Novel magnetic drive oblique gear pair with oblique air-gap magnetic field

A technology of air-gap magnetic field and magnetic transmission, applied in transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of small torque of permanent magnet gear transmission, and achieve high reliability, long life and no mechanical wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

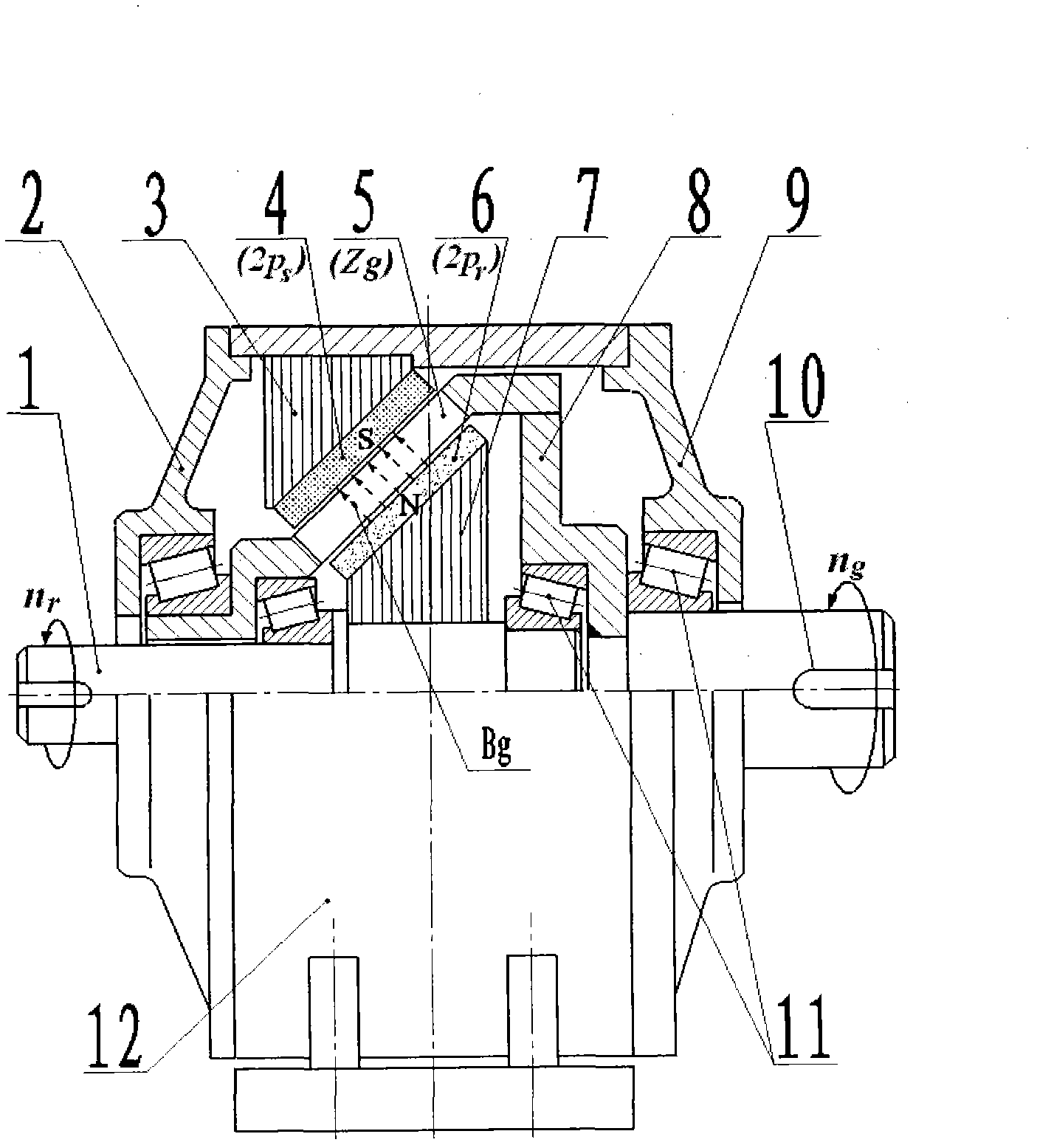

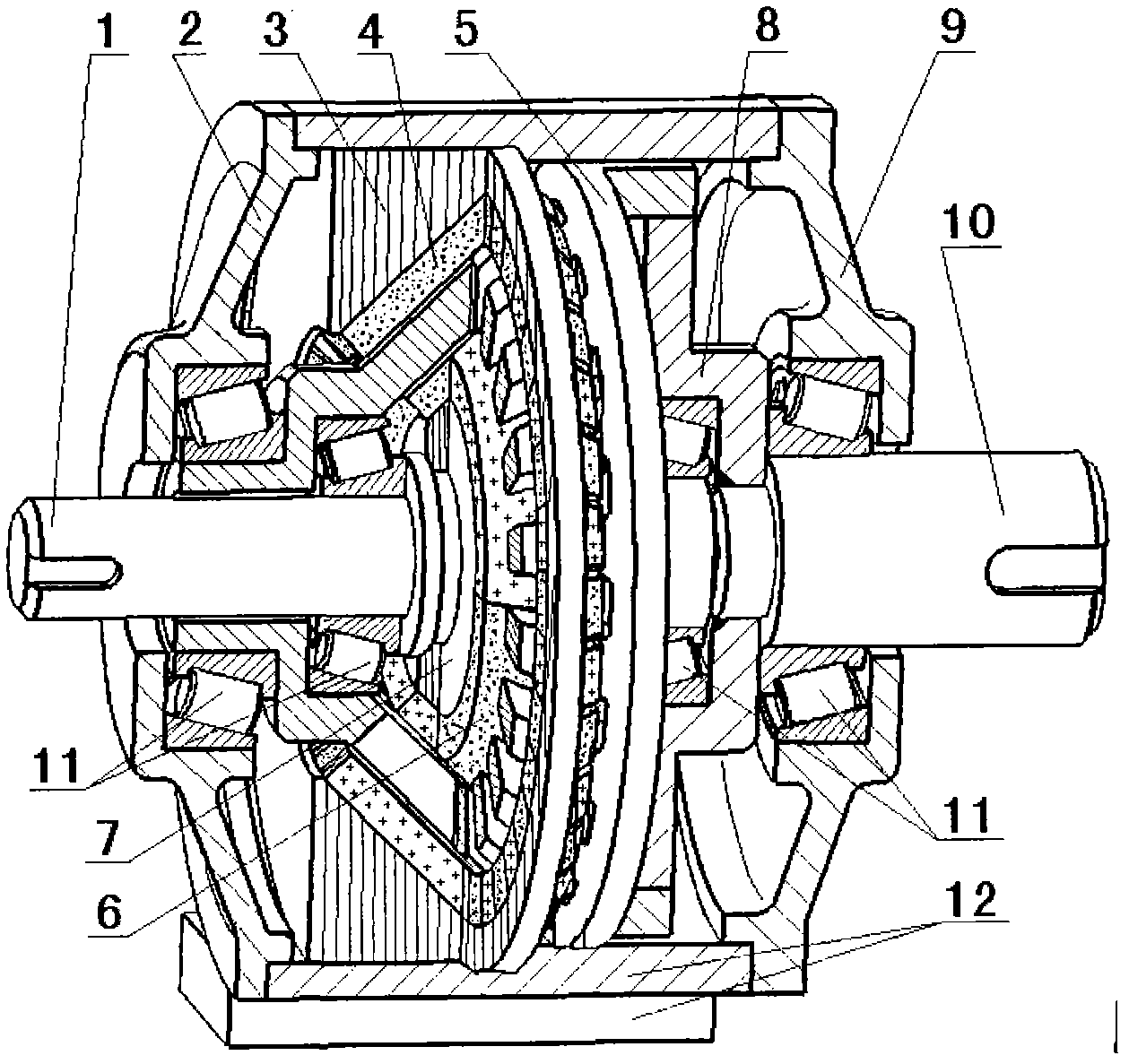

