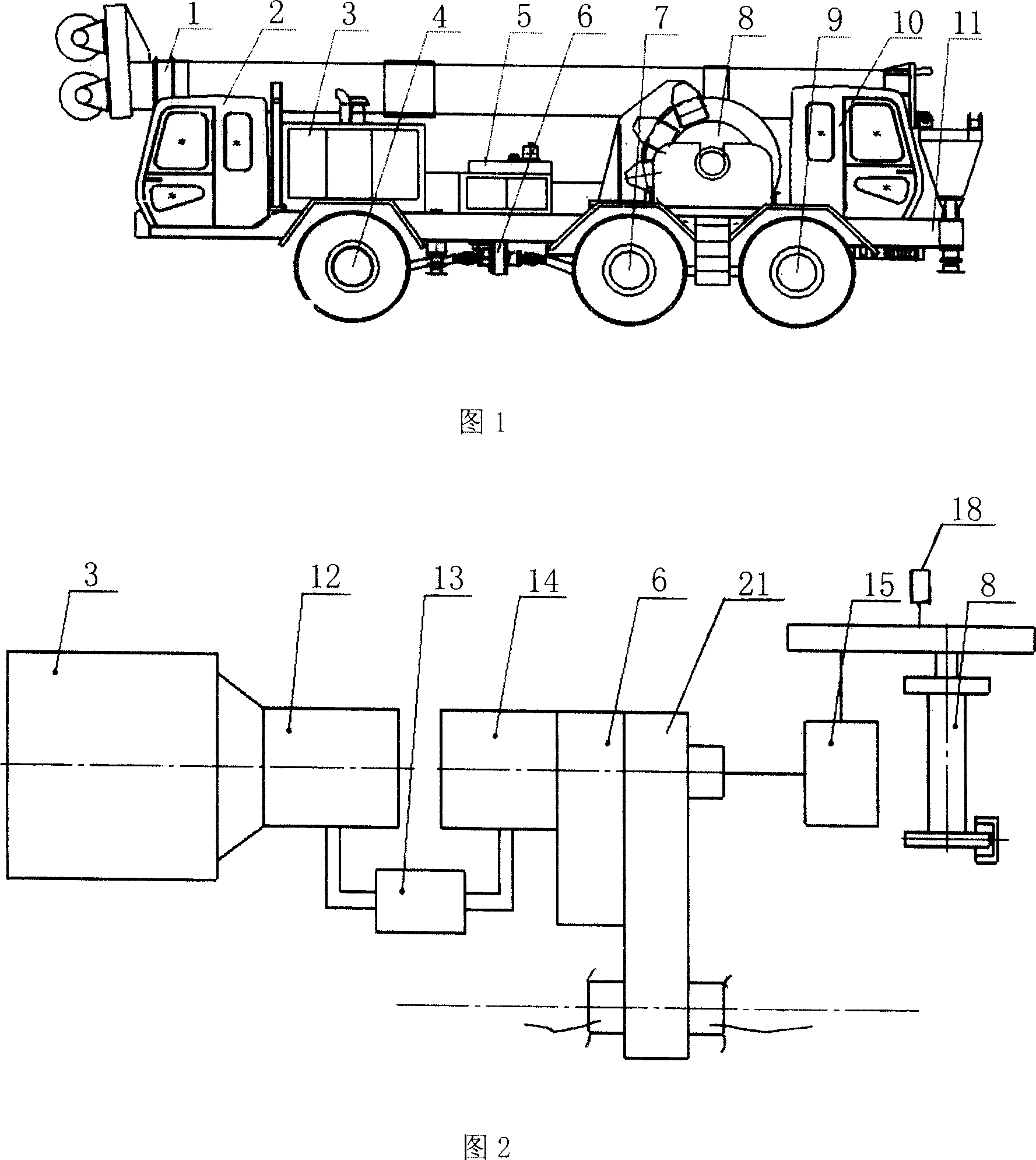

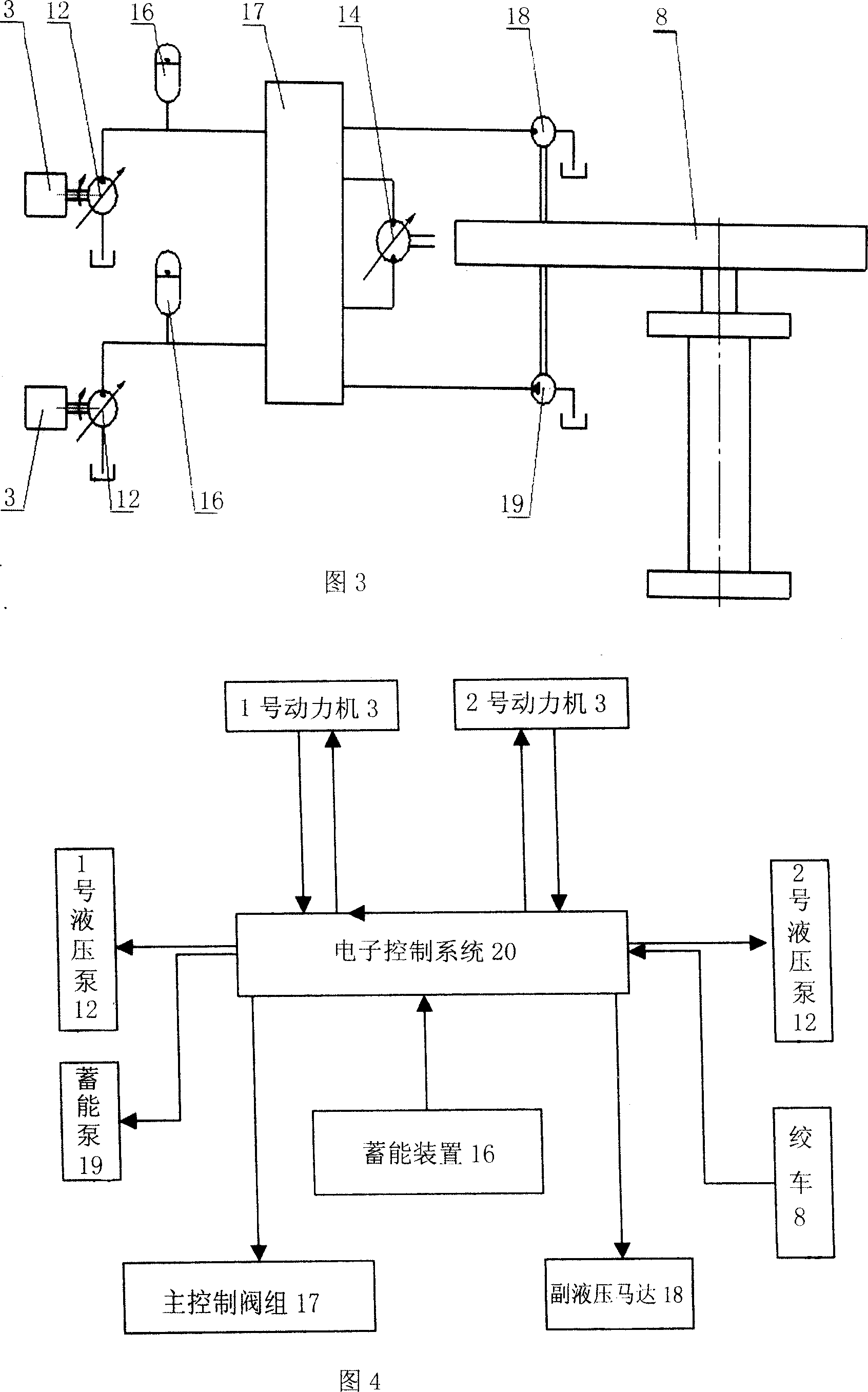

[0022] Referring to Fig. 1-Fig. 4, a kind of hybrid power workover rig comprises vehicle frame 11 and derrick 1 installed on it, cab 2, power machine 3, front, middle and rear axles 4, 7, 9, hydraulic oil tank 5 , gearbox 6, winch 8 and operating room 10 and transmission system, hydraulic system and electronic control system, transmission system includes the power take-off device connected on the transmission shaft of middle axle 7 and rear axle 9 and the gearbox 6 connected in sequence on one side , the main hydraulic motor 14, the reversing valve 13, the hydraulic pump 12 and the power machine 3, and the corner box 15 connected in sequence, the secondary hydraulic motor 18 and the winch 8 are installed on the other side, and the hydraulic system includes the winch and the secondary hydraulic pressure connected to it in sequence. Motor 18, energy storage pump 19, main hydraulic motor 14, main control valve group 17, energy storage device 16, hydraulic pump 12 and power machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com