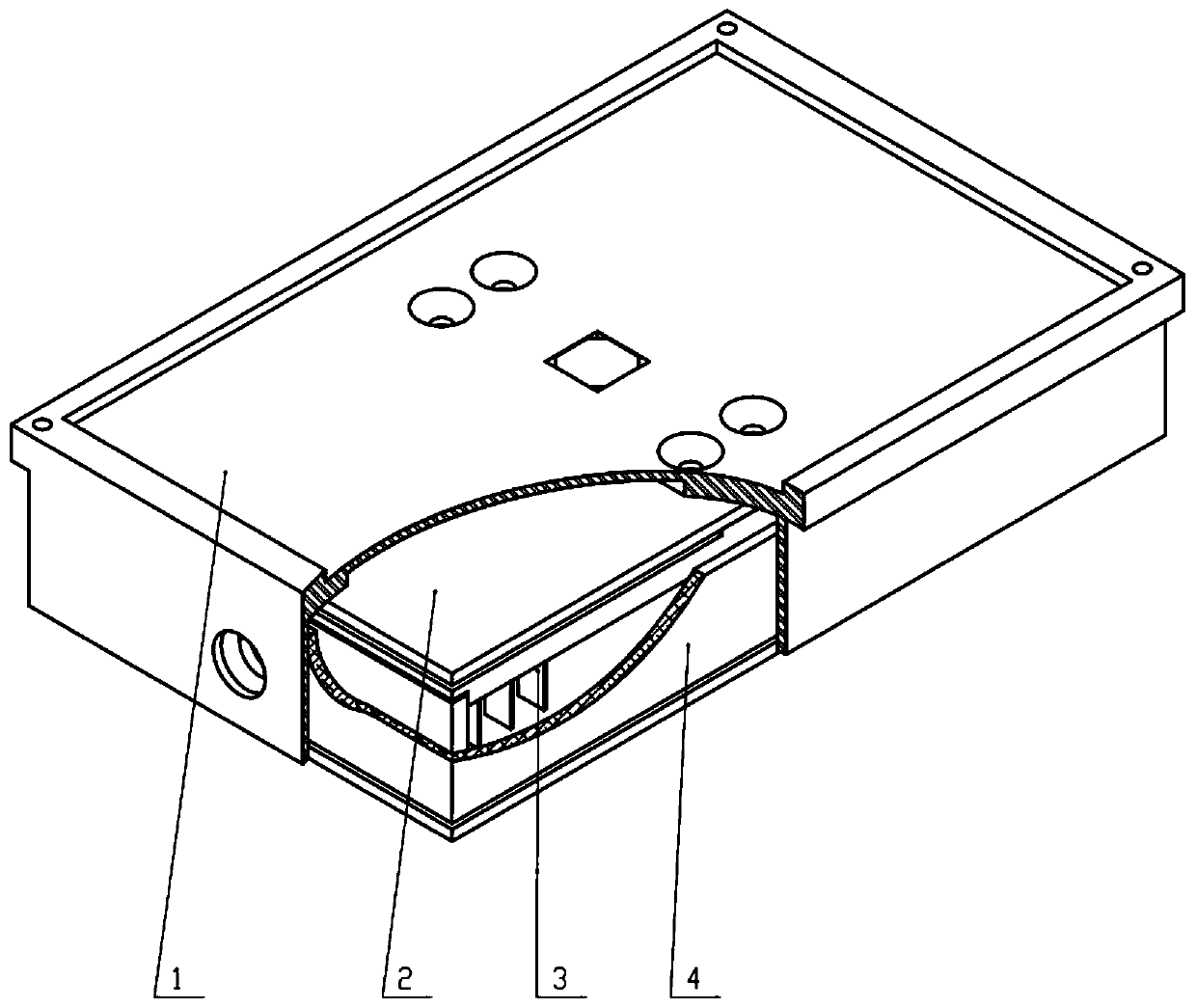

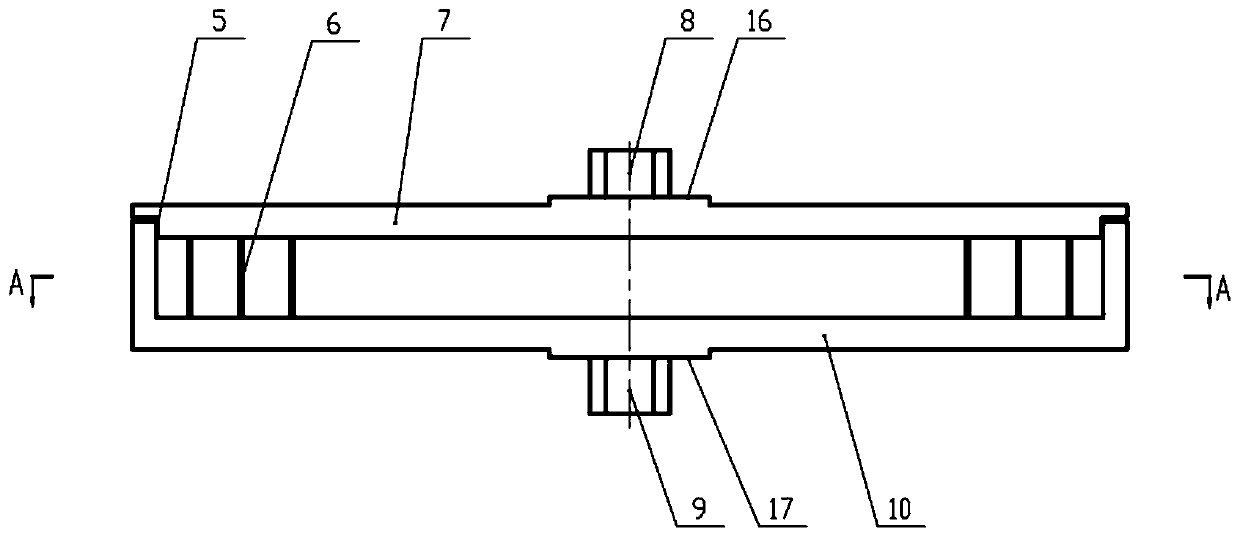

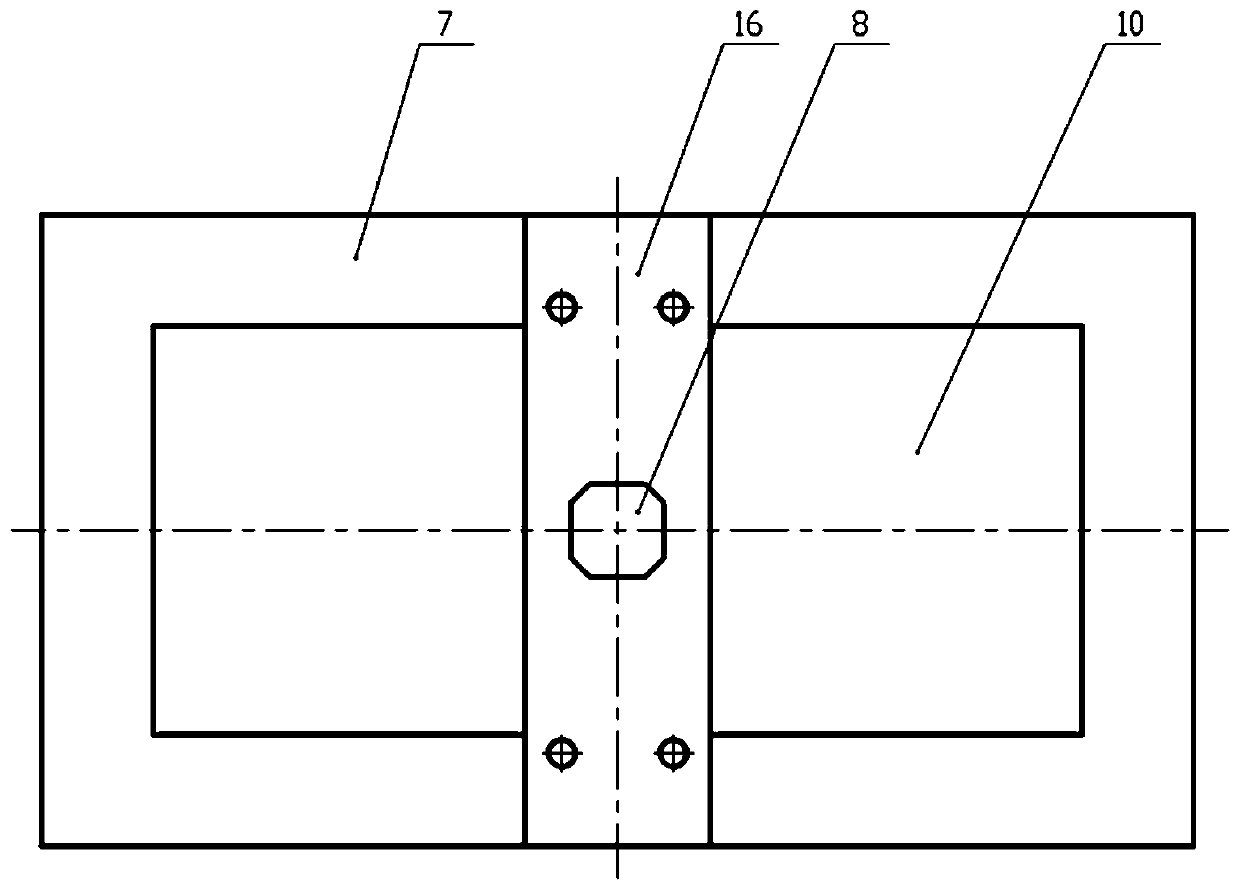

Surface frictional resistance wind tunnel measurement method based on box type frictional resistance balance

A frictional resistance, wind tunnel measurement technology, applied in measurement devices, machine/structural component testing, aerodynamic testing, etc., can solve the problem of difficulty in resisting pressure gradient load interference on the test surface and temperature interference, weak self-rigidity, and difficulty in operation. Large and other problems, to achieve good thermal insulation protection, prevent channeling from entering, and reduce the effect of temperature conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] The test wind tunnel of this embodiment is a hypersonic wind tunnel. The test model 11 of the present embodiment is a flat plate model, and the lower surface of the front edge of the test model 11 is processed with wedges facing the incoming flow of the wind tunnel.

[0087] The test results show that the box-type friction resistance balance used in the wind tunnel measurement method of surface friction resistance based on the box-type friction resistance balance of the present invention can measure the friction resistance in the range of 0.2N to 5N, and the minimum resolution is 0.001N. Accurate measurement under the normal force of 100N, pitching moment of 5N m and other disturbance loads of comparable magnitude.

[0088] The test results prove that the surface friction resistance wind tunnel measurement method based on the box friction resistance balance of the present invention has low cost, high performance and easy operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com