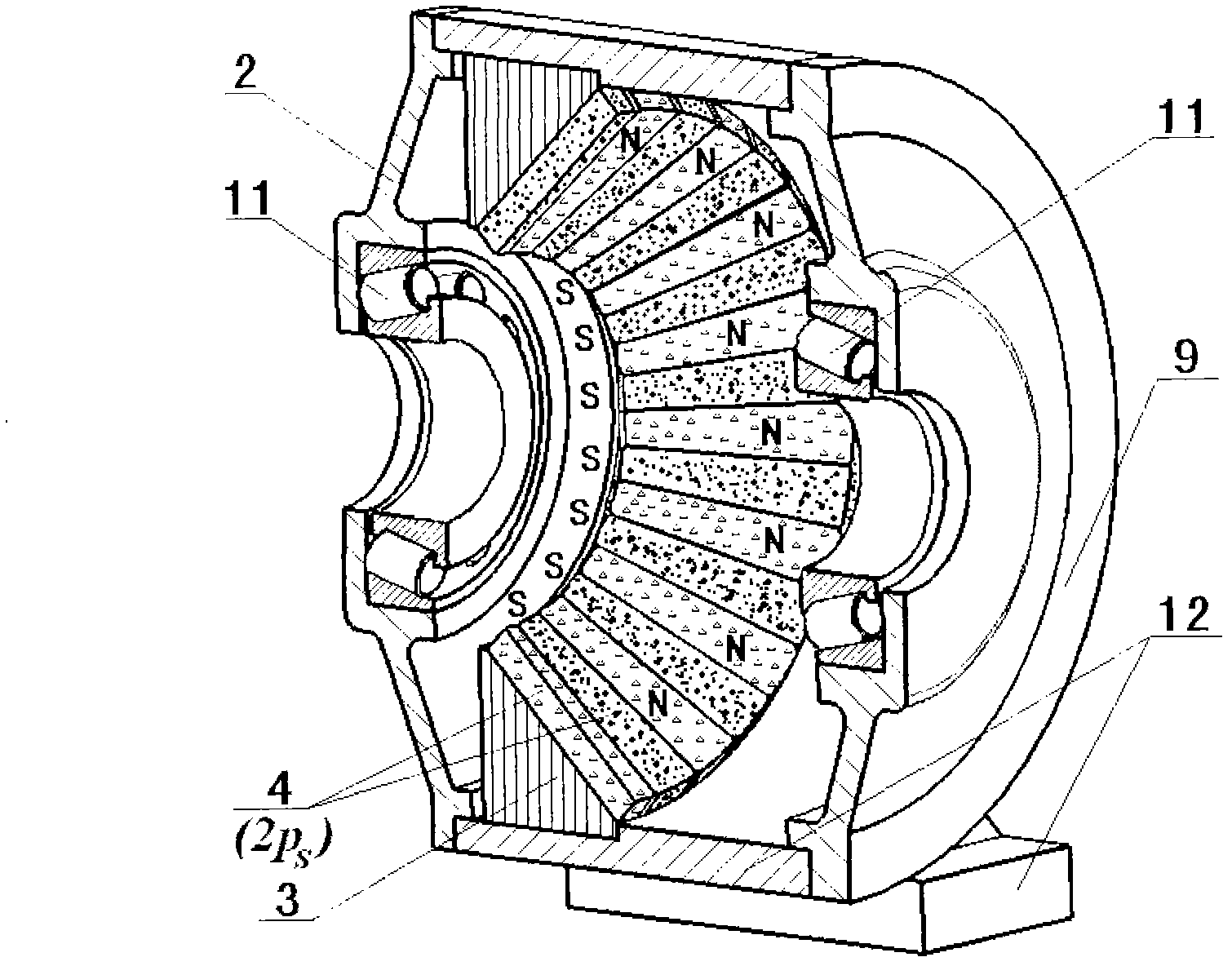

[0026] figure 1 The illustrated embodiment is a half-sectional view of the planar structure of a novel magnetic transmission helical gear pair with an oblique air gap magnetic field according to the present invention, figure 2 It is a composite sectional view of a three-dimensional structure of a novel magnetic transmission helical gear pair with an oblique air gap magnetic field described in the present invention. In this embodiment, the number of magnetic poles of the driving wheel is 2p r = 4 poles, the number of stator poles is 2p s = 34 poles, the number of teeth of the ferromagnetic grid of the driven wheel Zg = 19, the speed transmission ratio Its internal structural relationship features are as follows:

[0027] 1. The magnetic transmission helical gear pair of the new oblique air gap magnetic field is distributed with 2p r An outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com