Power battery temperature correction method and system, medium and equipment

A power battery and battery current technology, which is applied in the repair/maintenance of secondary batteries, secondary batteries, circuits, etc., can solve the problems that the heat effect of contact resistance cannot be ignored, the heat effect of bus discharge cannot be ignored, and the accuracy of temperature acquisition will be affected. Achieve the effects of preventing jumps and jitters, smoothing temperature, and smoothing power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

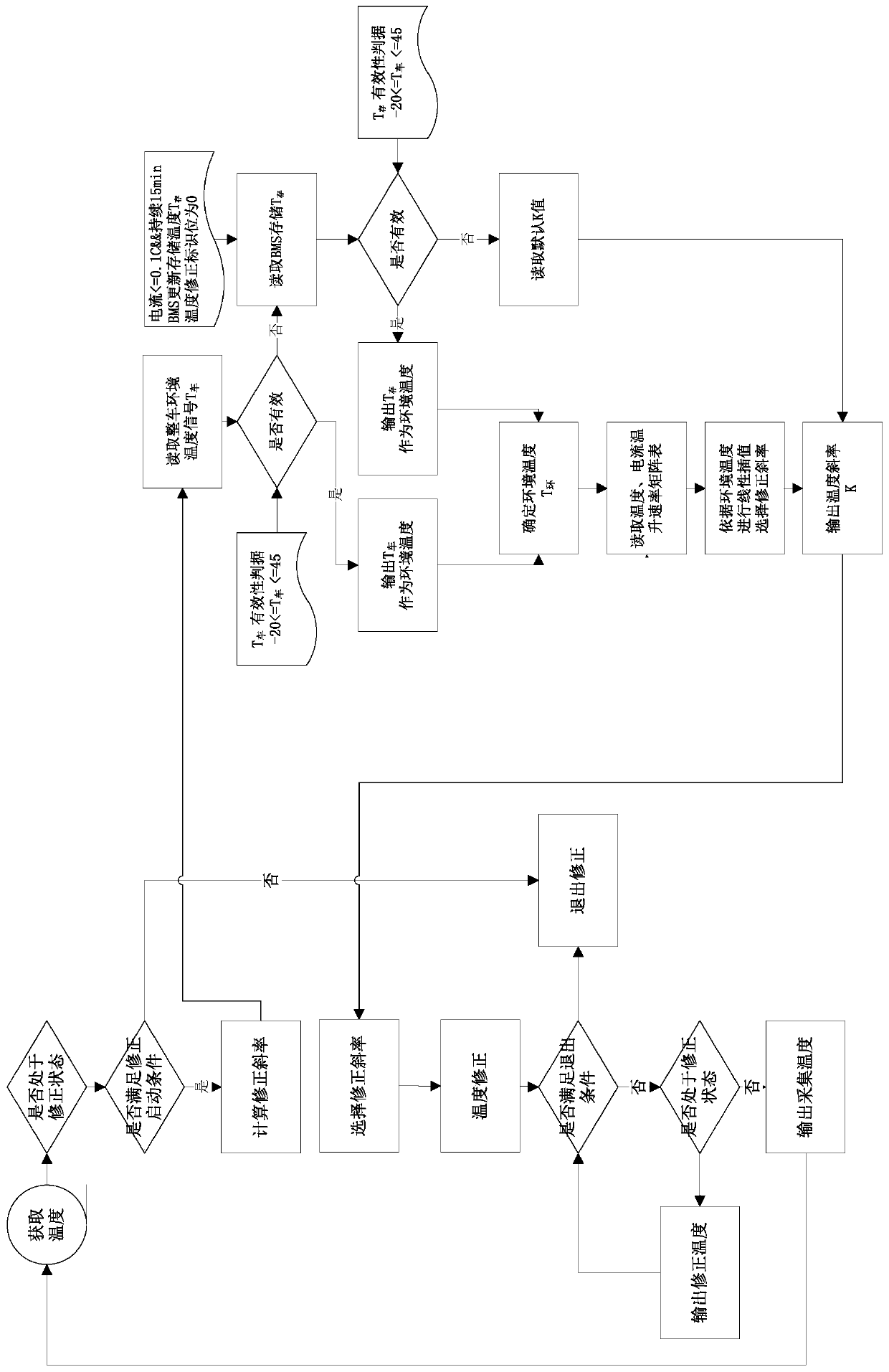

[0052] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

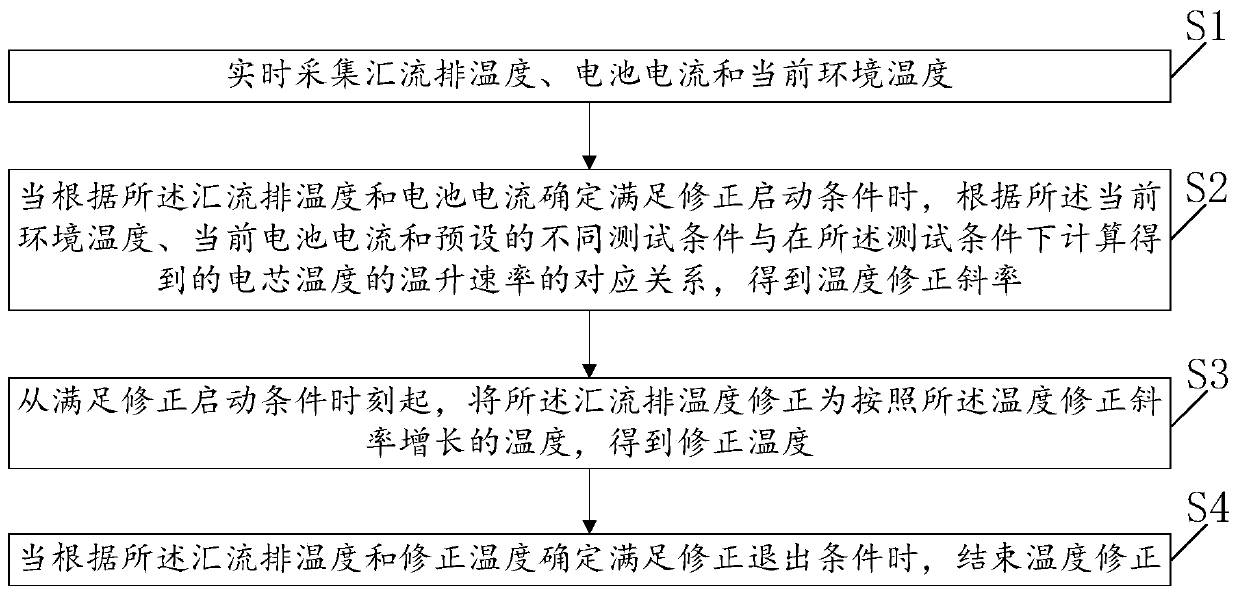

[0053] figure 1 A flow chart of a power battery temperature correction method provided by an embodiment of the present invention, as shown in figure 1 As shown, the method includes:

[0054] S1. Collect bus temperature, battery current and current ambient temperature in real time.

[0055] Specifically, the temperature of the bus bar and the current ambient temperature can be obtained by measuring the temperature sensor arranged at the corresponding position, and the battery current can be obtained by the current measuring device arranged in the circuit.

[0056] S2. When it is determined according to the temperature of the bus bar and the battery current that the modified starting condition is met, according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com